check engine MITSUBISHI 3000GT 1993 2.G Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: 3000GT, Model: MITSUBISHI 3000GT 1993 2.GPages: 738, PDF Size: 35.06 MB

Page 530 of 738

Downloaded from www.Manualslib.com manuals search engine 54-34CHASSIS ELECTRICAL - Meters and Gauges216FO14C

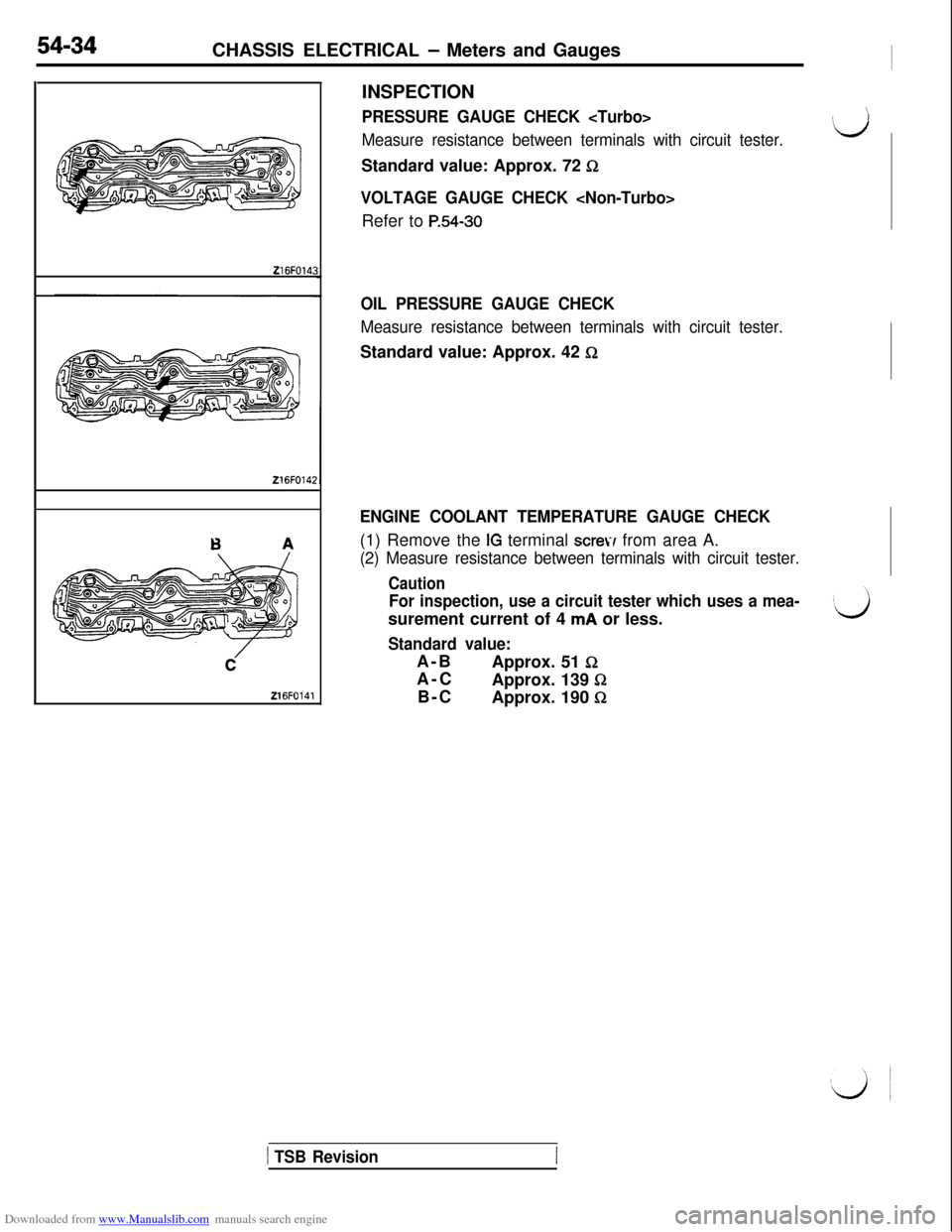

216FO14:216FO141INSPECTION

PRESSURE GAUGE CHECK

Measure resistance between terminals with circuit tester.Standard value: Approx. 72

&2

VOLTAGE GAUGE CHECK

P.54-30

OIL PRESSURE GAUGE CHECK

Measure resistance between terminals with circuit tester.Standard value: Approx. 42

Q

ENGINE COOLANT TEMPERATURE GAUGE CHECK(1) Remove the

IG terminal scre\;/ from area A.

