stop start MITSUBISHI 3000GT 1992 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1992, Model line: 3000GT, Model: MITSUBISHI 3000GT 1992 2.GPages: 738, PDF Size: 35.06 MB

Page 54 of 738

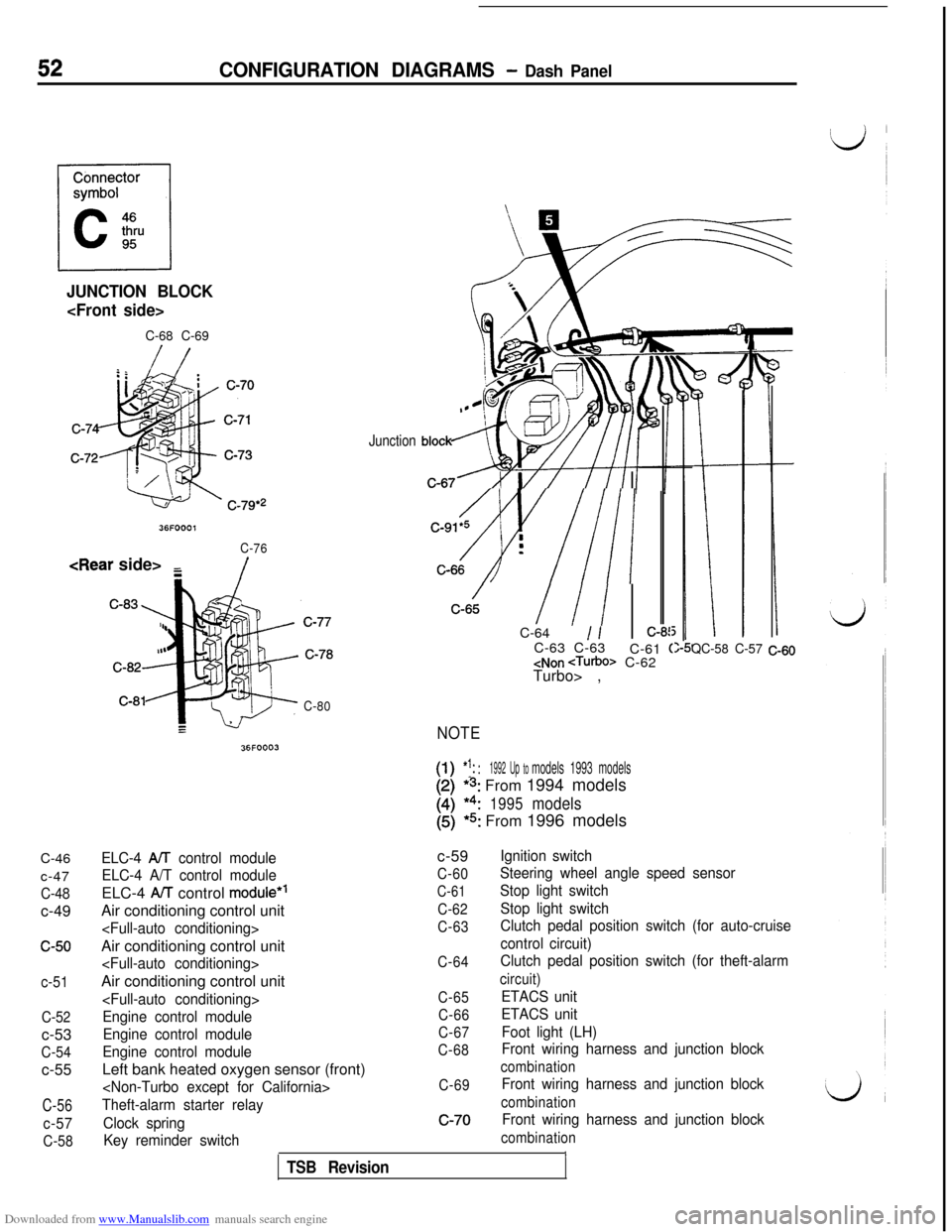

Downloaded from www.Manualslib.com manuals search engine 52CONFIGURATION DIAGRAMS - Dash Panel

JUNCTION BLOCK

C-68 C-69C-46

c-47

C-48c-49

c-50

c-51

C-52c-53

C-54c-55

C-56

c-57

C-58

36FOOOl

C-76

/

C-80

36FOOO3

Junction

/C-91*5 i

Av///I :-C-64

1 /:-8!C-63 C-63

C-61

(

Turbo> ,

NOTE

[-I!1:: :1992 Up tomodels 1993 models

*s: From 1994 models

*4:1995models

(5)*5: From 1996 models

QC-58 C-57 C-60

ELC-4 AA control module

ELC-4 A/T control moduleELC-4

AiT control module*’Air conditioning control unit

Engine control module

Engine control module

Engine control moduleLeft bank heated oxygen sensor (front)

Theft-alarm starter relay

Clock spring

Key reminder switchc-59

C-60

C-61

C-62

C-63

C-64

C-65

C-66

C-67

C-68

C-69c-70

Ignition switch

Steering wheel angle speed sensor

Stop light switch

Stop light switch

Clutch pedal position switch (for auto-cruise

control circuit)

Clutch pedal position switch (for theft-alarm

circuit)

ETACS unit

ETACS unit

Foot light (LH)

Front wiring harness and junction block

combination

Front wiring harness and junction block

combination

Front wiring harness and junction block

combinationITSB Revision

Page 63 of 738

Downloaded from www.Manualslib.com manuals search engine 61

i

CIRCUIT

DlAG.RAMS

CONTENTSActive Aero Circuit.........................

428Active Exhaust System Circuit..............

370

Anti-lock Braking System (ABS) Circuit......322

Auto-cruise Control Circuit..................380

Back-up Light...........................54-85

Buzzer Circuit.............................208

Car Telephone Circuit......................435

Central Door Locking Circuit................222

Charging System..........................16-3

Cigarette Lighter Circuit.................54-120

Cooling Circuit.............................176

Defogger Circuit........................54-193Dome Light, Foot Light and Ignition Key

Cylinder Illumination Light................54-72

Door Light and Luggage Compartment

Light...................................54-81

ELC-4 A/T Circuit..........................186

Electronic Control Suspension (ECS) Circuit . . 352

Fog Light Circuit.........................

