wheel MINI COOPER CONVERTIBLE 2016 Repair Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2016, Model line: COOPER CONVERTIBLE, Model: MINI COOPER CONVERTIBLE 2016Pages: 252, PDF Size: 5.41 MB

Page 196 of 252

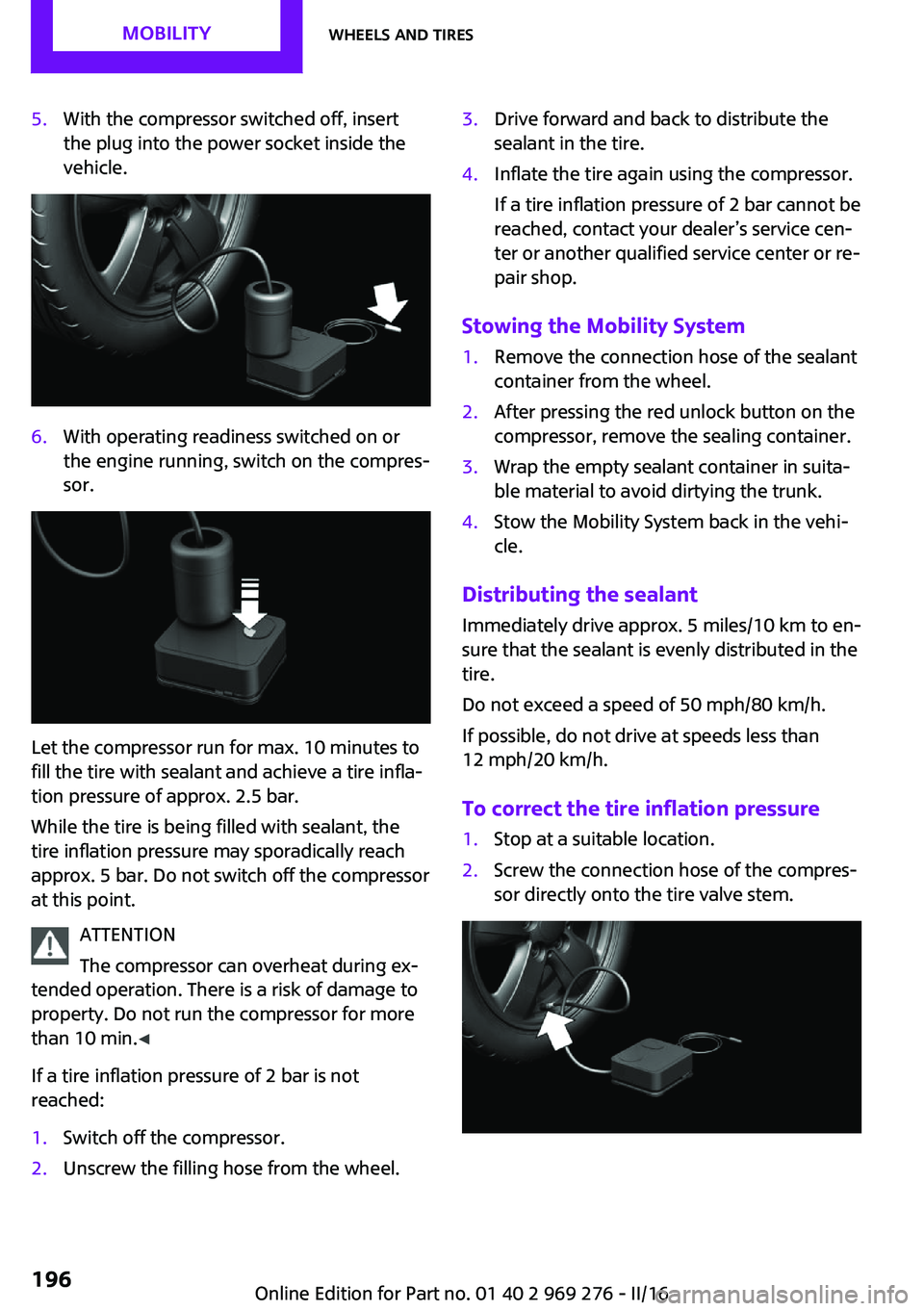

5.With the compressor switched off, insert

the plug into the power socket inside the

vehicle.6.With operating readiness switched on or

the engine running, switch on the compres‐

sor.

Let the compressor run for max. 10 minutes to

fill the tire with sealant and achieve a tire infla‐

tion pressure of approx. 2.5 bar.

While the tire is being filled with sealant, the

tire inflation pressure may sporadically reach

approx. 5 bar. Do not switch off the compressor

at this point.

ATTENTION

The compressor can overheat during ex‐

tended operation. There is a risk of damage to

property. Do not run the compressor for more

than 10 min. ◀

If a tire inflation pressure of 2 bar is not

reached:

1.Switch off the compressor.2.Unscrew the filling hose from the wheel.3.Drive forward and back to distribute the

sealant in the tire.4.Inflate the tire again using the compressor.

If a tire inflation pressure of 2 bar cannot be

reached, contact your dealer’s service cen‐

ter or another qualified service center or re‐

pair shop.

Stowing the Mobility System

1.Remove the connection hose of the sealant

container from the wheel.2.After pressing the red unlock button on the

compressor, remove the sealing container.3.Wrap the empty sealant container in suita‐

ble material to avoid dirtying the trunk.4.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive approx. 5 miles/10 km to en‐

sure that the sealant is evenly distributed in the

tire.

Do not exceed a speed of 50 mph/80 km/h.

If possible, do not drive at speeds less than

12 mph/20 km/h.

To correct the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose of the compres‐

sor directly onto the tire valve stem.Seite 196MOBILITYWheels and tires196

Online Edition for Part no. 01 40 2 969 276 - II/16

Page 197 of 252

3.Insert the connector into a power socket in‐

side the vehicle.4.Correct the tire inflation pressure to at least

2.0 bar.▷Increase pressure: with the ignition

turned on or the engine running, switch

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible speed

of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor, refer to

page 113.

Reinitialize the Tire Pressure Monitor, refer to

page 109.

Replace the nonworking tire and the sealant

container of the Mobility System as soon as

possible.

