ESP MINI Paceman 2014 (Mini Connected) Service Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2014, Model line: Paceman, Model: MINI Paceman 2014Pages: 282, PDF Size: 6.76 MB

Page 225 of 282

Conform to Federal Safety Requirements

All passenger car tires must conform to

Federal Safety Requirements in addition to

these grades. ◀

Treadwear

The treadwear grade is a comparative rating based on the wear rate of the tire when tested

under controlled conditions on a specified gov‐

ernment test course. For example, a tire graded

150 would wear one and one-half (1 1/2) times

as well on the government course as a tire graded 100. The relative performance of tires

depends upon the actual conditions of their

use, however, and may depart significantly

from the norm due to variations in driving hab‐

its, service practices and differences in road

characteristics and climate.

TractionThe traction grades, from highest to lowest, are

AA, A, B, and C.

Those grades represent the tire’s ability to stop

on wet pavement as measured under control‐

led conditions on specified government test

surfaces of asphalt and concrete. A tire marked

C may have poor traction performance.

The traction grade assigned to this tire is based

on straight-ahead braking traction tests, and

does not include acceleration, cornering, hy‐

droplaning, or peak traction characteristics.

Temperature

The temperature grades are A, the highest, B,

and C, representing the tire’s resistance to the

generation of heat and its ability to dissipate

heat when tested under controlled conditions

on a specified indoor laboratory test wheel.

Sustained high temperature can cause the ma‐

terial of the tire to degenerate and reduce tire

life, and excessive temperature can lead to

sudden tire failure. The grade C corresponds to

a level of performance which all passenger car

tires must meet under the Federal Motor Vehi‐cle Safety Standard No. 109. Grades B and A

represent higher levels of performance on the

laboratory test wheel than the minimum re‐

quired by law.

Temperature grade for this tire

The temperature grade for this tire is es‐

tablished for a tire that is properly inflated and

not overloaded. Excessive speed, underinfla‐

tion, or excessive loading, either separately or

in combination, can cause heat buildup and

possible tire failure. ◀

RSC – Run-flat tires

The symbol identifying run-flat tires is a circle

with the letters RSC on the sidewall, refer to

page 228.

M+S

Winter and all-season tires.

These have better winter properties than

summer tires.

XL

Designation for specially reinforced tires.

Tire treadSummer tiresThe tread depth should not be less than

0.12 in/3 mm, although European legislation,

for example, requires a minimum tread depth

of only 0.063 in/1.6 mm. At tread depths less

than 0.12 in/3 mm, there is a great danger of

hydroplaning even in low water depths and at

raised speeds.

Winter tires

The suitability of winter tires for winter driving

is reduced noticeably when their tread depth

becomes less than 0.16 in/4 mm.Seite 225Wheels and tiresMobility225

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 227 of 282

Changing wheels and

tires

Mounting Information on mounting tires

Have mounting and balancing performed

only by a service center or tire specialist.

If this work is not carried out properly, there is

the danger of subsequent damage and related

safety hazards. ◀

Wheel and tire combination Information on the right wheel and tire combi‐

nation and rim version for your vehicle can be

obtained from the service center.

Incorrect wheel and tire combinations impair

the function of a variety of systems such as ABS

or DSC.

To maintain good handling and vehicle re‐

sponse, use only tires with a single tread con‐

figuration from a single manufacturer.

Following tire damage, have the original wheel

and tire combination remounted on the vehicle

as soon as possible.

Approved wheels and tires

The manufacturer of your vehicle recom‐

mends that you use only wheels and tires that

have been approved for your particular vehicle

model.

For example, despite having the same official

size ratings, variations can lead to body contact

and with it, the risk of severe accidents.

The manufacturer of your vehicle cannot evalu‐

ate non-approved wheels and tires to deter‐

mine if they are suited for use, and therefore

cannot ensure the operating safety of the vehi‐

cle if they are mounted. ◀Wheels with electronics for TPM Tire

Pressure Monitor

When mounting new tires or changing from

summer to winter tires or vice versa, only use

wheels with TPM electronics; otherwise, the

Tire Pressure Monitor will not be able to detect

a flat tire, refer to page 87. Your service center

will be glad to advise you.

Recommended tire brands

For each tire size, the manufacturer of your ve‐

hicle recommends certain tire brands. These

are indicated by the clearly visible marking on

the tire sidewall.

With proper use, these tires meet the highest

standards for safety and handling.

Retreaded tires

The manufacturer of your vehicle does not rec‐

ommend the use of retreaded tires.