(2) Measure resistance between terminals with circuit tester.

Caution

For inspection, use a circuit tester which uses a mea-surement current of 4

mA or less.

Standard value:A-B

Approx. 51

SzA-C

Approx. 139

QB-C

Approx. 190

R

1 TSB Revision

Page 532 of 738

Downloaded from www.Manualslib.com manuals search engine 54-36CHASSIS ELECTRICAL - Lighting System

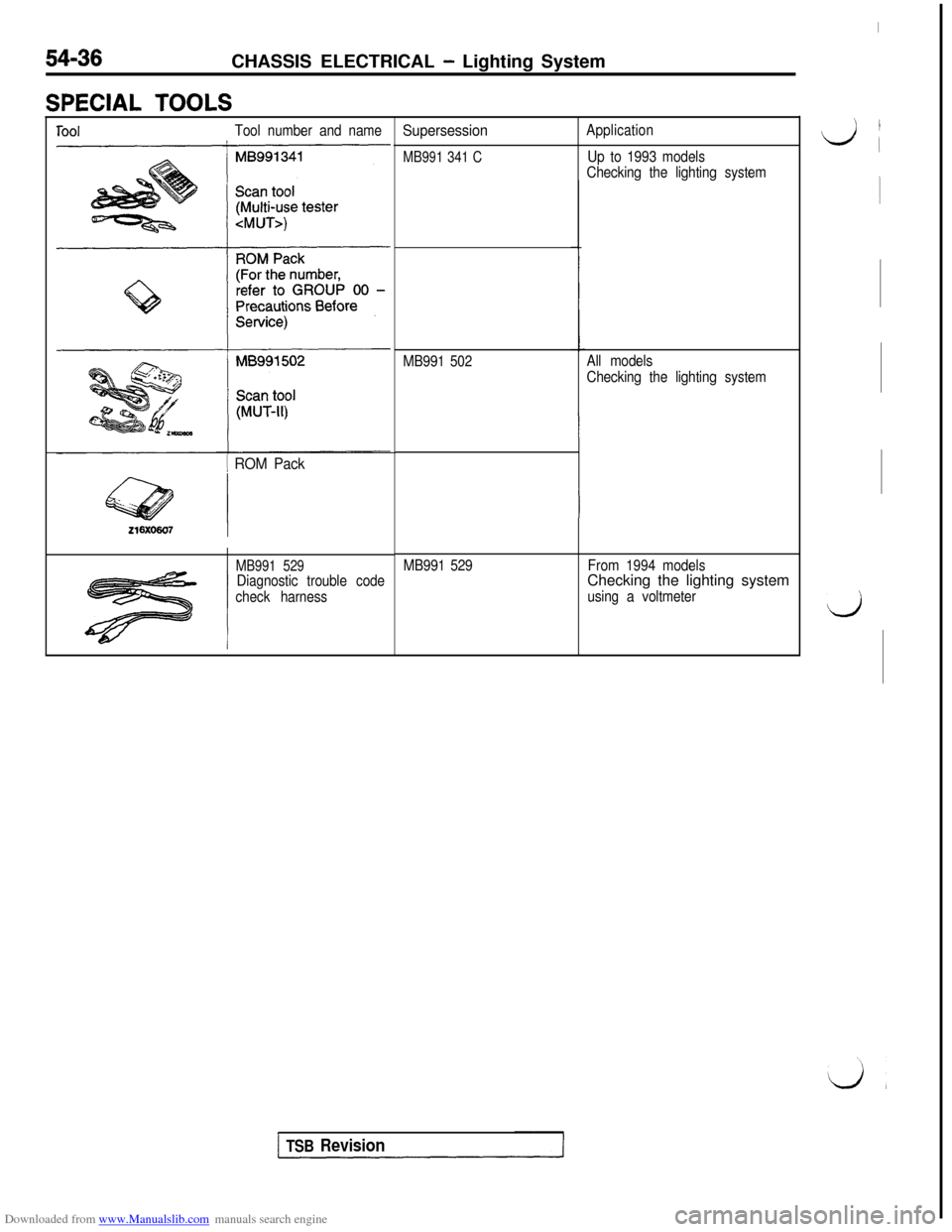

SPECIAL TOOLS

ToolTool number and name

1 ROM Pack

MB991 529Diagnostic trouble code

check harness

Supersession

MB991 341 C

Application

Up to 1993 models