Snow chains Fine-link snow chains

The manufacturer of your vehicle recommends use of fine-link snow chains. Certain types of

fine-link snow chains have been tested by the

manufacturer of the vehicle and recommended

as road-safe and suitable.

Information regarding suitable snow chains is

available from a dealer’s service center or an‐ other qualified service center or repair shop.

Use

WARNING

With the mounting of snow chains on un‐

suitable tires, the snow chains can come into

contact with vehicle parts. There is a risk of ac‐

cidents or a risk of property damage. Only

mount snow chains on tires that are designated

by their manufacturer as suitable for the use of

snow chains. ◀

Use only in pairs on the front wheels, equipped

with the tires of the following size:▷175/65 R 15.▷175/60 R 16.

John Cooper Works:

▷185/50 R 17.

Follow the snow chain manufacturer's instruc‐

tions.

Make sure that the snow chains are always suf‐

ficiently tight. Re-tighten as needed according

to the snow chain manufacturer's instructions.

Do not initialize the Flat Tire Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

Do not initialize the Tire Pressure Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

When driving with snow chains, briefly activate

Dynamic Traction Control if needed.

Maximum speed with snow chains

Do not exceed a speed of 30 mph/50 km/h

when using snow chains.

Seite 197Wheels and tiresMOBILITY197

Online Edition for Part no. 01 40 2 969 276 - II/16

Page 211 of 252

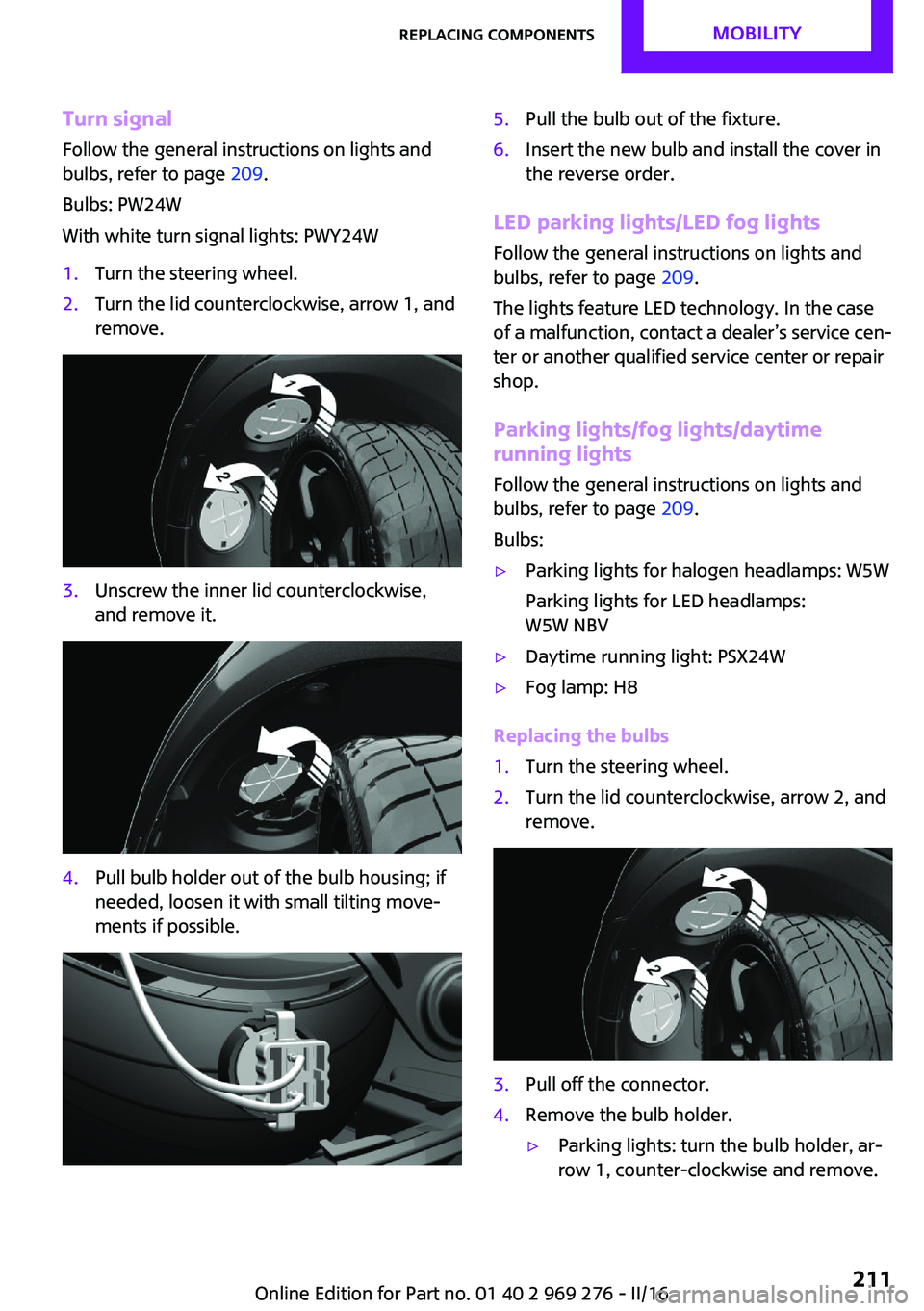

Turn signalFollow the general instructions on lights and

bulbs, refer to page 209.

Bulbs: PW24W

With white turn signal lights: PWY24W1.Turn the steering wheel.2.Turn the lid counterclockwise, arrow 1, and

remove.3.Unscrew the inner lid counterclockwise,

and remove it.4.Pull bulb holder out of the bulb housing; if

needed, loosen it with small tilting move‐

ments if possible.5.Pull the bulb out of the fixture.6.Insert the new bulb and install the cover in

the reverse order.

LED parking lights/LED fog lights

Follow the general instructions on lights and

bulbs, refer to page 209.

The lights feature LED technology. In the case

of a malfunction, contact a dealer’s service cen‐

ter or another qualified service center or repair

shop.

Parking lights/fog lights/daytime

running lights

Follow the general instructions on lights and

bulbs, refer to page 209.

