engine MINI Hardtop 2 Door 2015 Repair Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2015, Model line: Hardtop 2 Door, Model: MINI Hardtop 2 Door 2015Pages: 251, PDF Size: 11.4 MB

Page 198 of 251

Viscosity grades for engine oils

When selecting an engine oil, ensure that

the engine oil belongs to one of the viscosity

grades SAE 0W-40, SAE 0W-30, SAE 5W-40, and

SAE 5W-30 or malfunctions or engine damage

may occur. ◀

The engine oil quality is critical for the life of the

engine.

Suitable engine oil types You can add engine oils that meet the follow‐

ing oil rating standards:Gasoline engineBMW Longlife-01BMW Longlife-01 FE

Further information regarding the oil specifica‐

tions and viscosities of MINI engine oils can be

inquired with the service center.

Alternative engine oil types

If an engine oil suitable for continuous use is

not available, up to 1 US quart/liter of an en‐

gine oil with the following oil rating can be

added:

Gasoline engineAPI SM or superior oil rating

Engine oil change:

The vehicle manufacturer recommends that

you let the service center change the motor oil.

Seite 194MOBILITYEngine oil194

Online Edition for Part no. 01 40 2 961 140 - II/15

Page 199 of 251

CoolantVehicle features and op‐

tions

This chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and sys‐

tems. The respectively applicable country provi‐

sions must be observed when using the respec‐

tive features and systems.

Hints Danger of burns from hot engine

Do not open the cooling system while the

engine is hot; otherwise, esliding coolant may

cause burns. ◀

Suitable additives

Only use suitable additives; otherwise,

engine damage may occur. The additives are

harmful to your health. ◀

Coolant consists of water and additives.

Not all commercially available additives are

suitable for your vehicle. Ask your service cen‐

ter for suitable additives.

Coolant level Checking

There are yellow Min and Max marks in the

coolant reservoir.1.Let the engine cool.2.Turn the coolant reservoir lid counterclock‐

wise to unscrew and open it.3.The coolant level is correct if it lies between

the minimum and maximum marks in the

filler neck.

Adding

1.Let the engine cool.2.Turn the coolant reservoir lid counterclock‐

wise to unscrew and open it.3.If the coolant is low, slowly add coolant up

to the specified level; do not overfill.Seite 195CoolantMOBILITY195

Online Edition for Part no. 01 40 2 961 140 - II/15

Page 201 of 251

MaintenanceVehicle features and op‐

tions

This chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and sys‐

tems. The respectively applicable country provi‐

sions must be observed when using the respec‐

tive features and systems.

MINI maintenance system

The maintenance system indicates required

maintenance measures, and thereby provides

support in maintaining road safety and the op‐

erational reliability of the vehicle.

In some cases scopes and intervals may vary

according to the country-specific version. Re‐

placement work, spare parts, fuels and lubri‐

cants and wear materials are calculated sepa‐

rately. Additional information is available from

the service center.

Condition Based Service

CBS

Sensors and special algorithms take into ac‐

count the driving conditions of your vehicle.

Based on this, Condition Based Service recog‐

nizes the maintenance requirements.

The system makes it possible to adapt the

amount of maintenance corresponding to your

user profile.

Detailed information on service requirements,

refer to page 65, can be displayed on the radio.For service data

Information on the required maintenance is

continuously stored in the remote control. Your

service center will read out this data and sug‐

gest the right array of service procedures for

your vehicle.

Therefore, hand your service specialist the re‐

mote control that you used most recently.

Storage periods

Storage periods during which the vehicle bat‐

tery was disconnected are not taken into ac‐

count.

If this occurs, have a service center update the

time-dependent maintenance procedures, such

as checking brake fluid and, if needed, chang‐

ing the engine oil and the microfilter/activated-

charcoal filter.

Service and Warranty In‐

formation Booklet for

US models and Warranty

and Service Guide Book‐

let for Canadian models

Please consult your Service and Warranty Infor‐

mation Booklet for US models and Warranty

and Service Guide Booklet for Canadian models

for additional information on service require‐

ments.

