tow MINI Hardtop 2 Door 2010 User Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2010, Model line: Hardtop 2 Door, Model: MINI Hardtop 2 Door 2010Pages: 174, PDF Size: 2.96 MB

Page 96 of 174

Things to remember when driving

94

Cargo loading

To avoid loading the tires beyond their

approved carrying capacity, never over-

load the vehicle. Overloading can lead to over-

heating and increases the rate at which damage

develops inside the tires. The ultimate result can

assume the form of a sudden blowout.<

Avoid fluid spills in the cargo bay as they

could damage the vehicle.<

MINI: cargo bay

Cargo bay cover

Do not place any objects on the cover;

otherwise, they could endanger the car's

occupants, e.g. in the case of braking or sudden

swerving, or they may damage the cover.<

When you open the liftgate, the cargo bay cover

is raised.

To load bulky luggage, the cover can be

removed.

1.Unhook the lift straps from the liftgate.

2.Pull the cover out of the holders toward the

rear.

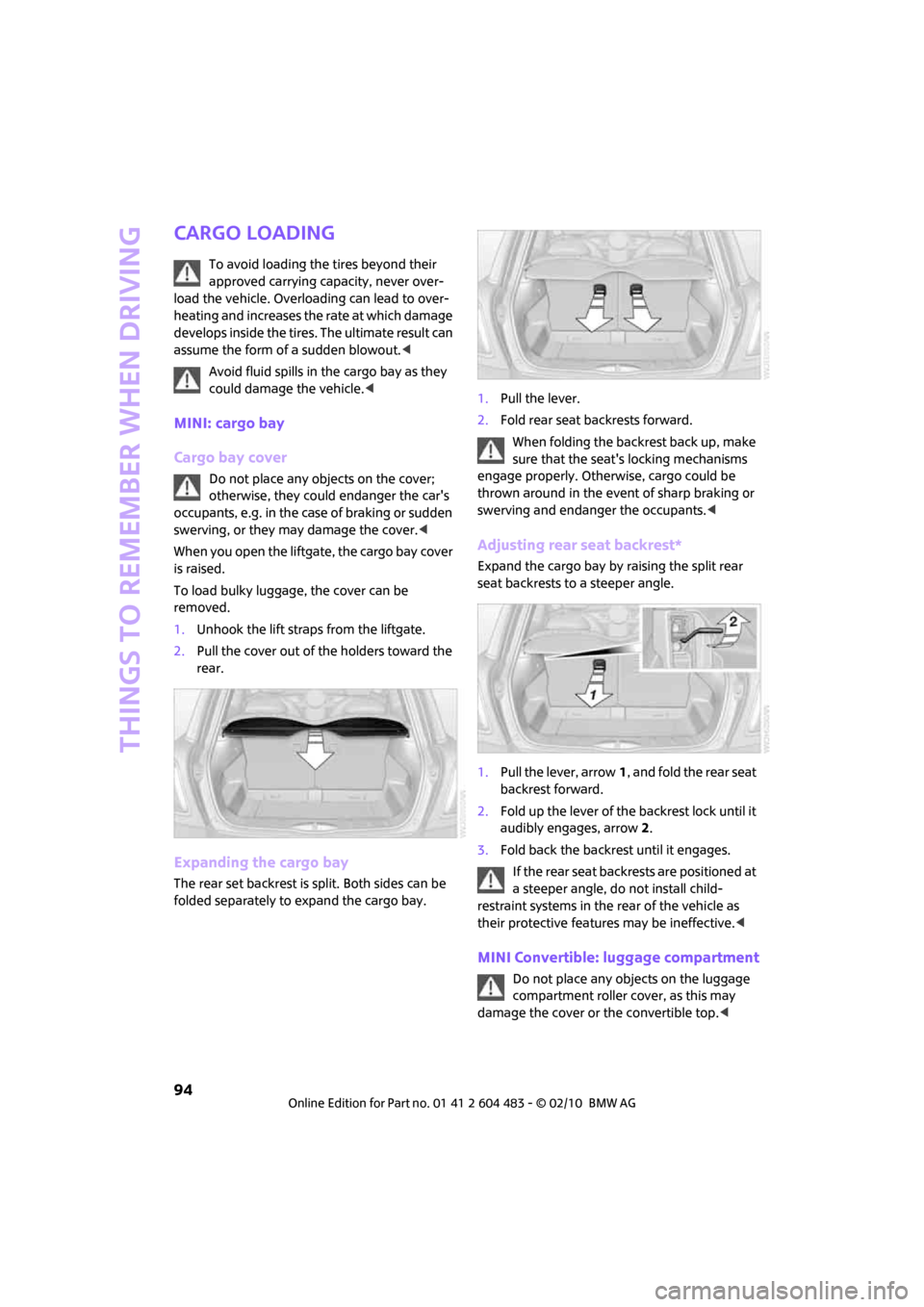

Expanding the cargo bay

The rear set backrest is split. Both sides can be

folded separately to expand the cargo bay.1.Pull the lever.

2.Fold rear seat backrests forward.

When folding the backrest back up, make

sure that the seat's locking mechanisms

engage properly. Otherwise, cargo could be

thrown around in the event of sharp braking or

swerving and endanger the occupants.<

Adjusting rear seat backrest*

Expand the cargo bay by raising the split rear

seat backrests to a steeper angle.

