flat tire MINI COOPER CONVERTIBLE 2007 User Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2007, Model line: COOPER CONVERTIBLE, Model: MINI COOPER CONVERTIBLE 2007Pages: 172, PDF Size: 1.9 MB

Page 111 of 172

109

OVERVIEW REPAIRSOPERATIONCONTROLS DATA INDEX

TIRE CODING TIRE CONDITION Traction The traction grades, from highest to low-

est, are AA, A, B, and C.

Those grades represent the tire‘s ability to

stop on wet pavement as measured under

controlled conditions on specified govern-

ment test surfaces of asphalt and concrete.

A tire marked C may have poor traction per-

formance.

The traction grade assigned to this

tire is based on straight-ahead brak-

ing traction tests, and does not include

acceleration, cornering, hydroplaning, or

peak traction characteristics.

to the generation of heat and its ability to

dissipate heat when tested under con-

trolled conditions on a specified indoor lab-

oratory test wheel.

Sustained high temperature can cause the

material of the tire to degenerate and

reduce tire life, and excessive temperature

can lead to sudden tire failure. The grade C

corresponds to a level of performance

which all passenger car tires must meet

under the Federal Motor Vehicle Safety

Standard No. 109. Grades B and A represent

higher levels of performance on the labora-

tory test wheel than the minimum required

by law.

The temperature grade for this tire is

established for a tire that is properly

inflated and not overloaded. Excessive

speed, underinflation, or excessive loading,

either separately or in combination, can

cause heat buildup and possible tire fail-

ure.

the side of the tire, refer to page111.M+SWinter and all-season tires.

These have better winter performance

properties than summer tires.

Inspect your tires frequently for tread wear,

signs of damage and for foreign objects

lodged in the tread. Check the tread depth.Tire treadTread depth should not be allowed to go

below 1/8 in/3 mm even though in Europe,

for example, the legally specified minimum

tread depth is only 1/16 in/1.6 mm.

Below 1/8 in/3 mm tread depth, there is a

very high danger of hydroplaning at higher

speeds, even with only small amounts of

water on the road.

At tread depths below approx. 1/6 in/

4 mm, the ability of winter tires to cope

with winter driving conditions decreases

perceptibly. For safety reasons, new tires

should be mounted.

Page 113 of 172

111

OVERVIEW REPAIRSOPERATIONCONTROLS DATA INDEX

RUN-FLAT TIRES

*

You will recognize Run-Flat Tires by a circu-

lar symbol containing the letters RSC on

the side of the tire.

Run-Flat Tires consist of conditionally self-

supporting tires and special rims. The tire

reinforcement ensures that driving

remains possible to a restricted degree in

the event of a pressure drop or even a flat

tire.

For information on continuing to drive with

a flat tire, refer to Flat tire warning,

page75.

Tire change set

In case of a flat tire, the tire change

set is not needed, since your vehicle

has Run-Flat Tires.

When changing a tire, always observe the

safety measures and the procedure for

changing tires starting on page133.<

Your vehicle is additionally equipped with a

tire change set.

In the MINI COOPER and MINI COOPER Con-

vertible this is located in the luggage com-

partment under the floor mat.

In the MINI COOPER S and MINI COOPER S

Convertible, the tire change set is located in

a separate bag which is attached to the

lashing eyelets on the luggage compart-

ment floor by means of tie-down straps.

Have new wheels and tires mounted

only by your MINI Dealer or a special-

ized tire shop that has specially trained per-

sonnel working in accordance with the

specifications of the MINI manufacturer.

Work that is improperly carried out could

result in consequential damage and pose

safety hazards.<

Retreaded tires

The manufacturer of your MINI rec-

ommends that you avoid using

retreaded tires, as this could impair driving

safety. This is due to possible variations in

casing structures and, in some cases, to

their extreme age, factors which can lead

to limited durability.<

Page 114 of 172

112

NEW WHEELS AND TIRESThe correct wheels and tires

The manufacturer of your MINI rec-

ommends mounting only wheels and

tires that it has specifically approved for

use on your particular model. Although

other wheels and tires may theoretically

have the same dimensions, variations in

factors such as manufacturing tolerances

can result in contact between tire and

bodywork, ultimately leading to serious

accidents. The manufacturer of your MINI

cannot evaluate non-approved wheels and

tires to determine if they are suited for use,

and therefore cannot ensure the operating

safety of the vehicle if they are mounted.<

Your MINI Dealer will be glad to inform you

about the correct wheel and tire combina-

tion for your vehicle.