Bulbs:

▷Parking lights for halogen headlamps: W5W

Parking lights for LED headlamps:

W5W NBV▷Daytime running light: PSX24W▷Fog lamp: H8

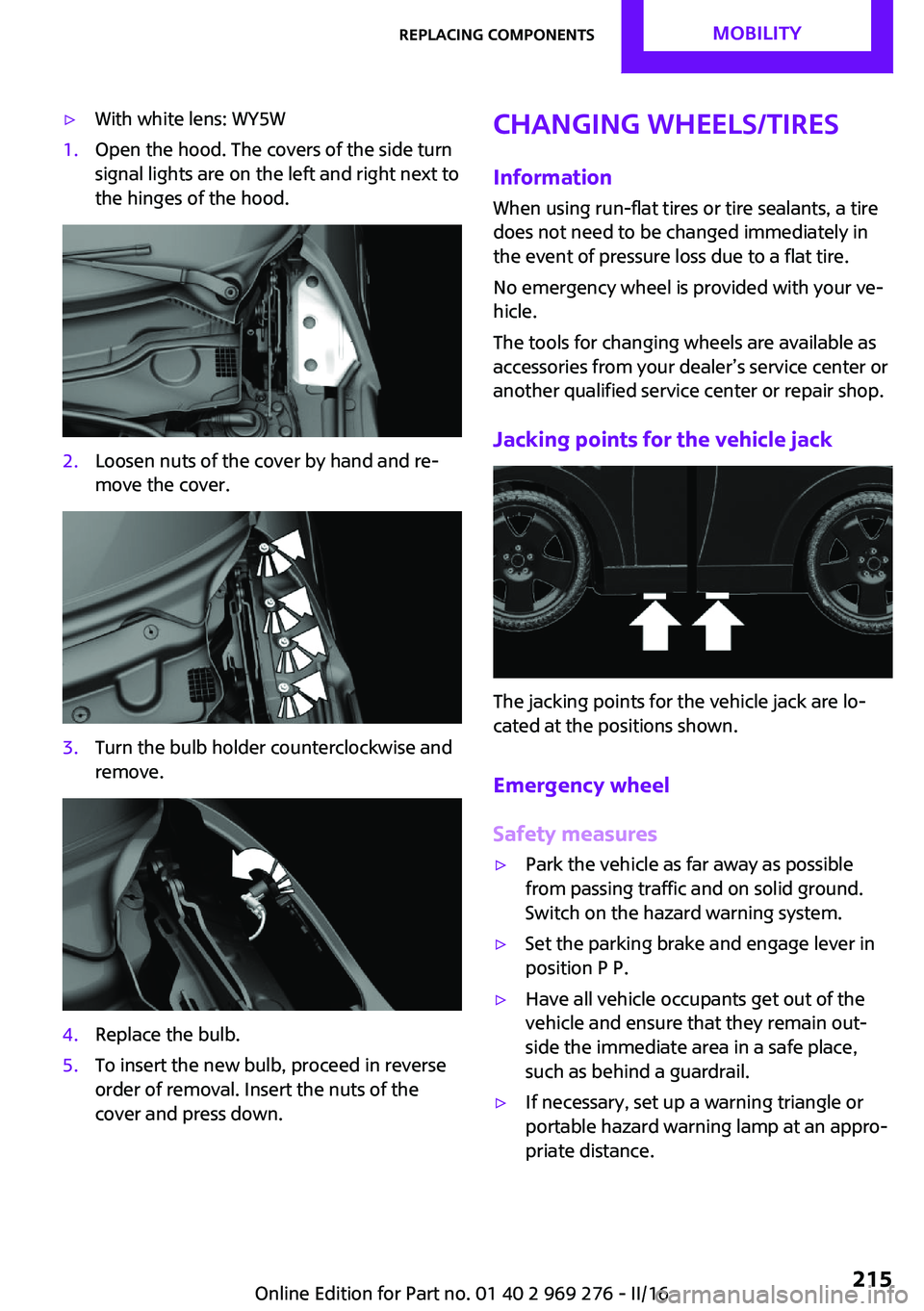

Replacing the bulbs

1.Turn the steering wheel.2.Turn the lid counterclockwise, arrow 2, and

remove.3.Pull off the connector.4.Remove the bulb holder.▷Parking lights: turn the bulb holder, ar‐

row 1, counter-clockwise and remove.Seite 211Replacing componentsMOBILITY211

Online Edition for Part no. 01 40 2 969 276 - II/16

Page 215 of 252

▷With white lens: WY5W1.Open the hood. The covers of the side turn

signal lights are on the left and right next to

the hinges of the hood.2.Loosen nuts of the cover by hand and re‐

move the cover.3.Turn the bulb holder counterclockwise and

remove.4.Replace the bulb.5.To insert the new bulb, proceed in reverse

order of removal. Insert the nuts of the

cover and press down.Changing wheels/tires

InformationWhen using run-flat tires or tire sealants, a tire

does not need to be changed immediately in

the event of pressure loss due to a flat tire.

No emergency wheel is provided with your ve‐

hicle.

The tools for changing wheels are available as

accessories from your dealer’s service center or

another qualified service center or repair shop.

