tow MINI Paceman 2014 (Mini Connected) Owner's Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2014, Model line: Paceman, Model: MINI Paceman 2014Pages: 282, PDF Size: 6.76 MB

Page 226 of 282

Minimum tread depth

Wear indicators in the tread base are distrib‐

uted around the circumference of the tire and

are marked on the tire sidewall with TWI, Tread

Wear Indicator. When the tire tread has been

worn down to the wear indicators, a tread has

reached a depth of 0.063 in/1.6 mm.

Tire damage

General information Inspect your tires often for damage, foreign ob‐

jects lodged in the tread, and tread wear.

Notes

Driving over rough or damaged road surfaces,

as well as debris, curbs and other obstacles can

cause serious damage to wheels, tires and sus‐

pension parts. This is more likely to occur with

low-profile tires, which provide less cushioning

between the wheel and the road. Be careful to

avoid road hazards and reduce your speed, es‐

pecially if your vehicle is equipped with low-

profile tires.

Indications of tire damage or other vehicle de‐

fects:

▷Unusual vibrations during driving.▷Unusual handling such as a strong ten‐

dency to pull to the left or right.

Damage can be caused by driving over curbs,

road damage and similar situations.

In case of tire damage

If there are indications of tire damage, re‐

duce your speed immediately and have the

wheels and tires checked right away; other‐

wise, there is the increased risk of an accident.

Drive carefully to the next service center or tire

shop.

If necessary, have the vehicle towed.

Otherwise, tire damage can present a life-

threatening hazard to vehicle occupants and

other road users. ◀

Repair of tire damage

For safety reasons, the manufacturer of

your vehicle recommends that you do not have

damaged tires repaired; they should be re‐

placed. Otherwise, damage can occur as a re‐

sult. ◀

Tire age RecommendationFor several reasons, among other things be‐

cause of beginning brittleness, the manufac‐

turer of your MINI recommends mounting new

tires at the latest after six years, regardless of

the actual wear.

Manufacture date The date of manufacture of the tires is specified

in the tire label:

DOT … 2313: the tire was manufactured in

week 23 of 2013.Seite 226MobilityWheels and tires226

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 229 of 282

▷If a warning triangle or portable hazard

warning lamp is required, set it up on the

roadside at an appropriate distance from

the rear of the vehicle. Comply with all

safety guidelines and regulations. ◀

The procedure to correct a flat tire depends on

the equipment in the vehicle:

▷Run-flat tires, refer to page 228.▷MINI Mobility System, refer to page 229.

MINI Mobility System

Notes

▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant bottle.▷Use of the Mobility System may be ineffec‐

tive if tire damage is greater than approx.

1/8 in/4 mm in size.▷Contact the nearest service center if the tire

cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

bottle and apply it to the steering wheel.

