engine oil MITSUBISHI 3000GT 1992 2.G Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1992, Model line: 3000GT, Model: MITSUBISHI 3000GT 1992 2.GPages: 738, PDF Size: 35.06 MB

Page 531 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System

LIGHTING SYSTEM

54-35

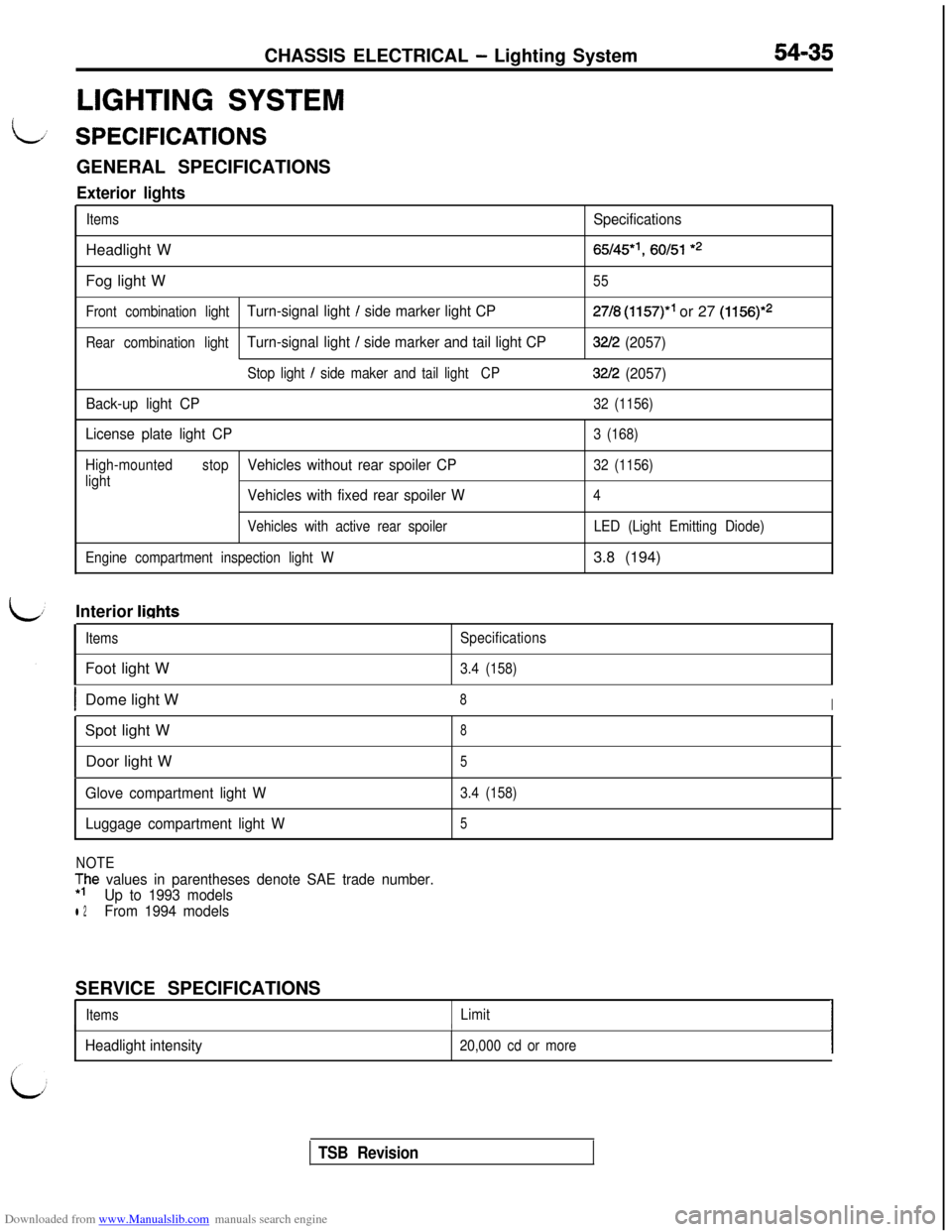

L/ SPECIFICATIONSGENERAL SPECIFICATIONS

Exterior lights

ItemsSpecificationsHeadlight W

65/45*‘, 60151 *2Fog light W

55

Front combination light

Turn-signal light / side marker light CP27/8 (1157)” or 27 (1156)*2

Rear combination lightTurn-signal light / side marker and tail light CP32/2 (2057)

Stop light / side maker and tail lightCP32/2 (2057)

Back-up light CP

32 (1156)

License plate light CP3 (168)

High-mountedstop

Vehicles without rear spoiler CP32 (1156)

light

Vehicles with fixed rear spoiler W4

Vehicles with active rear spoiler

Engine compartment inspection light WLED (Light Emitting Diode)3.8 (194)

Interior

lights

ItemsFoot light WSpecifications

3.4 (158)

IDome light W8ISpot light W

8Door light W

5

Glove compartment light W

Luggage compartment light W3.4 (158)

5

NOTE

;he values in parentheses denote SAE trade number.

Up to 1993 models

l 2From 1994 modelsSERVICE SPECIFICATIONS

ItemsLimitI

Headlight intensity

I

20,000 cd or moreI

TSB Revision

Page 533 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System54-37

i

TROUBLESHOOTING

LHEADLIGHT

OPERATION

lTurn the lighting switch to “HEAD”, and the con-

tact point of the headlight relay will be closedto turn “ON” the headlight relay.

lWhen the dimmer switch is placed in the LO

position, the headlight low-beams go on. On

vehicles up to 1993 model, when the switch

is placed in the HI position, the headlight high-

beams go on. On vehicles from 1994 model,when the switch is placed in the HI position,

the headlight high-beams and low-beams go

on.

When the high-beam is lit or when the passing

switch is activated, the high-beam indicator lightwill be lit.

If the driver’s door is opened after the ignition

switch is turned to “OFF” or the ignition switchis turned to “OFF” after the driver’s door is

opened when the headlights are lit, the currentwhich flows to the coil side of the headlight

relay will be cut off by the light automatic shut-OFF unit opening the contact point, and the

headlight relay will be turned “OFF” to automati-

cally shut off the headlights.l

To turn the headlights on again after they are

automatically shut off, turn the lighting switchto “OFF” once and then back to “HEAD”, or

turn the ignition switch to “ACC” or “ON”, and

the

aut0mati.c shut-OFF will be cancelled andthe current will flow from the light automatic

shut-OFF unit to the coil side of the headlightrelay again to close the contact point. Thus,

the headlight relay will be turned “ON” to turnon the headlights.

NOTEWhen the lighting switch is at “HEAD”, the light

automatic shut-OFF system is valid for tail lights,

parking and side marker lights, license plate light,

illumination light, etc.(Refer to

P.54-70.)

l

When the lighting switch is placed in the HEAD

position, current flows through multi-purpose

fuse (6) to the lighting switch, and the ETACScontrol unit. Then the UP timer circuit in the

LETACS control unit is operated, and currentflows from the ETACS control unit to the U con-tact of the pop-up motor U/D (UP/DOWN)

switch, the coil of the pop-up motor relay and

ground, causing the contacts of the pop-up mo-

tor relay to close.

When the contacts of the pop-up motor relay

close, current flows through the contacts of the

pop-up motor relay to the pop-up motor and

ground, causing the pop-up motor to rotate,

which brings the headlights to the UP position.