Retreaded tires

Possibly substantial variations in the de‐

sign and age of the tire casing structures can

limit service life and have a negative impact on

road safety. ◀

Winter tires The manufacturer of your vehicle recommends

winter tires for winter roads or at temperatures

below +45 ℉/+7 ℃.

Although so-called all-season M+S tires do pro‐

vide better winter traction than summer tires,

they do not provide the same level of perform‐

ance as winter tires.

Seite 227Wheels and tiresMobility227

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 228 of 282

Maximum speed of winter tires

If the maximum speed of the vehicle is higher

than the permissible speed for the winter tires,

then display a corresponding sign in the field of

vision. You can obtain this sign from the tire

specialist or from your service center.

Maximum speed for winter tires

Do not exceed the maximum speed for

the winter tires; otherwise, tire damage and ac‐

cidents can occur. ◀

Run-flat tires When mounting new tires or changing fromsummer to winter tires or vice versa, use run-

flat tires for your own safety. Also, a compact

wheel is not available in case of a flat tire. Your

service center will be glad to advise you.

Rotating wheels between axles

Different wear patterns occur on the front and

rear axles, depending on the individual condi‐

tions of use.

To ensure even wear on the tires, the wheels

can be rotated between the axles. Your service

center will be glad to advise you.

After changing the tires, check the tire inflation

pressure and correct it if necessary.