1.Pull the lever, arrow1, and fold the rear seat

backrest forward.

2.Fold up the lever of the backrest lock until it

audibly engages, arrow2.

3.Fold back the backrest until it engages.

If the rear seat backrests are positioned at

a steeper angle, do not install child-

restraint systems in the rear of the vehicle as

their protective features may be ineffective.<

MINI Convertible: luggage compartment

Do not place any objects on the luggage

compartment roller cover, as this may

damage the cover or the convertible top.<

Page 98 of 174

Things to remember when driving

96

2.Determine the combined weight of the

driver and passengers that will be riding in

your vehicle.

3.Subtract the combined weight of the driver

and passengers from XXX kilograms or YYY

pounds.

4.The resulting figure equals the available

amount of cargo and luggage load capacity.

For example, if the XXX amount equals

1,400 lbs and there will be four 150 lbs pas-

sengers in your vehicle, the amount of avail-

able cargo and luggage load capacity is

650 lbs:

1,400 lbs minus 750 lbs = 650 lbs.

5.Determine the combined weight of luggage

and cargo being loaded on the vehicle. That

weight may not safely exceed the available

cargo and luggage load capacity calculated

in step 4.

6.I f y o u r v e h icl e w i ll be t o w i n g a t r a il e r , pa r t o f

the load from your trailer will be transferred

to your vehicle. Consult the manual for

transporting a trailer to determine how this

may reduce the available cargo and luggage

load capacity of your vehicle.

Load

The permissible load is the sum of the occu-

pants' weights and the weight of the cargo. The

greater the weight of the occupants, the less

cargo/luggage can be transported.

Stowing cargo

>Position heavy objects as low and as far for-

ward as possible, ideally directly behind the

rear seat backrests.

>Cover sharp edges and corners.>For very heavy cargo when the rear seat is

not occupied, secure each safety belt in the

respective opposite buckle.

>Do not stack higher than the top edge of the

backrests.

MINI

MINI Convertible

Securing cargo

>Secure smaller and lighter items using

retaining or draw straps

*.

>Heavy-duty cargo straps

* for securing larger

and heavier objects are available at your

MINI dealer. Four lashing eyes are provided

for attaching the cargo straps. Two of them

are located on the forward wall of the cargo

bay.

Comply with the information enclosed with

the load-securing devices.

Page 115 of 174

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

113

meet under the Federal Motor Vehicle Safety

Standard No. 109. Grades B and A represent lev-

els of performance on the laboratory test wheel

that exceed the minimum required by law.

The temperature grade for this tire is

established for a tire that is properly

inflated and not overloaded. Excessive speed,

underinflation, or excessive loading, either sep-

arately or in combination, can cause heat

buildup and possible tire failure.<

RSC - run-flat tires*

You will recognize run-flat tires by a circular

symbol containing the letters RSC on the side of

the tire, page114.

M+S

Winter and all-season tires.

These have better winter properties than sum-

mer tires.

XL

Designation for specially reinforced tires.

Tire condition

Inspect your tires regularly for tread wear, signs

of damage and for foreign objects lodged in the

tread. Check the tread depth.

Tread depth

The tread depth should not drop below 1/8 in/

3 mm, although, for example, European legisla-

tion only specifies a minimum tread depth of

1/16 in/1.6 mm. At tread depths below 1/8 in/

3 mm there is an increased risk of high-speed

hydroplaning, even when only small amounts of

water are present on the road surface.

Winter tires

When winter tires wear down past a tread depth

of 1/6 in/4 mm, they become perceptibly less

suitable for winter conditions. In the interest of

safety, new tires should be installed.

Minimum tread depth

Wear indicators in the base of the tread groove

are distributed around the tire's circumference;

the letters TWI, for Tread Wear Indicator, on the

tire's sidewalls identify tires that incorporate

these wear indicators. When tire tread is worn

down to the level of the wear indicators, the

remaining tread depth is 1/16 in/1.6 mm.

Tire damage

Due to low-profile tires, please note that wheels,

tires and suspensions parts are more susceptible

to road hazards and consequential damages.

Unusual vibrations encountered during normal

vehicle operation can indicate tire failure or

some other vehicle defect. This can, for exam-

ple, be caused by driving over curbs. The same

applies to any other abnormal road behavior,

such as pulling severely to the right or left.

In these cases, reduce speed immediately

and have wheels and tires thoroughly

checked. To do so, drive carefully to the nearest

MINI dealer or tire shop that works according to

MINI repair procedures with correspondingly

trained personnel. If necessary, have the vehicle

towed there.

Otherwise, tire damage can be extremely dan-

gerous for vehicle occupants and other road

users.<

Tire age

The manufacturing date of tires is contained in

the tire coding:

DOT ... 0810 means that the tire was manufac-

tured in week 8 of 2010.