The pop-up motor rotates until the automatic

UP stop position is reached, then the contactsof the interlocked U/D (UP/DOWN) switch

change from the U to D contacts. As a result,

the contacts of the pop-up motor relay opento cut off the current supplied to the pop-up

motor. Then the pop-up motor ceases to rotate,

holding the headlights in the UP position.l

When the lighting switch is placed in the TAIL

or OFF position, current flows through the multi-

purpose fuse (6) to the lighting switch, and the

ETACS control unit. Then the DOWN timer cir-

cuit in the ETACS control unit is operated and

current flows from the ETACS control unit to

the DOWN contacts of the pop-up motor U/D

(UP/DOWN) switch, the coil of the pop-up motor

relay and ground, causing the contacts of the

pop-up motor relay to close.

When the contacts of the pop-up motor relay

close, current flows through the contacts of the

pop-up motor relay to the pop-up motor andground, causing the pop-up motor to rotate,

which brings the headlights to the DOWN posi-

tion.

The pop-up motor rotates until the automatic

DOWN stop position is reached, then the con-

tacts of the interlocked U/D (UP/DOWN) switch

change from the D to U contacts. As a result,

the contacts of the pop-up motor relay open

to cut off current supply to the pop-up motor.

Then the pop-up motor ceases to rotate, holding

the headlights in the DOWN position.

When the pop-up switch is placed in the UP

position, current flows through multi-purpose

fuse (6) to the lighting switch, the pop-up switch

and the ETACS control unit, which brings the

headlights to the UP position and holds them

in the UP position just like when they are oper-

ated by the lighting switch.l

When the pop-up switch is placed in the DOWN

position, current flows through the multi-purpose

fuse (6) to the lighting switch, the pop-up switch

and the ETACS control unit, which brings the

headlights to the DOWN position and holds them

in the DOWN position just like when they are

operated by the lighting switch.

TSB Revision

Page 558 of 738

Downloaded from www.Manualslib.com manuals search engine 54-62CHASSIS ELECTRICAL - Lighting System

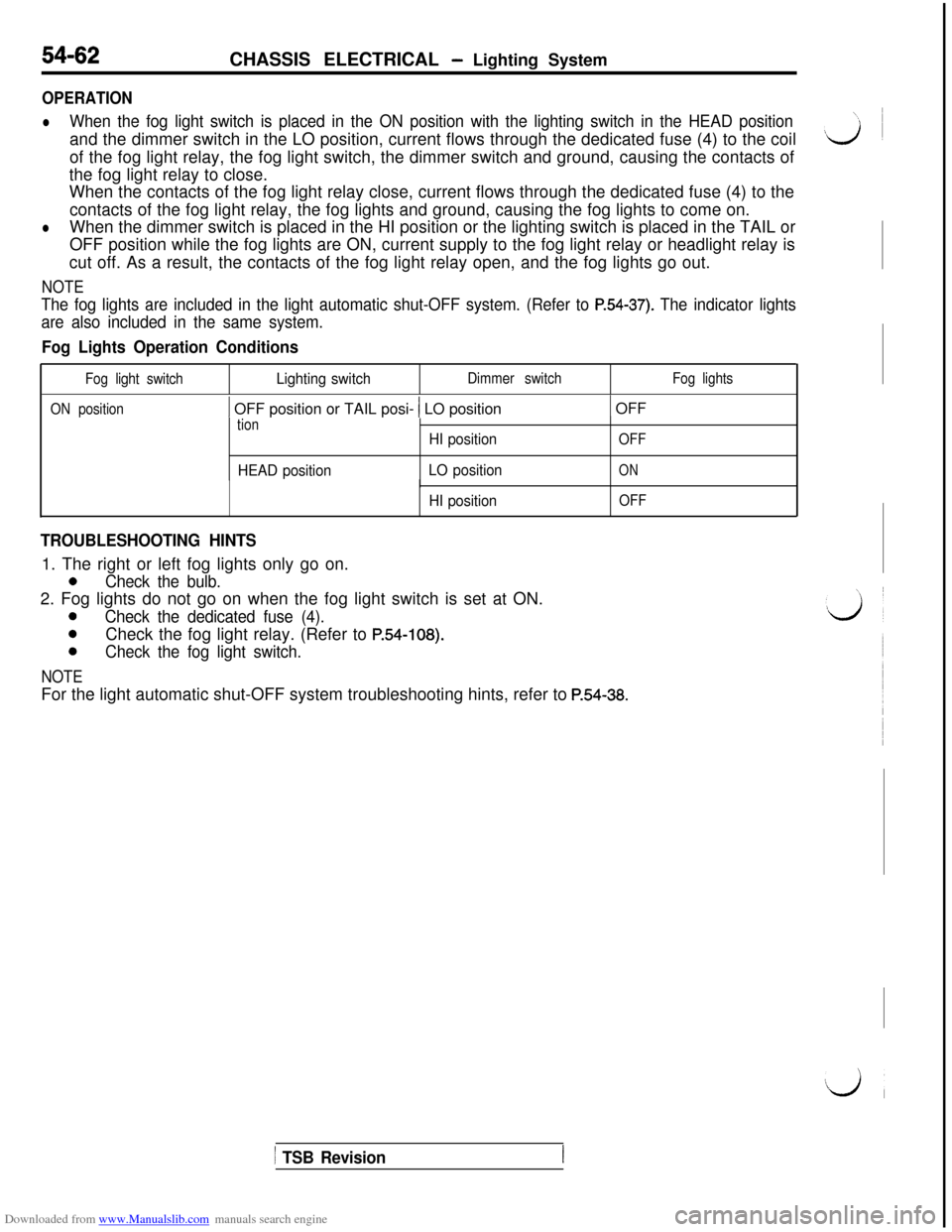

OPERATION

lWhen the fog light switch is placed in the ON position with the lighting switch in the HEAD positionand the dimmer switch in the LO position, current flows through the dedicated fuse (4) to the coil

of the fog light relay, the fog light switch, the dimmer switch and ground, causing the contacts of

the fog light relay to close.

When the contacts of the fog light relay close, current flows through the dedicated fuse (4) to the

contacts of the fog light relay, the fog lights and ground, causing the fog lights to come on.

lWhen the dimmer switch is placed in the HI position or the lighting switch is placed in the TAIL or

OFF position while the fog lights are ON, current supply to the fog light relay or headlight relay is

cut off. As a result, the contacts of the fog light relay open, and the fog lights go out.

NOTE

The fog lights are included in the light automatic shut-OFF system. (Refer to P.54-37). The indicator lights

are also included in the same system.

Fog Lights Operation Conditions

Fog light switchLighting switchDimmer switchFog lights

ON position

1 OFF position or TAIL posi- 1 LO position1 OFF

tion

HEAD positionHI position

LO position

OFF

ON

HI position

I

OFF

TROUBLESHOOTING HINTS1. The right or left fog lights only go on.

0Check the bulb.2. Fog lights do not go on when the fog light switch is set at ON.

0Check the dedicated fuse (4).

0Check the fog light relay. (Refer to P.54-108).

0Check the fog light switch.

NOTEFor the light automatic shut-OFF system troubleshooting hints, refer to

P.54-38.