Checking the lighting system

MB991 502All models

Checking the lighting system

MB991 529From 1994 modelsChecking the lighting system

using a voltmeter

I

‘, I

L/i

1

d

TSB Revision

Page 534 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Liahting System

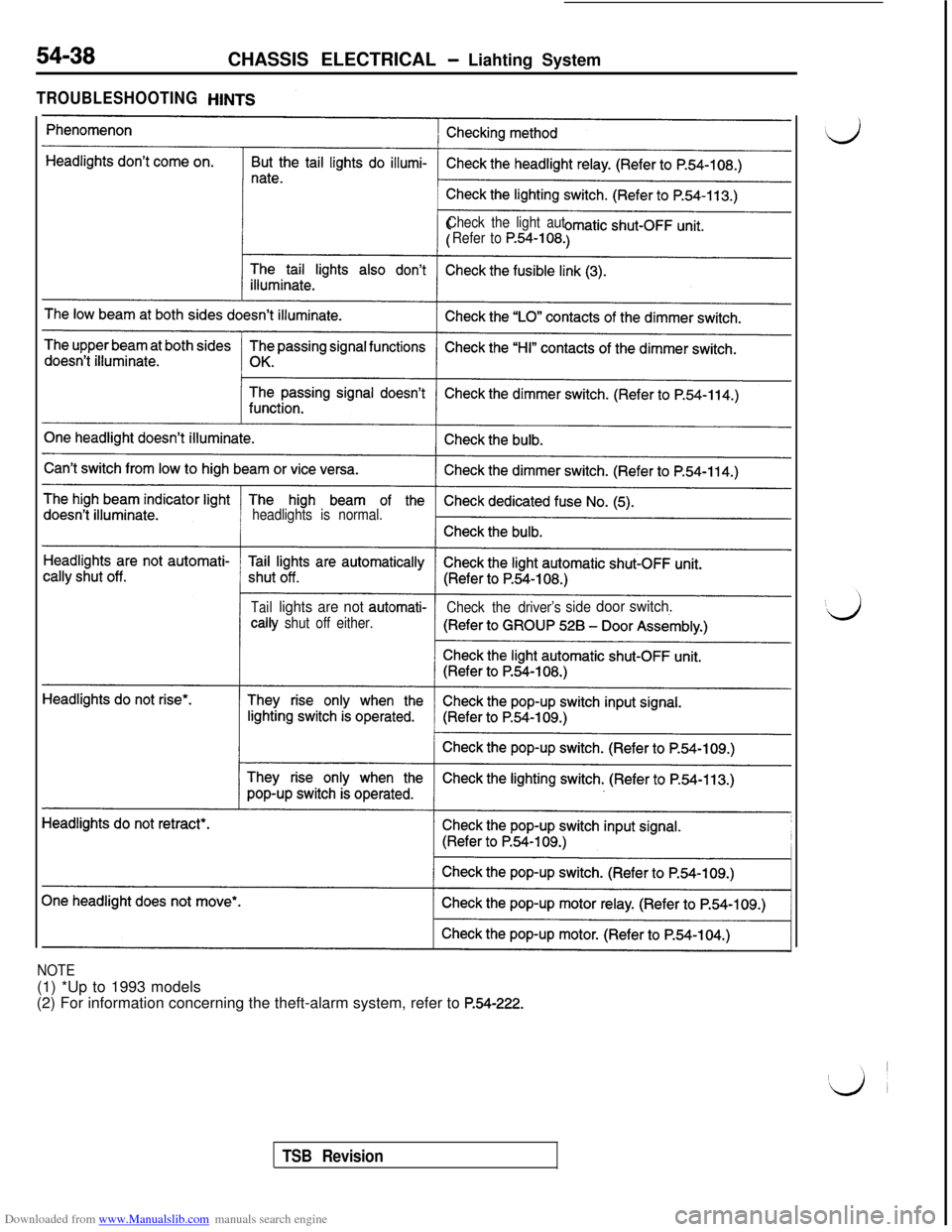

TROUBLESHOOTING

Check the light aut

Refer to

P.54-108.

headlights is normal.

Taillights are not automati-

Check the driver’ssidedoor switch.tally

shut off either.

NOTE(1) *Up to 1993 models

(2) For information concerning the theft-alarm system, refer to

P.54-222.