54-58

Full Auto Air Conditioning’ Circuit............272Glove Box Light, Vanity Mirror

Light and Inspection Light Circuit..........

54-84

Headlight...............................

54-40

Heater Circuit.............................,239

Horn..................................54-116

How to Read Circuit Diagrams..............

62

Ignition System.........................16-32

Manual Air Conditioning Circuit.............242

Meter and Gauges Circuit...............54-12

MFI Circuit................................84

Power Distribution Circuit...................68

Power Seat Circuit....:...................416

Power Window Circuit.....................212

Radio and Tape Player................54-124

Rear. Wiper and Washer Circuit............318

Remote Controlled Mirror Circuit...........320

Starting System.........................16-20

Stop Light.............................54-98

Sunroof Circuit.............................442

Supplemental Restraint System (SRS)

Circuit....................................374

Taillight, Parking/Side Marker Light and

License Plate Light Circuit................54-64

Tension-reducer Type Seat Belt Circuit......423

Theft-alarm System....................54-206

Top Stack Circuit.........................438

Turn-signal Light and Hazard Light.......54-90

Windshield Wiper and Washer Circuit........316

I

LiI

Page 76 of 738

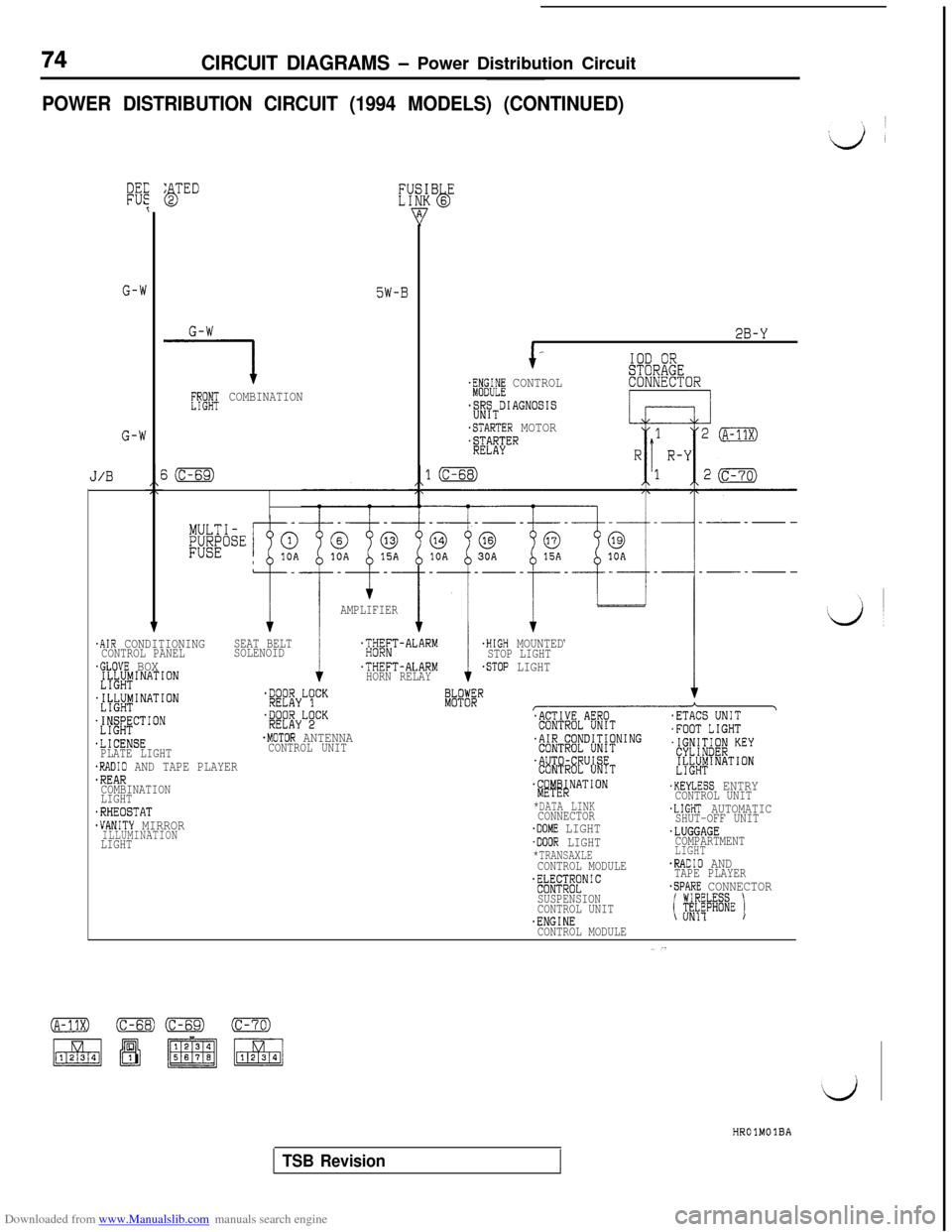

Downloaded from www.Manualslib.com manuals search engine CIRCUIT DIAGRAMS - Power Distribution Circuit

POWER DISTRIBUTION CIRCUIT (1994 MODELS) (CONTINUED)

,ij ’

G-W

G-W

J/B

5W-B

G-W

[Pgfi; COMBINATION

.AIR CONDITIONINGSEAT BELT.HIGH MOUNTEDCONTROL PANELSOLENOIDT'#;;T-ALARMSTOP LIGHT.GLOVE BOX.THEFT-ALARM.STOP LIGHT.ILJ&INATION

HORN RELAY

MULTI-

RE"""

AMPLIFIER

2B-Y*

+-IOD ORSTORAGE43WFE CONTROLCONNECTOR

S;SRTDIAGNOSIS

.STARTER MOTOR

~3%""