1 TSB Revision

Page 566 of 738

Downloaded from www.Manualslib.com manuals search engine 54-70CHASSIS ELECTRICAL - Lighting System

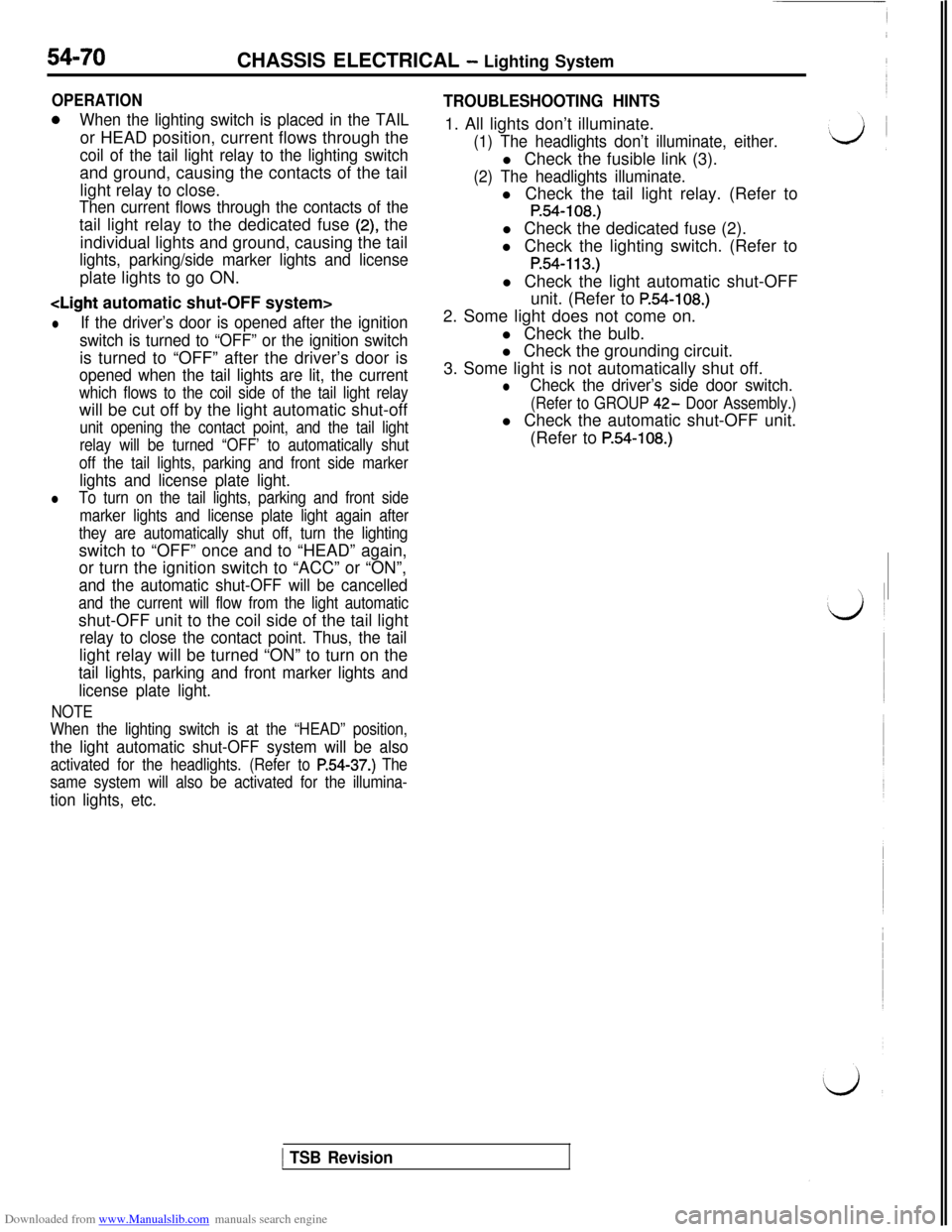

OPERATION

0When the lighting switch is placed in the TAILor HEAD position, current flows through the

coil of the tail light relay to the lighting switchand ground, causing the contacts of the tail

light relay to close.

Then current flows through the contacts of thetail light relay to the dedicated fuse

(2) the

individual lights and ground, causing the tail

lights, parking/side marker lights and licenseplate lights to go ON.

lIf the driver’s door is opened after the ignition

switch is turned to “OFF” or the ignition switchis turned to “OFF” after the driver’s door is

opened when the tail lights are lit, the current

which flows to the coil side of the tail light relaywill be cut off by the light automatic shut-off

unit opening the contact point, and the tail light

relay will be turned “OFF’ to automatically shut

off the tail lights, parking and front side marker

lights and license plate light.

lTo turn on the tail lights, parking and front side

marker lights and license plate light again after

they are automatically shut off, turn the lightingswitch to “OFF” once and to “HEAD” again,

or turn the ignition switch to “ACC” or “ON”,

and the automatic shut-OFF will be cancelled

and the current will flow from the light automaticshut-OFF unit to the coil side of the tail light

relay to close the contact point. Thus, the taillight relay will be turned “ON” to turn on the

tail lights, parking and front marker lights and

license plate light.

NOTE

When the lighting switch is at the “HEAD” position,

the light automatic shut-OFF system will be also

activated for the headlights. (Refer to P.54-37.) The

same system will also be activated for the illumina-

tion lights, etc.

TROUBLESHOOTING HINTS1. All lights don’t illuminate.

(1) The headlights don’t illuminate, either.l Check the fusible link (3).

(2) The headlights illuminate.l Check the tail light relay. (Refer to

P.54-108.)l Check the dedicated fuse (2).

l Check the lighting switch. (Refer to

P.54-113.)l Check the light automatic shut-OFF

unit. (Refer to

P.54-108.)2. Some light does not come on.

l Check the bulb.

l Check the grounding circuit.

3. Some light is not automatically shut off.

lCheck the driver’s side door switch.

(Refer to GROUP 42- Door Assembly.)l Check the automatic shut-OFF unit.

(Refer to

P.54-108.)