Page 119 of 174

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

117

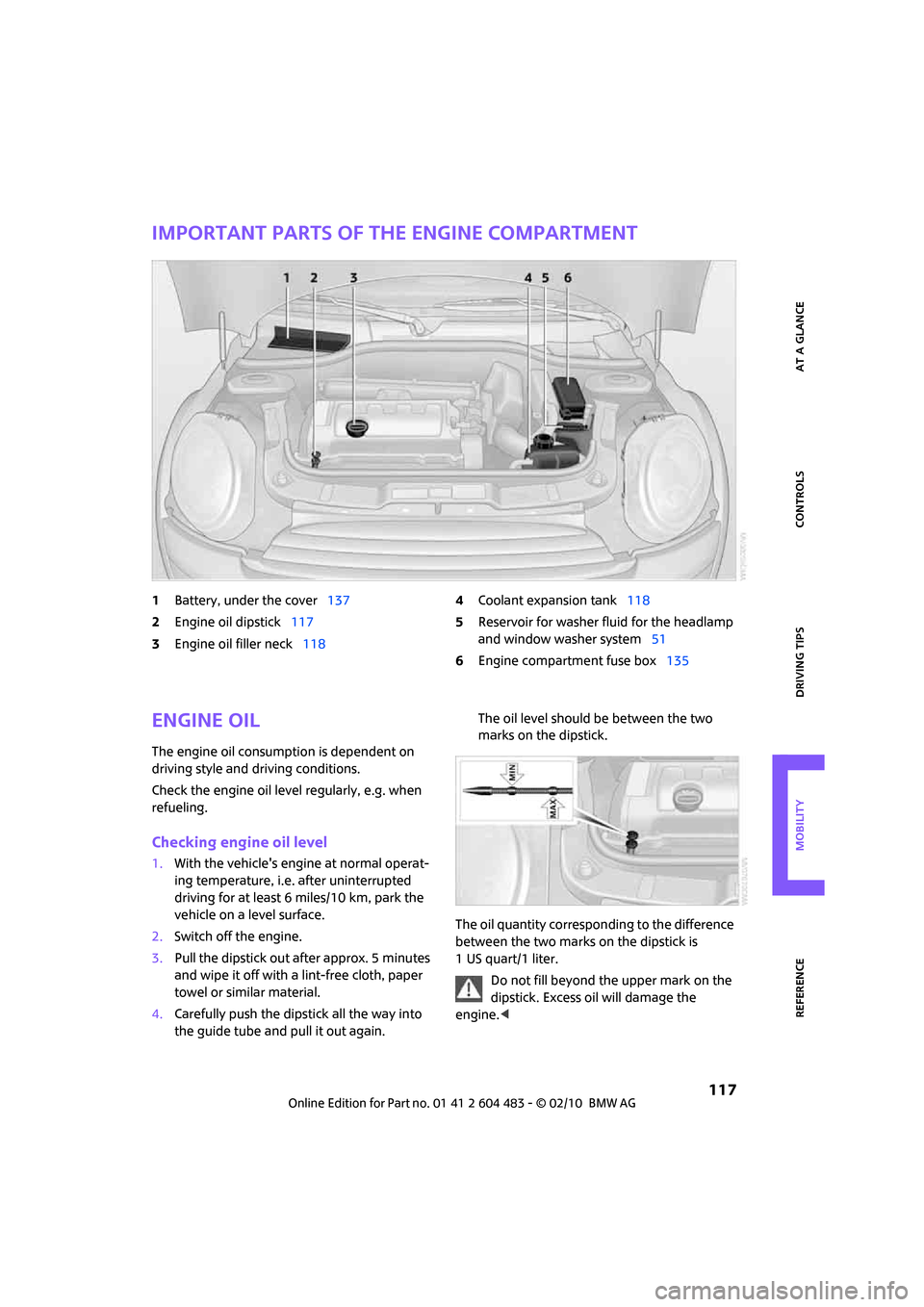

Important parts of the engine compartment

1Battery, under the cover137

2Engine oil dipstick117

3Engine oil filler neck1184Coolant expansion tank118

5Reservoir for washer fluid for the headlamp

and window washer system51

6Engine compartment fuse box135

Engine oil

The engine oil consumption is dependent on

driving style and driving conditions.

Check the engine oil level regularly, e.g. when

refueling.

Checking engine oil level

1.With the vehicle's engine at normal operat-

ing temperature, i.e. after uninterrupted

driving for at least 6 miles/10 km, park the

vehicle on a level surface.

2.Switch off the engine.

3.Pull the dipstick out after approx. 5 minutes

and wipe it off with a lint-free cloth, paper

towel or similar material.

4.Carefully push the dipstick all the way into

the guide tube and pull it out again. The oil level should be between the two

marks on the dipstick.

The oil quantity corresponding to the difference

between the two marks on the dipstick is

1USquart/1liter.

Do not fill beyond the upper mark on the

dipstick. Excess oil will damage the

engine.<

Page 124 of 174

Care

122

Steam jets/high-pressure washers

When using steam jets or high-pressure

washers, ensure that you maintain suffi-

cient clearance to the vehicle and do not exceed

a temperature of 1407/606.

If the distance is too close, the pressure too high,

or the temperature too high, parts of the vehicle

can be damaged, or water can penetrate.

Observe the operating instructions for high-

pressure washers.<

Do not spray sensors such as Park Dis-

tance Control with high-pressure washers

for a long time or at a distance of less than 1 ft/

30 cm.<

Manual washing

Use a great deal of water and, if necessary, car

shampoo when washing your car by hand. Clean

the vehicle with a sponge or a washing brush

applying a slight amount of pressure.

Before cleaning the windshield, deacti-

vate the rain sensor or turn off the ignition

to prevent unintentional wiping.<

Observe local regulations regarding wash-

ing vehicles by hand.<

Headlamps

Do not wipe dry and do not use abrasive or cor-

rosive cleaning agents. Remove dirt and con-

tamination, such as insects, by soaking with

shampoo and then washing with plenty of

water.