The correct wheel and tire combination is

also important for various systems that

would otherwise be impaired, e.g. ABS or

DSC.

To maintain good handling and vehicle

response, use only tires of a single brand

and tread configuration. In the event of tire

damage, remount the previous wheel and

tire combination as soon as possible.

Run-Flat TiresFor your own safety, use Run-Flat Tires

when mounting new tires or replacing

summer tires with winter tires or vice

versa. Keep in mind that no spare wheel is

available in the event of a flat. Your MINI

Dealer will be glad to advise you.

For safety reasons, the manufacturer

of your MINI recommends having

Run-Flat Tires replaced, not repaired, if they

are damaged.<

Tire designationFor each tire size, the manufacturer of your

MINI recommends certain tire brands. You

can recognize these by the clearly visible

designation on the tire's sidewall.

When used properly these tires meet the

highest standards regarding safety and

handling characteristics.

Page 115 of 172

113

OVERVIEW REPAIRSOPERATIONCONTROLS DATA INDEX

NEW WHEELS AND TIRES SNOW CHAINS

*

Special characteristics of winter tires

The manufacturer of your MINI recom-

mends winter tires for driving in adverse

winter road conditions. While all-season

tires with the M+S designation provide bet-

ter winter traction than summer tires, they

generally do not achieve the full perfor-

mance of winter tires.

Observe speed ratings:

Never exceed the maximum speed

for which the winter tires are rated.

tect the tires against contact with oil,

grease and fuel. Do not exceed the tire

inflation pressure specified on the tire side-

wall.

Only certain types of snow chains have

been tested by the manufacturer of your

MINI, classified as road-safe and recom-

mended. Contact your MINI Dealer for

more details. Their use is only permitted in

pairs on the front wheels on winter tires of

the following types:

>175/65 R 15 M+S

>175/60 R 16 M+S.

When fitting, comply with the manufac-

turer's instructions. With chains, do not

exceed a speed of 30 mph / 50 km/h.

Do not initialize the Flat Tire Monitor

after attaching snow chains to the

tires.

When driving with snow chains, it can be

helpful to switch off the ASC or DSC for a

brief period, refer to page72.<

Page 130 of 172

128

ONBOARD TOOL KIT WIPER BLADESThe picture shows as an example the tire

change set with onboard tools for vehicles

with the space-saver spare tire.

Depending on the equipment version, your

vehicle is equipped with a special onboard

tool kit stored at the locations described

below:

Tire change set with onboard tools for

space-saver spare tireIn the luggage compartment under the

floor mat.MINI Mobility System with tire change

set and onboard toolsIn the luggage compartment under the

floor mat.Tire change set and onboard tool kit

with Run-Flat TiresMINI COOPER and MINI COOPER Convert-

ible:

>In the luggage compartment under the

floor mat.

MINI COOPER S and MINI COOPER S Con-

vertible:

>Tire change set:

in the luggage compartment in a sepa-

rate pouch

>Onboard tool kit:

in the luggage compartment under the

floor mat.

Windshield wiper1. Rotate the wiper arm completely out

2. Set the wiper blade at an angle

3. Press the securing spring, see arrow

4. Unhook the wiper blade towards the

windshield

5. Pull the wiper blade past the wiper arm

toward the top

6. Insert the new wiper blade

7. Press into position until you hear it

engage.

Page 135 of 172

133

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

REPAIRING A FLAT TIRE SPACE-SAVER SPARE TIRE

*

Safety measures in the event of a

flat:

Park the vehicle as far away from flowing

traffic as possible, and switch on the haz-

ard warning flashers.

Turn the steering wheel to the straight-

ahead wheel position and engage the

steering lock. Engage the parking brake and

shift into 1st or reverse gear – selector lever

in P.

All passengers should be outside the vehi-

cle and well away from your immediate

working area – behind a guardrail, for

instance.