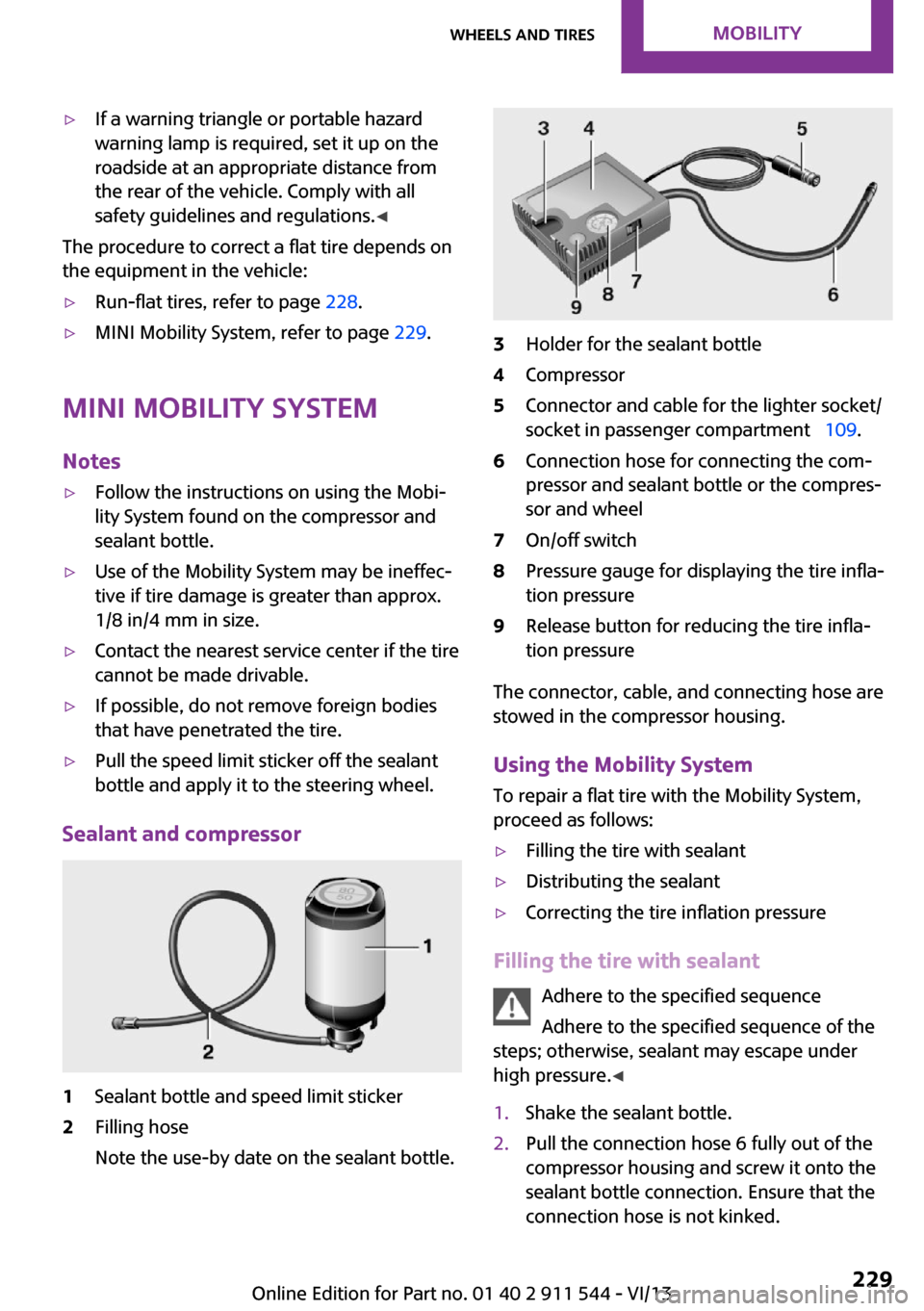

Sealant and compressor

1Sealant bottle and speed limit sticker2Filling hose

Note the use-by date on the sealant bottle.3Holder for the sealant bottle4Compressor5Connector and cable for the lighter socket/

socket in passenger compartment 109.6Connection hose for connecting the com‐

pressor and sealant bottle or the compres‐

sor and wheel7On/off switch8Pressure gauge for displaying the tire infla‐

tion pressure9Release button for reducing the tire infla‐

tion pressure

The connector, cable, and connecting hose are

stowed in the compressor housing.

Using the Mobility System

To repair a flat tire with the Mobility System,

proceed as follows:

▷Filling the tire with sealant▷Distributing the sealant▷Correcting the tire inflation pressure