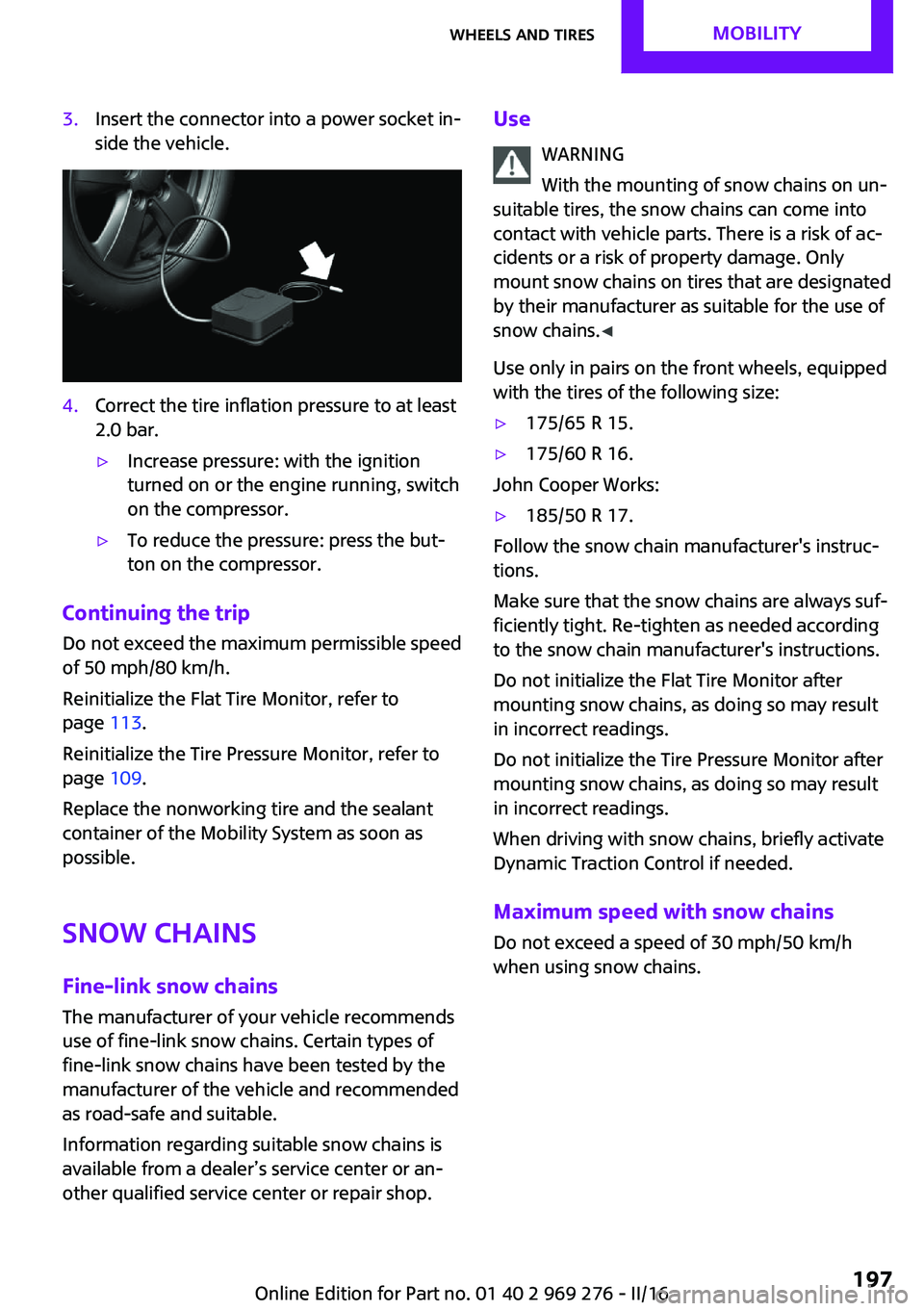

Jacking points for the vehicle jack

The jacking points for the vehicle jack are lo‐

cated at the positions shown.

Emergency wheel

Safety measures

▷Park the vehicle as far away as possible

from passing traffic and on solid ground.

Switch on the hazard warning system.▷Set the parking brake and engage lever in

position P P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.▷If necessary, set up a warning triangle or

portable hazard warning lamp at an appro‐

priate distance.Seite 215Replacing componentsMOBILITY215

Online Edition for Part no. 01 40 2 969 276 - II/16

Page 216 of 252

▷Perform wheel change only on a flat, solid

and slip-resistant surface. On soft or slip‐

pery ground, for example, snow, ice, tiles,

etc., the vehicle or vehicle jack can slip

away to the side.▷Do not place wood blocks or similar items

under the vehicle jack; otherwise, it cannot

reach its carrying capacity because of the

restricted height.▷If the vehicle is raised, do not lie under the

vehicle and do not start the engine; other‐

wise, a fatal hazard exists.

Information

WARNING

The vehicle jack is optimized for lifting

the vehicle and for the jacking points on the ve‐

hicle only. There is a a risk of injury. Do not lift

any other vehicle or cargo using the vehicle

jack. ◀

Removing the emergency wheel The emergency wheel is housed in a well on

the underbody of the vehicle. The screw con‐

nection of the emergency wheel is in the cargo

area underneath the floor mat, on the floor of

the storage compartment for the onboard vehi‐

cle tool kit.