LIGHI~~~l&INATION

dM&CT'ON

.LICENSEPLATE LIGHT.RADIO AND TAPE PLAYER.REARCOMBINATION

LIGHT

.RHEOSTAT.VANITY MIRRORILLUMINATIONLIGHT

*fi;;~yL~CK

'i&fEyLgCK

.MOTOR ANTENNACONTROL UNIT

$#~~NATION

*DATA LINKCONNECTOR.DOME LIGHT.DOOR LIGHT*TRANSAXLECONTROL MODULE

.KEYLESS ENTRYCONTROL UNIT,LIGHT AUTOMATICSHUT-OFF UNIT.LUGGAGECOMPARTMENTLIGHT.RADIO ANDTAPE PLAYER.SPARE CONNECTOR

i ~~~@i~wE I

E~;LE;[~NIC

SUSPENSION

CONTROL UNIT

.ENGINE\ UN11/

CONTROL MODULE

HROlMOlBA

TSB Revision

Page 451 of 738

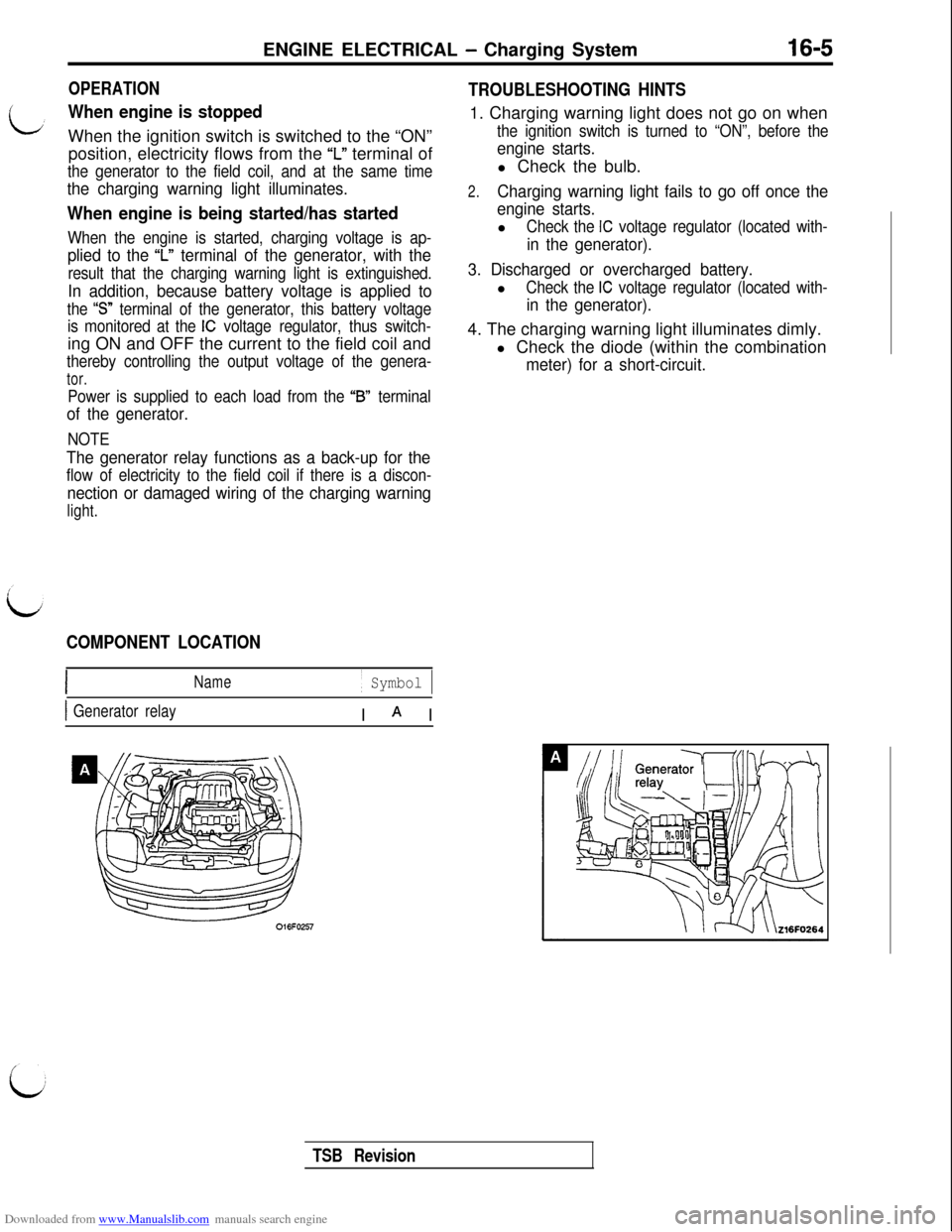

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-5

OPERATION

When engine is stoppedWhen the ignition switch is switched to the “ON”

position, electricity flows from the

‘I” terminal of

the generator to the field coil, and at the same time

the charging warning light illuminates.

When engine is being started/has started

When the engine is started, charging voltage is ap-

plied to the ‘I” terminal of the generator, with the

result that the charging warning light is extinguished.

In addition, because battery voltage is applied to

the “S” terminal of the generator, this battery voltage

is monitored at the

IC voltage regulator, thus switch-ing ON and OFF the current to the field coil and

thereby controlling the output voltage of the genera-

tor.

Power is supplied to each load from the “B” terminal

of the generator.

NOTE

The generator relay functions as a back-up for the

flow of electricity to the field coil if there is a discon-

nection or damaged wiring of the charging warning

light.

COMPONENT LOCATION

Name/ Symbol 1

1 Generator relayI A I

TROUBLESHOOTING HINTS1. Charging warning light does not go on when

the ignition switch is turned to “ON”, before the

engine starts.l Check the bulb.

2.Charging warning light fails to go off once the

engine starts.l

Check the IC voltage regulator (located with-

in the generator).

3. Discharged or overcharged battery.l

Check the IC voltage regulator (located with-

in the generator).4. The charging warning light illuminates dimly.

l Check the diode (within the combination

meter) for a short-circuit.

TSB Revision

Page 469 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-23

OPERATION

L

0For models equipped with the M/T, the clutch

pedal position switch contact is switched OFF

when the clutch pedal is depressed; when the

ignition switch is then switched to the “ST’ posi-tion, electricity flows to the starter relay and

the starter motor, the contact (magnetic switch)of the starter is switched ON and the starter

motor is activated.