Filling the tire with sealant

Adhere to the specified sequence

Adhere to the specified sequence of the

steps; otherwise, sealant may escape under

high pressure. ◀

1.Shake the sealant bottle.2.Pull the connection hose 6 fully out of the

compressor housing and screw it onto the

sealant bottle connection. Ensure that the

connection hose is not kinked.Seite 229Wheels and tiresMobility229

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 230 of 282

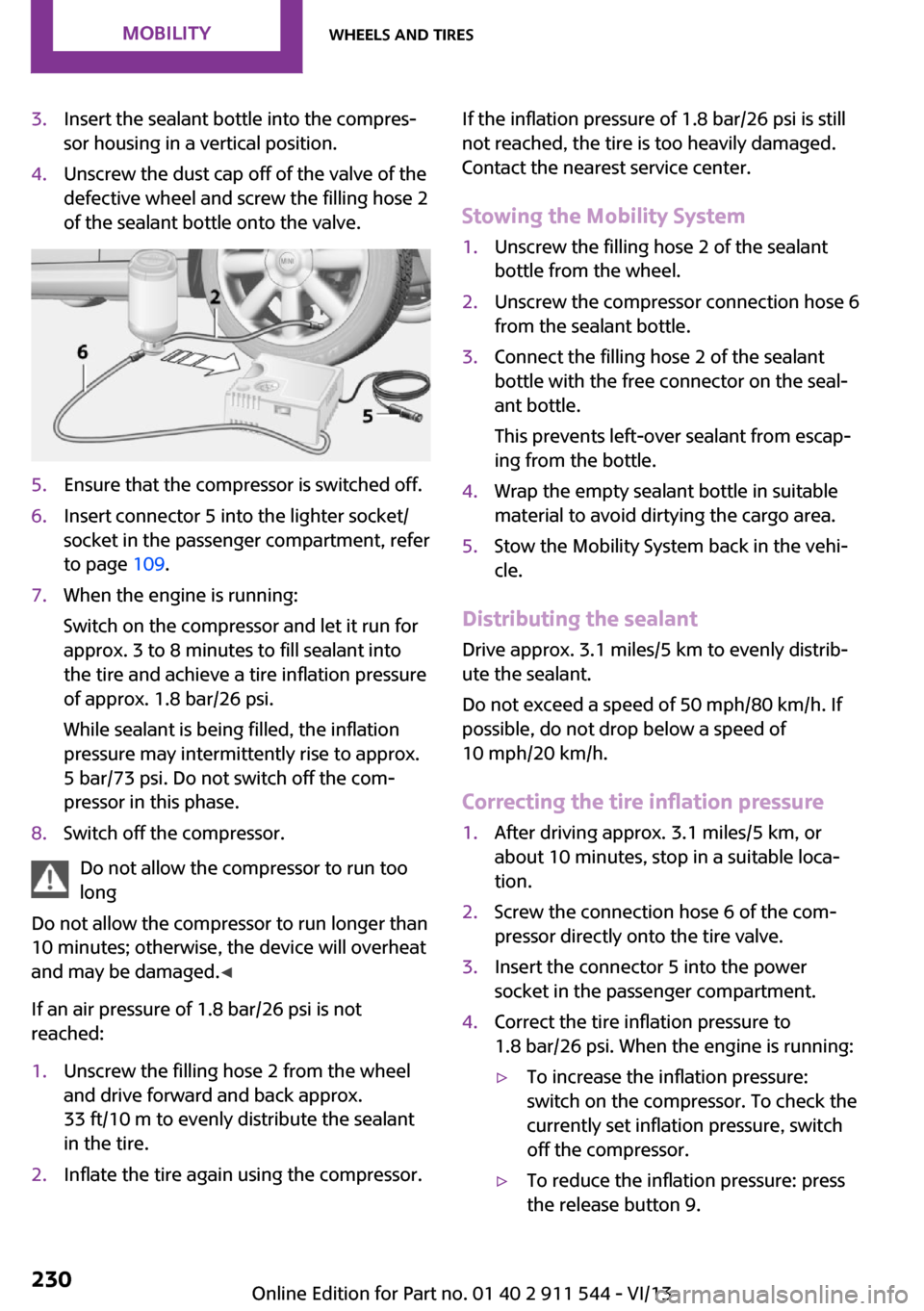

3.Insert the sealant bottle into the compres‐

sor housing in a vertical position.4.Unscrew the dust cap off of the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.5.Ensure that the compressor is switched off.6.Insert connector 5 into the lighter socket/

socket in the passenger compartment, refer

to page 109.7.When the engine is running:

Switch on the compressor and let it run for

approx. 3 to 8 minutes to fill sealant into

the tire and achieve a tire inflation pressure

of approx. 1.8 bar/26 psi.

While sealant is being filled, the inflation

pressure may intermittently rise to approx.

5 bar/73 psi. Do not switch off the com‐

pressor in this phase.8.Switch off the compressor.

Do not allow the compressor to run too

long

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged. ◀

If an air pressure of 1.8 bar/26 psi is not

reached:

1.Unscrew the filling hose 2 from the wheel

and drive forward and back approx.

33 ft/10 m to evenly distribute the sealant

in the tire.2.Inflate the tire again using the compressor.If the inflation pressure of 1.8 bar/26 psi is still

not reached, the tire is too heavily damaged.

Contact the nearest service center.

Stowing the Mobility System1.Unscrew the filling hose 2 of the sealant

bottle from the wheel.2.Unscrew the compressor connection hose 6

from the sealant bottle.3.Connect the filling hose 2 of the sealant

bottle with the free connector on the seal‐

ant bottle.

This prevents left-over sealant from escap‐

ing from the bottle.4.Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Drive approx. 3.1 miles/5 km to evenly distrib‐

ute the sealant.

Do not exceed a speed of 50 mph/80 km/h. If

possible, do not drop below a speed of

10 mph/20 km/h.

Correcting the tire inflation pressure

1.After driving approx. 3.1 miles/5 km, or

about 10 minutes, stop in a suitable loca‐

tion.2.Screw the connection hose 6 of the com‐

pressor directly onto the tire valve.3.Insert the connector 5 into the power

socket in the passenger compartment.4.Correct the tire inflation pressure to

1.8 bar/26 psi. When the engine is running:▷To increase the inflation pressure:

switch on the compressor. To check the

currently set inflation pressure, switch

off the compressor.▷To reduce the inflation pressure: press

the release button 9.Seite 230MobilityWheels and tires230

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 234 of 282

Engine oilVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

Engine oil General information

Engine oil consumption depends on the driving

style and the conditions of use. A highly sporty

driving style, for example, results in considera‐

bly higher engine oil consumption.

Therefore, regularly check the engine oil level

after refueling.

Checking the oil level with a dip stick1.Park the vehicle on level ground when the

engine is at operating temperature, i.e., af‐

ter driving continuously for at least

6 2 miles/10 km.2.Switch the engine off.3.After approx. 5 minutes, pull out the dip

stick and wipe it off with a lint-free cloth,

paper towel, etc.4.Carefully insert the dip stick all the way into

the measuring tube and pull it out again.The oil level must be between the two

marks on the dip stick.

The oil quantity between the two marks on the

dip stick equals approx. 1 US quart/1 liter.