If a portable hazard warning lamp is avail-

able, set it up on the roadside at an appro-

priate distance from the rear of the vehicle.

Comply with all safety guidelines and regu-

lations.<

In the event of a flat tire, different proce-

dures should be followed depending on the

equipment included in your vehicle:

>Vehicles with Run-Flat Tires, refer to

page111

>Vehicles with a space-saver spare tire,

refer to the following section

>Vehicles with MINI Mobility System,

refer to page137.

To change a space-saver spare tire, proceed

as follows:

>Remove space-saver spare tire, refer to

the section after the next one

>Prepare for tire change, refer to page135

>Jack up the vehicle, refer to page136

>Mount the space-saver spare tire, refer

to page136

>Tighten the lug bolts, refer to page136

>Drive with space-saver spare tire, refer to

page135.

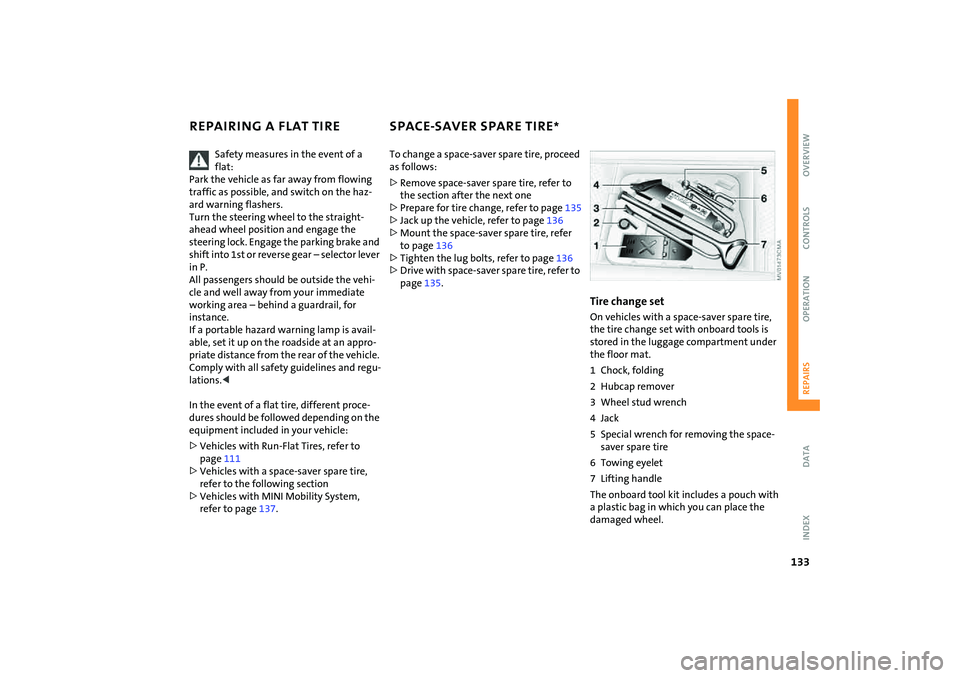

Tire change setOn vehicles with a space-saver spare tire,

the tire change set with onboard tools is

stored in the luggage compartment under

the floor mat.

1 Chock, folding

2 Hubcap remover

3 Wheel stud wrench

4Jack

5 Special wrench for removing the space-

saver spare tire

6 Towing eyelet

7 Lifting handle

The onboard tool kit includes a pouch with

a plastic bag in which you can place the

damaged wheel.

Page 137 of 172

135

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

SPACE-SAVER SPARE TIRE

*

CHANGING TIRES

9. Pull out the space-saver spare tire

towards the rear underneath the vehi-

cle

10. Position the space-saver spare tire with

the valve facing upwards

11. Unscrew the valve extension from the

valve of the space-saver spare tire

12. Unscrew the dust cap from the exten-

sion and place it on the valve of the

space-saver spare tire.

Due to its different dimensions, the

damaged wheel cannot be placed in

the recess for the space-saver spare tire.<

Driving with the space-saver spare tireDrive cautiously. Do not exceed a speed of

50 mph / 80 km/h.