NOTEIf the ignition switch is switched to the “ST

position without the clutch pedal being de-

pressed, electricity flows to the starter relay

(coil), the clutch pedal position switch (contacts)

and to ground, with the result that the contacts

of the starter relay are switched OFF, and, be-

cause the power to the starter motor is thereby

interrupted, the starter motor is not activated.lFor models equipped with the

AIT, when the

ignition switch is switched to the “ST’ position

while the selector lever is at the “P” or “N” posi-

tion, the contact (magnetic switch) of the starter

is switched ON and the starter motor is activated.

TROUBLESHOOTING HINTSThe starter motor does not operate at all.

l Check the starter (coil).

lCheck for poor contact at the battery terminals

and starter.l Check Park/Neutral position switch.

l Check clutch pedal position switch.

l Check starter relay.

l Check theft-alarm starter relay.

l Check key reminder switch.

i

/’

L&J

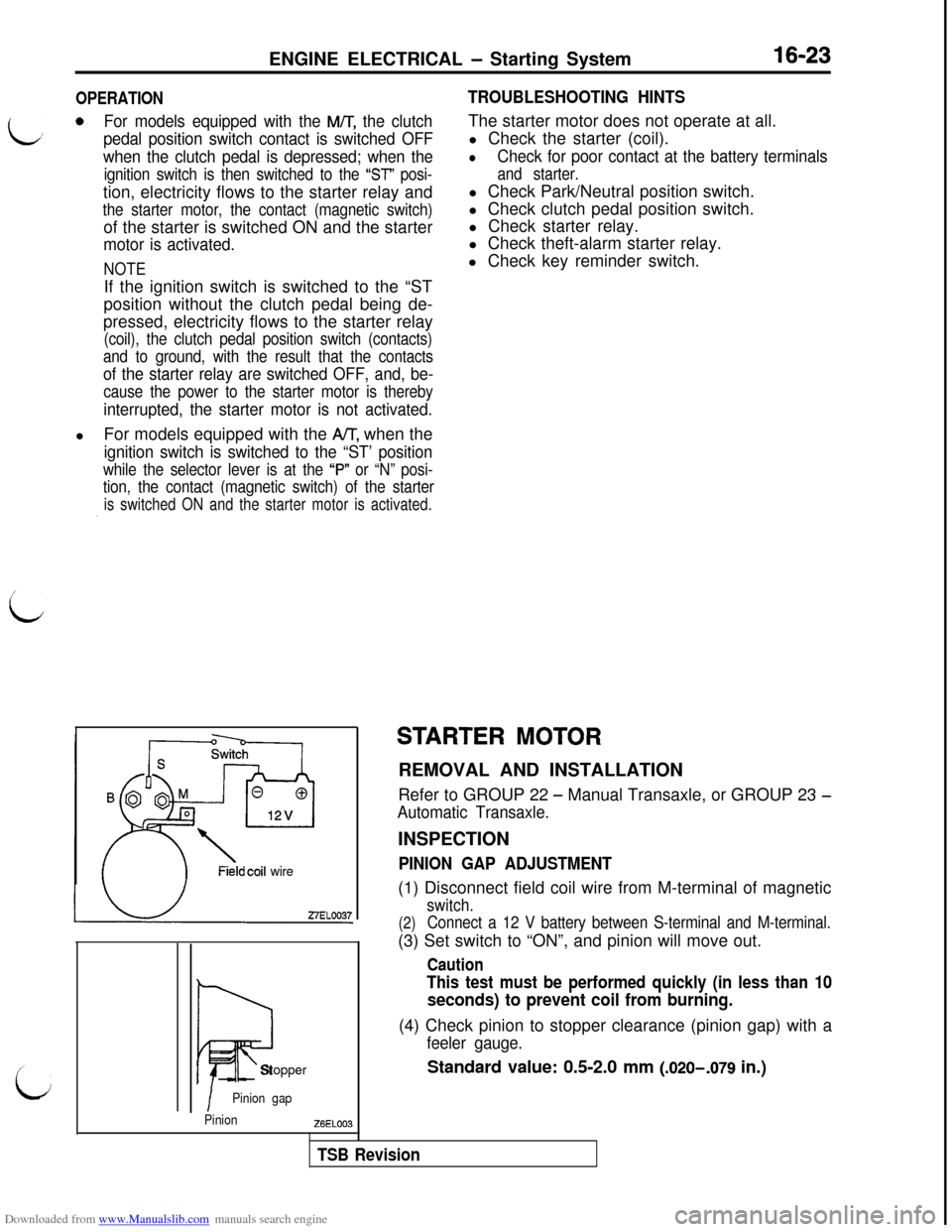

Fieldcoil wire

Iii?Stopper

IPinion gap

PinionZ6EL003

STARTER MOTORREMOVAL AND INSTALLATION

Refer to GROUP 22

- Manual Transaxle, or GROUP 23 -

Automatic Transaxle.INSPECTION

PINION GAP ADJUSTMENT(1) Disconnect field coil wire from M-terminal of magnetic

switch.

(2)Connect a 12 V battery between S-terminal and M-terminal.(3) Set switch to “ON”, and pinion will move out.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(4) Check pinion to stopper clearance (pinion gap) with a

feeler gauge.

Standard value: 0.5-2.0 mm (.020-,079 in.)