TSB Revision

Page 552 of 738

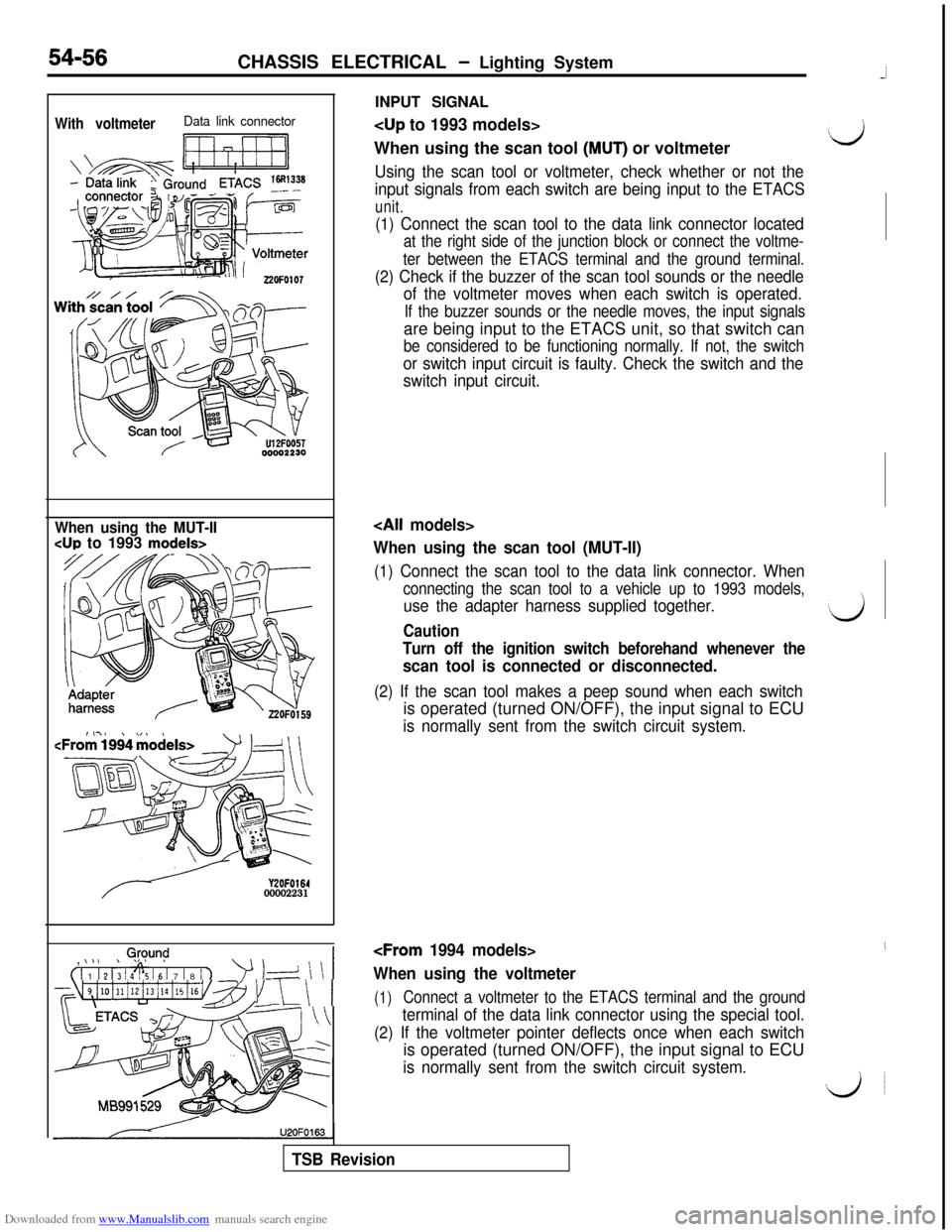

Downloaded from www.Manualslib.com manuals search engine INPUT SIGNALWith voltmeterData link connector

Ii ri7-11

When using the scan tool (MUT) or voltmeter‘d

Using the scan tool or voltmeter, check whether or not the

input signals from each switch are being input to the ETACS

unit.

54-56CHASSIS ELECTRICAL - Lighting System

(1) Connect the scan tool to the data link connector located

at the right side of the junction block or connect the voltme-

ter between the ETACS terminal and the ground terminal.

(2) Check if the buzzer of the scan tool sounds or the needle

of the voltmeter moves when each switch is operated.

If the buzzer sounds or the needle moves, the input signalsare being input to the ETACS unit, so that switch can

be considered to be functioning normally. If not, the switch

or switch input circuit is faulty. Check the switch and the

switch input circuit.

