tires MINI Coupe 2014 Owner's Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2014, Model line: Coupe, Model: MINI Coupe 2014Pages: 224, PDF Size: 5.46 MB

Page 164 of 224

Maximum speed of winter tires

If the maximum speed of the vehicle is higher

than the permissible speed for the winter tires,

then display a corresponding sign in the field of

vision. You can obtain this sign from the tire

specialist or from your service center.

Maximum speed for winter tires

Do not exceed the maximum speed for

the winter tires; otherwise, tire damage and ac‐

cidents can occur. ◀

Run-flat tires When mounting new tires or changing fromsummer to winter tires or vice versa, use run-

flat tires for your own safety. Also, a compact

wheel is not available in case of a flat tire. Your

service center will be glad to advise you.

Rotating wheels between axles

Different wear patterns occur on the front and

rear axles, depending on the individual condi‐

tions of use.

To ensure even wear on the tires, the wheels

can be rotated between the axles. Your service

center will be glad to advise you.

After changing the tires, check the tire inflation

pressure and correct it if necessary.

Storage Store wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

sure indicated on the side wall of the tire.Run-flat tires

Label

The symbol identifying run-flat tires is a circle

with the letters RSC on the sidewall.

Run-flat tires are tires with special rims that

support themselves for a limited period of time.

The sidewall reinforcement ensures that the

tire can continue to be used to a limited extent

if it has lost pressure and even if it has become

completely depressurized.

For continued driving in the event of a flat tire,

refer to page 84.

Correcting a flat tire Safety measures in case of a breakdown

▷Park the vehicle as far as possible

from passing traffic and on solid

ground. Switch on the hazard warn‐

ing system.▷Let the steering wheel lock engage with the

wheels in the straight-ahead position, set

the handbrake, and engage first gear or re‐

verse, or engage selector lever position P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.Seite 164MobilityWheels and tires164

Online Edition for Part no. 01 40 2 911 475 - VI/13

Page 165 of 224

▷If a warning triangle or portable hazard

warning lamp is required, set it up on the

roadside at an appropriate distance from

the rear of the vehicle. Comply with all

safety guidelines and regulations. ◀

The procedure to correct a flat tire depends on

the equipment in the vehicle:

▷Run-flat tires, refer to page 164.▷MINI Mobility System, refer to page 165.▷Wheel change with a compact wheel, refer

to page 181.

MINI Mobility System

Notes

▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant bottle.▷Use of the Mobility System may be ineffec‐

tive if tire damage is greater than approx.

1/8 in/4 mm in size.▷Contact the nearest service center if the tire

cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

bottle and apply it to the steering wheel.

Sealant and compressor

1Sealant bottle and speed limit sticker2Filling hose

Note the use-by date on the sealant bottle.3Holder for the sealant bottle4Compressor5Connector and cable for the lighter socket/

socket in passenger compartment 102.6Connection hose for connecting the com‐

pressor and sealant bottle or the compres‐

sor and wheel7On/off switch8Pressure gauge for displaying the tire infla‐

tion pressure9Release button for reducing the tire infla‐

tion pressure

The connector, cable, and connecting hose are

stowed in the compressor housing.

Using the Mobility System

To repair a flat tire with the Mobility System,

proceed as follows:

▷Filling the tire with sealant▷Distributing the sealant▷Correcting the tire inflation pressure

Filling the tire with sealant

Adhere to the specified sequence

Adhere to the specified sequence of the

steps; otherwise, sealant may escape under

high pressure. ◀

1.Shake the sealant bottle.2.Pull the connection hose 6 fully out of the

compressor housing and screw it onto the

sealant bottle connection. Ensure that the

connection hose is not kinked.Seite 165Wheels and tiresMobility165

Online Edition for Part no. 01 40 2 911 475 - VI/13

Page 166 of 224

3.Insert the sealant bottle into the compres‐

sor housing in a vertical position.4.Unscrew the dust cap off of the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.5.Ensure that the compressor is switched off.6.Insert connector 5 into the lighter socket/

socket in the passenger compartment, refer

to page 102.7.When the engine is running:

Switch on the compressor and let it run for

approx. 3 to 8 minutes to fill sealant into

the tire and achieve a tire inflation pressure

of approx. 1.8 bar/26 psi.

While sealant is being filled, the inflation

pressure may intermittently rise to approx.