Do not exceed the high mark.

Do not exceed the high mark of the dip

stick. Overfilling oil damages the engine. ◀

Adding engine oil

Filler neck

Add a maximum quantity of 1 US quart/1 liter

of oil only after the corresponding message ap‐

pears on the Control Display or, in diesel en‐

gines, after the oil level is just above the low

mark of the dip stick, refer to page 234.

Add oil promptly

Add oil within the next 30 miles/50 km;

otherwise, engine damage could result. ◀

Seite 234MobilityEngine oil234

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 239 of 282

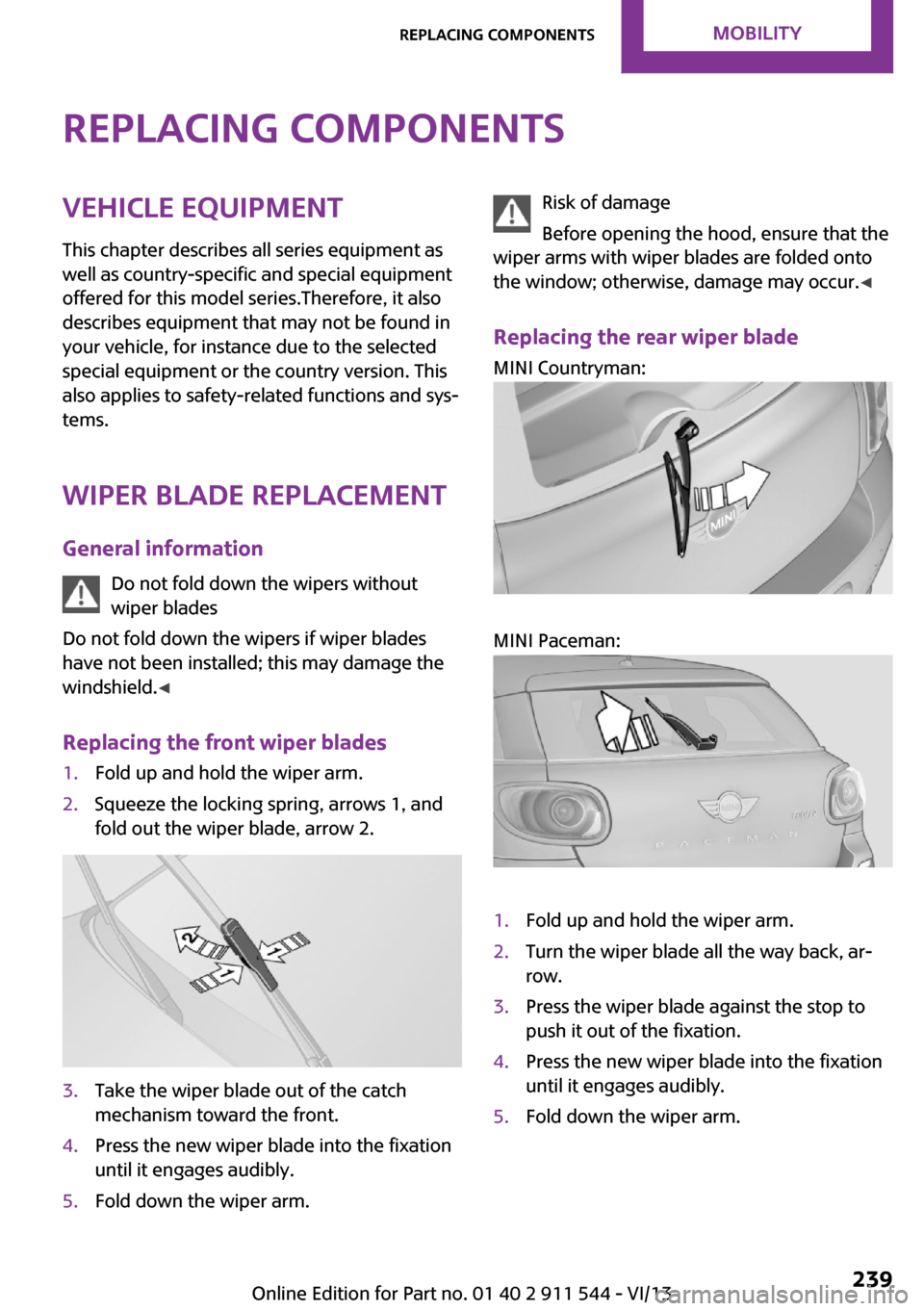

Replacing componentsVehicle equipmentThis chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

Wiper blade replacement General information Do not fold down the wipers without

wiper blades

Do not fold down the wipers if wiper blades

have not been installed; this may damage the

windshield. ◀

Replacing the front wiper blades1.Fold up and hold the wiper arm.2.Squeeze the locking spring, arrows 1, and

fold out the wiper blade, arrow 2.3.Take the wiper blade out of the catch

mechanism toward the front.4.Press the new wiper blade into the fixation

until it engages audibly.5.Fold down the wiper arm.Risk of damage

Before opening the hood, ensure that the

wiper arms with wiper blades are folded onto

the window; otherwise, damage may occur. ◀

Replacing the rear wiper blade

MINI Countryman:

MINI Paceman:

1.Fold up and hold the wiper arm.2.Turn the wiper blade all the way back, ar‐

row.3.Press the wiper blade against the stop to

push it out of the fixation.4.Press the new wiper blade into the fixation

until it engages audibly.5.Fold down the wiper arm.Seite 239Replacing componentsMobility239

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 250 of 282

the battery, or to the engine or body

ground of the vehicle to be started.