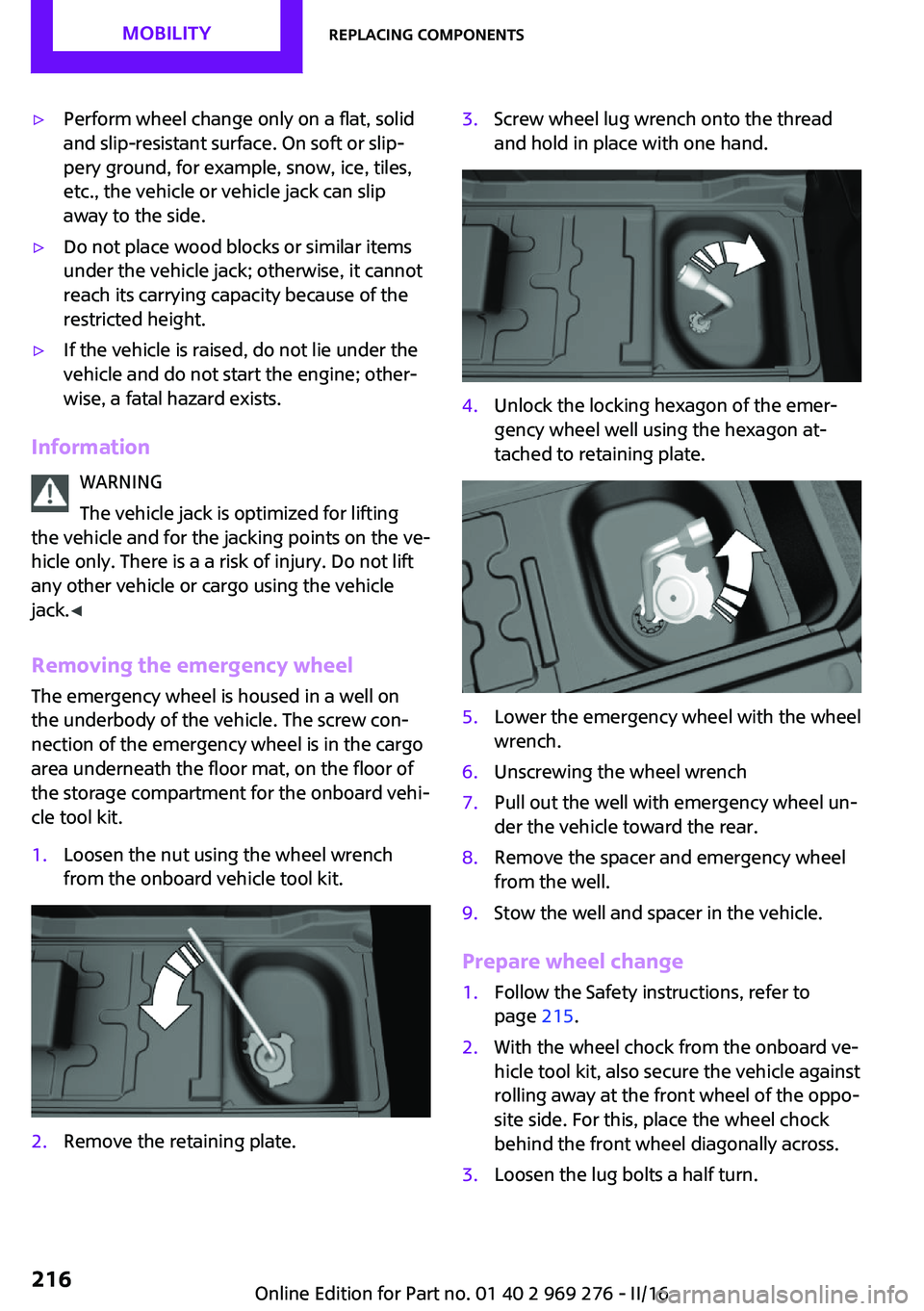

1.Loosen the nut using the wheel wrench

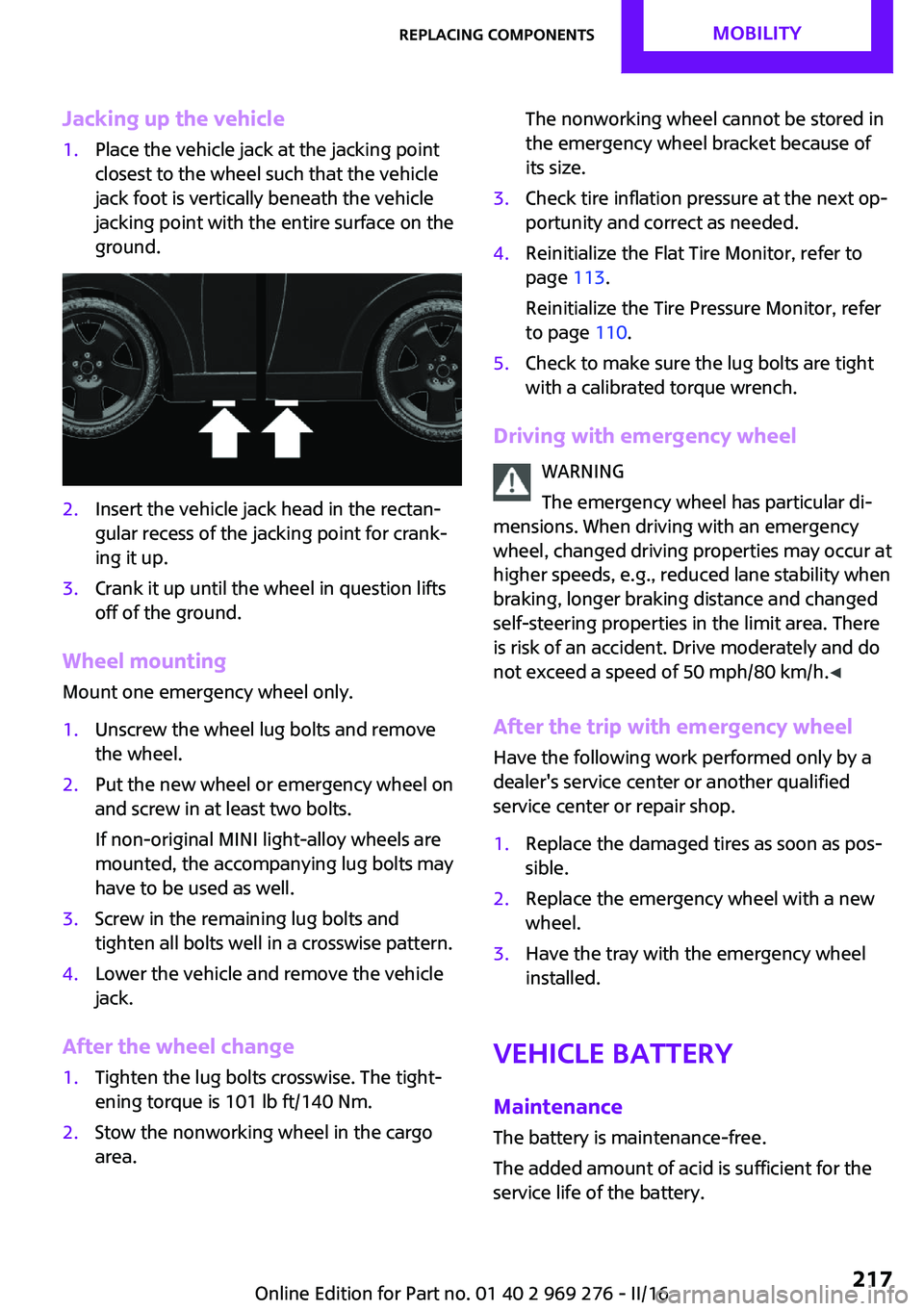

from the onboard vehicle tool kit.2.Remove the retaining plate.3.Screw wheel lug wrench onto the thread

and hold in place with one hand.4.Unlock the locking hexagon of the emer‐

gency wheel well using the hexagon at‐

tached to retaining plate.5.Lower the emergency wheel with the wheel

wrench.6.Unscrewing the wheel wrench7.Pull out the well with emergency wheel un‐

der the vehicle toward the rear.8.Remove the spacer and emergency wheel

from the well.9.Stow the well and spacer in the vehicle.