1 TSB Revision

Page 601 of 738

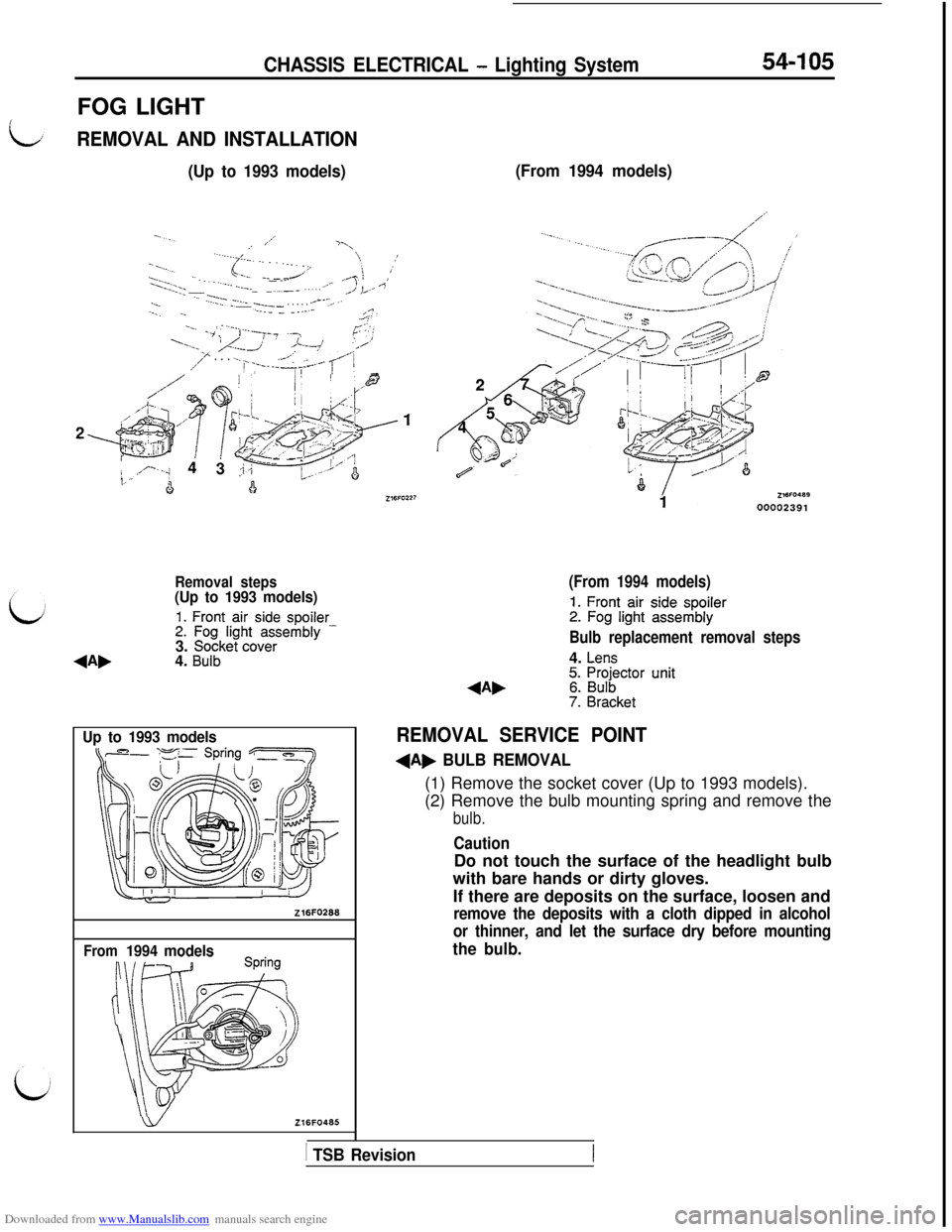

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System54-105FOG LIGHT

REMOVAL AND INSTALLATION

(Up to 1993 models)

,’

..-.-f .- . . .._ 1’yI’-’--.._ . . . ./’‘._,/‘.:‘. . . . . .--ye=.,/‘c’ !:I’:.;; ____-... _.__-.-__~___. . . . . ._./i L.- -3...-.._:.y- .‘...-____ y--. . . . . --‘-T---..-_ -_--._ _ __.-.-.;.? ::.._/ ; .--_.‘7 ,,-y-? ..-,r-; ‘;

‘....lr/I..j ,/L7 rl,-’/I” . . . ..-. ~ -,-.-A:..____ p

A’7----p--*@

,,A..

*~~~~1;’ -“‘.,.

, ‘!U ,.I,/ Ii

8, $&$Jqk2&

4&;. +I+ ’

,,, ’ .’- ‘-I,i

4!a

Removal steps(Up to 1993 models)

1. Front air side spoiler2. Fog light assembly -3. Socket cover4. Bulb

Up to 1993 models

Z16FO268

From1994 models

wZl6FO465

(From 1994 models)

(From 1994 models)

1. Front air side spoiler2. Fog light assembly

Bulb replacement removal steps4.

Lens5. Projector unit6. Bulb7. Bracket

REMOVAL SERVICE POINT

+A, BULB REMOVAL(1) Remove the socket cover (Up to 1993 models).

(2) Remove the bulb mounting spring and remove the

bulb.

CautionDo not touch the surface of the headlight bulb

with bare hands or dirty gloves.

If there are deposits on the surface, loosen and

remove the deposits with a cloth dipped in alcohol

or thinner, and let the surface dry before mounting

the bulb.

1 TSB Revision

Page 603 of 738

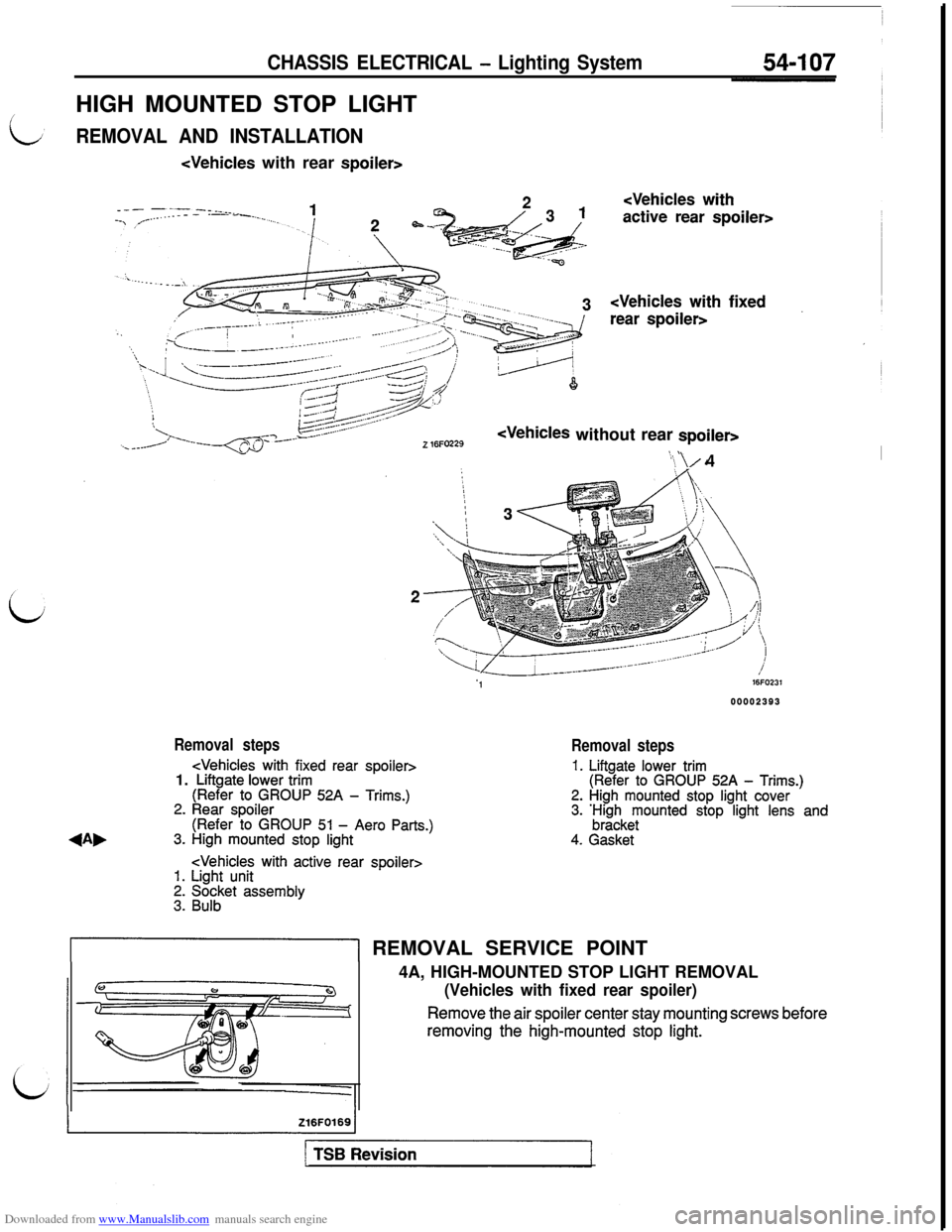

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting SystemHIGH MOUNTED STOP LIGHT

REMOVAL AND INSTALLATION

Z 16FO229Z 16FO229

‘\ \/4

116FcJ23100002393 00002393

Removal steps

Removal steps

1. Liftgate lower trim(Refer to GROUP 52A - Trims.)2. High mounted stop light cover3. ;;z;keyounted stop light lens and

4. Gasket

&I REMOVAL SERVICE POINT

4A, HIGH-MOUNTED STOP LIGHT REMOVAL

(Vehicles with fixed rear spoiler)

Remove the air spoiler center stay mounting screws beforeremoving the high-mounted stop

light.