Body ground:

Starting the engine

Never use spray fluids to start the engine.

1.Start the engine of the assisting vehicle and

let it run for several minutes at a slightly in‐

creased idle speed.2.Start the engine of the vehicle being started

in the usual way.

If the first starting attempt is not successful,

wait a few minutes before making another

attempt in order to allow the discharged

battery to recharge.3.Let both engines run for several minutes.4.Disconnect the jumper cables in the reverse

order.

Check the battery and recharge if necessary.

Tow-starting and towing

Notes Observe applicable laws and regulations

Observe applicable laws and regulations

for tow-starting and towing. ◀

No additional passengers

Do not transport any passengers other

than the driver in a vehicle that is being

towed. ◀

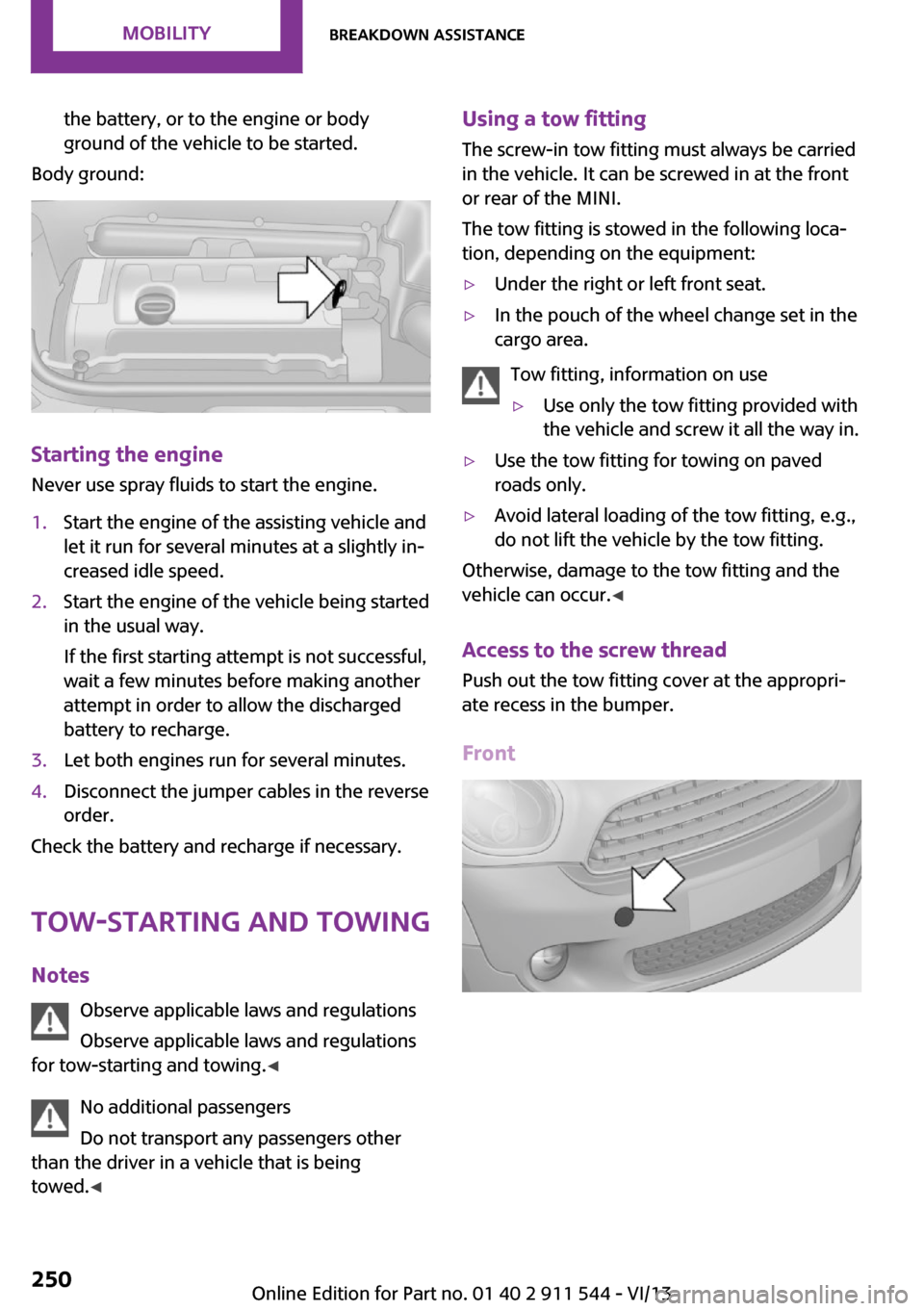

Using a tow fitting

The screw-in tow fitting must always be carried

in the vehicle. It can be screwed in at the front

or rear of the MINI.