Prepare wheel change

1.Follow the Safety instructions, refer to

page 215.2.With the wheel chock from the onboard ve‐

hicle tool kit, also secure the vehicle against

rolling away at the front wheel of the oppo‐

site side. For this, place the wheel chock

behind the front wheel diagonally across.3.Loosen the lug bolts a half turn.Seite 216MOBILITYReplacing components216

Online Edition for Part no. 01 40 2 969 276 - II/16

Page 217 of 252

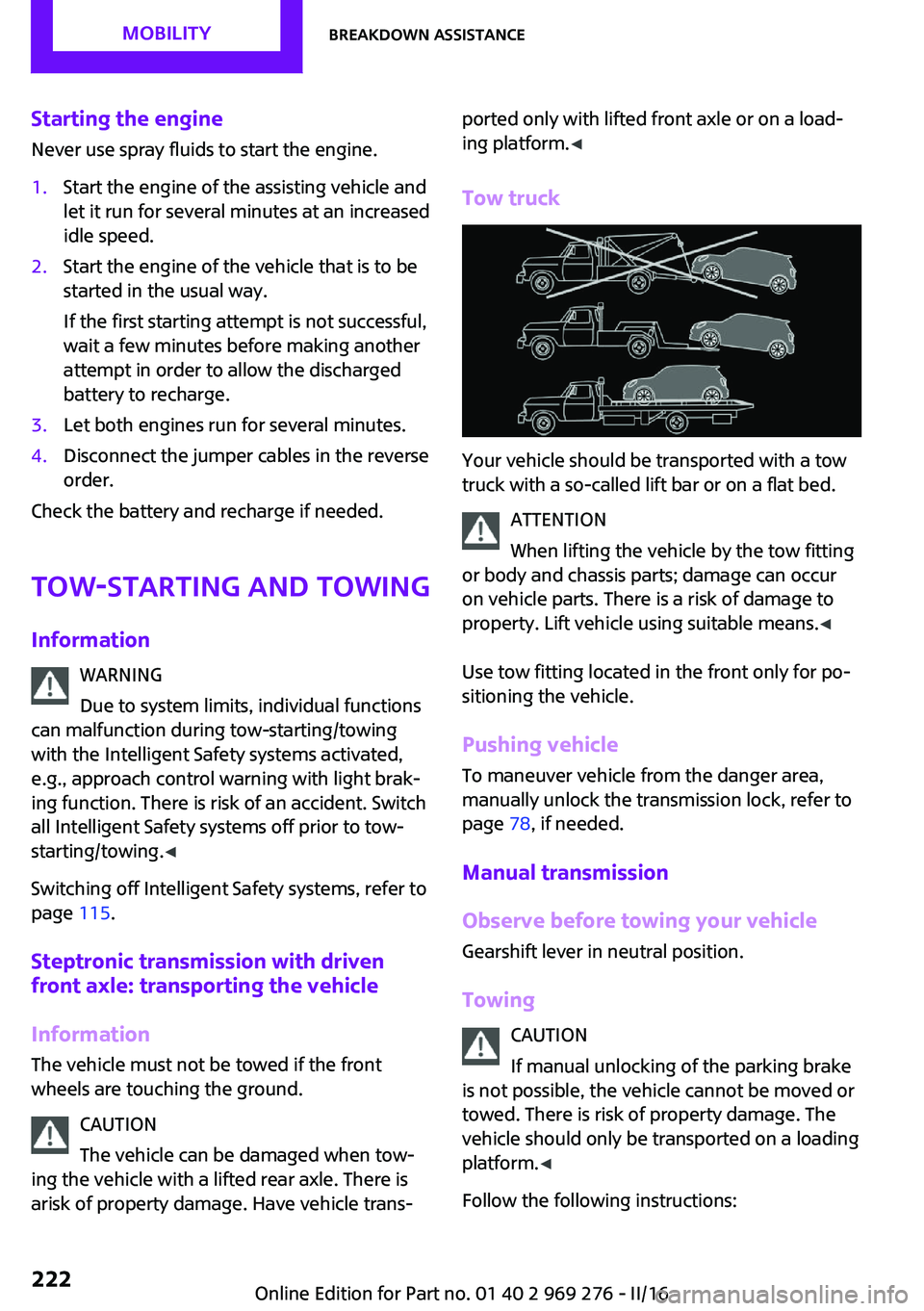

Jacking up the vehicle1.Place the vehicle jack at the jacking point

closest to the wheel such that the vehicle

jack foot is vertically beneath the vehicle

jacking point with the entire surface on the

ground.2.Insert the vehicle jack head in the rectan‐

gular recess of the jacking point for crank‐

ing it up.3.Crank it up until the wheel in question lifts

off of the ground.

Wheel mounting

Mount one emergency wheel only.

1.Unscrew the wheel lug bolts and remove

the wheel.2.Put the new wheel or emergency wheel on

and screw in at least two bolts.

If non-original MINI light-alloy wheels are

mounted, the accompanying lug bolts may

have to be used as well.3.Screw in the remaining lug bolts and

tighten all bolts well in a crosswise pattern.4.Lower the vehicle and remove the vehicle

jack.

After the wheel change

1.Tighten the lug bolts crosswise. The tight‐

ening torque is 101 lb ft/140 Nm.2.Stow the nonworking wheel in the cargo

area.The nonworking wheel cannot be stored in

the emergency wheel bracket because of

its size.3.Check tire inflation pressure at the next op‐

portunity and correct as needed.4.Reinitialize the Flat Tire Monitor, refer to

page 113.

Reinitialize the Tire Pressure Monitor, refer

to page 110.5.Check to make sure the lug bolts are tight

with a calibrated torque wrench.

Driving with emergency wheel

WARNING

The emergency wheel has particular di‐

mensions. When driving with an emergency wheel, changed driving properties may occur at

higher speeds, e.g., reduced lane stability when

braking, longer braking distance and changed

self-steering properties in the limit area. There

is risk of an accident. Drive moderately and do

not exceed a speed of 50 mph/80 km/h. ◀

After the trip with emergency wheel

Have the following work performed only by a

dealer's service center or another qualified

service center or repair shop.

1.Replace the damaged tires as soon as pos‐

sible.2.Replace the emergency wheel with a new

wheel.3.Have the tray with the emergency wheel

installed.

Vehicle battery

Maintenance

The battery is maintenance-free.