Maintenance and repair should be performed

by your service center. Make sure to have regu‐

lar maintenance procedures recorded in the ve‐

hicle's Service and Warranty Information Book‐

let for US models, and in the Warranty and

Service Guide Booklet for Canadian models.

These entries are proof of regular maintenance.Seite 197MaintenanceMOBILITY197

Online Edition for Part no. 01 40 2 961 140 - II/15

Page 202 of 251

Socket for OBD Onboard

Diagnosis

Note Socket for Onboard Diagnosis

The socket for onboard diagnostics may

only be used by the service center or a work‐

shop that operates in accordance with the

specifications of the vehicle manufacturer with

correspondingly trained personnel and other

authorized persons. Otherwise, use may result

in operating problems for the vehicle. ◀

Position

There is an OBD socket on the driver's side for

checking the primary components in the vehi‐

cle's emissions.

Emissions

▷The warning lamp lights up:

Emissions are deteriorating. Have

the vehicle checked as soon as pos‐

sible.▷The warning lamp flashes under certain cir‐

cumstances:

This indicates that there is excessive misfir‐

ing in the engine.

Reduce the vehicle speed and have the sys‐

tem checked immediately; otherwise, seri‐

ous engine misfiring within a brief period

can seriously damage emission controlcomponents, in particular the catalytic con‐

verter.Seite 198MOBILITYMaintenance198

Online Edition for Part no. 01 40 2 961 140 - II/15

Page 211 of 251

Jacking points for the vehicle jack

The jacking points for the vehicle jack are lo‐

cated at the positions shown.

Emergency wheel

Hints Safety measures in case of a breakdown

or a wheel change

▷Park the vehicle as far away as possible

from passing traffic and on solid ground.

Switch on the hazard warning system.▷Set the parking brake, and engage first gear

or selector lever position P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.▷If necessary, set up a warning triangle or

portable hazard warning lamp at an appro‐

priate distance. Comply with all safety

guidelines and regulations.▷Perform wheel change only on a flat, solid

and slip-resistant surface. On soft or slip‐

pery ground, e.g., snow, ice, tiles, etc., the

vehicle or vehicle jack can slip away to the

side.▷Do not place wood blocks or similar items

under the vehicle jack; otherwise, it cannot

reach its carrying capacity because of the

restricted height.▷If the vehicle is raised, do not lie under the

vehicle and do not start the engine; other‐

wise, a fatal hazard exists. ◀Use the vehicle jack only for changing

wheels

Use the vehicle jack only for changing wheels.

Do not attempt to use it to jack up a different

type of vehicle or cargo of any kind; otherwise,

this could cause material damage and personal

injury. ◀

Removing the emergency wheel The emergency wheel is housed in a well on

the underbody of the vehicle. The screw con‐

nection of the emergency wheel is located in

the trunk under the floor mat, on the floor of

the storage compartment for the wheel chang‐

ing set.1.Loosen the nut from the wheel change set

using the wheel wrench.2.Remove the retaining plate.3.Screw wheel lug wrench onto the thread

and hold in place with one hand.Seite 207Replacing componentsMOBILITY207

Online Edition for Part no. 01 40 2 961 140 - II/15

Page 213 of 251

The defective wheel cannot be stored in the

emergency wheel bracket because of its

size.3.Check tire inflation pressure at the next op‐

portunity and correct as needed.4.Reinitialize the Flat Tire Monitor, refer to

page 85.

Reinitialize the Tire Pressure Monitor, refer

to page 82.5.Replace the damaged tires as soon as pos‐

sible.

Driving with emergency wheel

Watch the speed when driving with the

emergency wheel

Drive conservatively and do not exceed a speed

of 50 mph/80 km/h; otherwise, changed driving

characteristics such as reduced lane stability

while braking, extended braking distance and

changed self-steering properties in the limit

area. ◀

Mount one emergency wheel only

Only a single emergency wheel may be

mounted. Reinstall wheels and tires of the orig‐

inal size as quickly as possible; otherwise, there

is a safety risk. ◀

Vehicle battery

Maintenance

The battery is maintenance-free, i.e., the elec‐

trolyte will last for the life of the battery.