Storage Store wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

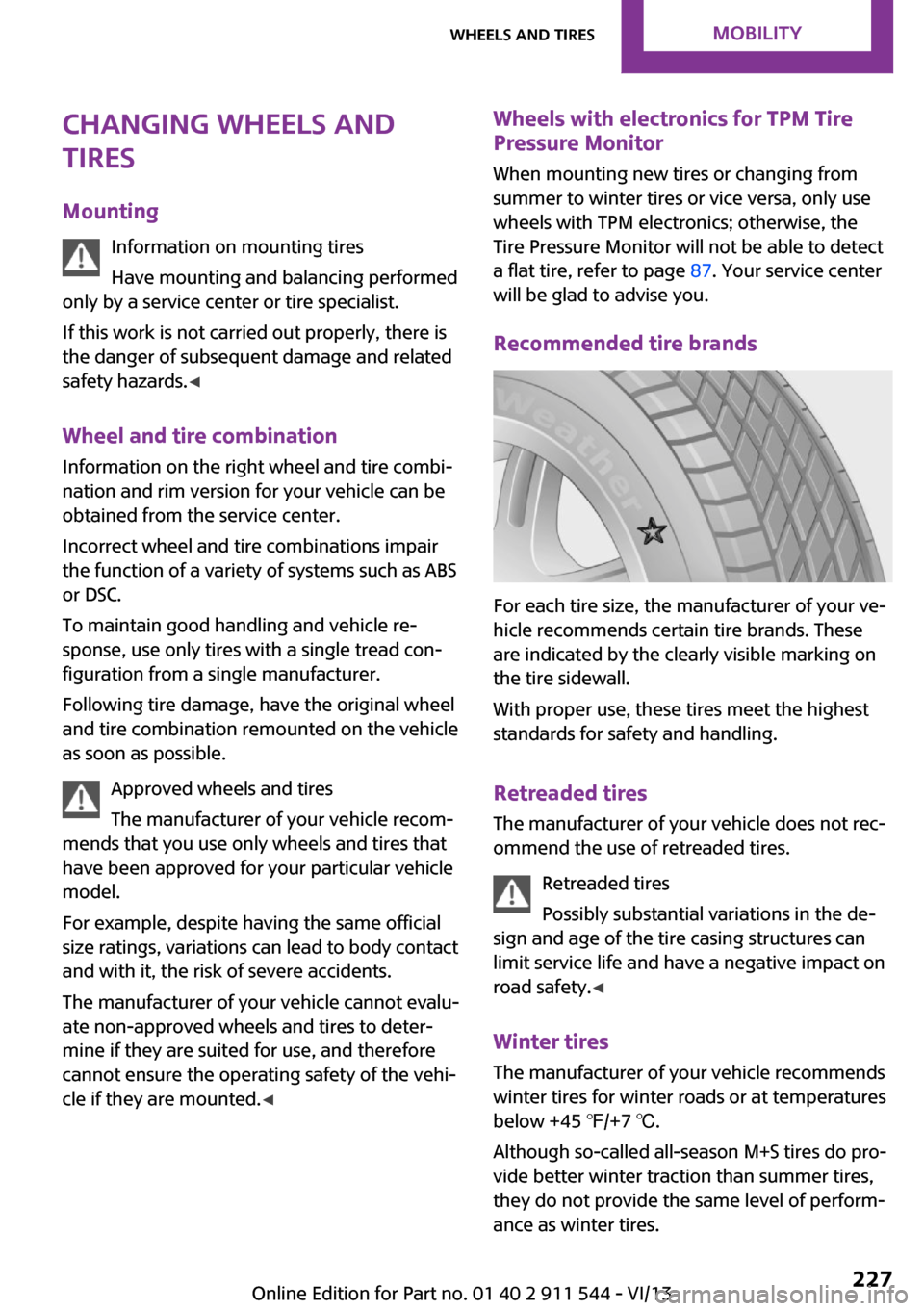

sure indicated on the side wall of the tire.Run-flat tires

Label

The symbol identifying run-flat tires is a circle

with the letters RSC on the sidewall.

Run-flat tires are tires with special rims that

support themselves for a limited period of time.

The sidewall reinforcement ensures that the

tire can continue to be used to a limited extent

if it has lost pressure and even if it has become

completely depressurized.

For continued driving in the event of a flat tire,

refer to page 86.

Correcting a flat tire Safety measures in case of a breakdown

▷Park the vehicle as far as possible

from passing traffic and on solid

ground. Switch on the hazard warn‐

ing system.▷Let the steering wheel lock engage with the

wheels in the straight-ahead position, set

the handbrake, and engage first gear or re‐

verse, or engage selector lever position P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.Seite 228MobilityWheels and tires228

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 234 of 282

Engine oilVehicle equipment

This chapter describes all series equipment as

well as country-specific and special equipment

offered for this model series.Therefore, it also

describes equipment that may not be found in

your vehicle, for instance due to the selected

special equipment or the country version. This

also applies to safety-related functions and sys‐

tems.

Engine oil General information

Engine oil consumption depends on the driving

style and the conditions of use. A highly sporty

driving style, for example, results in considera‐

bly higher engine oil consumption.

Therefore, regularly check the engine oil level

after refueling.

Checking the oil level with a dip stick1.Park the vehicle on level ground when the

engine is at operating temperature, i.e., af‐

ter driving continuously for at least

6 2 miles/10 km.2.Switch the engine off.3.After approx. 5 minutes, pull out the dip

stick and wipe it off with a lint-free cloth,

paper towel, etc.4.Carefully insert the dip stick all the way into

the measuring tube and pull it out again.The oil level must be between the two

marks on the dip stick.

The oil quantity between the two marks on the

dip stick equals approx. 1 US quart/1 liter.