The added amount of acid is sufficient for the

service life of the battery.

Seite 217Replacing componentsMOBILITY217

Online Edition for Part no. 01 40 2 969 276 - II/16

Page 222 of 252

Starting the engineNever use spray fluids to start the engine.1.Start the engine of the assisting vehicle and

let it run for several minutes at an increased

idle speed.2.Start the engine of the vehicle that is to be

started in the usual way.

If the first starting attempt is not successful,

wait a few minutes before making another

attempt in order to allow the discharged

battery to recharge.3.Let both engines run for several minutes.4.Disconnect the jumper cables in the reverse

order.

Check the battery and recharge if needed.

Tow-starting and towing

Information WARNING

Due to system limits, individual functions

can malfunction during tow-starting/towing

with the Intelligent Safety systems activated,

e.g., approach control warning with light brak‐

ing function. There is risk of an accident. Switch

all Intelligent Safety systems off prior to tow-

starting/towing. ◀

Switching off Intelligent Safety systems, refer to

page 115.

Steptronic transmission with driven

front axle: transporting the vehicle

Information The vehicle must not be towed if the front

wheels are touching the ground.

CAUTION

The vehicle can be damaged when tow‐

ing the vehicle with a lifted rear axle. There is

arisk of property damage. Have vehicle trans‐

ported only with lifted front axle or on a load‐

ing platform. ◀

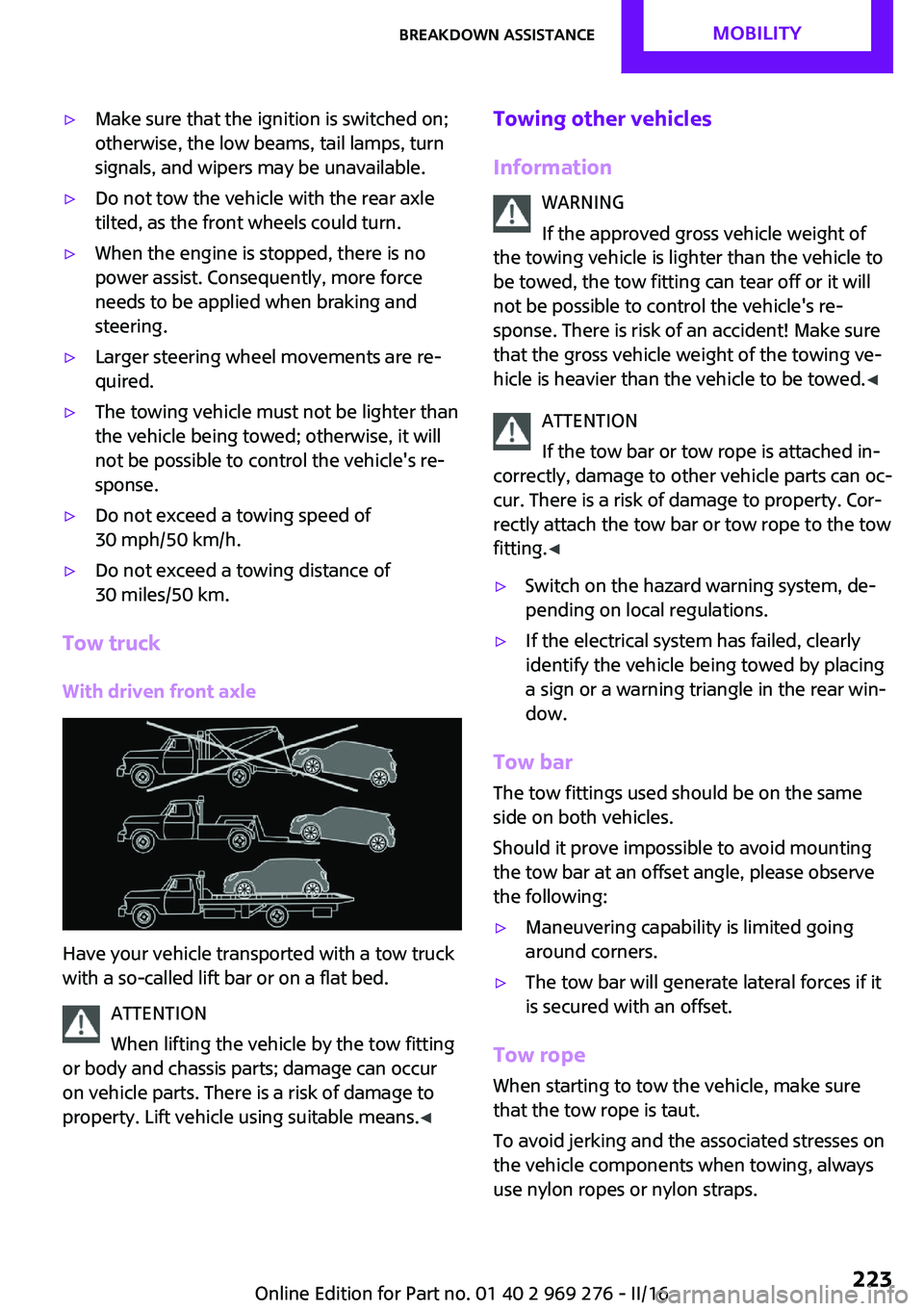

Tow truck

Your vehicle should be transported with a tow

truck with a so-called lift bar or on a flat bed.

ATTENTION

When lifting the vehicle by the tow fitting

or body and chassis parts; damage can occur

on vehicle parts. There is a risk of damage to

property. Lift vehicle using suitable means. ◀

Use tow fitting located in the front only for po‐

sitioning the vehicle.

Pushing vehicle

To maneuver vehicle from the danger area,

manually unlock the transmission lock, refer to

page 78, if needed.

Manual transmission

Observe before towing your vehicle

Gearshift lever in neutral position.