5 bar/73 psi. Do not switch off the com‐

pressor in this phase.8.Switch off the compressor.

Do not allow the compressor to run too

long

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If an air pressure of 1.8 bar/26 psi is not

reached:

1.Unscrew the filling hose 2 from the wheel

and drive forward and back approx.

33 ft/10 m to evenly distribute the sealant

in the tire.2.Inflate the tire again using the compressor.If the inflation pressure of 1.8 bar/26 psi is still

not reached, the tire is too heavily damaged.

Contact the nearest service center.

Stowing the Mobility System1.Unscrew the filling hose 2 of the sealant

bottle from the wheel.2.Unscrew the compressor connection hose 6

from the sealant bottle.3.Connect the filling hose 2 of the sealant

bottle with the free connector on the seal‐

ant bottle.

This prevents left-over sealant from escap‐

ing from the bottle.4.Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Drive approx. 3.1 miles/5 km to evenly distrib‐

ute the sealant.

Do not exceed a speed of 50 mph/80 km/h. If

possible, do not drop below a speed of

10 mph/20 km/h.

Correcting the tire inflation pressure

1.After driving approx. 3.1 miles/5 km, or

about 10 minutes, stop in a suitable loca‐

tion.2.Screw the connection hose 6 of the com‐

pressor directly onto the tire valve.3.Insert the connector 5 into the power

socket in the passenger compartment.4.Correct the tire inflation pressure to

1.8 bar/26 psi. When the engine is running:▷To increase the inflation pressure:

switch on the compressor. To check the

currently set inflation pressure, switch

off the compressor.▷To reduce the inflation pressure: press

the release button 9.Seite 166MobilityWheels and tires166

Online Edition for Part no. 01 40 2 911 475 - VI/13

Page 167 of 224

Do not allow the compressor to run too

long

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If the inflation pressure is not maintained, take

the vehicle on another drive, distributing the

sealant, refer to page 166. Then repeat steps

1 to 4 once.

If the inflation pressure of 1.8 bar/26 psi is still

not reached, the tire is too heavily damaged.

Contact the nearest service center.

Continuing the trip Note the maximum speed

Do not exceed the maximum speed of

50 mph/80 km/h; otherwise, accidents can oc‐

cur. ◀

Replace the defective tire as soon as possible

and have the wheel balanced.

Have the Mobility System refilled.

Snow chains

Only certain fine-link snow chains have been

tested by MINI, classified as safe for use, and

recommended. Consult your service center for more information.

Use only in pairs on the front wheels, equipped

with tires of the following size:▷175/65 R 15 M+S▷175/60 R 16 M+S

John Cooper Works:

▷185/50 R 17 86 H M+S XL RSC

Observe the manufacturer's instructions when

mounting snow chains. Do not exceed a speed

of 30 mph or 50 km/h when using snow chains.

Do not initialize the Flat Tire Monitor if snow

chains are mounted; otherwise, the instrument

might issue an incorrect reading. When driving

with snow chains, it may be useful to tempora‐

rily deactivate DSC or activate DTC, refer to

page 89.Seite 167Wheels and tiresMobility167

Online Edition for Part no. 01 40 2 911 475 - VI/13

Page 175 of 224

Replacing componentsVehicle equipmentThis chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

Tool kit Depending on the vehicle equipment, your ve‐

hicle contains a special onboard vehicle tool kit

that is stowed under the flat loading floor in the

cargo area.

With Mobility System1Sealant bottle2Hex key3Pulling hook4Vehicle jack5Lug bolts wrench6Screwdriver/cross-head, tow fitting7CompressorWith run-flat tires or compact wheel

The onboard vehicle tool kit contains a pouch

holding a plastic bag in which you can stow the

defective wheel.1Folding wheel chock and cover for the de‐

fective wheel2Pulling hook3Lug bolts wrench4Vehicle jack5Special wrench for releasing the compact

wheel6Screwdriver/cross-head7Tow fitting8Lifting handle

Wiper blade replacement

General information Do not fold down the wipers withoutwiper blades

Do not fold down the wipers if wiper blades

have not been installed; this may damage the

windshield. ◀

Seite 175Replacing componentsMobility175

Online Edition for Part no. 01 40 2 911 475 - VI/13

Page 181 of 224

1.Squeeze the clips, arrows, and remove the

bulb holder.2.Pull off the bulb and replace it.3.Insert the new bulb and bulb holder in re‐

verse order.4.Re-engage the bulb holder so that it audi‐

bly clicks into place.