The tow fitting is stowed in the following loca‐

tion, depending on the equipment:▷Under the right or left front seat.▷In the pouch of the wheel change set in the

cargo area.

Tow fitting, information on use

▷Use only the tow fitting provided with

the vehicle and screw it all the way in.▷Use the tow fitting for towing on paved

roads only.▷Avoid lateral loading of the tow fitting, e.g.,

do not lift the vehicle by the tow fitting.

Otherwise, damage to the tow fitting and the

vehicle can occur. ◀

Access to the screw thread Push out the tow fitting cover at the appropri‐

ate recess in the bumper.

Front

Seite 250MobilityBreakdown assistance250

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 251 of 282

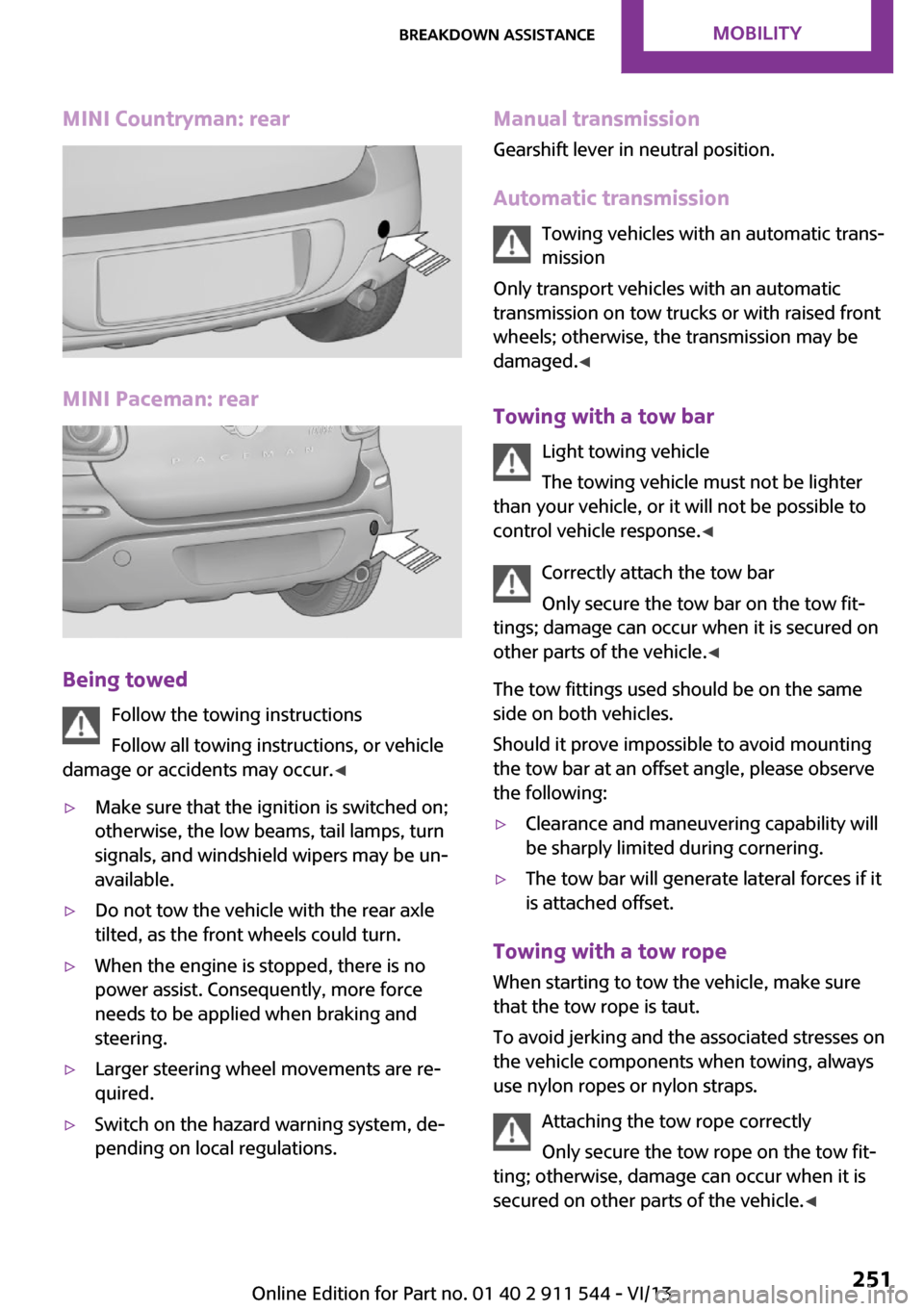

MINI Countryman: rear

MINI Paceman: rear

Being towedFollow the towing instructions

Follow all towing instructions, or vehicle

damage or accidents may occur. ◀

▷Make sure that the ignition is switched on;