Do not remove accumulated ice and snow with

an ice scraper; use window deicers instead.

Windows

Clean the outside and inside of the windows and

mirrors with a window cleaner.

Do not clean the mirrors with cleaners

containing quartz.<

Wiper blades

Clean with soapy water and change regularly to

prevent the formation of streaks.Wax, preservatives and dirt on the win-

dows cause streaks when the windshield

wipers are on, and can cause premature wear of

the wiper blades and interfere with the rain sen-

sor.<

Care of the convertible top

The appearance and service life of the convert-

ible top largely depends on its proper care and

operation.

Please follow these instructions:

>Never attempt to fold and stow the convert-

ible top in the convertible compartment

when the top is wet or frozen. Otherwise,

water stains, mildew, and chafe marks may

occur.

>If water spots occur on the inside headliner

despite precautions, remove them using a

microfiber cloth and interior cleaner.

>If the vehicle is parked in an enclosed area

for a longer period of time, make sure that

there is sufficient ventilation.

>Remove any bird droppings immediately,

since they have corrosive properties which

will corrode the convertible top and damage

the rubber seals.

When attempting to remove stains from

the convertible top, do not use spot

removers, paint thinners, solvents, gasoline, or

similar fluids. These cleaners may damage the

rubber seals. The improper care or cleaning

methods may cause the convertible top and its

seams to leak.<

Use special convertible top cleaning agents if

attempting to remove heavy stains.

Always read and follow the manufacturer's

instructions.

Use an impregnating agent to treat the convert-

ible top once a year.

Paintwork, care

Regular care helps your vehicle retain its value

and protects the paint from the long-term

effects of aggressive substances.

Page 127 of 174

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

125

Replacing components

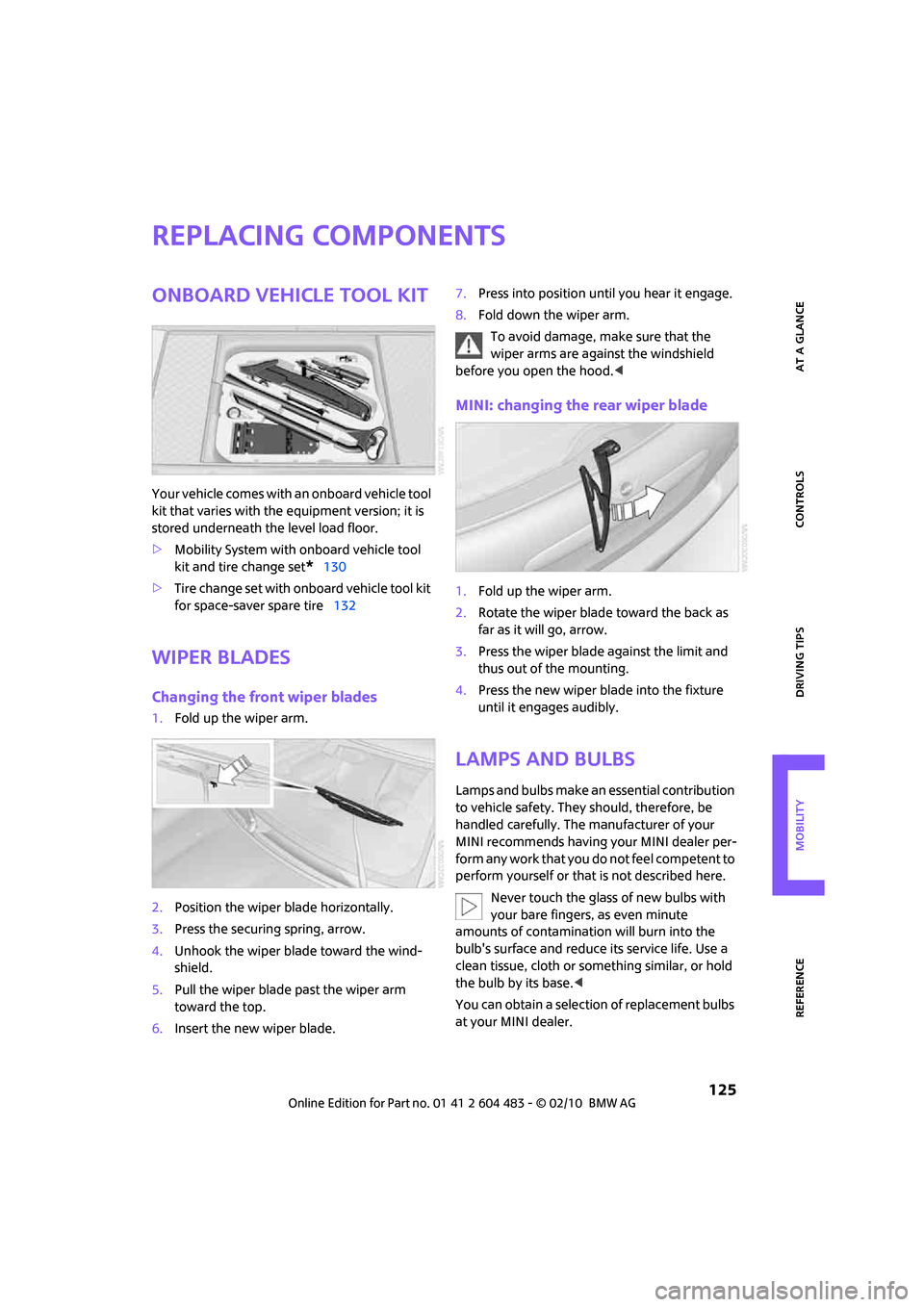

Onboard vehicle tool kit

Your vehicle comes with an onboard vehicle tool

kit that varies with the equipment version; it is

stored underneath the level load floor.