Page 611 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Horn54-115

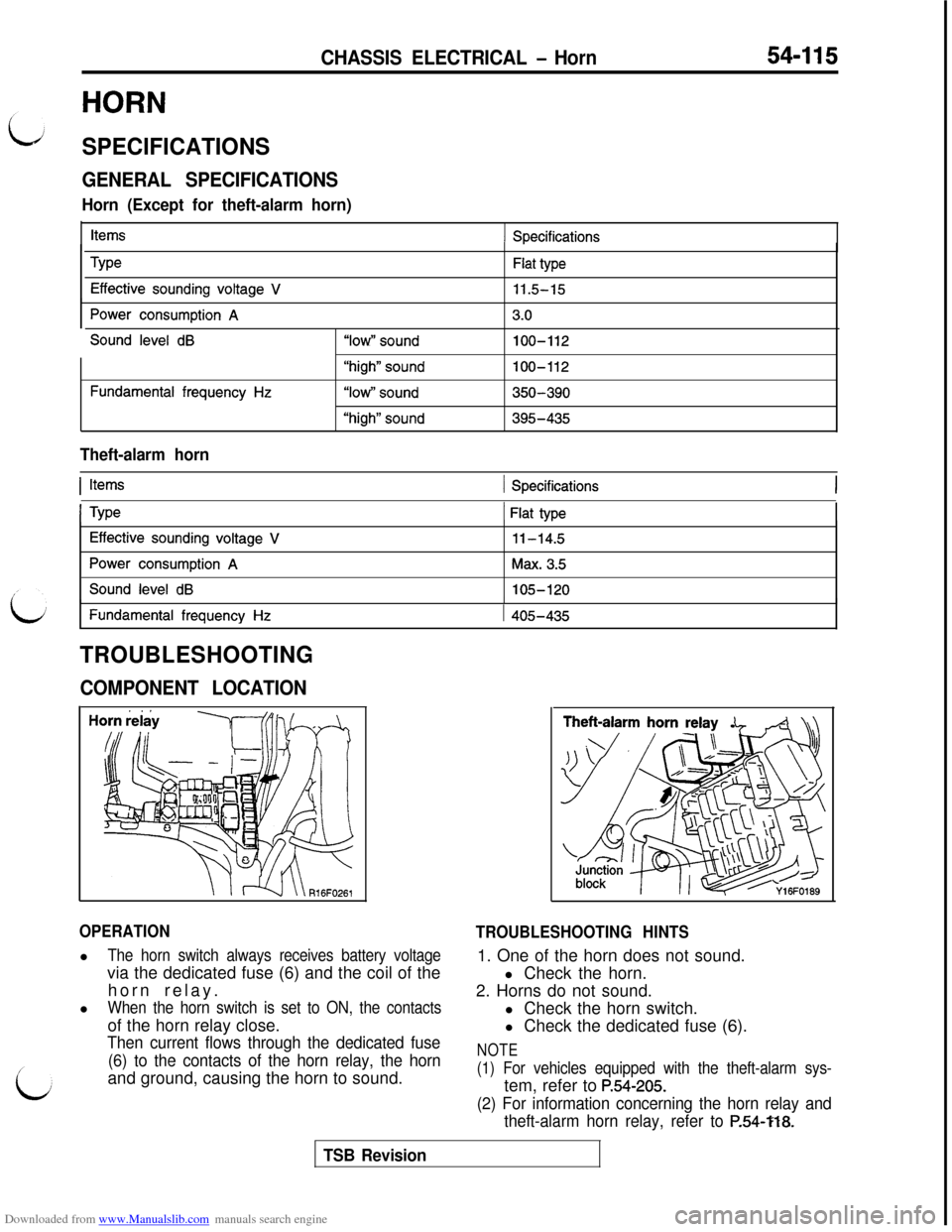

HORN

SPECIFICATIONS

GENERAL SPECIFICATIONS

Horn (Except for theft-alarm horn)

ItemsI Specifications

Type

Effective sounding voltage V

Power consumption A

Sound level dB

Fundamental frequency Hz

“low” sound

“high” sound

“low” sound

“high” sound

Fiat type

11.5-15

3.0

100-112

100-112350-390395-435

Theft-alarm horn

1 ItemsI Specifications

1 Type1 Flat typeI

Effective sounding voltage V

Power consumption A

Sound level dB

Fundamental frequency Hz

11-14.5

Max. 3.5

105-120I

I 405-435

TROUBLESHOOTING

COMPONENT LOCATION

OPERATIONl

The horn switch always receives battery voltagevia the dedicated fuse (6) and the coil of the

horn relay.

l

When the horn switch is set to ON, the contactsof the horn relay close.

Then current flows through the dedicated fuse

(6) to the contacts of the horn relay, the hornand ground, causing the horn to sound.1. One of the horn does not sound.

TROUBLESHOOTING HINTSl Check the horn.

2. Horns do not sound.

l Check the horn switch.

l Check the dedicated fuse (6).

NOTE

(1) For vehicles equipped with the theft-alarm sys-tem, refer to

P.54-205.

(2) For information concerning the horn relay and

theft-alarm horn relay, refer to

P.54-?18.

TSB Revision

Page 660 of 738

Downloaded from www.Manualslib.com manuals search engine 54-164CHASSIS ELECTRICAL - Radio and Tape Player