otherwise, the low beams, tail lamps, turn

signals, and windshield wipers may be un‐

available.▷Do not tow the vehicle with the rear axle

tilted, as the front wheels could turn.▷When the engine is stopped, there is no

power assist. Consequently, more force

needs to be applied when braking and

steering.▷Larger steering wheel movements are re‐

quired.▷Switch on the hazard warning system, de‐

pending on local regulations.Manual transmission

Gearshift lever in neutral position.

Automatic transmission Towing vehicles with an automatic trans‐

mission

Only transport vehicles with an automatic

transmission on tow trucks or with raised front

wheels; otherwise, the transmission may be

damaged. ◀

Towing with a tow bar Light towing vehicle

The towing vehicle must not be lighter

than your vehicle, or it will not be possible to

control vehicle response. ◀

Correctly attach the tow bar

Only secure the tow bar on the tow fit‐

tings; damage can occur when it is secured on

other parts of the vehicle. ◀

The tow fittings used should be on the same

side on both vehicles.

Should it prove impossible to avoid mounting

the tow bar at an offset angle, please observe

the following:▷Clearance and maneuvering capability will

be sharply limited during cornering.▷The tow bar will generate lateral forces if it

is attached offset.

Towing with a tow rope

When starting to tow the vehicle, make sure

that the tow rope is taut.

To avoid jerking and the associated stresses on

the vehicle components when towing, always

use nylon ropes or nylon straps.