When using the MUT-II

CUP to 1993 models>

Y2OFO16400002231,

0,@y.m$

( 1 1 1 2 1; 1 4% 16 1 7 1 8 / 1

’ 1-d \ \ 1

~~~4i10illi12i13illi15i16v~~~1 \ \ 1U2OFO163

When using the scan tool (MUT-II)

(1) Connect the scan tool to the data link connector. When

connecting the scan tool to a vehicle up to 1993 models,

use the adapter harness supplied together.‘dCaution

Turn off the ignition switch beforehand whenever the

scan tool is connected or disconnected.

(2) If the scan tool makes a peep sound when each switchis operated (turned ON/OFF), the input signal to ECU

is normally sent from the switch circuit system.

When using the voltmeter

(1)Connect a voltmeter to the ETACS terminal and the ground

terminal of the data link connector using the special tool.

(2) If the voltmeter pointer deflects once when each switchis operated (turned ON/OFF), the input signal to ECU

is normally sent from the switch circuit system.

do

TSB Revision

Page 558 of 738

Downloaded from www.Manualslib.com manuals search engine 54-62CHASSIS ELECTRICAL - Lighting System

OPERATION

lWhen the fog light switch is placed in the ON position with the lighting switch in the HEAD positionand the dimmer switch in the LO position, current flows through the dedicated fuse (4) to the coil

of the fog light relay, the fog light switch, the dimmer switch and ground, causing the contacts of

the fog light relay to close.

When the contacts of the fog light relay close, current flows through the dedicated fuse (4) to the

contacts of the fog light relay, the fog lights and ground, causing the fog lights to come on.

lWhen the dimmer switch is placed in the HI position or the lighting switch is placed in the TAIL or

OFF position while the fog lights are ON, current supply to the fog light relay or headlight relay is

cut off. As a result, the contacts of the fog light relay open, and the fog lights go out.

NOTE

The fog lights are included in the light automatic shut-OFF system. (Refer to P.54-37). The indicator lights

are also included in the same system.

Fog Lights Operation Conditions

Fog light switchLighting switchDimmer switchFog lights

ON position

1 OFF position or TAIL posi- 1 LO position1 OFF

tion

HEAD positionHI position

LO position

OFF

ON

HI position

I

OFF

TROUBLESHOOTING HINTS1. The right or left fog lights only go on.

0Check the bulb.2. Fog lights do not go on when the fog light switch is set at ON.

0Check the dedicated fuse (4).

0Check the fog light relay. (Refer to P.54-108).

0Check the fog light switch.

NOTEFor the light automatic shut-OFF system troubleshooting hints, refer to

P.54-38.

1 TSB Revision

Page 566 of 738