John Cooper Works: aerodynamic bumper

The lamps are accessed via the rear side or the

underside of the bumper.

1.Remove the bulb holder by turning it coun‐

terclockwise, arrow.2.Pull off the bulb and replace it.3.Insert the new bulb and bulb holder in re‐

verse order.

License plate lamps

5-watt bulb, C 5 W

Replacing1.Push the lamp to the left in the catch of the

lamp housing using the screwdriver, ar‐

row 1.2.Take out the lamp, arrow 2.3.Replace the bulb.4.Insert the lamp.

Center brake lamp

This lamp uses LED technology for operation.

Contact your service center in the event of a

malfunction.

Changing wheels Notes

Wheel change for run-flat tires:

▷Prepare for the wheel change, refer to

page 183.▷Jack up the vehicle, refer to page 183.▷Tighten the lug bolts, refer to page 184.

Compact wheel

Wheel change with a compact wheel:

▷Remove the compact wheel, refer to

page 182.▷Prepare for the wheel change, refer to

page 183.▷Jack up the vehicle, refer to page 183.▷Mount the compact wheel, refer to

page 183.Seite 181Replacing componentsMobility181

Online Edition for Part no. 01 40 2 911 475 - VI/13

Page 183 of 224

driving characteristics could result, for example

reduced track stability on braking, extended

braking distance, and altered self-steering

characteristics in the limit range. In conjunction

with winter tires, these characteristics are more

pronounced. ◀

Only mount one compact wheel

Only one compact wheel may be

mounted. Restore the wheels and tires to their

original size as quickly as possible. Failure to do

so is a safety risk. ◀

Check the tire inflation pressure at the next op‐

portunity and correct it if necessary. Replace

the defective tire as soon as possible and have

the new wheel balanced.

Preparing wheel change

Observe the safety precautions regarding flat

tires, refer to page 164.

Additional safety precautions in the event

of a wheel change

Change the wheel only on a level, firm surface

which is not slippery.

The vehicle or the jack could slip to the side if

you attempt to raise the vehicle on a soft or

slippery surface, snow, ice, tiles, etc. Do not use

a wooden block or similar object as a support

base for the jack, as this would prevent it from

extending to its full support height and reduce

its load-carrying capacity.

To avoid serious or fatal injury: never lie under

the vehicle, and never start the engine while it

is supported by the jack. ◀1.Place the folding wheel chock behind the

front wheel of the other vehicle side; if the

vehicle is on an incline, place it in front of

this wheel. If the vehicle is parked on a

steep incline, additionally secure the vehi‐

cle against rolling.2.Expose the lug bolts if necessary.3.Loosen the lug bolts a half turn.Jacking up vehicle

The vehicle jack is designed for changing

wheels only.

The vehicle jack is designed for changing

wheels only. Do not attempt to raise another

vehicle model with it or to raise any load of any

kind. To do so could cause accidents and per‐

sonal injury. ◀

1.Position the vehicle jack at the jacking point

closest to the wheel.

The entire surface of the jack base must

rest on the ground vertically beneath the

jacking point.2.Guide the jack head into the rectangular re‐

cess of the jacking point when cranking up.3.Jack the vehicle up until the wheel you are

changing is raised from the ground.