TSB Revision

Page 470 of 738

Downloaded from www.Manualslib.com manuals search engine 16-24ENGINE ELECTRICAL - Starting System

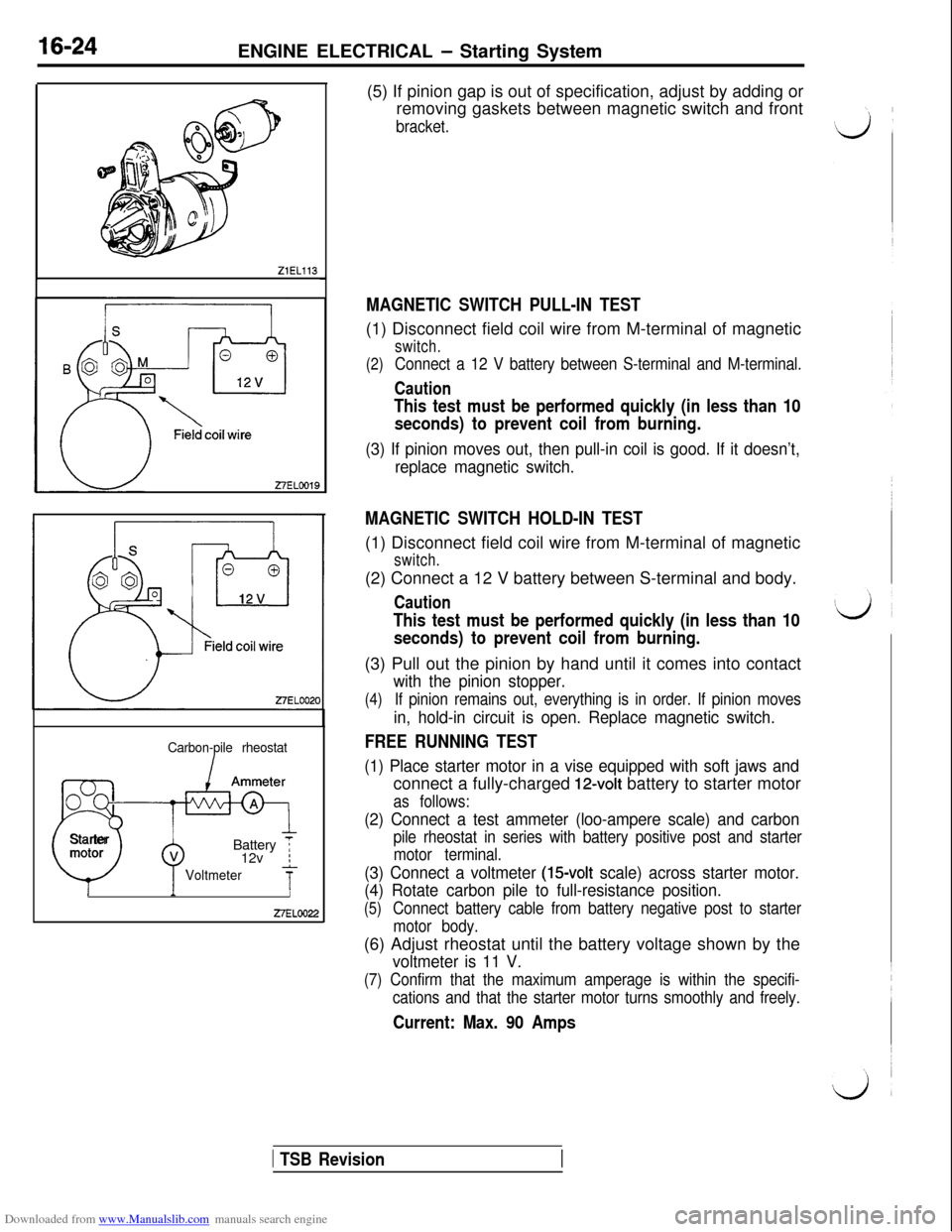

ZlEL11327ELOOlQ

0

5

Startermotor

Carbon-pile rheostat

-I-Battery

i12v I

Voltmeter7-II27ELOO22(5) If pinion gap is out of specification, adjust by adding or

removing gaskets between magnetic switch and front

bracket.

MAGNETIC SWITCH PULL-IN TEST(1) Disconnect field coil wire from M-terminal of magnetic

switch.

(2)

Connect a 12 V battery between S-terminal and M-terminal.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.

(3) If pinion moves out, then pull-in coil is good. If it doesn’t,

replace magnetic switch.

MAGNETIC SWITCH HOLD-IN TEST(1) Disconnect field coil wire from M-terminal of magnetic

switch.(2) Connect a 12 V battery between S-terminal and body.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(3) Pull out the pinion by hand until it comes into contact

with the pinion stopper.

(4)If pinion remains out, everything is in order. If pinion moves

in, hold-in circuit is open. Replace magnetic switch.

FREE RUNNING TEST

(1) Place starter motor in a vise equipped with soft jaws andconnect a fully-charged

12-volt battery to starter motor

as follows:

(2) Connect a test ammeter (loo-ampere scale) and carbon

pile rheostat in series with battery positive post and starter

motor terminal.

(3) Connect a voltmeter (15volt scale) across starter motor.

(4) Rotate carbon pile to full-resistance position.

(5)Connect battery cable from battery negative post to starter

motor body.(6) Adjust rheostat until the battery voltage shown by the

voltmeter is 11 V.

(7) Confirm that the maximum amperage is within the specifi-

cations and that the starter motor turns smoothly and freely.

Current: Max. 90 Amps

1 TSB Revision

Page 472 of 738

Downloaded from www.Manualslib.com manuals search engine 16-26ENGINE ELECTRICAL - Starting System