Do not exceed the high mark.

Do not exceed the high mark of the dip

stick. Overfilling oil damages the engine. ◀

Adding engine oil

Filler neck

Add a maximum quantity of 1 US quart/1 liter

of oil only after the corresponding message ap‐

pears on the Control Display or, in diesel en‐

gines, after the oil level is just above the low

mark of the dip stick, refer to page 234.

Add oil promptly

Add oil within the next 30 miles/50 km;

otherwise, engine damage could result. ◀

Seite 234MobilityEngine oil234

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 240 of 282

Lamp and bulb replace‐

ment

Notes

Lamps and bulbs Lamps and bulbs make an essential contribu‐

tion to vehicle safety. Therefore, exercise cau‐

tion when handling lamps and bulbs.

The manufacturer of the vehicle recommends

that you entrust corresponding procedures to

the service center if you are unfamiliar with

them or they are not described here.

You can obtain a selection of replacement

bulbs at the service center.

Danger of burns

Only change bulbs when they are cool;

otherwise, there is the danger of getting

burned. ◀

Working on the lighting system

When working on the lighting system,

you should always switch off the lights affected

to prevent short circuits.

To avoid possible injury or equipment damage

when replacing bulbs, observe any instructions

provided by the bulb manufacturer. ◀

Do not touch the bulbs

Do not touch the glass of new bulbs with

your bare hands, as even minute amounts of

contamination will burn into the bulb's surface

and reduce its service life.

Use a clean tissue, cloth or something similar,

or hold the bulb by its base. ◀

Caring for the headlamps, refer to page 255.

For bulb replacement that is not described

here, please contact the service center or a

workshop that works according to the repair

procedures of the manufacturer with corre‐

spondingly trained personnel.For checking and adjusting headlamp aim,

please contact your MINI dealer.

Light-emitting diodes LEDs Light-emitting diodes installed behind translu‐

cent lenses serve as the light source for many

of the controls and displays in the vehicle.

These light-emitting diodes, which operate us‐

ing a concept similar to that applied in conven‐

tional lasers, are officially designated as Class 1

light-emitting diodes.