Your service center will be glad to advise you

on questions regarding the battery.

Battery replacement Use approved vehicle batteries only

Only use vehicle batteries that have been

approved for your vehicle by the manufacturer;

otherwise, the vehicle could be damaged and

systems or functions may not be fully availa‐

ble. ◀

After a battery replacement, have the battery

registered on the vehicle by your service center

to ensure that all comfort features are fully

available and that any Check Control messages

are no longer displayed.

Charging the battery

General information Make sure that the battery is always sufficiently

charged to guarantee that the battery remains

usable for its full service life.

The battery may need to be charged in the fol‐

lowing cases:▷When making frequent short-distance

drives.▷If the vehicle is not used for prolonged peri‐

ods, longer than a month.▷Steptronic transmission: when parked for

long periods of time in selector lever posi‐

tion D, R or N.

Note

Do not connect charging devices to the

12 volt socket in the vehicle

Do not connect battery chargers to the factory-

installed 12 volt sockets in the vehicle as this

may damage the vehicle battery due to an in‐ creased power consumption. ◀

Starting aid terminals In the vehicle, only charge the battery via the

starting aid terminals, refer to page 212, in the

engine compartment with the engine off.

Power failure

After a temporary power loss, some equipment

needs to be reset.

Individual settings need to be reprogrammed:

▷Time: update.Seite 209Replacing componentsMOBILITY209

Online Edition for Part no. 01 40 2 961 140 - II/15

Page 215 of 251

Breakdown assistanceVehicle features and op‐

tions

This chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and sys‐

tems. The respectively applicable country provi‐

sions must be observed when using the respec‐

tive features and systems.