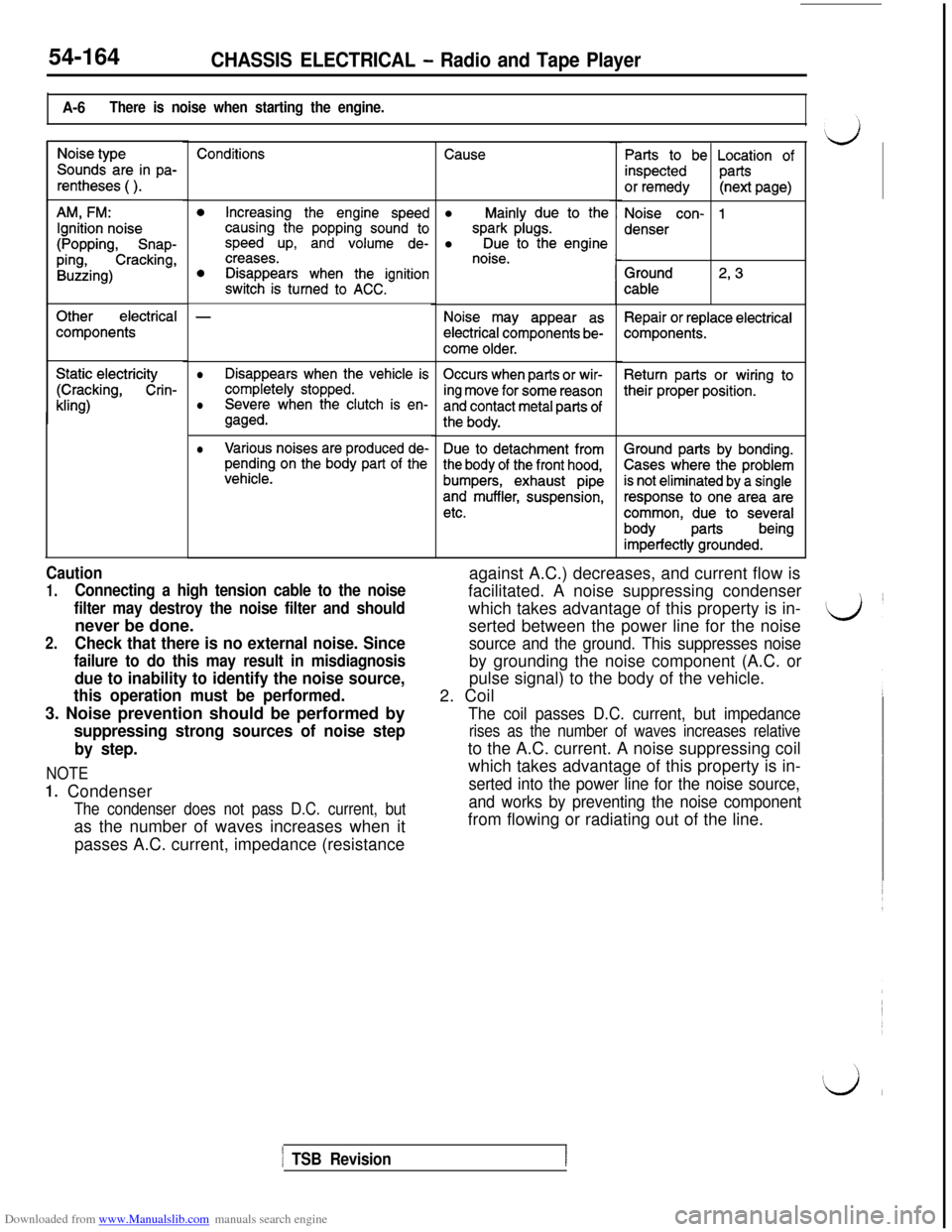

A-6There is noise when starting the engine.

Noise type

Sounds are in pa-

rentheses ( ).

AM, FM:

Ignition noise

(Popping, Snap-

ping,Cracking,

Buzzing)

Otherelectrical

components

Static electricity

(Cracking, Crin-

kling)

Conditions

0Increasing the engine speedcausing the popping sound tospeed up, and volume de-creases.0Disappears when the ignitionswitch is turned to ACC.

-

lDisappears when the vehicle is

completely stopped.Occurs when parts or wir-

Severe when the clutch is en-ing move for some reasonlgaged.and contact metal parts of

the body.

lVarious noises are produced de-pending on the body part of thevehicle.

Due to detachment from

the body of the front hood,

bumpers, exhaust pipe

and muffler, suspension,

etc.

Causel

Mainly due to the

spark plugs.l Due to the enginenoise.

Noise may appear as

electrical components be-

come older.

Parts to be Location of

inspectedparts

or remedy(next page)

Noise con- 1

denser

Ground

cable2, 3

Repair or replace electricalcomponents.

Return parts or wiring to

their proper position.

Caution

1.Connecting a high tension cable to the noise

filter may destroy the noise filter and shouldnever be done.

2.Check that there is no external noise. Since

failure to do this may result in misdiagnosis

due to inability to identify the noise source,

this operation must be performed.3. Noise prevention should be performed by

suppressing strong sources of noise step

by step.

NOTE

1. Condenser

The condenser does not pass D.C. current, butas the number of waves increases when it

passes A.C. current, impedance (resistanceagainst A.C.) decreases, and current flow is

facilitated. A noise suppressing condenser

which takes advantage of this property is in-

serted between the power line for the noise

source and the ground. This suppresses noiseby grounding the noise component (A.C. or

pulse signal) to the body of the vehicle.

2. Coil

The coil passes D.C. current, but impedance

rises as the number of waves increases relativeto the A.C. current. A noise suppressing coil

which takes advantage of this property is in-

serted into the power line for the noise source,

and works by preventing the noise componentfrom flowing or radiating out of the line.

1 TSB Revision

Ground parts by bonding.

Cases where the problem

is not eliminated by a single

response to one area are

common, due to several

bodypartsbeing

imperfectly grounded.