Do not remove the covers

Do not remove the covers, and never

stare into the unfiltered light for several hours;

otherwise, irritation of the retina could result. ◀

Headlamp glass

Condensation can form on the inside of the

headlamps in cool or humid weather. When the

light is switched on, the condensation evapo‐ rates after a short time. The headlamps do notneed to be changed.

If the condensation in the headlamps does not

evaporate after trips with the lights switched

on, and the amount of moisture in the head‐

lamps increases, for example if water droplets

form, have them checked by your service cen‐

ter.

Bi-xenon headlamps These bulbs have a very long life and the likeli‐

hood of failure is very low, provided that they

are not switched on and off excessively. If a

bulb should nevertheless fail, you can continue

driving cautiously with the front fog lamps, pro‐

vided this is permitted by local laws.

Do not perform work/bulb replacement

on xenon headlamps

Have any work on the xenon lighting system,

including bulb replacement, performed only by

a service center.Seite 240MobilityReplacing components240

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 245 of 282

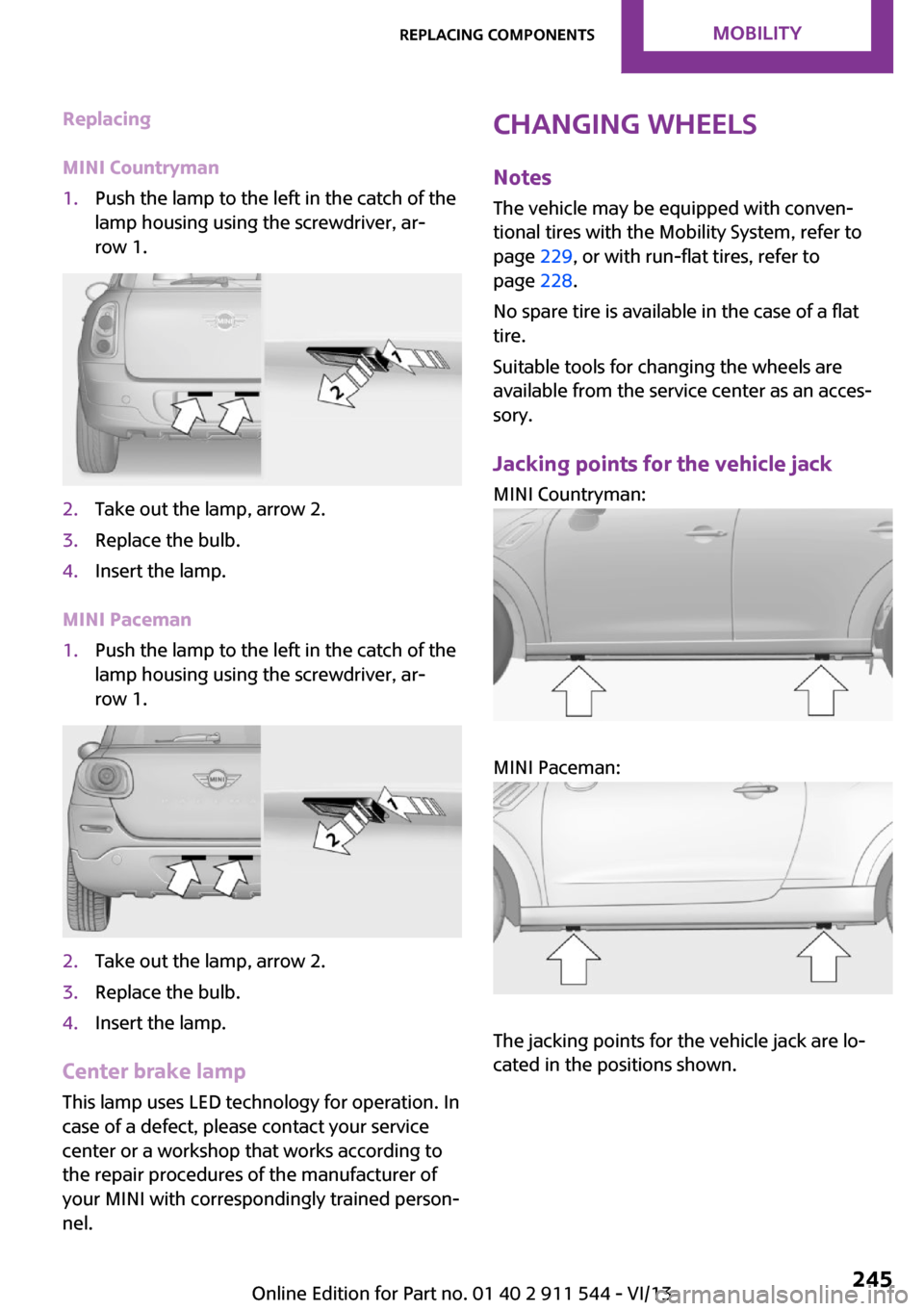

Replacing

MINI Countryman1.Push the lamp to the left in the catch of the

lamp housing using the screwdriver, ar‐

row 1.2.Take out the lamp, arrow 2.3.Replace the bulb.4.Insert the lamp.