Mounting the compact wheel

1.Unscrew the lug bolts and remove the

wheel.2.Remove accumulations of mud or dirt from

the mounting surfaces of the wheel and

hub. Also clean the lug bolts.Seite 183Replacing componentsMobility183

Online Edition for Part no. 01 40 2 911 475 - VI/13

Page 215 of 224

C

California Proposition 65 Warning 7

Car battery, refer to Vehicle battery 184

Car care products 192

Care, displays 195

Care, vehicle 192

Cargo area– Comfort Access 29– Emergency activation, refer

to Unlocking manually 27– Emergency unlocking 28– Opening from the out‐

side 27

Cargo area lamp, refer to Inte‐

rior lamps 78

Cargo area tailgate, refer to Tailgate 27

Car horn, refer to Horn 12

Carpet, care 194

Car phone, refer to Tele‐ phone 138

Car wash 191

CBC, Cornering Brake Con‐ trol 89

CBS Condition Based Serv‐ ice 173

CD/DVD drives, care 195

Center console, refer to Around the center con‐

sole 15

Central locking

– Comfort Access 28– From the inside 25– From the outside 22

Central locking system

– Concept 21– From the outside 21

Changes, technical, refer to

Safety 6

Changing wheels/tires 163

Check Control 72

Children, transporting 50

Child restraint fixing system LATCH 52

Child restraint fixing sys‐

tems 50

Child restraint fixing systems, mounting 50

Child seat, mounting 50

Child seats, refer to Transport‐ ing children safely 50

Chrome parts, care 194

Circulation of air, refer to Re‐ circulated air mode 97, 99

Cleaning, displays 195

Cleaning, refer to Care 191

Climate 96

Climate mode– Ventilation 101

Clock 65

Clock

– 12h/24h format 69

Closing

– From the inside 25– From the outside 22

Clutch, breaking in 112

Cockpit 12

Cold start, refer to Starting the engine 56

Combination instrument, refer to Displays 14

Combination switch, refer to Turn signal/high beams/

headlamp flasher 58

Combination switch, refer to Washer/wiper system 59

Comfort Access

– In the car wash 30– Replacing the battery 30

Comfort area, refer to Around

the center console 15

Compact wheel, inflation pres‐ sure 158

Compartment for remote con‐ trol, refer to Ignition lock 55

Computer 66

Computer, displaying informa‐ tion 66

Condition Based Service CBS 173

Confirmation signals for vehi‐

cle locking/unlocking 23

Consumption, refer to Aver‐ age fuel consumption 67