Page 731 of 738

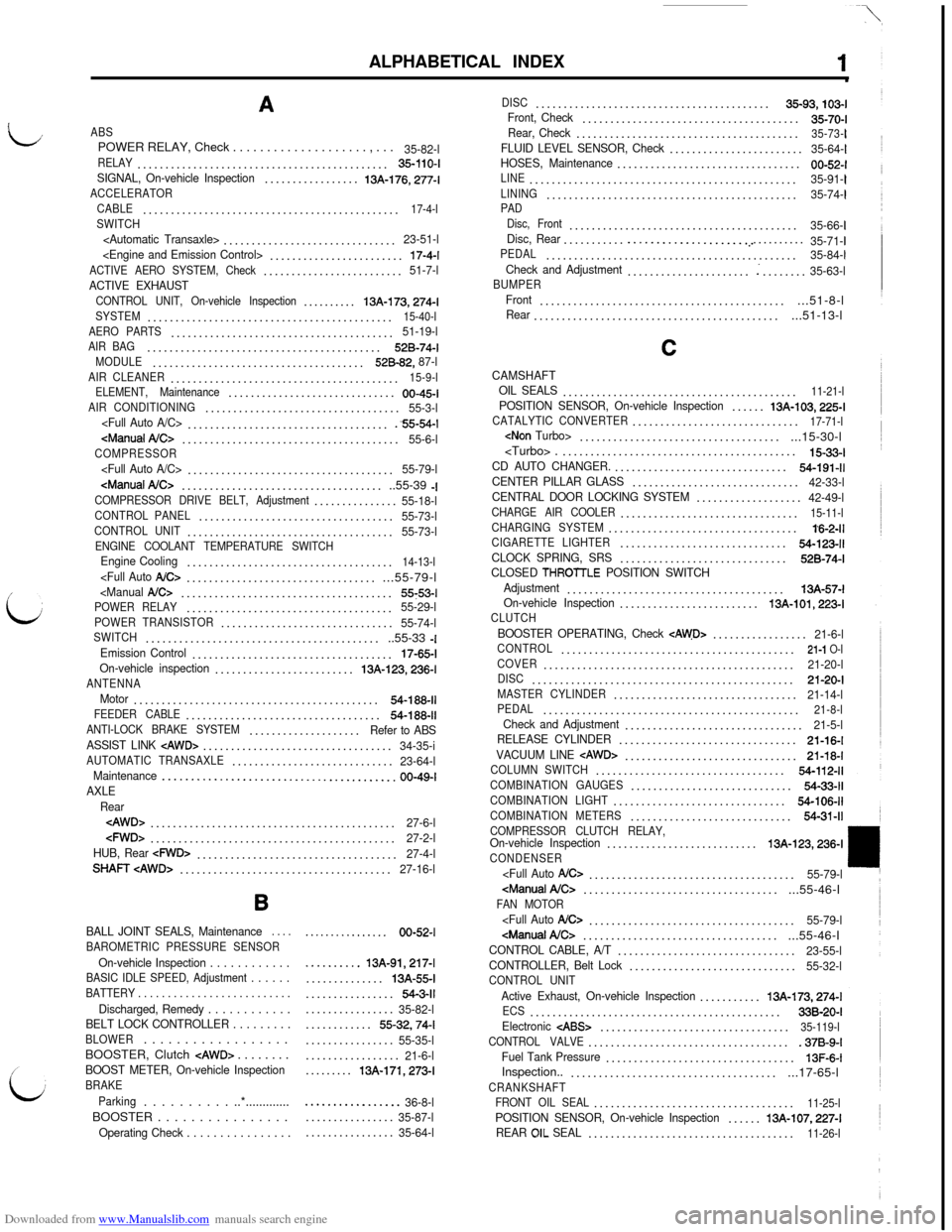

Downloaded from www.Manualslib.com manuals search engine ALPHABETICAL INDEX1

A

iiABSPOWER RELAY, Check . . . . . . . . . . . . . . . . . . . . , . . .

35-82-lRELAY.............................................35-110-1SIGNAL, On-vehicle Inspection.................13A-176,277-iACCELERATOR

CABLE..............................................

17-4-l

SWITCH

ACTIVE AERO SYSTEM, Check.........................

51-7-l

ACTIVE EXHAUST

CONTROL UNIT, On-vehicle Inspection..........13A-173,274-lSYSTEM............................................15-40-l

AERO PARTS........................................51-19-lAIR BAG..........................................520-74-lMODULE......................................528-82, 87-lAIR CLEANER.........................................15-9-l

ELEMENT, Maintenance..............................00-45-lAIR CONDITIONING...................................55-3-l

55-18-lCONTROL PANEL...................................55-73-lCONTROL UNIT.....................................55-73-lENGINE COOLANT TEMPERATURE SWITCHEngine Cooling.....................................14-13-l

ASSIST LINK

Maintenance

.........................................00-49-IAXLE

Rear

HUB, Rear -&VD>

....................................

27-4-lSHAFT

B

BALL JOINT SEALS, Maintenance. . . .

BAROMETRIC PRESSURE SENSOR

On-vehicle Inspection . . . . . . . . . . . .BASIC IDLE SPEED, Adjustment . . . . . .

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . .

Discharged, Remedy . . . . . . . . . . . .

BELT LOCK CONTROLLER . . . . . . . . .

BLOWER. . . . . . . . . . . . . . . . . .

BOOSTER, Clutch

Parking. . . . . . . . . . ..*.............

BOOSTER . . . . . . . . . . . . . . . .

Operating Check . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .00-52-l

..........13A-91,217-l..............

13A-55-l................64-3-11................35-82-l............55-32,74-t................

55-35-l.................21-6-l.........13A-171,273-l

.................36-8-l................35-87-l................35-64-l

DISC..........................................35-93,103-l

Front, Check.......................................35-70-IRear, Check........................................35-73-lFLUID LEVEL SENSOR, Check........................35-64-l

HOSES, Maintenance.................................00-52-I

LINE................................................35-91-lLINING.............................................35-74-lPAD

Disc, Front.........................................

35-66-l

Disc, Rear.............~..................>..........35-71-lPEDAL.............................................35-84-l

Check and Adjustment......................

:........35-63-lBUMPERFront...............................................51-8-lRear...............................................51-13-l

CAMSHAFT

OIL SEALS..........................................

11-21-lPOSITION SENSOR, On-vehicle Inspection......13A-103,225-lCATALYTIC CONVERTER..............................17-71-l

..........................................

15-33-lCD AUTO CHANGER................................54-191-11CENTER PILLAR GLASS..............................42-33-l

CENTRAL DOOR LOCKING SYSTEM...................42-49-lCHARGE AIR COOLER................................15-11-l

CHARGING SYSTEM..................................l.6-2-11CIGARETTE LIGHTER..............................54-123-k

CLOCK SPRING, SRS..............................528-74-I

CLOSED THROTTLE POSITION SWITCH

Adjustment.......................................

13A-57-lOn-vehicle Inspection.........................13A-101,223-lCLUTCH

BOOSTER OPERATING, Check

MASTER CYLINDER.................................21-14-lPEDAL..............................................21-8-lCheck and Adjustment................................21-5-l

RELEASE CYLINDER................................21-16-IVACUUM LINE cAWD>...............................21-18-I

COLUMN SWITCH..................................54-112-11COMBINATION GAUGES.............................54-33-kCOMBINATION LIGHT...............................54-106-11COMBINATION METERS.............................54-31-11COMPRESSOR CLUTCH RELAY,On-vehicle Inspection...........................13A-123,236-lCONDENSER

Active Exhaust, On-vehicle Inspection...........13A-173,274-lECS.............................................338-20-I

Electronic CABS>..................................35-119-l

CONTROL VALVE.....................................37B-9-l

Fuel Tank Pressure..................................13F-6-IInspection..

........................................17-65-l

CRANKSHAFT

FRONT OIL SEAL....................................