MINI Paceman

1.Push the lamp to the left in the catch of the

lamp housing using the screwdriver, ar‐

row 1.2.Take out the lamp, arrow 2.3.Replace the bulb.4.Insert the lamp.

Center brake lamp

This lamp uses LED technology for operation. In

case of a defect, please contact your service

center or a workshop that works according to

the repair procedures of the manufacturer of

your MINI with correspondingly trained person‐

nel.

Changing wheels

Notes

The vehicle may be equipped with conven‐

tional tires with the Mobility System, refer to

page 229, or with run-flat tires, refer to

page 228.

No spare tire is available in the case of a flat

tire.

Suitable tools for changing the wheels are

available from the service center as an acces‐

sory.

Jacking points for the vehicle jack MINI Countryman:

MINI Paceman:

The jacking points for the vehicle jack are lo‐

cated in the positions shown.

Seite 245Replacing componentsMobility245

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 249 of 282

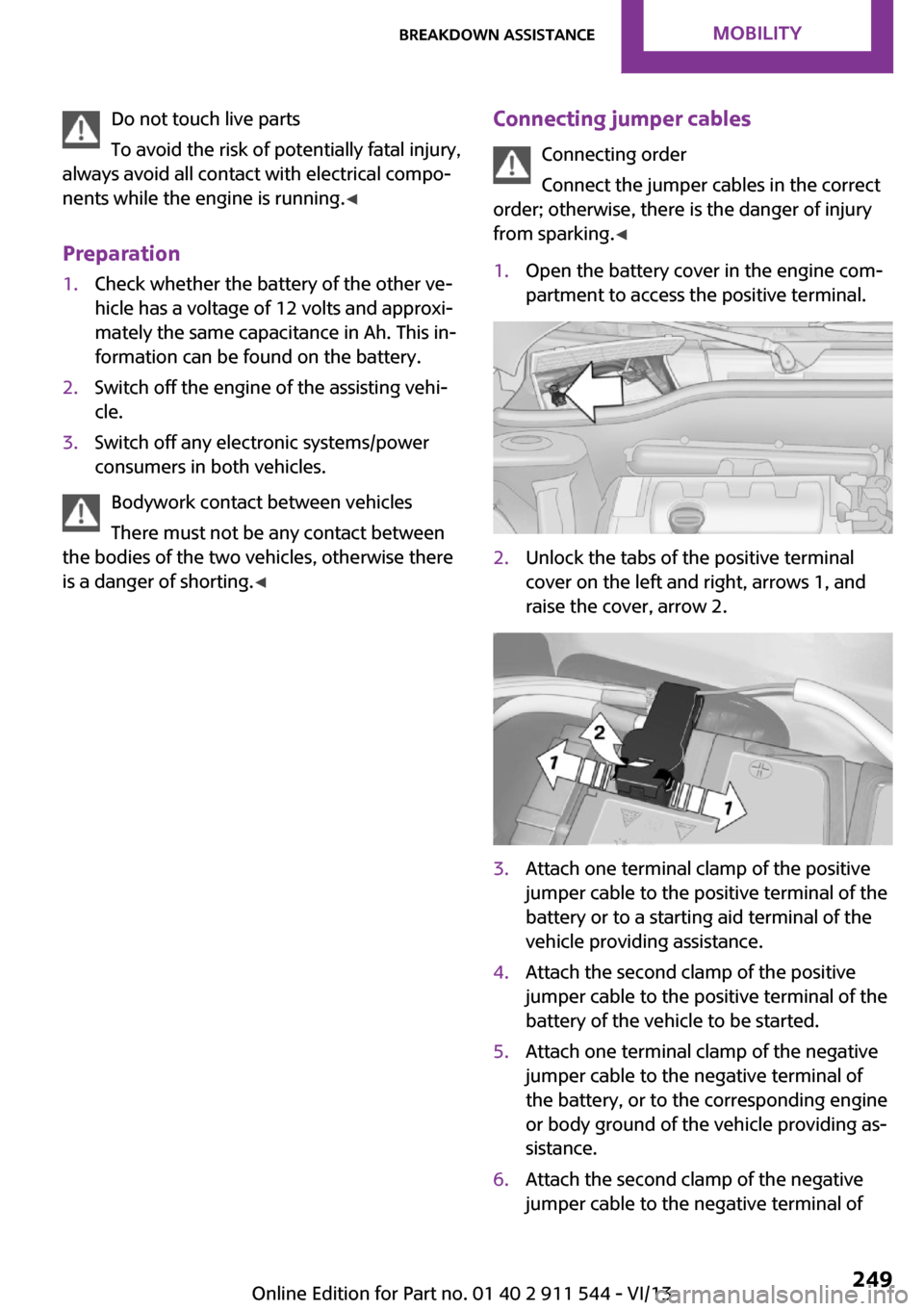

Do not touch live parts

To avoid the risk of potentially fatal injury,

always avoid all contact with electrical compo‐

nents while the engine is running. ◀

Preparation1.Check whether the battery of the other ve‐

hicle has a voltage of 12 volts and approxi‐

mately the same capacitance in Ah. This in‐

formation can be found on the battery.2.Switch off the engine of the assisting vehi‐

cle.3.Switch off any electronic systems/power

consumers in both vehicles.

Bodywork contact between vehicles

There must not be any contact between

the bodies of the two vehicles, otherwise there

is a danger of shorting. ◀

Connecting jumper cables

Connecting order

Connect the jumper cables in the correct

order; otherwise, there is the danger of injury

from sparking. ◀1.Open the battery cover in the engine com‐

partment to access the positive terminal.2.Unlock the tabs of the positive terminal

