wheel MINI COOPER 2010 Owner's Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2010, Model line: COOPER, Model: MINI COOPER 2010Pages: 174, PDF Size: 2.82 MB

Page 132 of 174

Replacing components

130

Repairing a flat tire

Safety measures in the event of a

breakdown:

Park the vehicle as far as possible from moving

traffic and switch on the hazard warning

flashers.

Turn the steering wheel until the front wheels

are in the straight-ahead position and engage

the steering wheel lock. Engage the parking

brake and shift into 1st or reverse gear or place

the selector lever in position P.

All passengers should be outside the vehicle and

in a safe place, e.g. behind a guardrail.

Erect a warning triangle or warning flasher at the

appropriate distance if necessary. Comply with

all safety guidelines and regulations.<

In the event of a flat tire, different procedures

should be followed depending on the equip-

ment included in your vehicle:

>MINI Mobility System, refer to the following

section

>Run-flat tires, page114

>Tire change with space-saver spare tire,

page132

MINI Mobility System with onboard

vehicle tool kit and tire change set*

Preparations

Use of the MINI Mobility System may be ineffec-

tive if the tire puncture measures approx. 1/8 in/

4 mm or more. Contact the nearest MINI dealer

if the tire cannot be made drivable with the

Mobility System.

Do not remove foreign bodies which have pen-

etrated the tire if possible.

Follow the instructions on using the Mobil-

ity System found on the compressor and

the sealant bottle.<

Remove the adhesive label for the speed limit

from the sealant bottle and affix it to the steer-

ing wheel.The Mobility System with onboard vehicle tool

kit and tire change set

* is located under the

floor mat in the cargo bay.

1Sealant bottle

2Hexagon wrench

*

3Vehicle jack*

4Wheel stud wrench

5Flat screwdriver/Phillips screwdriver, towing

eyelet

6Compressor

7Package with valve removal tool

Sealant and compressor

1Sealant bottle and adhesive label with speed

limit

2Filling hose

Note the use-by date on the sealant

bottle.<

Page 133 of 174

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

131

3Plug and cable for the socket in the vehicle

interior, page89

4Holder for the sealant bottle

5Compressor

6Pressure gauge for indicating the tire infla-

tion pressure

7On/off switch

8Release button for reducing the tire inflation

pressure

9Connection hose to connect the compressor

and sealant bottle or the compressor and

wheel

Connector, cable and connection hose are

stored in the compressor housing.

Using the Mobility System

To repair a tire puncture with the Mobility Sys-

tem, proceed as follows:

>Fill the tire with sealant

>Distribute the sealant

>Correct the tire inflation pressure

Filling the tire with sealant

Proceed in the specified order; otherwise,

sealant may emerge under high

pressure.<

1.Shake the sealant bottle.

2.Pull the connection hose9 out of the com-

pressor housing fully and screw it onto the

connector of the sealant bottle. Make sure

that the hose is not kinked.

3.Insert the sealant bottle on the compressor

housing in an upright position.4.Unscrew the dust cap from the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.

5.Ensure that the compressor is switched off.

6.Insert the plug 3 into the lighter socket/

power socket in the vehicle interior,

page89.

7.With the engine running:

Switch on the compressor and let is run for

approx. 3 to 8 minutes to fill the tire with

sealant and achieve a tire inflation pressure

of approx. 26 psi/180 kPa.

When the tire is being filled with seal-

ant, the inflation pressure may spo-

radically reach approx. 73 psi/500 kPa. Do

not switch off the compressor in this

phase.<

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be

damaged.<

8.Switch off the compressor.

If an air pressure of 26 psi/180 kPa is not

reached:

1.Unscrew the filling hose 2 from the wheel

and drive the vehicle forward and backward

approx. 33 ft/10 m to distribute the liquid

sealant in the tire evenly.

2.Inflate the tire again with the compressor.

If an inflation pressure of 26 psi/180 kPa

still cannot be reached, the tire is too

heavily damaged. Please contact the nearest

MINI dealer.<

Detach the connection hose 9 and filling hose 2

from the sealant bottle connection and tire

valve.

Page 134 of 174

Replacing components

132

Wrap the empty sealant bottle in suitable mate-

rial to avoid dirtying the cargo bay. Stow the

Mobility System back in the vehicle.