Downloaded from www.Manualslib.com manuals search engine 54-70CHASSIS ELECTRICAL - Lighting System

OPERATION

0When the lighting switch is placed in the TAILor HEAD position, current flows through the

coil of the tail light relay to the lighting switchand ground, causing the contacts of the tail

light relay to close.

Then current flows through the contacts of thetail light relay to the dedicated fuse

(2) the

individual lights and ground, causing the tail

lights, parking/side marker lights and licenseplate lights to go ON.

lIf the driver’s door is opened after the ignition

switch is turned to “OFF” or the ignition switchis turned to “OFF” after the driver’s door is

opened when the tail lights are lit, the current

which flows to the coil side of the tail light relaywill be cut off by the light automatic shut-off

unit opening the contact point, and the tail light

relay will be turned “OFF’ to automatically shut

off the tail lights, parking and front side marker

lights and license plate light.

lTo turn on the tail lights, parking and front side

marker lights and license plate light again after

they are automatically shut off, turn the lightingswitch to “OFF” once and to “HEAD” again,

or turn the ignition switch to “ACC” or “ON”,

and the automatic shut-OFF will be cancelled

and the current will flow from the light automaticshut-OFF unit to the coil side of the tail light

relay to close the contact point. Thus, the taillight relay will be turned “ON” to turn on the

tail lights, parking and front marker lights and

license plate light.

NOTE

When the lighting switch is at the “HEAD” position,

the light automatic shut-OFF system will be also

activated for the headlights. (Refer to P.54-37.) The

same system will also be activated for the illumina-

tion lights, etc.

TROUBLESHOOTING HINTS1. All lights don’t illuminate.

(1) The headlights don’t illuminate, either.l Check the fusible link (3).

(2) The headlights illuminate.l Check the tail light relay. (Refer to

P.54-108.)l Check the dedicated fuse (2).

l Check the lighting switch. (Refer to

P.54-113.)l Check the light automatic shut-OFF

unit. (Refer to

P.54-108.)2. Some light does not come on.

l Check the bulb.

l Check the grounding circuit.

3. Some light is not automatically shut off.

lCheck the driver’s side door switch.

(Refer to GROUP 42- Door Assembly.)l Check the automatic shut-OFF unit.

(Refer to

P.54-108.)

1 TSB Revision

Page 574 of 738

Downloaded from www.Manualslib.com manuals search engine 54-78CHASSIS ELECTRICAL - Lighting System

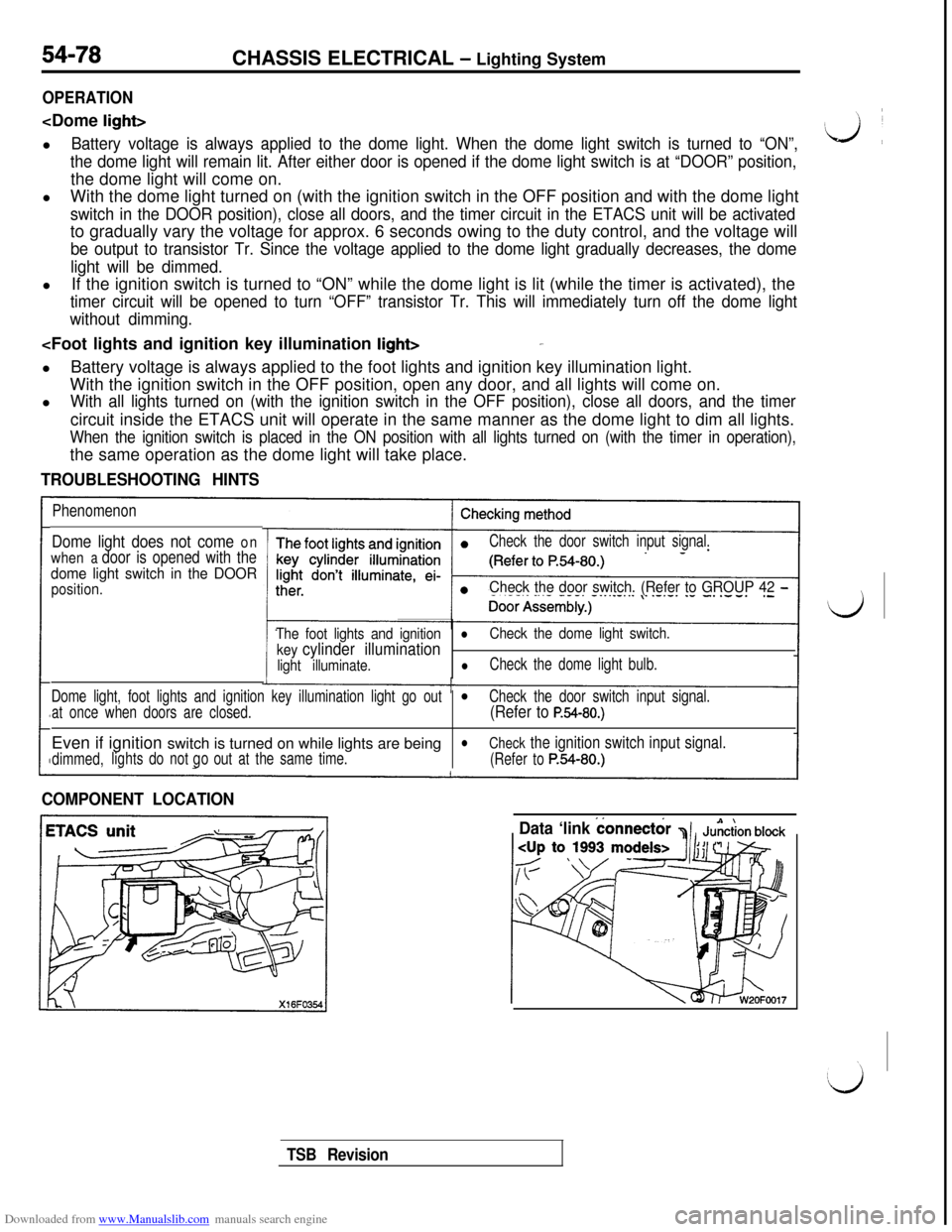

OPERATION

Battery voltage is always applied to the dome light. When the dome light switch is turned to “ON”,