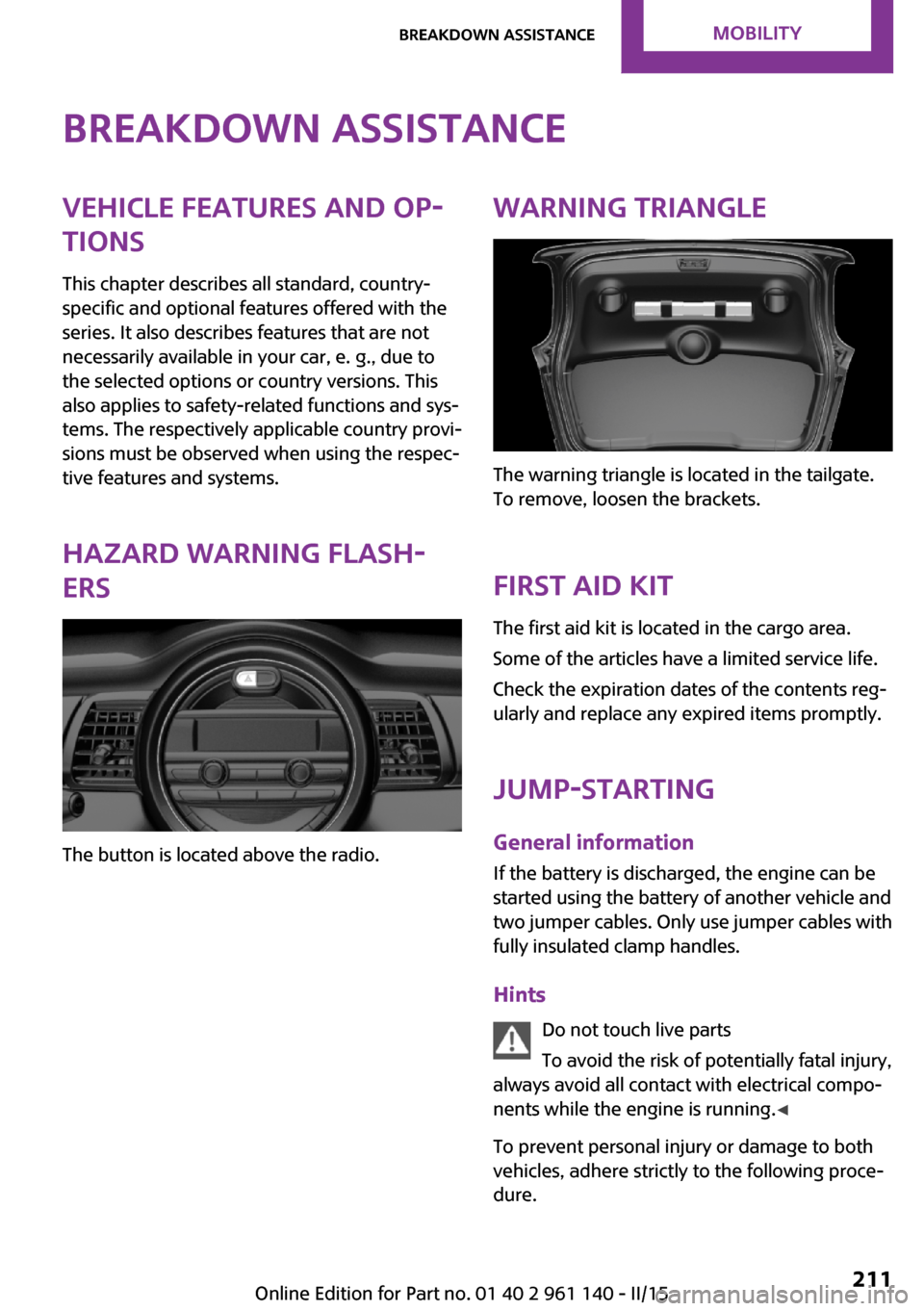

Hazard warning flash‐

ers

The button is located above the radio.

Warning triangle

The warning triangle is located in the tailgate.

To remove, loosen the brackets.

First aid kit

The first aid kit is located in the cargo area.

Some of the articles have a limited service life.

Check the expiration dates of the contents reg‐

ularly and replace any expired items promptly.

Jump-starting

General information If the battery is discharged, the engine can be

started using the battery of another vehicle and

two jumper cables. Only use jumper cables with

fully insulated clamp handles.

Hints Do not touch live parts

To avoid the risk of potentially fatal injury,

always avoid all contact with electrical compo‐

nents while the engine is running. ◀

To prevent personal injury or damage to both

vehicles, adhere strictly to the following proce‐

dure.

Seite 211Breakdown assistanceMOBILITY211

Online Edition for Part no. 01 40 2 961 140 - II/15

Page 216 of 251

PreparationBodywork contact between vehicles

Make sure that there is no contact be‐

tween the bodywork of the two vehicles; other‐

wise, there is a danger of short circuits. ◀1.Check whether the battery of the other ve‐

hicle has a voltage of 12 volts. This informa‐

tion can be found on the battery.2.Switch off the engine of the assisting vehi‐

cle.3.Switch off any electronic systems/power

consumers in both vehicles.

Starting aid terminals

Connecting order

Connect the jumper cables in the correct

order to prevent risk of injury from arcing. ◀

The so-called starting aid terminal in the engine

compartment acts as the battery's positive ter‐

minal.

Open the lid of the starting aid terminal.

The body ground acts as the negative terminal

of the battery.

Connecting the cables

1.Pull off the lid of the starting aid terminal.2.Attach one terminal clamp of the positive

jumper cable to the positive terminal of the

battery, or to the corresponding starting aid

terminal of the vehicle providing assistance.3.Attach the terminal clamp on the other end

of the cable to the positive terminal of the

battery, or to the corresponding starting aid

terminal of the vehicle to be started.4.Attach one terminal clamp of the negative

jumper cable to the negative terminal of

the battery, or to the corresponding engine

or body ground of assisting vehicle.5.Attach the second terminal clamp to the

negative terminal of the battery, or to the

corresponding engine or body ground of

the vehicle to be started.

Starting the engine

Never use spray fluids to start the engine.

1.Start the engine of the assisting vehicle and

let it run for several minutes at an increased

idle speed.2.Start the engine of the vehicle that is to be

started in the usual way.