Distributing the sealant

Immediately drive approx. 3 mls/5 km to evenly

distribute the sealant.

Do not exceed speeds of 50 mph/

80 km/h.

If possible, do not drop below 10 mph/

20 km/h.<

Correcting the tire inflation pressure

1.After driving approx. 3 mls/5 km or ten min-

utes, stop at a suitable location.

2.Screw the connection hose 2 of the com-

pressor directly onto the tire valve.

3.Insert the plug 3 into the power socket in the

vehicle interior.

4.Correct the inflation pressure to 26 psi/

180 kPa. With the engine running:

>To increase the inflation pressure: switch on

the compressor. To check the current infla-

tion pressure, switch off the compressor.

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be

damaged.<

>To decrease the inflation pressure: press the

release button 5.

If the tire cannot maintain the inflation

pressure, drive the vehicle again, refer to

Distributing the sealant. Then repeat steps

1to4.

If an inflation pressure of 26 psi/180 kPa still

cannot be reached, the tire is too heavily dam-

aged. Contact the nearest MINI dealer.<

Driving on

Do not exceed the permitted maximum

speed of 50 mph/80 km/h; doing so may

result in an accident.<

Replace the defective tire as soon as possible

and have the new wheel/tire assembly bal-

anced.Have the Mobility System refilled.

Changing wheels

Space-saver spare tire*

To change a space-saver spare tire, proceed as

follows:

>Remove the space-saver spare tire,

page133

>Prepare for tire change, page133

>Jack up vehicle, page134

>Mount space-saver spare tire, page134

>Tighten lug bolts, page134

>Drive with space-saver spare tire, page133

Tire change set for a space-saver

spare tire*

On vehicles with a space-saver spare tire, the

tire change set with onboard tools is stored

under the floor mat in the cargo bay.

1Chock, folding

2Hub cover remover

3Wheel stud wrench

4Vehicle jack

5Special wrench for removing the space-

saver spare tire

6Flat screwdriver/Phillips screwdriver

7Towing eyelet

8Lifting handle

The onboard vehicle tool kit includes a pouch

with a plastic bag in which you can place the

damaged wheel.

Page 135 of 174

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

133

Removing the space-saver spare tire

The screw connection of the space-saver spare

tire is under the floor mat in the cargo bay, on

the base of the storage compartment for the tire

change set.

1.Unscrew the screw connection with the spe-

cial wrench.

2.Take out the cover panel.

3.Screw the lifting handle from the onboard

vehicle tool kit onto the thread.

4.Raise the lifting handle slightly.

5.Squeeze the securing spring.

6.The space-saver spare tire is released and

must be held by the lifting handle.

7.Lower the space-saver spare tire with the

lifting handle.

8.Unscrew the lifting handle.9.Pull the space-saver spare tire underneath

the vehicle out towards the rear.

10.Position the space-saver spare tire with the

valve facing upward.

11.Unscrew the valve extension from the valve

of the space-saver spare tire.

12.Unscrew the dust cap from the extension

and place it on the valve of the space-saver

spare tire.

Due to its different dimensions, the dam-

aged wheel cannot be placed in the recess

for the space-saver spare tire.<

Driving with the space-saver spare tire

Drive cautiously and do not exceed a

speed of 50 mph/80 km/h. Changes may

occur in vehicle handling such as lower track sta-

bility during braking, longer braking distances

and changes in self-steering properties when

close to the handling limit. These properties are

more noticeable with winter tires.<

Only one space-saver spare tire may be

mounted at one time. Mount a wheel and

tire of the original size as soon as possible, to

avoid any safety risks.<

Check the tire inflation pressure at the ear-

liest opportunity and correct it if neces-

sary. Replace the defective tire as soon as possi-

ble and have the new wheel/tire assembly

balanced.<

Preparing for a tire change

Observe the safety precautions regarding

flat tires on page130.<

Additional safety measures when chang-

ing tires:

Page 136 of 174

Replacing components

134

Only change the tire when parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

Do not lie under the vehicle or start the engine

when the vehicle is supported by the jack; other-

wise, there is a risk of fatal injury.<

1.Place the foldable chock

* behind the front

wheel on the other side of the vehicle or in

front of the wheel if the vehicle is on an

incline. If the wheel is changed on a surface

with a more severe slope, take additional

precautions to secure the vehicle from

rolling.