the dome light will remain lit. After either door is opened if the dome light switch is at “DOOR” position,the dome light will come on.

lWith the dome light turned on (with the ignition switch in the OFF position and with the dome light

switch in the DOOR position), close all doors, and the timer circuit in the ETACS unit will be activatedto gradually vary the voltage for approx. 6 seconds owing to the duty control, and the voltage will

be output to transistor Tr. Since the voltage applied to the dome light gradually decreases, the dome

light will be dimmed.lIf the ignition switch is turned to “ON” while the dome light is lit (while the timer is activated), the

timer circuit will be opened to turn “OFF” transistor Tr. This will immediately turn off the dome light

without dimming.

With the ignition switch in the OFF position, open any door, and all lights will come on.

l

With all lights turned on (with the ignition switch in the OFF position), close all doors, and the timercircuit inside the ETACS unit will operate in the same manner as the dome light to dim all lights.

When the ignition switch is placed in the ON position with all lights turned on (with the timer in operation),the same operation as the dome light will take place.

TROUBLESHOOTING HINTS

Phenomenon

Dome light does not come on

when

a door is opened with the

dome light switch in the DOOR

position.

Check the door switch input signal.

Check the door switch. (Refer to GROUP 42 -

The foot lights and ignitionl

key cylinder illumination

Check the dome light switch.

light illuminate.

lCheck the dome light bulb.

Dome light, foot lights and ignition key illumination light go out

l

at once when doors are closed.Check the door switch input signal.(Refer to P.54-80.)Even if ignition switch is turned on while lights are being

l

dimmed,lightsdo notout at the same time.

Check the ignition switch input signal.

go

(Refer toP.54-80.)

COMPONENT LOCATION

Data ‘link

connect&

TSB Revision

Page 576 of 738

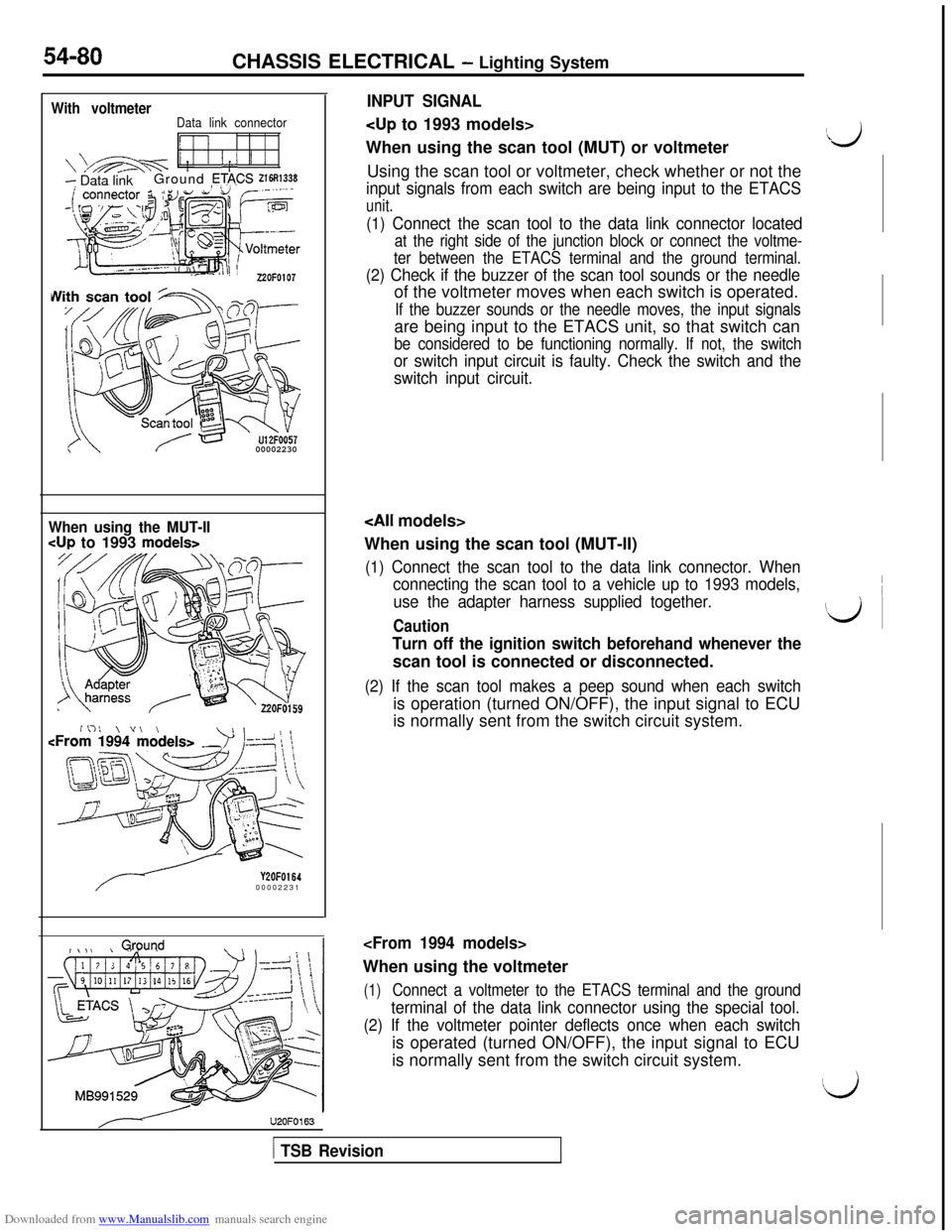

Downloaded from www.Manualslib.com manuals search engine With voltmeterData link connector

’‘:’ ’ ’- Data linkGround ETA,CS 21~33300002230

54-80CHASSIS ELECTRICAL - Lighting System

INPUT SIGNAL

When using the scan tool (MUT) or voltmeter

Using the scan tool or voltmeter, check whether or not the

input signals from each switch are being input to the ETACS

unit.

(1) Connect the scan tool to the data link connector located

at the right side of the junction block or connect the voltme-

ter between the ETACS terminal and the ground terminal.