11-25-lPOSITION SENSOR, On-vehicle Inspection......13A-107,227-l

REAR QIL SEAL.....................................11-26-l

Page 732 of 738

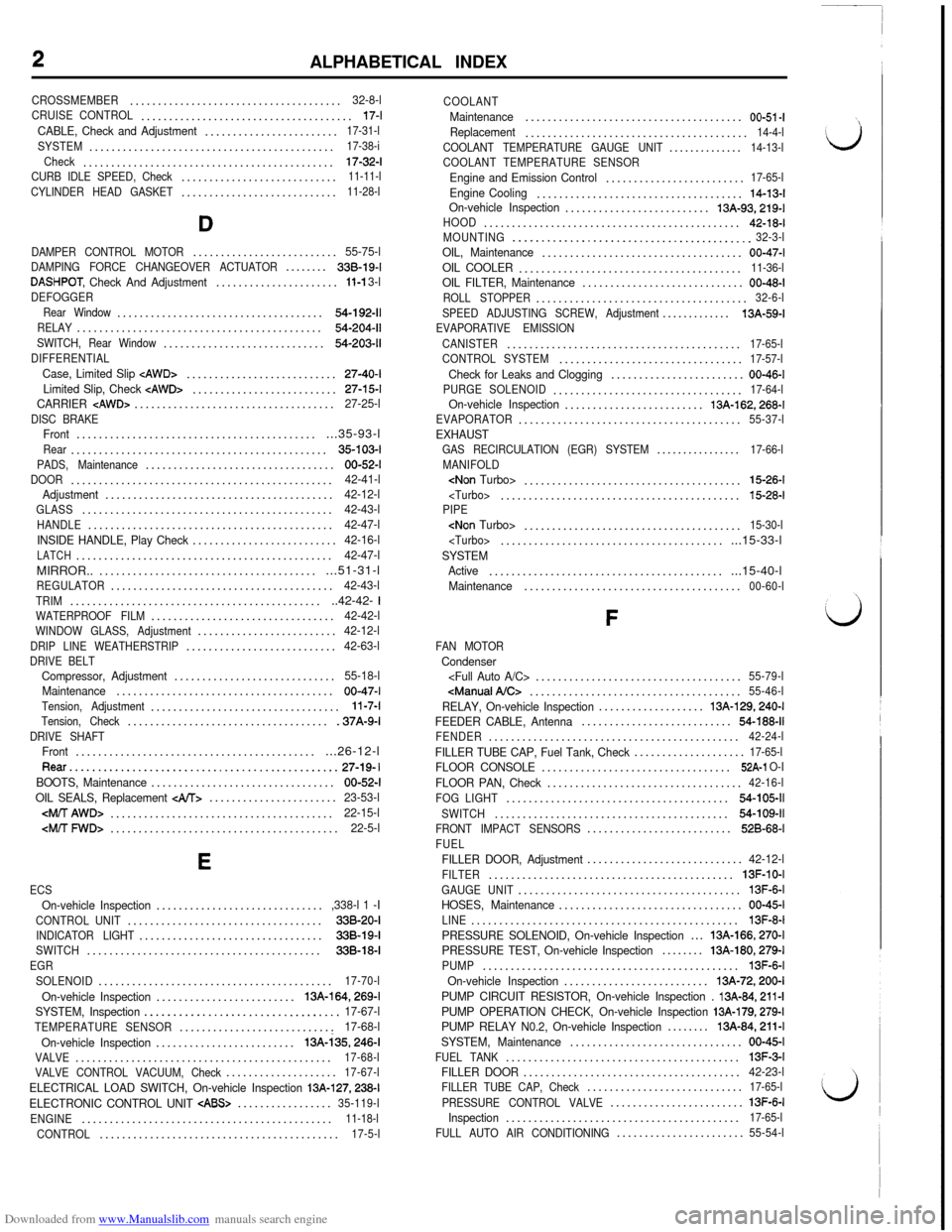

Downloaded from www.Manualslib.com manuals search engine ALPHABETICAL INDEX

CROSSMEMBER......................................32-8-lCRUISE CONTROL......................................17-t

CABLE, Check and Adjustment........................17-31-l

SYSTEM............................................17-38-i

Check.............................................

17-32-l

CURB IDLE SPEED, Check............................11-11-l

CYLINDER HEAD GASKET............................11-28-l

D

DAMPER CONTROL MOTOR..........................55-75-lDAMPING FORCE CHANGEOVER ACTUATOR........338-19-I

DASHPOT, Check And Adjustment......................11-l 3-lDEFOGGER

Rear Window.....................................54-192-11

RELAY............................................54-204-11

SWITCH, Rear Window.............................54-203-11

DIFFERENTIALCase, Limited Slip cAWD>...........................27-40-ILimited Slip, Check cAWD>..........................27-15-tCARRIER

DISC BRAKEFront..............................................35-93-lRear..............................................35-103-I

PADS, Maintenance..................................00-52-I

DOOR...............................................42-41-l

Adjustment.........................................42-12-lGLASS.............................................42-43-l

HANDLE............................................42-47-l

INSIDE HANDLE, Play Check..........................42-16-l

LATCH..............................................42-47-lMIRROR............................................51-31-l

REGULATOR........................................42-43-l

TRIM...............................................42-42- 1WATERPROOF FILM.................................42-42-lWINDOW GLASS, Adjustment.........................42-12-l

DRIP LINE WEATHERSTRIP...........................42-63-lDRIVE BELTCompressor, Adjustment.............................55-18-l

Maintenance.......................................00-47-I

Tension, Adjustment..................................11-7-l

Tension, Check.....................................37A-9-l

DRIVE SHAFTFront..............................................26-12-lRear...............................................27-19- I

BOOTS, Maintenance.................................00-52-l

OIL SEALS, Replacement

.......................23-53-l

E

ECSOn-vehicle Inspection..............................,338-l 1 -I

CONTROL UNIT...................................338-20-IINDICATOR LIGHT.................................338-19-ISWITCH..........................................338-18-I

EGR

SOLENOID..........................................17-70-l

On-vehicle Inspection.........................13A-164,269-l

SYSTEM, Inspection..................................17-67-l

TEMPERATURE SENSOR............................17-68-l

On-vehicle Inspection.........................13A-i35,246-I

VALVE..............................................17-68-l

VALVE CONTROL VACUUM, Check....................17-67-l

ELECTRICAL LOAD SWITCH, On-vehicle Inspection 13A-127,238-l

ELECTRONIC CONTROL UNIT

CABS>.................35-119-l

ENGINE.............................................11-18-l

CONTROL...........................................17-5-lCOOLANT

Maintenance.......................................00-51 -IReplacement........................................14-4-l

COOLANT TEMPERATURE GAUGE UNIT..............14-13-l

COOLANT TEMPERATURE SENSOR

Engine and Emission Control.........................17-65-l

Engine Cooling.....................................14-13-IOn-vehicle Inspection..........................13A-93,219-lHOOD..............................................42-18-l

MOUNTING..........................................32-3-lOIL, Maintenance....................................00-47-l

OIL COOLER........................................11-36-lOIL FILTER, Maintenance.............................00-48-l

ROLL STOPPER......................................32-6-l

SPEED ADJUSTING SCREW, Adjustment.............

13A-59-l

EVAPORATIVE EMISSION

CANISTER..........................................

17-65-l

CONTROL SYSTEM.................................17-57-l

Check for Leaks and Clogging........................00-46-l

PURGE SOLENOID..................................17-64-lOn-vehicle Inspection.........................13A-162,268-lEVAPORATOR........................................55-37-lEXHAUSTGAS RECIRCULATION (EGR) SYSTEM................17-66-l

MANIFOLD

PIPE

SYSTEM

Active.............................................15-40-l

Maintenance.......................................00-60-l

F

FAN MOTORCondenser

RELAY, On-vehicle Inspection...................13A-129.240-t

FEEDER CABLE, Antenna...........................54-188-11FENDER.............................................42-24-l

FILLER TUBE CAP, Fuel Tank, Check....................17-65-lFLOOR CONSOLE..................................52A-1 O-I

FLOOR PAN, Check...................................42-16-l

FOG LIGHT........................................54-105-11

SWITCH..........................................54-109-11FRONT IMPACT SENSORS..........................526-68-l

FUELFILLER DOOR, Adjustment............................42-12-l

FILTER............................................13F-10-I

GAUGE UNIT........................................13F-6-IHOSES, Maintenance.................................00-45-l

LINE................................................13F-8-I

PRESSURE SOLENOID, On-vehicle Inspection...13A-166,270-l

PRESSURE TEST, On-vehicle Inspection........13A-180,279-lPUMP..............................................13F-6-I

On-vehicle Inspection..........................13A-72,200-l

PUMP CIRCUIT RESISTOR, On-vehicle Inspection .

13A-84,211-lPUMP OPERATION CHECK, On-vehicle Inspection 13A-179,279-lPUMP RELAY N0.2, On-vehicle Inspection........13A-84,211-l

SYSTEM, Maintenance...............................00-45-I

FUEL TANK..........................................13F-3-IFILLER DOOR.......................................42-23-lFILLER TUBE CAP, Check............................17-65-l

PRESSURE CONTROL VALVE........................

13F-6-IInspection..........................................17-65-l

FULL AUTO AIR CONDITIONING.......................55-54-l