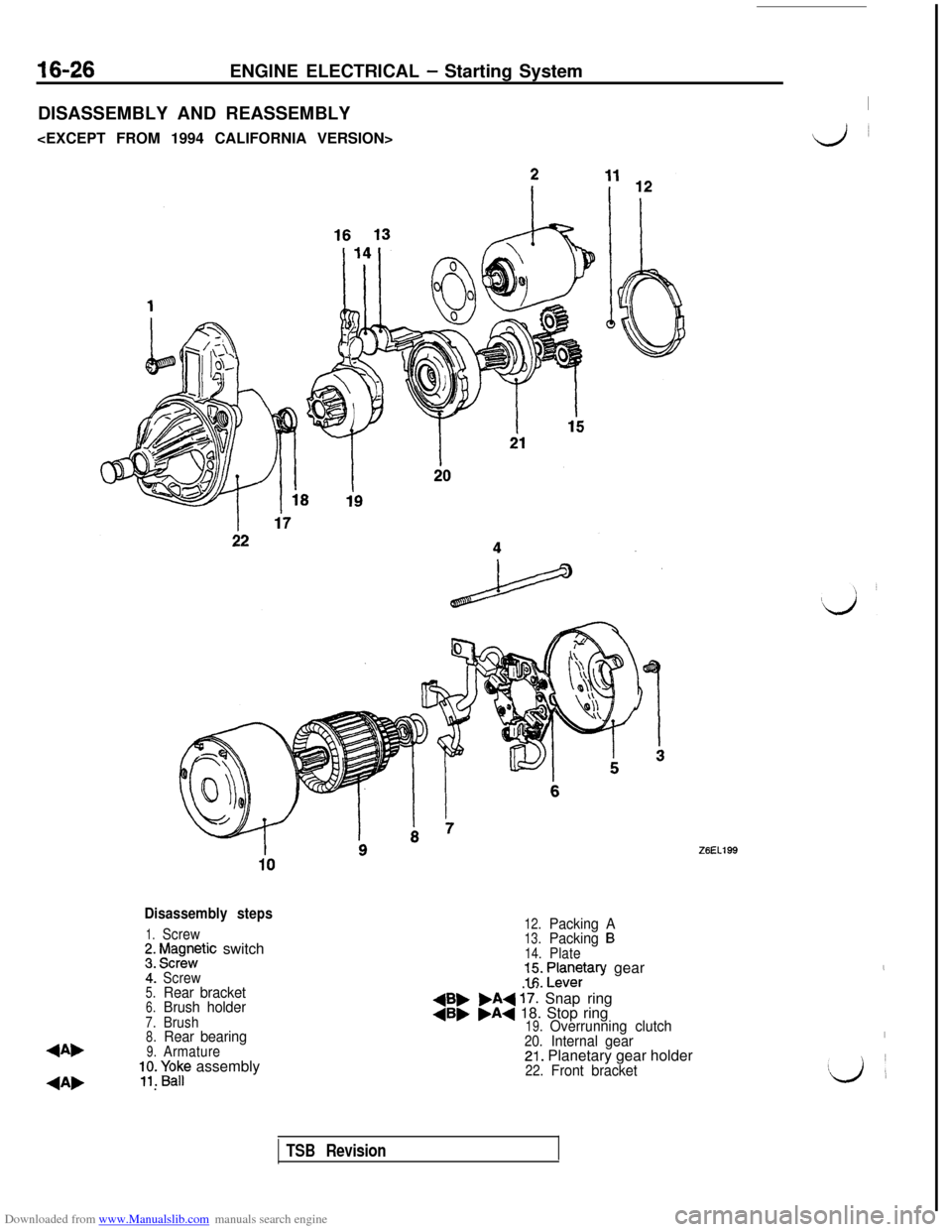

DISASSEMBLY AND REASSEMBLY

I

Lj~

Disassembly steps

1.Screw;. f$gnntic switch

4:Screw5.Rear bracket6.Brush holder7.Brush8.Rear bearing

4Ab9.Armature;;. paF assembly

4A, .

12.Packing A13.Packing B14.Plate=I:. ;an$ary gear

+B, .A+ 17: Snap ring4B, .A+ 18. Stop ring19.Overrunning clutch20.Internal gear21. Planetary gear holder22.Front bracket

,

I!Lj

’