2.Uncover the lug bolts if necessary.

If the wheel is equipped with a hub cover,

pry it off using the screwdriver from the tire

change kit.

3.Loosen the lug bolts by a half turn.

Jacking up the vehicle

The vehicle jack is designed for changing

wheels only. Do not attempt to raise

another vehicle model with it or to raise any load

of any kind. To do so could cause accidents and

personal injury.<

1.Place the jack at the jacking point closest to

the wheel.The jack base must be perpendicular to the

surface beneath the jacking point.

2.During jacking up, insert the jack head in the

square recess of the jacking point.

3.Jack the vehicle up until the wheel you are

changing is raised off the ground.

Mounting the space-saver spare tire

1.Unscrew the lug bolts and remove the

wheel.

2.Remove accumulations of mud or dirt from

the mounting surfaces of the wheel and

hub. Clean the lug bolts.

3.Lift the new wheel into place.

4.Screw at least two lug bolts finger-tight into

opposite bolt holes.

5.Screw in the remaining bolts.

6.Tighten all the lug bolts firmly in a diagonal

pattern.

7.Lower the vehicle.

8.Remove the jack.

Tightening the lug bolts

Tighten the lug bolts in a diagonal pattern.

Immediately have the wheels checked

with a calibrated torque wrench to ensure

that the lug bolts are firmly seated. Otherwise,

incorrectly tightened lug bolts can present a

safety hazard.<

Tightening torque: 103.3 lb ft or 140 Nm.

Replace the defective tire as soon as possible

and have the new wheel/tire assembly bal-

anced.

Page 140 of 174

Giving and receiving assistance

138

Access to screw thread

Push out the cover of the towing eye out of the

recess in the bumper.

Front

Rear

Being towed

Make sure that the ignition is switched on,

refer to page46; otherwise, the low

beams, tail lamps, turn signal indicators and

windshield wipers may be unavailable. Do not

tow the vehicle with just the rear axle raised, as

this would allow the steering to turn. <

There is no power assist while the engine is off.

Thus, braking and steering will require increased

effort.

Switch on the hazard warning flashers, depend-

ing on local regulations.

Manual transmission

Gearshift lever in neutral position.

Automatic transmission

Tow vehicles with automatic transmission

only with a tow truck or with the front

wheels lifted; otherwise, the transmission can be

damaged.<

Towing with a tow bar

The towing vehicle must not be lighter

than the towed vehicle; otherwise, it may

be impossible to maintain control.<

The tow fittings used should be on the same side

on both vehicles. Should it prove impossible to

avoid mounting the tow bar at an angle, please

observe the following:

>Clearance and maneuvering capability will

be sharply limited during cornering.

>The tow bar will generate lateral forces if it is

attached offset.

Attach the tow bar to the tow fittings only,

as attaching it to other parts of the vehicle

could result in damage.<

Towing with a tow rope

When starting off in the towing vehicle, make

sure that the tow rope is taut.

To avoid jerking and the associated

stresses on vehicle components when

towing, always use nylon ropes or nylon straps.