>Mobility System with onboard vehicle tool

kit and tire change set

*130

>Tire change set with onboard vehicle tool kit

for space-saver spare tire132

Wiper blades

Changing the front wiper blades

1.Fold up the wiper arm.

2.Position the wiper blade horizontally.

3.Press the securing spring, arrow.

4.Unhook the wiper blade toward the wind-

shield.

5.Pull the wiper blade past the wiper arm

toward the top.

6.Insert the new wiper blade.7.Press into position until you hear it engage.

8.Fold down the wiper arm.

To avoid damage, make sure that the

wiper arms are against the windshield

before you open the hood.<

MINI: changing the rear wiper blade

1.Fold up the wiper arm.

2.Rotate the wiper blade toward the back as

far as it will go, arrow.

3.Press the wiper blade against the limit and

thus out of the mounting.

4.Press the new wiper blade into the fixture

until it engages audibly.

Lamps and bulbs

Lamps and bulbs make an essential contribution

to vehicle safety. They should, therefore, be

handled carefully. The manufacturer of your

MINI recommends having your MINI dealer per-

f o r m a n y w o r k t h a t y o u d o n o t f e e l c o m p e t e n t t o

perform yourself or that is not described here.

Never touch the glass of new bulbs with

your bare fingers, as even minute

amounts of contamination will burn into the

bulb's surface and reduce its service life. Use a

clean tissue, cloth or something similar, or hold

the bulb by its base.<

You can obtain a selection of replacement bulbs

at your MINI dealer.

Page 132 of 174

Replacing components

130

>MINI Mobility System, refer to the following

section

>Run-flat tires, page114

>Tire change with space-saver spare tire,

page132

MINI Mobility System with onboard

vehicle tool kit and tire change set*

Preparations

Use of the MINI Mobility System may be ineffec-

tive if the tire puncture measures approx. 1/8 in/

4 mm or more. Contact the nearest MINI dealer

if the tire cannot be made drivable with the

Mobility System.

Do not remove foreign bodies which have pen-

etrated the tire if possible.

Follow the instructions on using the Mobil-

ity System found on the compressor and

the sealant bottle.<

Remove the adhesive label for the speed limit

from the sealant bottle and affix it to the steer-

ing wheel.

The Mobility System with onboard vehicle tool

kit and tire change set

* is located under the

floor mat in the cargo bay.