cover on the left and right, arrows 1, and

raise the cover, arrow 2.3.Attach one terminal clamp of the positive

jumper cable to the positive terminal of the

battery or to a starting aid terminal of the

vehicle providing assistance.4.Attach the second clamp of the positive

jumper cable to the positive terminal of the

battery of the vehicle to be started.5.Attach one terminal clamp of the negative

jumper cable to the negative terminal of

the battery, or to the corresponding engine

or body ground of the vehicle providing as‐

sistance.6.Attach the second clamp of the negative

jumper cable to the negative terminal ofSeite 249Breakdown assistanceMobility249

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 251 of 282

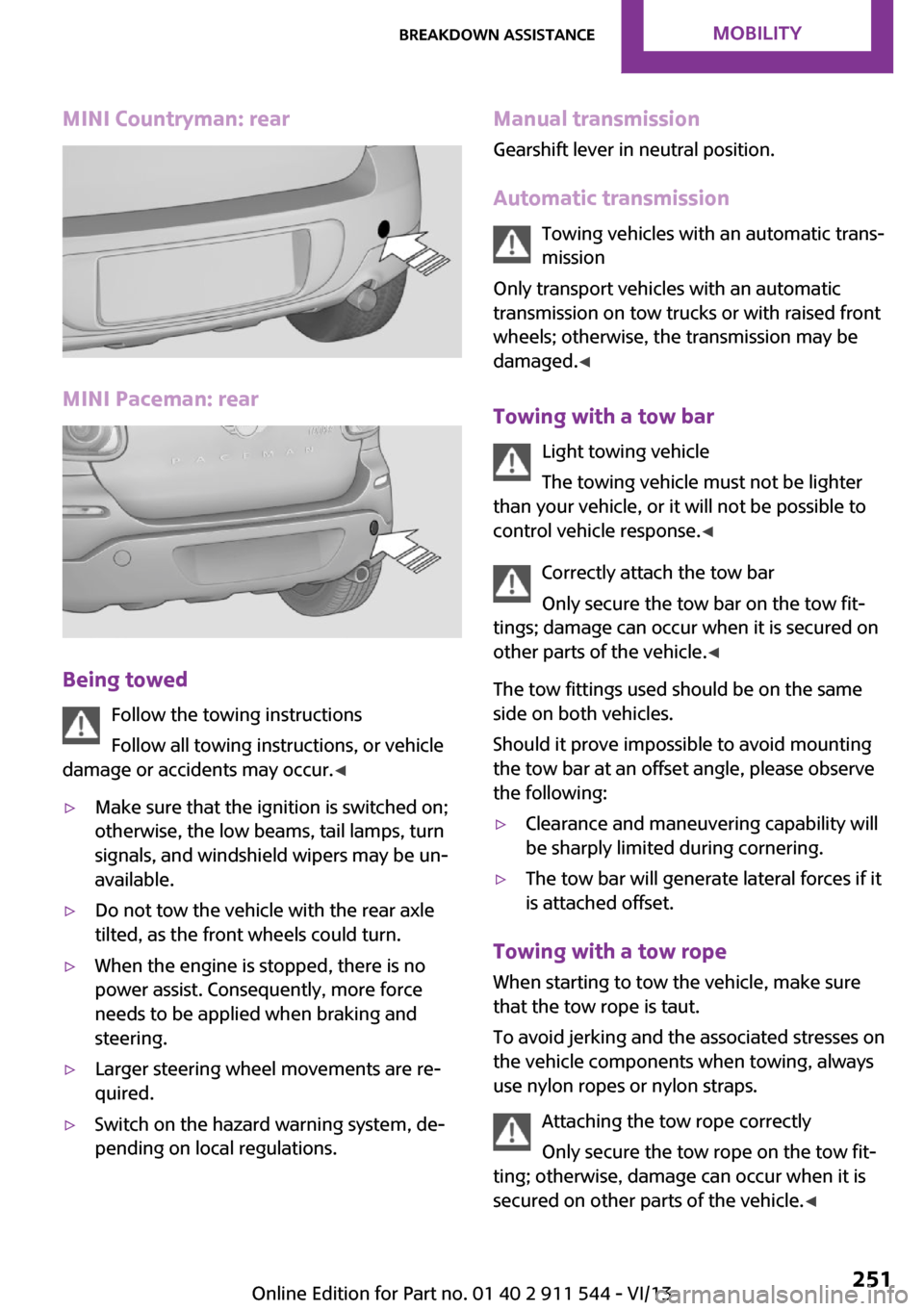

MINI Countryman: rear

MINI Paceman: rear

Being towedFollow the towing instructions

Follow all towing instructions, or vehicle

damage or accidents may occur. ◀

▷Make sure that the ignition is switched on;

otherwise, the low beams, tail lamps, turn

signals, and windshield wipers may be un‐

available.▷Do not tow the vehicle with the rear axle

tilted, as the front wheels could turn.▷When the engine is stopped, there is no

power assist. Consequently, more force

needs to be applied when braking and

steering.▷Larger steering wheel movements are re‐

quired.▷Switch on the hazard warning system, de‐

pending on local regulations.Manual transmission

Gearshift lever in neutral position.

Automatic transmission Towing vehicles with an automatic trans‐

mission

Only transport vehicles with an automatic

transmission on tow trucks or with raised front

wheels; otherwise, the transmission may be

damaged. ◀

Towing with a tow bar Light towing vehicle

The towing vehicle must not be lighter

than your vehicle, or it will not be possible to

control vehicle response. ◀

Correctly attach the tow bar

Only secure the tow bar on the tow fit‐

tings; damage can occur when it is secured on

other parts of the vehicle. ◀

The tow fittings used should be on the same

side on both vehicles.

Should it prove impossible to avoid mounting

the tow bar at an offset angle, please observe

the following:▷Clearance and maneuvering capability will

be sharply limited during cornering.▷The tow bar will generate lateral forces if it

is attached offset.

Towing with a tow rope

When starting to tow the vehicle, make sure

that the tow rope is taut.

To avoid jerking and the associated stresses on

the vehicle components when towing, always

use nylon ropes or nylon straps.

Attaching the tow rope correctly

Only secure the tow rope on the tow fit‐

ting; otherwise, damage can occur when it is

secured on other parts of the vehicle. ◀

Seite 251Breakdown assistanceMobility251

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 256 of 282

Vehicle paint

Regular care contributes to vehicle value reten‐

tion and protects the paintwork against the

long-term effects of paint-damaging substan‐

ces.

Environmental influences in areas with higher

air pollution or natural contaminants, such as

tree resin or pollen, can have an impact on the

vehicle paint. Therefore, it is important to tailor

the frequency and extent of your car care to

these influences.

Immediately remove especially aggressive sub‐

stances, such as spilled fuel, oil, grease, or bird

droppings, to prevent damage to the paint‐

work.

Correcting paint damage

Depending on the severity of the damage, re‐

pair stone impact damage or scratches imme‐

diately to prevent rust formation.

The manufacturer recommends having paint

damage corrected with a professional repair

paint job according to factory specifications us‐

ing original MINI paint materials.

Preservation

Preservation is needed when water no longer

beads off of the clean paint surfaces. Only use

paint preservation products that contain car‐

nauba or synthetic waxes.

Leather care The leather processed by the manufacturer is a

high quality natural product. Light graininess is

a typical feature of natural leather.

Particles of dust and road grime chafe in pores

and folds, and lead to increased wear and pre‐

mature degradation of the leather surface.

Therefore, remove dust from the leather regu‐

larly, using a cloth or vacuum cleaner.

Make especially sure that light-colored leather

is cleaned regularly as it is more susceptible to

soiling.Twice a year, treat the leather with a leather lo‐

tion as dirt and grease will attack the protective

layer of the leather.