TSB Revision

Page 473 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-27

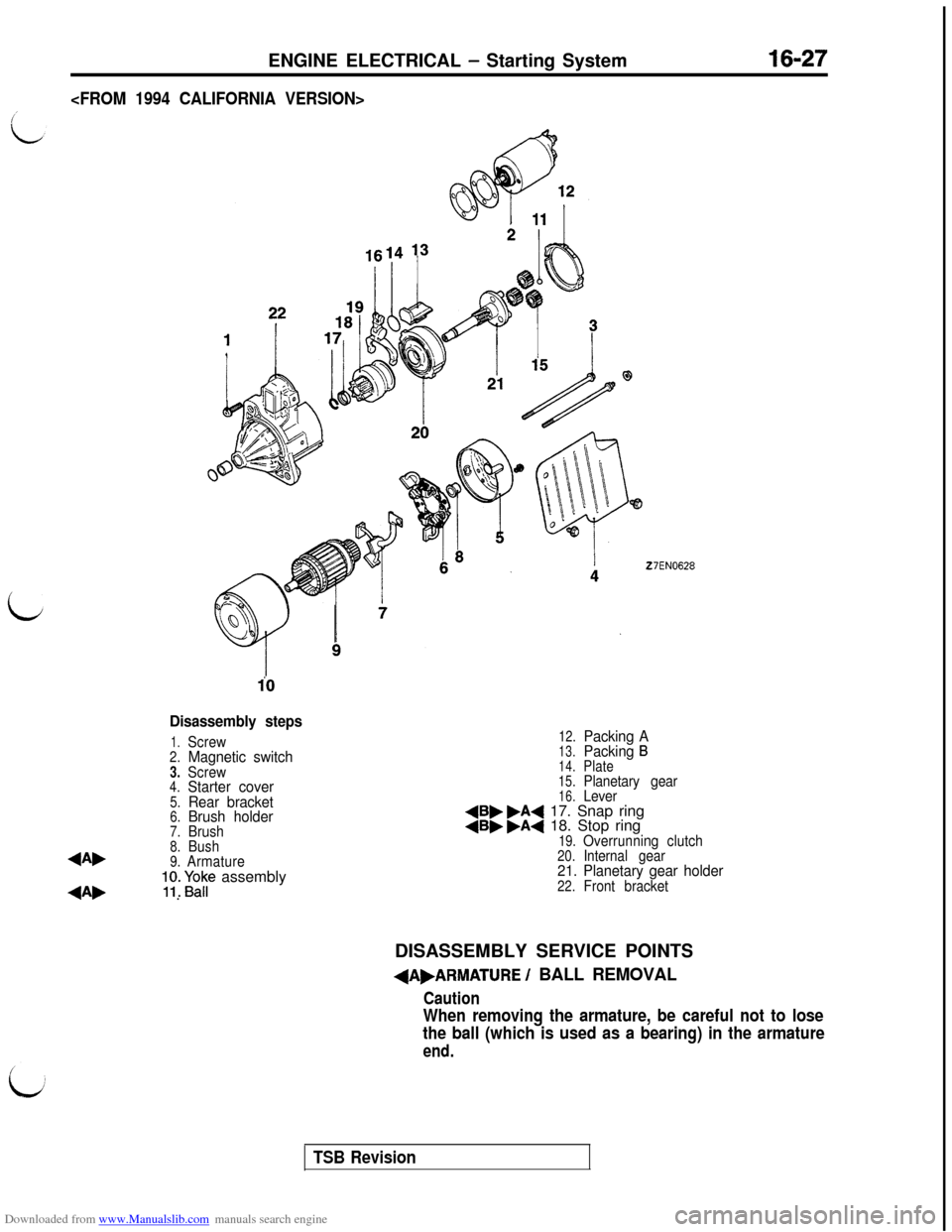

27EN0628

1'0

Disassembly steps

1.Screw2.Magnetic switch3.Screw4.Starter cover5.Rear bracket6.Brush holder7.Brush8.Bush4A,9.Armature;y. Fap assembly

4A, .

12.Packing A13.Packing B

14.Plate

15.Planetary gear16.Lever4B, .A4 17. Snap ring4B, .A4 18. Stop ring19.Overrunning clutch20.Internal gear21. Planetary gear holder22.Front bracketDISASSEMBLY SERVICE POINTS

+A,ARMATURE / BALL REMOVAL

Caution

When removing the armature, be careful not to lose

the ball (which is used as a bearing) in the armature

end.

TSB Revision

Page 474 of 738

Downloaded from www.Manualslib.com manuals search engine 16-28ENGINE ELECTRICAL - Starting System

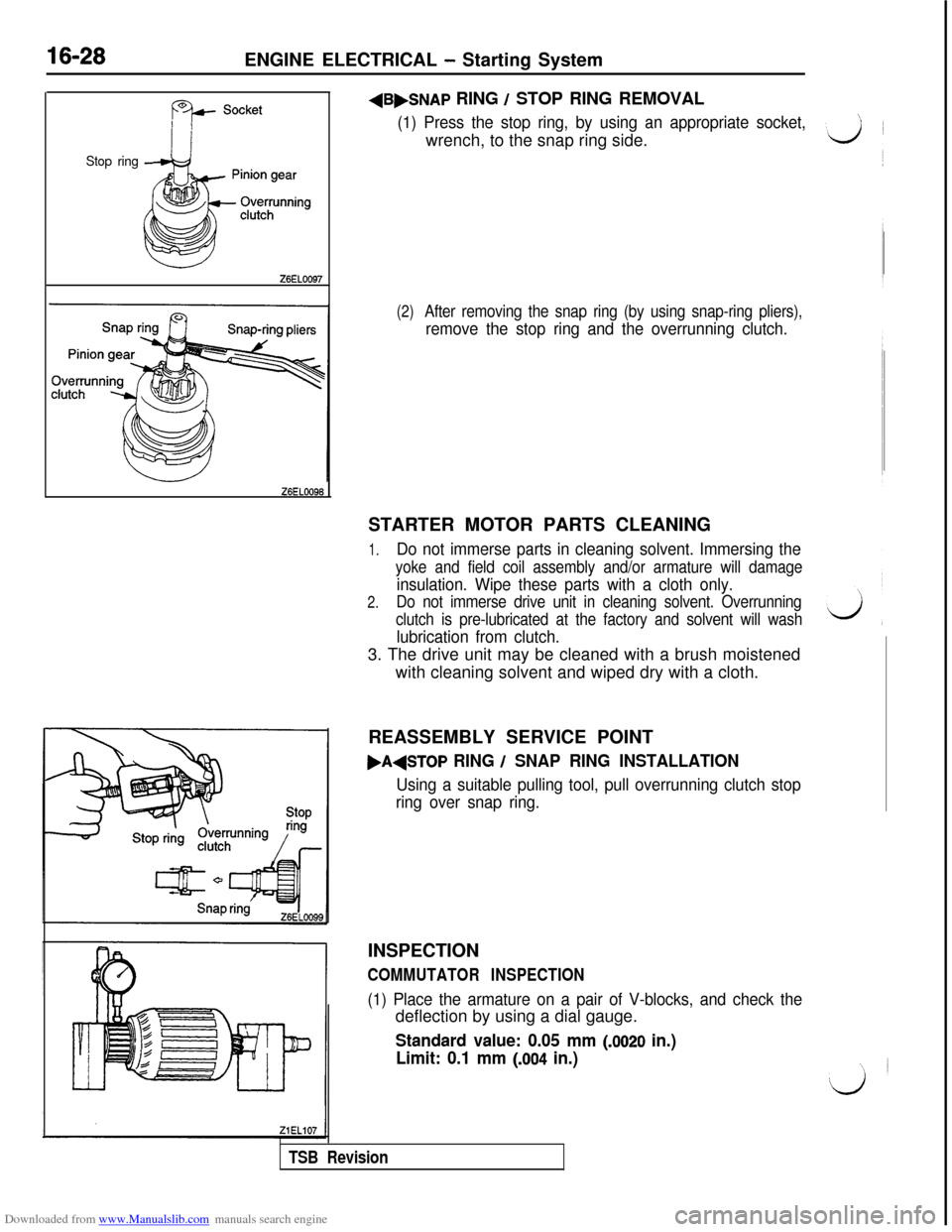

Stop ringZ6EL0097

Z6ELOO96+B,SNAP

RING / STOP RING REMOVAL

(1) Press the stop ring, by using an appropriate socket,wrench, to the snap ring side.

(2)After removing the snap ring (by using snap-ring pliers),

remove the stop ring and the overrunning clutch.STARTER MOTOR PARTS CLEANING

1.Do not immerse parts in cleaning solvent. Immersing the

yoke and field coil assembly and/or armature will damage

insulation. Wipe these parts with a cloth only.

2.Do not immerse drive unit in cleaning solvent. Overrunning

clutch is pre-lubricated at the factory and solvent will wash

lubrication from clutch.3. The drive unit may be cleaned with a brush moistened

with cleaning solvent and wiped dry with a cloth.