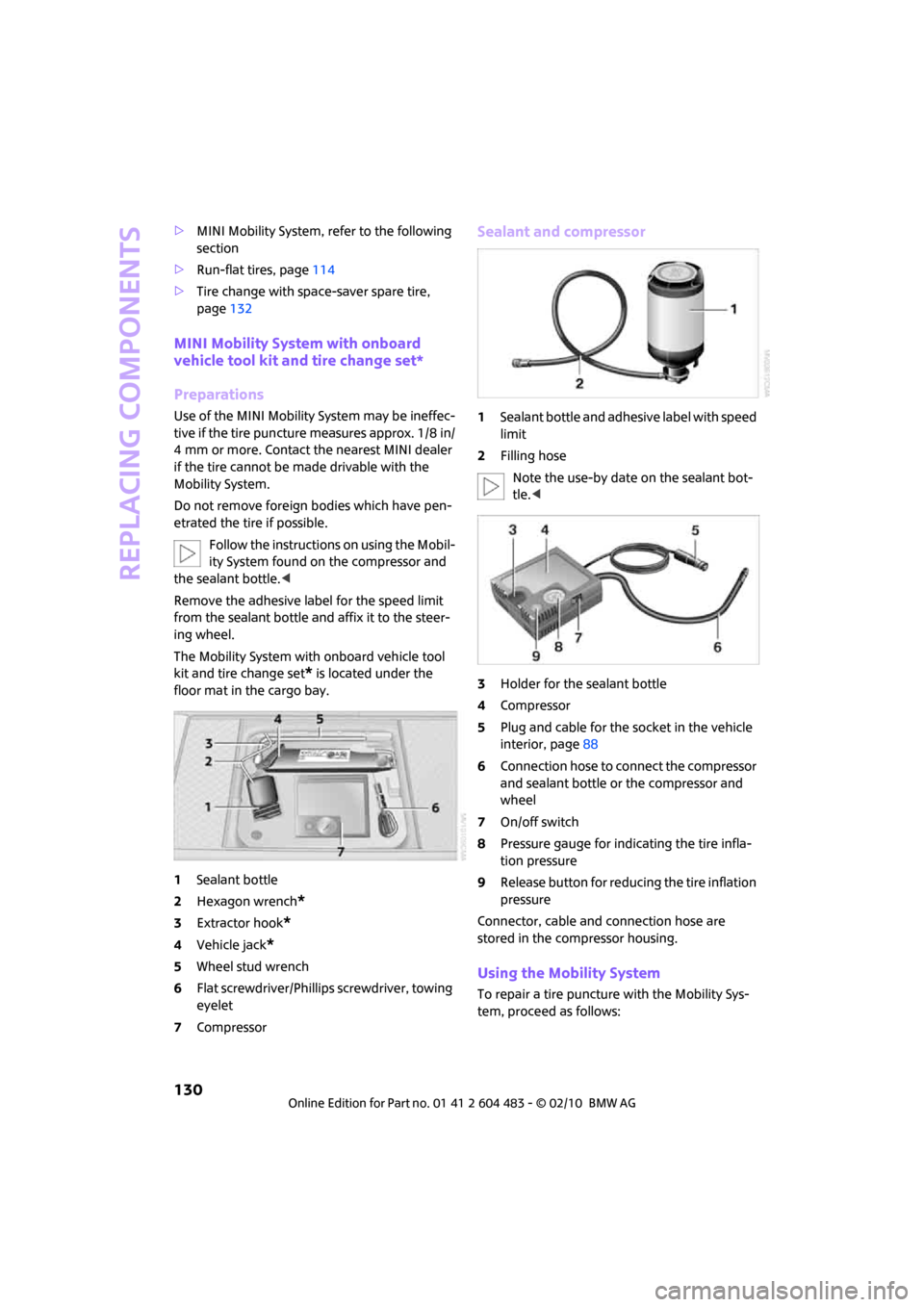

1Sealant bottle

2Hexagon wrench

*

3Extractor hook*

4Vehicle jack*

5Wheel stud wrench

6Flat screwdriver/Phillips screwdriver, towing

eyelet

7Compressor

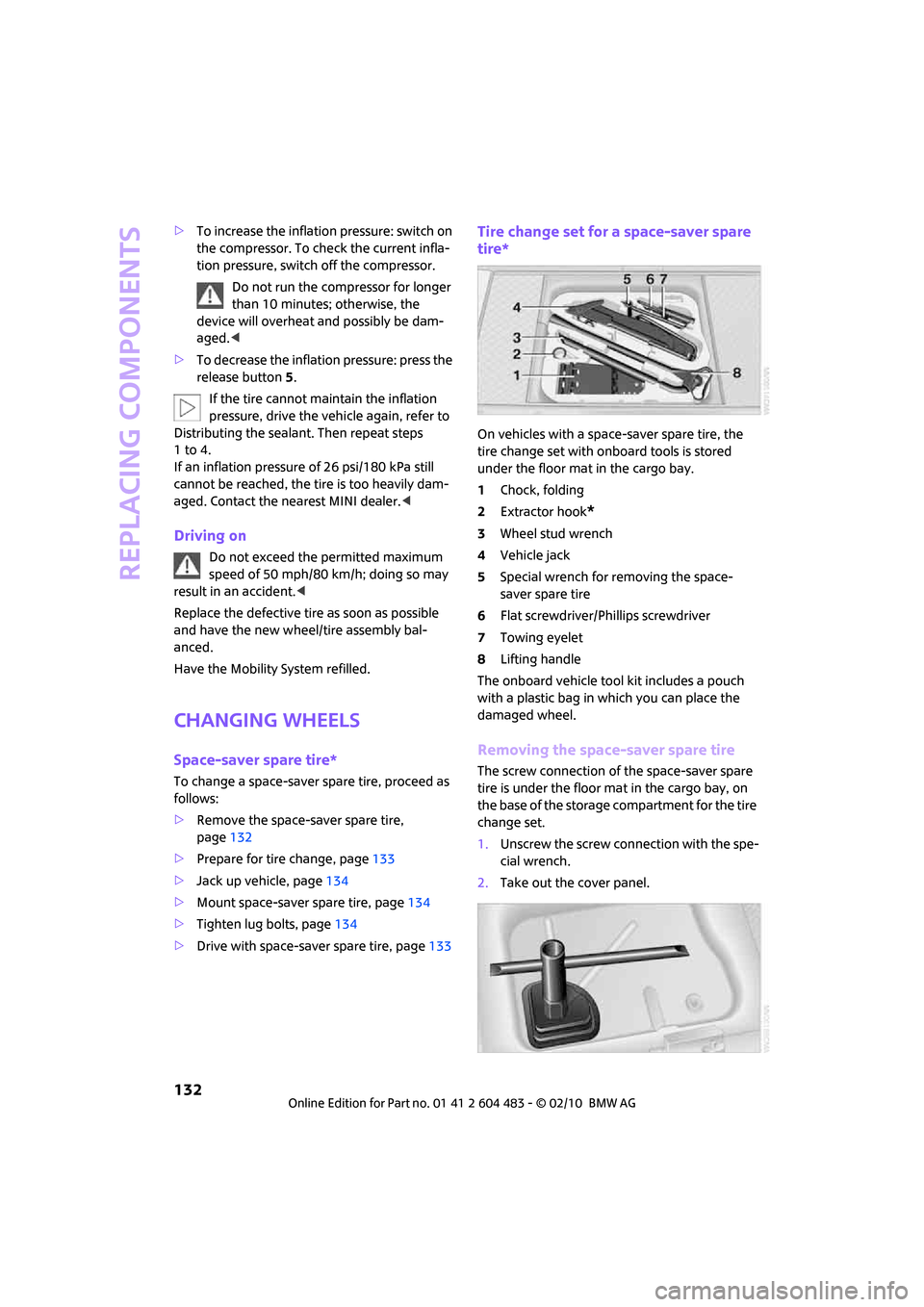

Sealant and compressor

1Sealant bottle and adhesive label with speed

limit

2Filling hose

Note the use-by date on the sealant bot-

tle.<

3Holder for the sealant bottle

4Compressor

5Plug and cable for the socket in the vehicle

interior, page88

6Connection hose to connect the compressor

and sealant bottle or the compressor and

wheel

7On/off switch

8Pressure gauge for indicating the tire infla-

tion pressure

9Release button for reducing the tire inflation

pressure

Connector, cable and connection hose are

stored in the compressor housing.