You must expect changes in vehicle han-

dling such as lower track stability during

braking, longer braking distances and

changes in self-steering properties when

close to the handling limit. These effects

are more pronounced when driving with

winter tires.

Only one space-saver spare tire may

be mounted at one time. Reinstall a

wheel and tire of the original size as soon

as possible.<

Check the tire inflation pressure at

the earliest opportunity and correct it

if necessary. Replace the defective tire as

soon as possible and have the new wheel/

tire assembly balanced.<

Additional safety measures in the

event of a tire change:

Change tires only on a flat, solid and non-

slippery surface.

The vehicle or the jack could slip sideways

on soft or slippery support surfaces, such as

snow, ice, flagstones, etc..

Do not use a wooden block or similar object

as a support base for the jack, as this would

prevent it from extending to its full support

height and reduce its load-carrying capac-

ity.

Do not lie under the vehicle or start the

engine when the vehicle is supported by

the jack – risk of fatal injury.<

Preparing for a tire change

Observe the safety precautions

regarding flat tires on page133.<

1. For vehicles with a space-saver spare

tire:

Place the folding chock behind the front

wheel on the other side of the vehicle;

on downward inclines, place it in front of

this wheel. If the wheel is changed on a

surface with a more severe slope, take

additional precautions to secure the

vehicle from rolling

2. Loosen the lug bolts by a half turn.

Page 139 of 172

137

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

MINI MOBILITY SYSTEM

*

MINI Mobility System

The MINI Mobility System is provided to

help you repair a flat tire. With the help of

this system you can apply a liquid sealant

on the inside of the tire, which seals the

damaged area and enables you to continue

to drive.Preparing for tire repair

Before using the MINI Mobility Sys-

tem read the warning and danger

precautions on the equipment.<

If possible, leave objects in which have

been forced into the tire.

Take off the tag regarding speed limits and

stick it onto the steering wheel.

Using the MINI Mobility SystemIn order to repair a flat tire with the MINI

Mobility System, proceed as follows:

>Pump in liquid sealant, refer to page138

>Reinflate the tire, refer to page138

>Distribute liquid sealant, refer to

page139

>Check tire inflation pressure, refer to

page139

>Drive on, refer to page139.

MINI Mobility System with onboard

tools The MINI Mobility System with tire change

set and onboard tools is located in the lug-

gage compartment under the floor mat:

1Jack

2 Wheel stud wrench

3 Hubcap remover

4 Wrench, screwdriver/Phillips screw-

driver, towing eyelet

5 Compressor, hose with manometer and

plug for cigarette lighter socket

6 Package with filling hose, valve remover

and valve core

7 Filling canister

8 Hex wrench/screwdriver

9 Adapter for wheel lug lock

Page 140 of 172

138

MINI MOBILITY SYSTEM

*

Pumping in liquid sealant

1. Shake the filling canister

2. Screw the filling hose onto the filling

canister

3. Unscrew the dust protection cap from

the valve of the defective tire

4. Screw out the valve core with the valve

remover. The valve remover is located in

a package with the filling hose.

Place the valve core and valve

remover only on clean surfaces.<

5. Remove the cap from the filling hose

6. Push the filling hose onto the tire valve

7. Hold the filling canister with the cap

down and squeeze.

Squeeze the entire contents of the canis-

ter into the tire

8. Remove filling hose

9. Screw valve core into the tire valve with

the valve remover.

In the event of a lost or dirty valve

core you will find another valve core

in a package with the filling hose.