Attaching the tow rope correctly

Only secure the tow rope on the tow fit‐

ting; otherwise, damage can occur when it is

secured on other parts of the vehicle. ◀

Seite 251Breakdown assistanceMobility251

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 252 of 282

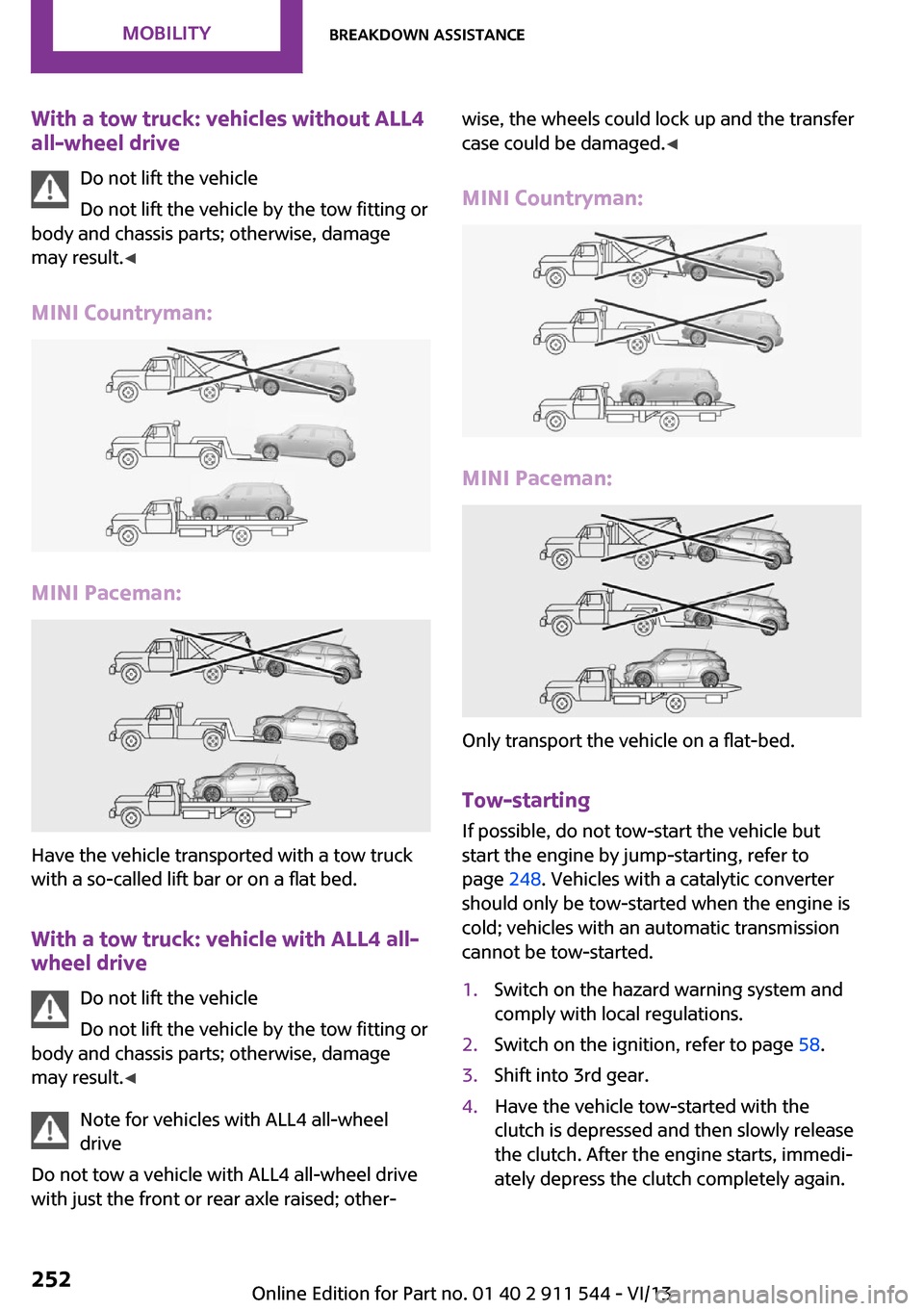

With a tow truck: vehicles without ALL4all-wheel drive

Do not lift the vehicle

Do not lift the vehicle by the tow fitting or

body and chassis parts; otherwise, damage

may result. ◀

MINI Countryman:

MINI Paceman:

Have the vehicle transported with a tow truck

with a so-called lift bar or on a flat bed.

With a tow truck: vehicle with ALL4 all-wheel drive

Do not lift the vehicle

Do not lift the vehicle by the tow fitting or

body and chassis parts; otherwise, damage

may result. ◀

Note for vehicles with ALL4 all-wheel

drive

Do not tow a vehicle with ALL4 all-wheel drive

with just the front or rear axle raised; other‐

wise, the wheels could lock up and the transfer

case could be damaged. ◀

MINI Countryman:

MINI Paceman:

Only transport the vehicle on a flat-bed.

Tow-starting

If possible, do not tow-start the vehicle but

start the engine by jump-starting, refer to page 248. Vehicles with a catalytic converter

should only be tow-started when the engine is

cold; vehicles with an automatic transmission

cannot be tow-started.

1.Switch on the hazard warning system and

comply with local regulations.2.Switch on the ignition, refer to page 58.3.Shift into 3rd gear.4.Have the vehicle tow-started with the

clutch is depressed and then slowly release

the clutch. After the engine starts, immedi‐

ately depress the clutch completely again.Seite 252MobilityBreakdown assistance252

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 253 of 282

5.Stop at a suitable location, remove the tow

bar or rope, and switch off the hazard

warning system.6.Have the vehicle checked.Seite 253Breakdown assistanceMobility253

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 254 of 282

CareVehicle equipmentThis chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

Car washes Notes Steam jets or high-pressure washers

When using steam jets or high-pressure

washers, hold them a sufficient distance away

and use a maximum temperature of

140 ℉/60 ℃.

Holding them too close or using excessively

high pressures or temperatures can cause dam‐

age or preliminary damage that may then lead

to long-term damage.

Follow the operating instructions for the high-

pressure washer. ◀

Do not direct steam or high-pressure washers

toward the labels applied by the manufacturer;

otherwise, damage may result.

Cleaning sensors/cameras with high-pres‐

sure washers

When using high-pressure washers, do not

spray the seals of the retractable hardtop and

the exterior sensors and cameras, for Park Dis‐ tance Control, for instance, for extended peri‐ods of time and only from a distance of at least

12 in/30 cm. ◀During the winter months

Ensure that the vehicle is washed more

frequently in winter. Intense soiling and road

salt can damage the vehicle. ◀

After washing the vehicle, apply the brakes

briefly to dry them; otherwise, braking action

can be reduced and corrosion of the brake

discs can occur.

Regularly remove foreign bodies, such as

leaves, from the area of the windshield when

the hood is open.

Washing in automatic car washes Give preference to cloth car washes or those

that use soft brushes in order to avoid paint

damage.

Do not use automatic high-pressure washers;

otherwise, water may drip into the interior in

the area of the windows.

Before driving into the car wash, check whether

the system is suitable for your MINI. Note the

following points:▷Vehicle dimensions, refer to page 260.▷If necessary: fold in the exterior mirrors, re‐

fer to page 51.▷Maximum permissible tire width.

Guide rails in car washes

Avoid car washes with guide rails higher

than 4 in/10 cm; otherwise, the vehicle chassis

could be damaged. ◀

Preparations before driving into the car wash:

▷Unscrew the road antenna.▷Deactivate the rain sensor to avoid unin‐

tentional wiper activation.▷Deactivate the rear window wiper and pro‐

tect it from damage. Ask the car wash oper‐

ator about any necessary protective meas‐

ures.Seite 254MobilityCare254

Online Edition for Part no. 01 40 2 911 544 - VI/13