Using the Mobility System

To repair a tire puncture with the Mobility Sys-

tem, proceed as follows:

Page 133 of 174

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

131

>Filling the tire with sealant

>Distribute the sealant

>Correct the tire inflation pressure

Filling the tire with sealant

Proceed in the specified order; otherwise,

sealant may emerge under high pres-

sure.<

1.Shake the sealant bottle.

2.Pull the connection hose9 out of the com-

pressor housing fully and screw it onto the

connector of the sealant bottle. Make sure

that the hose is not kinked.

3.Insert the sealant bottle on the compressor

housing in an upright position.

4.Unscrew the dust cap from the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.

5.Ensure that the compressor is switched off.

6.Insert the plug 3 into the lighter socket/

power socket in the vehicle interior,

page88.

7.With the engine running:

Switch on the compressor and let is run for

approx. 3 to 8 minutes to fill the tire with

sealant and achieve a tire inflation pressure

of approx. 26 psi/180 kPa.

When filling the tire with sealant, the

inflation pressure can briefly rise to

approx. 73 psi/500 kPa. Do not switch off

the compressor during this phase.<

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be dam-

aged.<8.Switch off the compressor.

If an air pressure of 26 psi/180 kPa is not

reached:

1.Unscrew the filling hose 2 from the wheel

and drive the vehicle forward and backward

approx. 33 ft/10 m to distribute the liquid

sealant in the tire evenly.

2.Inflate the tire again with the compressor.

If an inflation pressure of 26 psi/180 kPa

still cannot be reached, the tire is too

heavily damaged. Please contact the nearest

MINI dealer.<

Stowing Mobility System

1.Unscrew filler hose2 of the sealant bottle

from the wheel.

2.Unscrew connecting hose of the

compressor9 from the sealant bottle.

3.Connect the filler hose2 of the sealant bot-

tle to the unoccupied connection on the

sealant bottle.

This prevents the rest of the sealant from

escaping from the bottle.

4.Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo bay.

5.Stow Mobility System back in the vehicle.

Distributing the sealant

Immediately drive approx. 3 mls/5 km to evenly

distribute the sealant.

Do not exceed speeds of 50 mph/

80 km/h.

If possible, do not drop below 10 mph/

20 km/h.<

Correcting the tire inflation pressure

1.After driving approx. 3 mls/5 km or ten min-

utes, stop at a suitable location.

2.Screw the connection hose 2 of the com-

pressor directly onto the tire valve.

3.Insert the plug 3 into the power socket in the

vehicle interior.

4.Correct the inflation pressure to 26 psi/

180 kPa. With the engine running:

Page 134 of 174

Replacing components

132

>To increase the inflation pressure: switch on

the compressor. To check the current infla-

tion pressure, switch off the compressor.

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be dam-

aged.<

>To decrease the inflation pressure: press the

release button5.

If the tire cannot maintain the inflation

pressure, drive the vehicle again, refer to

Distributing the sealant. Then repeat steps

1to4.

If an inflation pressure of 26 psi/180 kPa still

cannot be reached, the tire is too heavily dam-

aged. Contact the nearest MINI dealer.<

Driving on

Do not exceed the permitted maximum

speed of 50 mph/80 km/h; doing so may

result in an accident.<

Replace the defective tire as soon as possible

and have the new wheel/tire assembly bal-

anced.

Have the Mobility System refilled.

Changing wheels

Space-saver spare tire*

To change a space-saver spare tire, proceed as

follows:

>Remove the space-saver spare tire,

page132

>Prepare for tire change, page133

>Jack up vehicle, page134

>Mount space-saver spare tire, page134

>Tighten lug bolts, page134

>Drive with space-saver spare tire, page133

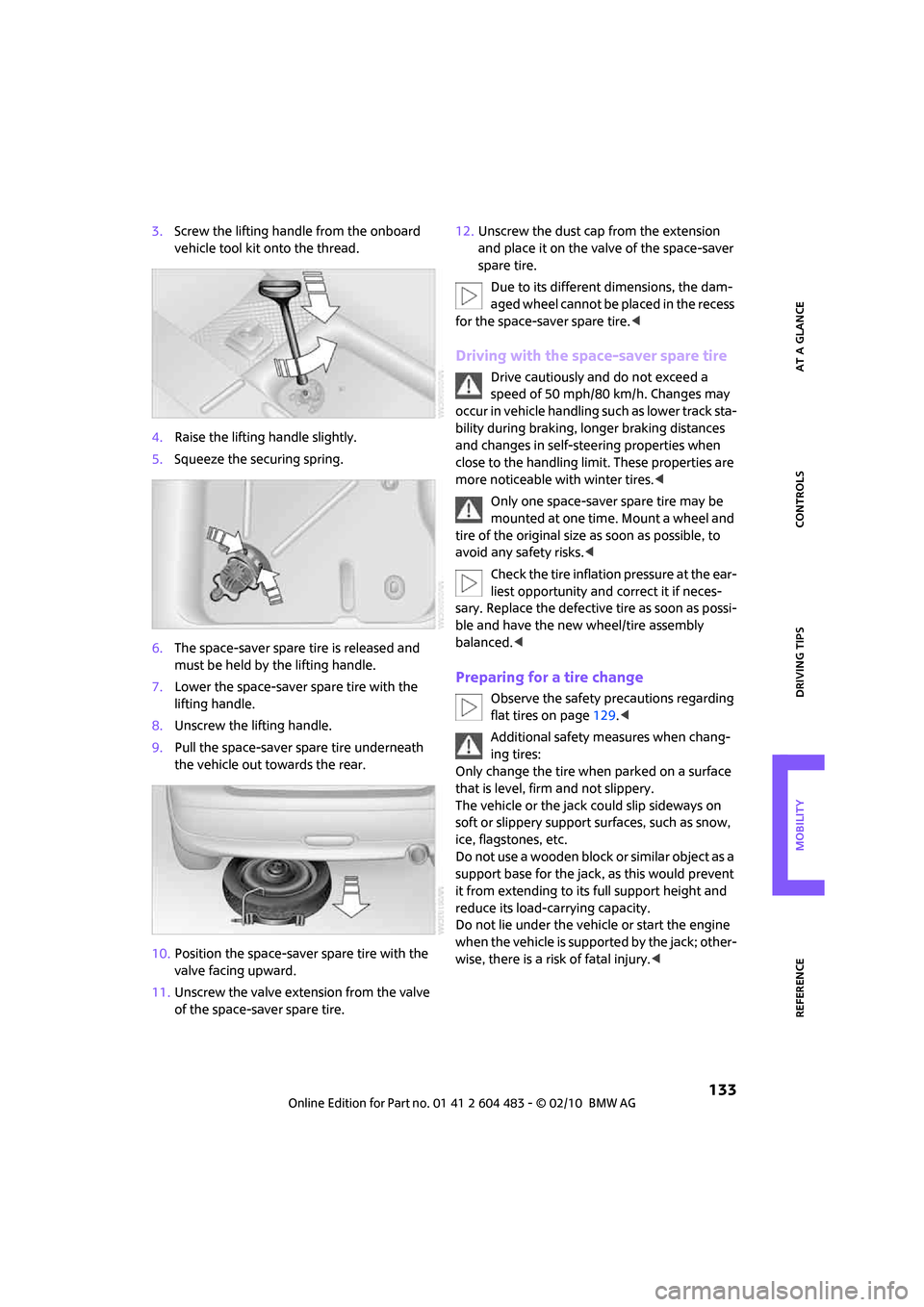

Tire change set for a space-saver spare

tire*

On vehicles with a space-saver spare tire, the

tire change set with onboard tools is stored

under the floor mat in the cargo bay.

1Chock, folding

2Extractor hook

*

3Wheel stud wrench

4Vehicle jack

5Special wrench for removing the space-

saver spare tire

6Flat screwdriver/Phillips screwdriver

7Towing eyelet

8Lifting handle

The onboard vehicle tool kit includes a pouch

with a plastic bag in which you can place the

damaged wheel.

Removing the space-saver spare tire

The screw connection of the space-saver spare

tire is under the floor mat in the cargo bay, on

the base of the storage compartment for the tire

change set.

1.Unscrew the screw connection with the spe-

cial wrench.

2.Take out the cover panel.

Page 135 of 174

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

133

3.Screw the lifting handle from the onboard

vehicle tool kit onto the thread.

4.Raise the lifting handle slightly.

5.Squeeze the securing spring.

6.The space-saver spare tire is released and

must be held by the lifting handle.

7.Lower the space-saver spare tire with the

lifting handle.

8.Unscrew the lifting handle.

9.Pull the space-saver spare tire underneath

the vehicle out towards the rear.

10.Position the space-saver spare tire with the

valve facing upward.

11.Unscrew the valve extension from the valve

of the space-saver spare tire.12.Unscrew the dust cap from the extension

and place it on the valve of the space-saver

spare tire.

Due to its different dimensions, the dam-

aged wheel cannot be placed in the recess

for the space-saver spare tire.<

Driving with the space-saver spare tire

Drive cautiously and do not exceed a

speed of 50 mph/80 km/h. Changes may

occur in vehicle handling such as lower track sta-

bility during braking, longer braking distances

and changes in self-steering properties when

close to the handling limit. These properties are

more noticeable with winter tires.<

Only one space-saver spare tire may be

mounted at one time. Mount a wheel and

tire of the original size as soon as possible, to

avoid any safety risks.<

Check the tire inflation pressure at the ear-

liest opportunity and correct it if neces-

sary. Replace the defective tire as soon as possi-

ble and have the new wheel/tire assembly

balanced.<

Preparing for a tire change

Observe the safety precautions regarding

flat tires on page129.<

Additional safety measures when chang-

ing tires:

Only change the tire when parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

Do not lie under the vehicle or start the engine

when the vehicle is supported by the jack; other-

wise, there is a risk of fatal injury.<