Upholstery material care

Vacuum regularly with a vacuum cleaner to re‐

move superficial soiling.

In case of heavy soiling, e.g., beverage stains,

use a soft sponge or lint-free microfiber cloth in

combination with a suitable interior cleaner.

Follow the instructions on the container.

Clean the upholstery material down to the

seams using large sweeping motions. Avoid

rubbing the material vigorously.

Damage from Velcro® fasteners

Open Velcro® fasteners on pants or other

articles of clothing can damage the seat covers.

Ensure that any Velcro® fasteners are closed. ◀

Caring for special components Interior plastic parts These include:▷Imitation leather surfaces▷Lamp lenses▷Indicator covers▷Matte components

Clean with water and a solvent-free plastic

cleaner if necessary.

Do not use cleansers that contain alcohol

or solvents

Do not use cleansers that contain alcohol or

solvents, such as lacquer thinners, heavy-duty

grease removers, fuel, or such; this could lead

to surface damage. ◀

Rubber seals Only treat with water or a rubber care product.

When cleaning rubber seals, do not use silicone

sprays or other care products containing sili‐

cone; otherwise, noise and damage may result.

Seite 256MobilityCare256

Online Edition for Part no. 01 40 2 911 544 - VI/13

Page 272 of 282

Consumption, refer to Aver‐age fuel consumption 70

Contacts 187, 203

Control Display 20

Control Display, care 257

Control Display, settings 73

Controls and displays 14

Control systems, driving stabil‐ ity 93

Convenient operation– Windows 34

Coolant temperature 69

Cooling function, switching on and off 103

Cooling, maximum 102

Cornering Brake Control, CBC 93

Corrosion on brake discs 124

Cradle for telephone or mobile phone, refer to Snap-in

adapter 200

Cruise control 96

Cupholders 108

Current fuel consumption 70

Current location, storing 138

Curve lights, refer to Adaptive Light Control 80

Cylinders, number of, refer to Engine data 260

D

Dashboard lighting, refer to Instrument lighting 80

Dashboard, refer to Cock‐ pit 14

Dashboard, refer to Dis‐ plays 16

Data, technical 260

Date

– Date format 73– Setting 73

Daytime running lights 79

Decorative trim, care 257

Defogging windows 100

Defroster

– Rear window 100, 103Defrosting windows 100

Defrost setting, refer to De‐ frosting windows 100

Destination entry via the ad‐ dress book 138

Destination guidance with in‐ termediate destinations 143

Destination input, naviga‐ tion 136

Digital compass 106

Digital radio 159

Dip stick, engine oil 234

Directional indicators, refer to Turn signals 61

Displacement, refer to Engine data 260

Display lighting, refer to In‐ strument lighting 80

Displays 16

Displays and controls 14

Displays, care 257

Displays, cleaning 257

Displays, refer to Instrument cluster 16

Disposal– Remote control battery 41

Distance warning, refer to

Park Distance Control

PDC 97

Door key, refer to Remote control with integrated

key 32

Door lock 35

Door lock, confirmation sig‐ nals 35

Doors, manual operation 36

Doors, unlocking and locking

– Confirmation signals 35– From the inside 36– From the outside 34

DOT Quality Grades 224

Drive-off assistant, refer to Hill drive-off assistant 95

Driving notes, breaking in 122

Driving off on hills, refer to Hill drive-off assistant 95

Driving on poor roads 125

Driving stability control sys‐ tems 93

Driving tips, refer to Driving notes 122

Dry air, refer to Cooling func‐ tion 103

DSC Dynamic Stability Con‐ trol 93

DTC Dynamic Traction Con‐ trol 94

DTMF suffix dialing 185, 197

Dynamic destination guid‐ ance 152

Dynamic Stability Control DSC 93

Dynamic Traction Control DTC 94

E Electrical malfunction– Door lock 36– Fuel filler flap 216

Electronic brake-force distri‐

bution 93

Electronic Stability Program ESP, refer to Dynamic Stabil‐

ity Control DSC 93

Emergency activation

– Automatic transmission, re‐

fer to Overriding selector

lever lock 67

Emergency operation, fuel

filler flap, unlocking man‐

ually 216

Emergency operation, refer to

Manual operation

– Door lock 36

Energy, saving, refer to Saving

fuel 130

Engine, breaking in 122

Engine compartment 232

Engine oil, adding 234

Engine oil, additives, refer to Approved engine oils 235

Seite 272ReferenceEverything from A to Z272

Online Edition for Part no. 01 40 2 911 544 - VI/13