Towing CAUTION

If manual unlocking of the parking brake

is not possible, the vehicle cannot be moved or

towed. There is risk of property damage. The

vehicle should only be transported on a loading

platform. ◀

Follow the following instructions:

Seite 222MOBILITYBreakdown assistance222

Online Edition for Part no. 01 40 2 969 276 - II/16

Page 223 of 252

▷Make sure that the ignition is switched on;

otherwise, the low beams, tail lamps, turn

signals, and wipers may be unavailable.▷Do not tow the vehicle with the rear axle

tilted, as the front wheels could turn.▷When the engine is stopped, there is no

power assist. Consequently, more force

needs to be applied when braking and

steering.▷Larger steering wheel movements are re‐

quired.▷The towing vehicle must not be lighter than

the vehicle being towed; otherwise, it will

not be possible to control the vehicle's re‐

sponse.▷Do not exceed a towing speed of

30 mph/50 km/h.▷Do not exceed a towing distance of

30 miles/50 km.

Tow truck

With driven front axle

Have your vehicle transported with a tow truck

with a so-called lift bar or on a flat bed.

ATTENTION

When lifting the vehicle by the tow fitting

or body and chassis parts; damage can occur

on vehicle parts. There is a risk of damage to

property. Lift vehicle using suitable means. ◀

Towing other vehicles

Information WARNING

If the approved gross vehicle weight of

the towing vehicle is lighter than the vehicle to

be towed, the tow fitting can tear off or it will

not be possible to control the vehicle's re‐ sponse. There is risk of an accident! Make sure

that the gross vehicle weight of the towing ve‐

hicle is heavier than the vehicle to be towed. ◀

ATTENTION

If the tow bar or tow rope is attached in‐

correctly, damage to other vehicle parts can oc‐ cur. There is a risk of damage to property. Cor‐

rectly attach the tow bar or tow rope to the tow

fitting. ◀▷Switch on the hazard warning system, de‐

pending on local regulations.▷If the electrical system has failed, clearly

identify the vehicle being towed by placing

a sign or a warning triangle in the rear win‐

dow.

Tow bar

The tow fittings used should be on the same

side on both vehicles.

Should it prove impossible to avoid mounting

the tow bar at an offset angle, please observe

the following:

▷Maneuvering capability is limited going

around corners.▷The tow bar will generate lateral forces if it

is secured with an offset.

Tow rope

When starting to tow the vehicle, make sure

that the tow rope is taut.

To avoid jerking and the associated stresses on

the vehicle components when towing, always

use nylon ropes or nylon straps.

Seite 223Breakdown assistanceMOBILITY223

Online Edition for Part no. 01 40 2 969 276 - II/16

Page 229 of 252

ATTENTION

Open Velcro® fasteners on articles of

clothing can damage the seat covers. There is a

risk of damage to property. Ensure that any

Velcro® fasteners are closed. ◀

Caring for special components Light-alloy wheels

When cleaning the vehicle, use only neutral

wheel cleaners having a pH value from 5 to 9.

Do not use abrasive cleaning agents or steam

jets above 140 ℉/60 ℃. Follow the manufac‐

turer's instructions.

Aggressive, acidic or alkaline cleaning agents

can destroy the protective layer of adjacent

components, such as the brake disk.

Chrome surfaces

Carefully clean components such as the radia‐

tor grille or door handles with an ample supply

of water, possibly with shampoo added, partic‐

ularly when they have been exposed to road

salt.

Rubber components Environmental influences can cause surface

soiling of rubber parts and a loss of gloss. For

cleaning, use only water and suitable care

products, the manufacturer of your vehicle rec‐

ommends original MINI care products.

Treat especially worn rubber parts with rubber

care agents at regular intervals. When cleaning

rubber seals, do not use any silicon-containing

car care products in order to avoid damage or

noises.

Fine wood parts Clean fine wood facing and fine wood compo‐

nents only with a moist rag. Then dry with a

soft cloth.

Plastic components

These include:▷Imitation leather surfaces.▷Roofliner.▷Lamp lenses.▷Instrument cluster cover.▷Matt black spray-coated components.▷Painted parts in the interior.

Clean with a microfiber cloth.

Dampen cloth lightly with water.

Do not soak the roofliner.

ATTENTION

Cleansers that contain alcohol or solvents,

such as lacquer thinners, heavy-duty grease re‐

movers, fuel, or such, can damage plastic parts.

There is a risk of damage to property. Clean

with a microfiber cloth. Dampen cloth lightly

with water. ◀

Safety belts Dirty belt straps impede the reeling action and

thus have a negative impact on safety.

WARNING

Chemical cleansers can destroy the safety

belt webbing. Missing protective effect of the

safety belts. There is a risk of injury or danger to

life. Use only a mild soapy solution for cleaning

the safety belts. ◀

Use only a mild soapy solution, with the safety

belts clipped into their buckles.

Do not allow the switchs to retract the safety

belts until they are dry.

Carpets and floor mats WARNING

Objects in the driver's floor area can limit

the pedal distance or block a depressed pedal.

There is risk of an accident. Stow objects in the

vehicle such that they are secured and cannot

enter into the driver's floor area. Use floor mats

that are suitable for the vehicle and can be

safely attached to the floor. Do not use loose

Seite 229CareMOBILITY229

Online Edition for Part no. 01 40 2 969 276 - II/16

Page 234 of 252

Technical dataVehicle features and op‐

tions

This chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are notnecessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and sys‐

tems. The respectively applicable country provi‐

sions must be observed when using the respec‐

tive features and systems.

Information

The technical data and specifications in this

Owner's Manual are used as guidance values.

The vehicle-specific data can deviate from this,

for example, due to the selected special equip‐

ment, country version or country-specific

measurement method. Detailed values can be

found in the approval documents, on labels onthe vehicle or can be obtained from a dealer’s

service center or another qualified service cen‐

ter or repair shop.

The information in the vehicle documents al‐

ways has priority over the information in this

Owner's Manual.

Dimensions

The dimensions can vary depending on the

model version, equipment or country-specific

measurement method.

The specified heights do not take into account

attached parts, for example, a roof antenna,roof racks or spoiler. The heights can deviate,

for example, due to the selected special equip‐

ment, tires, load and chassis version. MINI CONVERTIBLEWidth with mirrorsinches/mm76.1/1,932Width without mirrorsinches/mm68/1,727Heightinches/mm55.7/1,415Lengthinches/mm151.1-152.5/3,837-3,874Wheelbaseinches/mm98.2/2,495Smallest turning radius diam.ft/m35.5/10.8Seite 234REFERENCETechnical data234

Online Edition for Part no. 01 40 2 969 276 - II/16