Attach the tow rope to the tow fittings only, as

attaching it to other parts of the vehicle could

result in damage.<

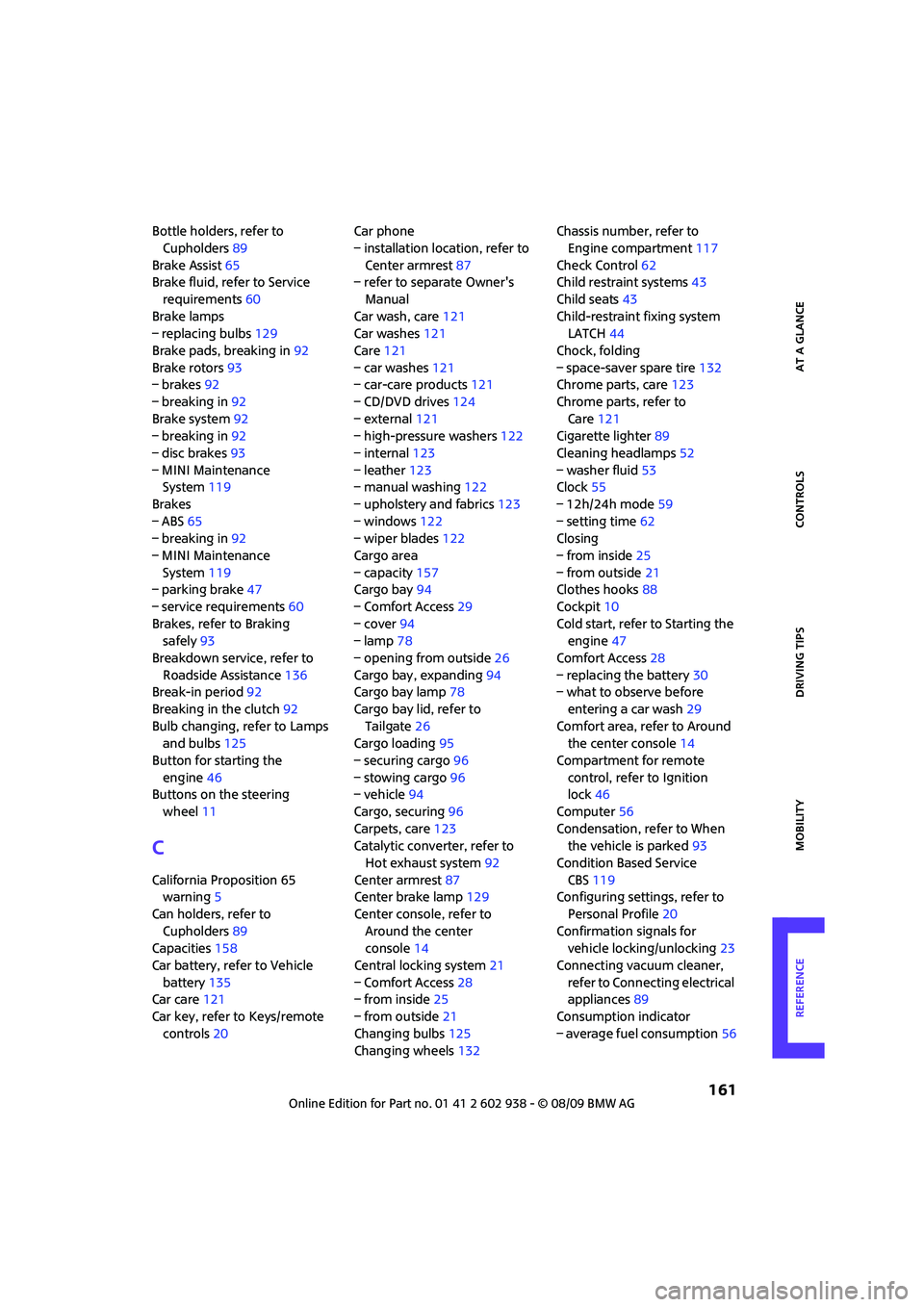

Towing with a tow truck

Have the MINI or MINI Convertible transported

by a tow truck with a so-called lift sling or on a

flatbed.

Do not lift the vehicle by a tow fitting or

body and chassis parts; otherwise, dam-

age may result.<

Page 150 of 174

Indicator and warning lamps

148

Vehicles with Flat Tire Monitor*

Light up in yellow and red:

>Tire damageCarefully bring the car to a stop.

Observe the information starting on

page67.

>Flat Tire Monitor not initializedInitialize Flat Tire Monitor, page67.

Light up in yellow:

Flat Tire Monitor failed. Punctures are

not indicatedHave the system checked.

Vehicles with Tire Pressure Monitor

*

Light up in yellow and red:

There is a flat tire or substantial loss

in tire pressureCarefully bring the car to a stop.

Observe the information starting on

page69.

Vehicles with Tire Pressure Monitor

*

Light up in yellow:

Tire Pressure Monitor not initializedCheck the inflation pressure and reset

the system, page70.

The small lamp flashes yellow and

then stays on, the large lamp lights

up in yellow:

>Tire Pressure Monitor failed.

Punctures are not indicatedHave the system checked.

>Wheel mounted without TPM

electronicsHave the system checked.

>The TPM is temporarily malfunc-

tioning due to other systems or

devices using the same radio fre-

quency.