Control Display, care 195

Controls and displays 12

Control systems, driving stabil‐ ity 89

Convenient operation– Windows 23

Convertible top 32

Convertible top

– Manual 38– Mechanical 38

Coolant temperature 66

Cooling function, switching on and off 100

Cooling, maximum 99

Cornering Brake Control, CBC 89

Corrosion on brake discs 114

Cradle for telephone or mobile phone, refer to Snap-in

adapter 145

Cruise control 93

Cupholders 102

Current fuel consumption 67

Curve lights, refer to Adaptive Light Control 76

Cylinders, number of, refer to Engine data 210

D

Dashboard lighting, refer to Instrument lighting 77

Dashboard, refer to Cock‐ pit 12

Dashboard, refer to Dis‐ plays 14

Data, technical 210

Date

– Display format 69– Setting 70

Daytime running lights 75

Decorative trim, care 194

Defogging windows 97

Seite 215Everything from A to ZReference215

Online Edition for Part no. 01 40 2 911 475 - VI/13

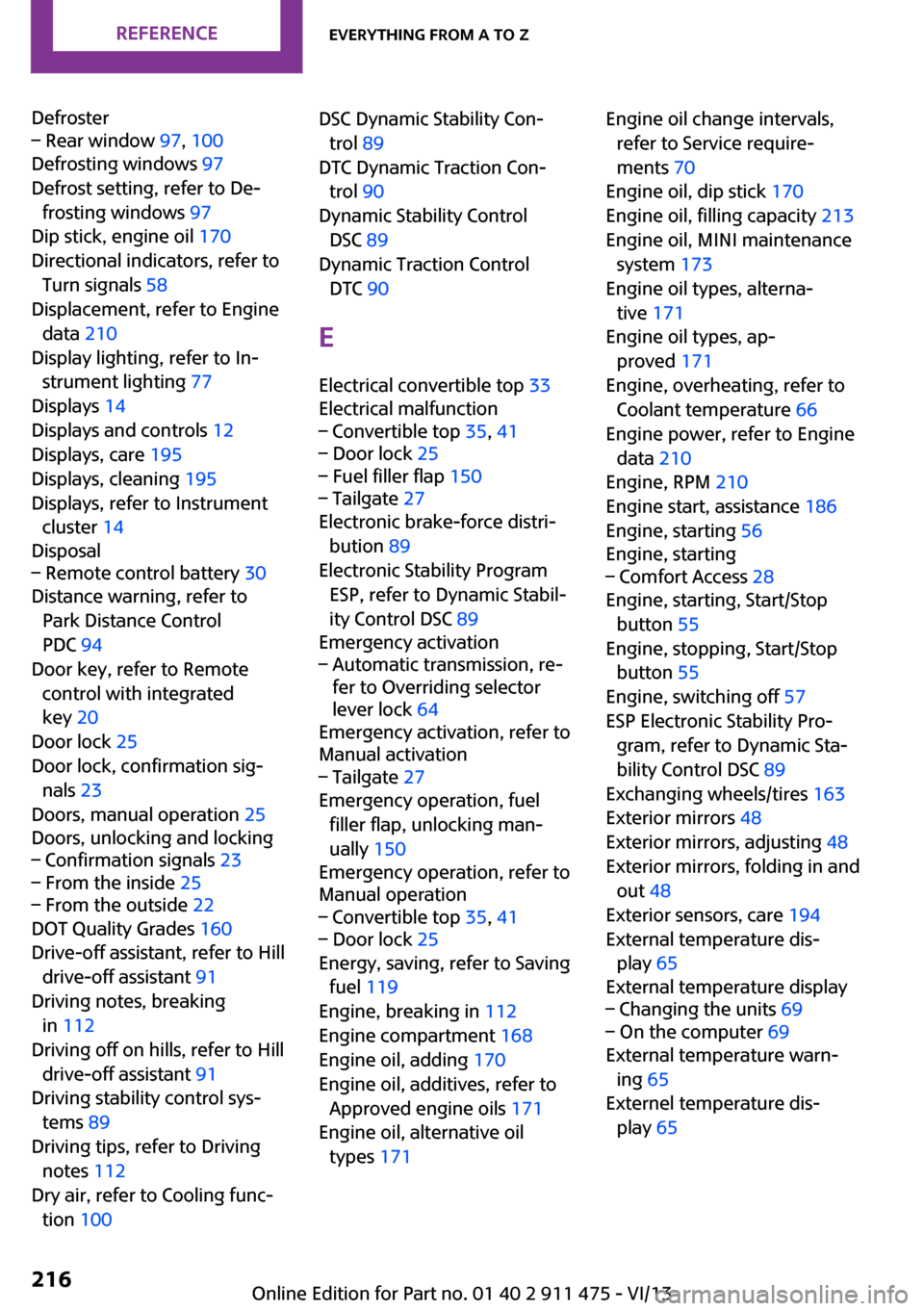

Page 216 of 224

Defroster– Rear window 97, 100

Defrosting windows 97

Defrost setting, refer to De‐ frosting windows 97

Dip stick, engine oil 170

Directional indicators, refer to Turn signals 58

Displacement, refer to Engine data 210

Display lighting, refer to In‐ strument lighting 77

Displays 14

Displays and controls 12

Displays, care 195

Displays, cleaning 195

Displays, refer to Instrument cluster 14

Disposal

– Remote control battery 30

Distance warning, refer to

Park Distance Control

PDC 94

Door key, refer to Remote

control with integrated

key 20

Door lock 25

Door lock, confirmation sig‐ nals 23

Doors, manual operation 25

Doors, unlocking and locking

– Confirmation signals 23– From the inside 25– From the outside 22

DOT Quality Grades 160

Drive-off assistant, refer to Hill drive-off assistant 91

Driving notes, breaking in 112

Driving off on hills, refer to Hill drive-off assistant 91

Driving stability control sys‐ tems 89

Driving tips, refer to Driving notes 112

Dry air, refer to Cooling func‐ tion 100

DSC Dynamic Stability Con‐

trol 89

DTC Dynamic Traction Con‐ trol 90

Dynamic Stability Control DSC 89

Dynamic Traction Control DTC 90

E Electrical convertible top 33

Electrical malfunction– Convertible top 35, 41– Door lock 25– Fuel filler flap 150– Tailgate 27