REASSEMBLY SERVICE POINT

,A+TOP RING / SNAP RING INSTALLATION

Using a suitable pulling tool, pull overrunning clutch stop

ring over snap ring.INSPECTION

COMMUTATOR INSPECTION

(1) Place the armature on a pair of V-blocks, and check thedeflection by using a dial gauge.

Standard value: 0.05 mm (JO20 in.)

Limit: 0.1 mm

(.004 in.)

TSB Revision

Page 612 of 738

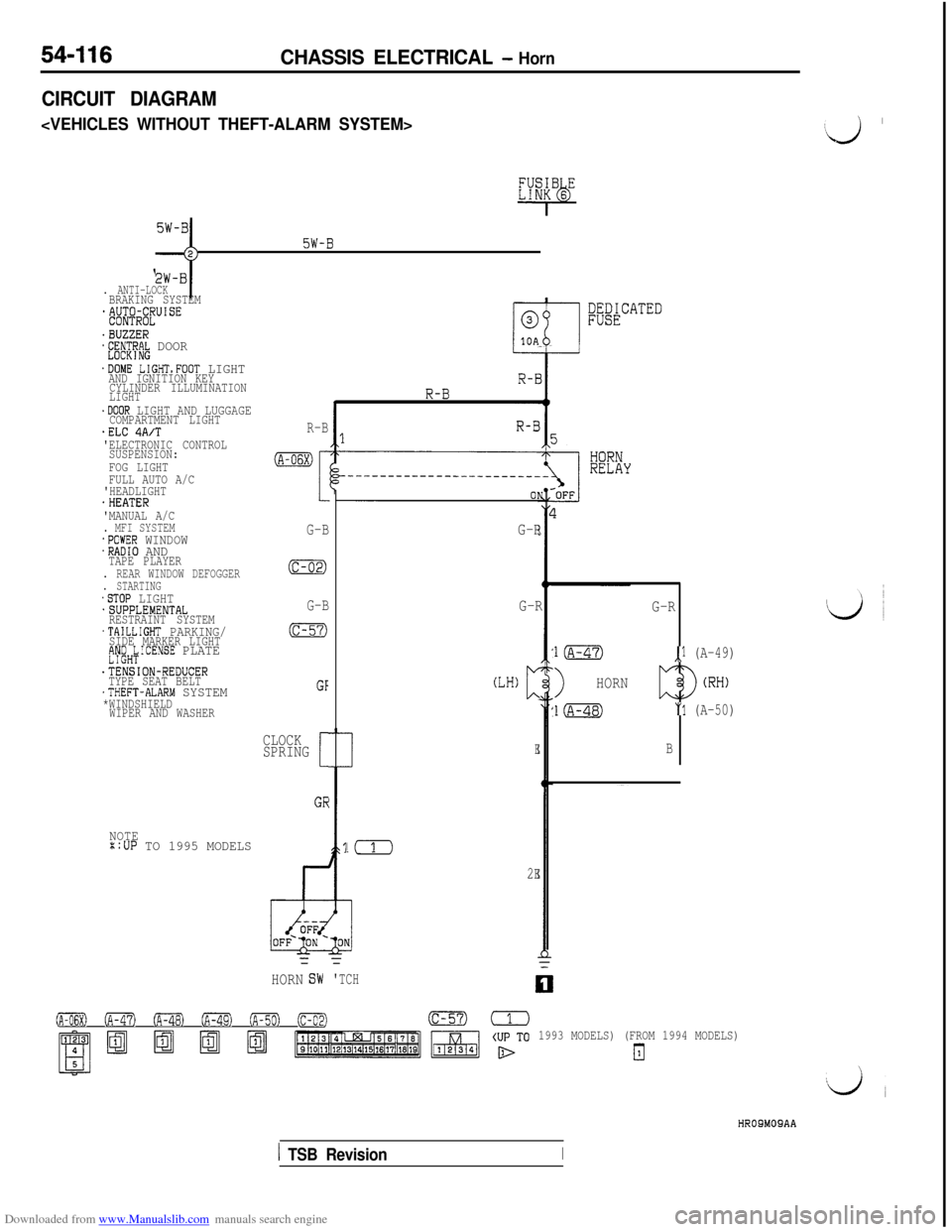

Downloaded from www.Manualslib.com manuals search engine 54-116CHASSIS ELECTRICAL - Horn

CIRCUIT DIAGRAM

c

5W-B;;-j

. ANTI-LOCKBRAKING SYSTEM*&$@lJUISE

.BUZZER*E;~CT~R~ DOOR

.DOME LIGHTsFOOT LIGHTAND IGNITION KEY

CYLINDER ILLUMINATION

LIGHT

.DOOR LIGHT AND LUGGAGECOMPARTMENT LIGHT.ELC 4A/T'ELECTRONIC CONTROL

SUSPENSION:

FOG LIGHT

FULL AUTO A/C

'HEADLIGHT

.HEATER

'MANUAL A/C

. MFI SYSTEM.POWER WINDOW.RADIO ANDTAPE PLAYER. REAR WINDOW DEFOGGER. STARTING.STOP LIGHT.SUPPLEMENTAL

RESTRAINT SYSTEM

.TAILLIGHT PARKING/SIDE MARKER LIGHTfJy;H;ICENSE PLATE

.TENSION-REDUCER

TYPE SEAT BELT

.THEFT-ALARM SYSTEM*WINDSHIELD

WIPER AND WASHER

NOTE::UP TO 1995 MODELS

R-B

(A-06X)

I

G-B

(c-02)

G-B

(c-57)

GF

CLOCK

SPRING

[

GE

;;&CATED

G-R

!(

2E=

HORNG-R

(LH)c

E

=

'TCH

G-R

l(A-47),l (A-49)

>HORN

l(A-48)"1 (A-50)

B

0 (A-47) oFa (A-49) ofiml (c-02)(c-57)=

1993 MODELS) (FROM 1994 MODELS)

El

‘J ’

HROSMOSAA

1 TSB RevisionI