12Cause What to do

Page 163 of 174

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

161

Bottle holders, refer to

Cupholders89

Brake Assist65

Brake fluid, refer to Service

requirements60

Brake lamps

– replacing bulbs129

Brake pads, breaking in92

Brake rotors93

– brakes92

– breaking in92

Brake system92

– breaking in92

– disc brakes93

– MINI Maintenance

System119

Brakes

– ABS65

– breaking in92

– MINI Maintenance

System119

– parking brake47

– service requirements60

Brakes, refer to Braking

safely93

Breakdown service, refer to

Roadside Assistance136

Break-in period92

Breaking in the clutch92

Bulb changing, refer to Lamps

and bulbs125

Button for starting the

engine46

Buttons on the steering

wheel11

C

California Proposition 65

warning5

Can holders, refer to

Cupholders89

Capacities158

Car battery, refer to Vehicle

battery135

Car care121

Car key, refer to Keys/remote

controls20Car phone

– installation location, refer to

Center armrest87

– refer to separate Owner's

Manual

Car wash, care121

Car washes121

Care121

– car washes121

– car-care products121

– CD/DVD drives124

– external121

– high-pressure washers122

– internal123

– leather123

– manual washing122

– upholstery and fabrics123

– windows122

– wiper blades122

Cargo area

– capacity157

Cargo bay94

– Comfort Access29

– cover94

– lamp78

– opening from outside26

Cargo bay, expanding94

Cargo bay lamp78

Cargo bay lid, refer to

Tailgate26

Cargo loading95

– securing cargo96

– stowing cargo96

– vehicle94

Cargo, securing96

Carpets, care123

Catalytic converter, refer to

Hot exhaust system92

Center armrest87

Center brake lamp129

Center console, refer to

Around the center

console14

Central locking system21

– Comfort Access28

– from inside25

– from outside21

Changing bulbs

125

Changing wheels132Chassis number, refer to

Engine compartment117

Check Control62

Child restraint systems43

Child seats43

Child-restraint fixing system

LATCH44

Chock, folding

– space-saver spare tire132

Chrome parts, care123

Chrome parts, refer to

Care121

Cigarette lighter89

Cleaning headlamps52

– washer fluid53

Clock55

– 12h/24h mode59

– setting time62

Closing

– from inside25

– from outside21

Clothes hooks88

Cockpit10

Cold start, refer to Starting the

engine47

Comfort Access28

– replacing the battery30

– what to observe before

entering a car wash29

Comfort area, refer to Around

the center console14

Compartment for remote

control, refer to Ignition

lock46

Computer56

Condensation, refer to When

the vehicle is parked93

Condition Based Service

CBS119

Configuring settings, refer to

Personal Profile20

Confirmation signals for

vehicle locking/unlocking23

Connecting vacuum cleaner,

refer to Connecting electrical

appliances89

Consumption indicator

– average fuel consumption56

Page 166 of 174

From A to Z

164

Glove compartment86

Grills, refer to Air vents80

Gross vehicle weight, refer to

Weights157

H

Halogen lamps

– replacing bulb126

Handbrake, refer to Parking

brake47

Hands-free system14

Hazard warning flashers14

Head airbags72

Head restraints39

– sitting safely37

Headlamp control,

automatic75

Headlamp flasher50

– indicator lamp11,140

Headlamps

– replacing bulb126

Headlamps, care122

Heated

– mirrors41

– rear window81,83

– seats40

Heating80

– mirrors41

– rear window81,83

– seats40

Heavy loads, refer to Stowing

cargo96

Height adjustment

– seats38

– steering wheel42

Height, refer to

Dimensions155

High beams77

– headlamp flasher77

– indicator lamp140

– replacing bulb126

High water, refer to Driving

through water93

Hill Assist66

Hills93

Holders for cups89

Homepage4Horn10

Hot exhaust system92

Hydroplaning92

I

Ice warning55

Icy roads, refer to Outside

temperature warning55

Ignition46

– switched off46

– switched on46

Ignition key position 1, refer to

Radio readiness46

Ignition key position 2, refer to

Ignition on46

Ignition key, refer to

Integrated key/remote

control20

Ignition lock46

Imprint2

Indicator and warning

lamps13,140

– Tire Pressure Monitor TPM70

Indicator lighting, refer to