Electronic brake-force distri‐

bution 89

Electronic Stability Program ESP, refer to Dynamic Stabil‐

ity Control DSC 89

Emergency activation

– Automatic transmission, re‐

fer to Overriding selector

lever lock 64

Emergency activation, refer to

Manual activation

– Tailgate 27

Emergency operation, fuel

filler flap, unlocking man‐

ually 150

Emergency operation, refer to

Manual operation

– Convertible top 35, 41– Door lock 25

Energy, saving, refer to Saving

fuel 119

Engine, breaking in 112

Engine compartment 168

Engine oil, adding 170

Engine oil, additives, refer to Approved engine oils 171

Engine oil, alternative oil types 171

Engine oil change intervals,

refer to Service require‐

ments 70

Engine oil, dip stick 170

Engine oil, filling capacity 213

Engine oil, MINI maintenance system 173

Engine oil types, alterna‐ tive 171

Engine oil types, ap‐ proved 171

Engine, overheating, refer to Coolant temperature 66

Engine power, refer to Engine data 210

Engine, RPM 210

Engine start, assistance 186

Engine, starting 56

Engine, starting– Comfort Access 28

Engine, starting, Start/Stop

button 55

Engine, stopping, Start/Stop

button 55

Engine, switching off 57

ESP Electronic Stability Pro‐ gram, refer to Dynamic Sta‐

bility Control DSC 89

Exchanging wheels/tires 163

Exterior mirrors 48

Exterior mirrors, adjusting 48

Exterior mirrors, folding in and out 48

Exterior sensors, care 194

External temperature dis‐ play 65

External temperature display

– Changing the units 69– On the computer 69

External temperature warn‐

ing 65

Externel temperature dis‐ play 65

Seite 216ReferenceEverything from A to Z216

Online Edition for Part no. 01 40 2 911 475 - VI/13

Page 218 of 224

I

Ice warning, refer to External temperature warning 65

Icy roads, refer to External temperature warning 65

Identification marks, run-flat tires 164

Identification marks, tires 160

Ignition 55

Ignition key position 1, refer to Radio ready state 55

Ignition key position 2, refer to Ignition on 55

Ignition key, refer to Remote control with integrated

key 20

Ignition lock 55

Ignition, switched off 56

Ignition, switched on 55

Indicator and warning lamps 15

Indicator and warning lamps– Tire Pressure Monitor

TPM 86

Indicator and warning lamps,

overview 196

Individual air distribution 97

Inflation pressure monitor, re‐ fer to Flat Tire Monitor 83

Inflation pressure monitor, re‐ fer to Tire Pressure Monitor

TPM 85

Inflation pressure, refer to Tire inflation pressure 154

Initializing, Flat Tire Monitor FTM 83

Instrument cluster, refer to Displays 14

Instrument lighting 77

Instruments, refer to Cock‐ pit 12

Integrated key 20

Interior lamps 78

Interior lamps

– Remote control 24

Interior mirror 48

Interior temperature, setting– Air conditioner 96– Automatic climate con‐

trol 98

Internet page 6

J Jump-starting 186

K

Keyless Go, refer to Comfort Access 28

Keyless opening and closing, refer to Comfort Access 28

Key Memory, refer to Personal Profile 21

Key, refer to Remote control with integrated key 20

Kickdown

– Automatic transmission with

Steptronic 63

Knocking control 152

L Lamp and bulb replacement, bulb replacement 176

Lamp, replacing, refer to Lamp and bulb replace‐

ment 176

Lamps 74

Lamps, automatic headlamp control 74

Lamps, parking lamps/low beams 74

Lap-and-shoulder belt, refer to Safety belts 46

LATCH child restraint fixing system 52

Leather, care 193

Leather care 193

LEDs, light-emitting di‐ odes 177

License plate lamp, bulb re‐ placement 179

Light-alloy wheels, care 194

Light-emitting diodes, LEDs 177

Lighter– Socket 102

Lighting

– Instruments 77

Lighting, lamp and bulb re‐

placement 176

Lighting, vehicle, refer to Lamps 74

Light switch 74

Lock buttons on doors, refer to Locking 26

Locking

– From the inside 26– From the outside 23– Setting the confirmation sig‐

nal 23– Without remote control, re‐

fer to Comfort Access 28

Locking, vehicle

– From the inside 25– From the outside 22

Longlife oils, alternative oil

types 171

Longlife oils, refer to Ap‐ proved engine oils 171

Low beams 74

Low beams

– Automatic 74

Low beams, automatic 74

Low beams, bulb replace‐ ment 177

Lower back support, refer to Lumbar support 45

Lumbar support 45

M

Main inspection, refer to Serv‐ ice requirements 70

Maintenance, refer to Service booklet

Maintenance, refer to Service requirements 70

Seite 218ReferenceEverything from A to Z218

Online Edition for Part no. 01 40 2 911 475 - VI/13