Please remember that the liquid canister

must be replaced every four years if the

equipment has not been used.<

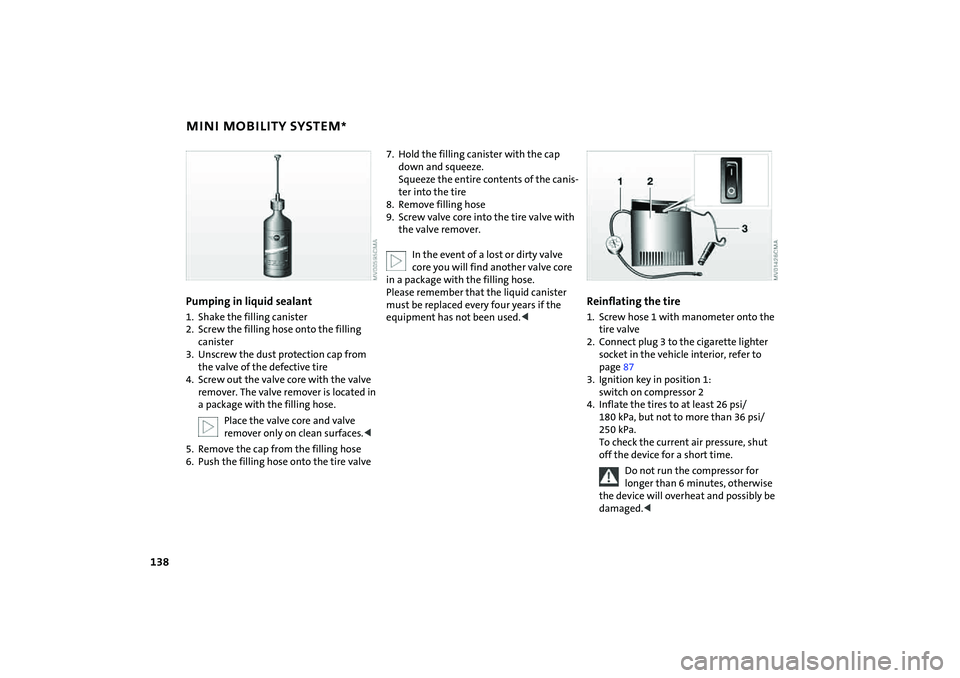

Reinflating the tire1. Screw hose 1 with manometer onto the

tire valve

2. Connect plug 3 to the cigarette lighter

socket in the vehicle interior, refer to

page87

3. Ignition key in position 1:

switch on compressor 2

4. Inflate the tires to at least 26 psi/

180 kPa, but not to more than 36 psi/

250 kPa.

To check the current air pressure, shut

off the device for a short time.

Do not run the compressor for

longer than 6 minutes, otherwise

the device will overheat and possibly be

damaged.<

Page 141 of 172

139

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

MINI MOBILITY SYSTEM

*

If an air pressure of 26 psi/180 kPa

cannot be reached, unscrew the

hose 1 and drive back and forth

about 33 ft/10 m so that the liquid seal-

ant is distributed in the tire. Afterwards

repeat the procedure.

If an air pressure of 26 psi/180 kPa is still

not reached, the tire is too badly dam-

aged. Please contact the nearest MINI

Dealer.<

5. Turn off compressor 2

6. Unscrew hose 1 from the tire valve

7. Store the MINI Mobility System back in

the vehicle.

The instructions for using the MINI

Mobility System are also given on the

equipment.<

Distributing liquid sealantImmediately drive for approx. 10 minutes,

so that the liquid sealant is uniformly dis-

tributed.

Do not exceed a speed of 40 mph /

60 km/h.

If possible do not drive at a speed lower

than 10 mph / 20 km/h.<

Checking tire inflation pressure1. After driving for approx. 10 minutes, pull

over at a suitable location

2. Screw hose with manometer back onto

the tire valve

3. Check the tire inflation pressures.

The tire inflation pressure must be

at least 18 psi/130 kPa. If it is not,

do not continue driving.<

If 18 psi/130 kPa are displayed:

4. Ignition key position 1:

switch on compressor 2. Correct the tire

inflation pressure to the specified value,

refer to the tire inflation pressure table

on page105

5. Replace the tire as soon as possible.

The use of the MINI Mobility System

may be ineffective with tire damage

larger than approx. 1/6in/4mm. Please

contact the nearest MINI Dealer if the tire

cannot be made drivable with the MINI

Mobility System.<

Driving on

Do not exceed the permitted maxi-

mum speed of 50 mph / 80 km/h;

otherwise an accident could happen.<

Replace the defective tire as soon as

possible and have the new wheel/tire

assembly balanced. Have the MINI Mobility

System refilled.<

Tire change setWhen changing a tire, always observe the

safety measures and the procedure for

changing tires starting on page133.

In case of a flat tire the tire change

set is not needed due to the availabil-

ity of the MINI Mobility System.<