Instrument lighting78

Individual air distribution82

Individual settings, refer to

Personal Profile20

Inflation pressure monitoring,

refer to Tire Pressure Monitor

TPM69

Initializing

– Flat Tire Monitor FTM67

– glass sunroof, electric30

Instrument cluster, refer to

Displays12

Instrument lighting78

Instrument panel, refer to

Cockpit10

Instrument panel, refer to

Displays12

Integrated key20

Integrated universal remote

control85

Interior lamps78

– remote control23Interior rearview mirror41

– automatic dimming

feature42

Interlock48

Intermittent mode of the

wipers51

Internet page4

J

Jacking points134

Jets, refer to Window washer

nozzles53

Jumpering, refer to Jump-

starting136

Jump-starting136

K

Key Memory, refer to Personal

Profile20

Key, refer to Keys/remote

controls20

Keyless go, refer to Comfort

Access28

Keyless opening and closing,

refer to Comfort Access28

Kickdown49

– automatic transmission with

Steptronic49

Knock control103

L

Lamps and bulbs, replacing

bulbs125

Lamps, refer to Parking lamps/

Low beams75

Lashing eyes, refer to Securing

cargo96

LATCH child-restraint fixing

system44

Leather care123

LEDs light-emitting diodes126

Length, refer to

Dimensions155

License plate lamp

– bulb replacement129

Page 167 of 174

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

165

Light switch75

Light-alloy wheels, care123

Light-emitting diodes

LEDs126

Lighter89

– socket89

Lighting

– lamps and bulbs125

– of the instruments78

– of vehicle, refer to Lamps75

Limit151

Load95

Load securing equipment,

refer to Securing cargo96

Lock buttons of doors, refer to

Locking25

Locking

– adjusting confirmation

signal23

– from inside25

– from outside22

– without remote control, refer

to Comfort Access28

Locking and unlocking doors

– confirmation signals23

– from inside25

– from outside21

Low beams75

– automatic75

– replacing bulb126

Lower back support, refer to

Lumbar support38

Luggage compartment

– emergency operation, refer

to Manual release26

– increasing the capacity95

– opening from the inside26

Luggage compartment lid

– emergency operation, refer

to Manual release26

Luggage compartment lid,

refer to Tailgate26

Luggage compartment, refer

to Cargo bay26

Luggage rack, refer to Roof-

mounted luggage rack97

Lumbar support38M

M+S tires, refer to Winter

tires115

Maintenance, refer to Service

Booklet

Maintenance system119

Malfunction

– convertible top34

– trunk lid26

Malfunction warnings, refer to

Check Control62

Manual air distribution82

Manual mode

– automatic transmission with

Steptronic49

Manual operation

– door lock24

– fuel filler flap102

– power convertible top34

– transmission lock, automatic

transmission50

– trunk lid26

Manual transmission48

Manual washing122

Master key, refer to Integrated

key/remote control20

Maximum cooling83

Maximum speed

– with winter tires115

Medical assistance, refer to

First aid pouch136

Microfilter

– for air conditioner82

– for automatic climate

control84

– MINI Maintenance

System119

Microfilter/activated-charcoal

filter

– MINI Maintenance

System119

Microphone for telephone14

MINI Internet page4

MINI Maintenance System119

Mirror dimming feature42Mirrors41

– exterior mirrors41

– heating41

– interior rearview mirror41

Mobile phone

– installation location, refer to

Center armrest87

– refer to separate Owner's

Manual

Mobile phone, installation

location, refer to Center

armrest87

Mobile phone, refer to the

separate Owner's Manual

Mobility System130

Modifications, technical, refer

to For your own safety5

Monitoring system for tire

pressures, refer to Flat Tire

Monitor67

Multifunction switch

– refer to Turn signals/

headlamp flasher50

– refer to Wiper system51

Multifunctional steering

wheel, refer to Buttons on

the steering wheel11

N

Neck support, refer to Head

restraints39

Nets, refer to Storage

compartments88

New tires114

Number of cylinders, refer to

Engine data154

Nylon rope, refer to Tow

rope138

O

OBD socket, refer to Socket for

Onboard Diagnosis119

Octane ratings, refer to Fuel

specifications103

Odometer55