If the first starting attempt is not successful,

wait a few minutes before making another

attempt in order to allow the discharged

battery to recharge.Seite 212MOBILITYBreakdown assistance212

Online Edition for Part no. 01 40 2 961 140 - II/15

Page 217 of 251

3.Let both engines run for several minutes.4.Disconnect the jumper cables in the reverse

order.

Check the battery and recharge if needed.

Tow-starting and towing

Note Tow-starting and towing

For towing the vehicle turn, switch off the

Intelligent Safety systems; otherwise malfunc‐

tions of the individual braking systems might

lead to accidents. ◀

Switching off Intelligent Safety systems, refer to

page 86.

Steptronic transmission: transporting

your vehicle

Note Your vehicle must not be towed if the front

wheels are touching the ground. Therefore,

contact a service center in the event of a break‐

down.

Tow the vehicle only with the front axle

raised

Have the vehicle towed only with the front axle raised or transported on a loading platform;

otherwise, damage may occur. ◀

Tow truck

Have your vehicle transported with a tow truck

with a so-called lift bar or on a flat bed.

Do not lift the vehicle

Do not lift the vehicle by the tow fitting or

body and chassis parts; otherwise, damage

may result. ◀

Use tow fitting located in the front only for po‐

sitioning the vehicle.

Manual transmission

Observe before towing your vehicle

Gearshift lever in neutral position.

Towing When the parking brake is blocked

The parking brake cannot be released

manually.

Do not tow the vehicle with the parking brake

blocked, or the vehicle can be damaged.

Contact your service center. ◀

Follow the towing instructions

Follow all towing instructions; otherwise,

vehicle damage or accidents may occur. ◀

▷Make sure that the ignition is switched on;

otherwise, the low beams, tail lights, turn

signals, and wipers may be unavailable.▷Do not tow the vehicle with the rear axle

tilted, as the front wheels could turn.Seite 213Breakdown assistanceMOBILITY213

Online Edition for Part no. 01 40 2 961 140 - II/15

Page 218 of 251

▷When the engine is stopped, there is no

power assist. Consequently, more force

needs to be applied when braking and

steering.▷Larger steering wheel movements are re‐

quired.▷The towing vehicle must not be lighter than

the vehicle being towed; otherwise, it will

not be possible to control the vehicle's re‐

sponse.

Tow truck

Have your vehicle transported with a tow truck

with a so-called lift bar or on a flat bed.

Do not lift the vehicle

Do not lift the vehicle by the tow fitting or

body and chassis parts; otherwise, damage

may result. ◀

Towing other vehicles

Hints Light towing vehicle

The towing vehicle must not be lighter

than the vehicle being towed; otherwise, it will

not be possible to control the vehicle's re‐ sponse. ◀

Attaching the tow bar/tow rope correctly

Attach the tow bar or tow rope to the tow

fitting; connecting it to other vehicle parts may

cause damage. ◀

▷Switch on the hazard warning system, de‐

pending on local regulations.▷If the electrical system has failed, clearly

identify the vehicle being towed by placing

a sign or a warning triangle in the rear win‐

dow.

Tow bar

The tow fittings used should be on the same

side on both vehicles.

Should it prove impossible to avoid mounting

the tow bar at an offset angle, please observe

the following:

▷Maneuvering capability is limited going

around corners.▷The tow bar will generate lateral forces if it

is secured with an offset.

Tow rope

When starting to tow the vehicle, make sure

that the tow rope is taut.

To avoid jerking and the associated stresses on

the vehicle components when towing, always

use nylon ropes or nylon straps.

Attaching the tow rope correctly

Only secure the tow rope on the tow fit‐

ting; otherwise, damage can occur when it is

secured on other parts of the vehicle. ◀

Tow fitting

The screw-in tow fitting should always be car‐

ried in the vehicle. It can be screwed in at the

front or rear of the MINI. It is located under the

Seite 214MOBILITYBreakdown assistance214

Online Edition for Part no. 01 40 2 961 140 - II/15