(2) Check if the buzzer of the scan tool sounds or the needleof the voltmeter moves when each switch is operated.

If the buzzer sounds or the needle moves, the input signalsare being input to the ETACS unit, so that switch can

be considered to be functioning normally. If not, the switch

or switch input circuit is faulty. Check the switch and the

switch input circuit.

When using the MUT-II

cup to 1993 models>

Y2OFOl6400002231

#\,I kQwnd\ \U2OFO163

When using the scan tool (MUT-II)

(1) Connect the scan tool to the data link connector. When

connecting the scan tool to a vehicle up to 1993 models,

use the adapter harness supplied together.

Caution

Turn off the ignition switch beforehand whenever thescan tool is connected or disconnected.

(2) If the scan tool makes a peep sound when each switchis operation (turned ON/OFF), the input signal to ECU

is normally sent from the switch circuit system.

(1)Connect a voltmeter to the ETACS terminal and the ground

terminal of the data link connector using the special tool.

(2) If the voltmeter pointer deflects once when each switchis operated (turned ON/OFF), the input signal to ECU

is normally sent from the switch circuit system.

Ii3

\ ~

id ~

!Lj

[ TSB Revision

Page 585 of 738

Downloaded from www.Manualslib.com manuals search engine 1. When operation is normal

l

When the ignition switch is switched to the

ON position, battery voltage is applied (viathe multipurpose fuse (11) and hazard

switch) to the turn-signal and hazard flasher

unit.l

When the turn-signal switch is switched to

the LH position,

Trl (within the flasher unit)

is switched ON and OFF repeatedly.

Then the contacts of the relay 1 (also within

the flasher unit) repeatedly switch from ON

to OFF, causing the turn-signal lights and

turn-signal indicator light LH to flash.l

When the turn-signal switch is switched to

the RH position, Tr2 (within the flasher unit)

is switched ON and OFF repeatedly.Then the contacts of relay 2 (also within

the flasher unit) repeatedly switch from ON

to OFF, causing the turn-signal lights and

turn-signal indicator light RH to flash.2. If one of the bulbs is burned out

lIf the LH (or RH) turn-signal light bulb is

burned-out, the resistance of the turn-signalcircuit as a whole increases, resulting in

Lshorter ON and OFF intervals of the LHTrl (or RH Tr2) and a higher flashing rateof the LH lights (or RH lights).CHASSIS ELECTRICAL

- Lighting System54-89

TURN-SIGNAL LIGHT AND HAZARD

L

LIGHT

OPERATION

ed to the “ON” position, the relay contactof the turn signal and hazard flasher unit

is switched ON and OFF repeatedly, in thesame manner as for the operation of the

turn-signal lights, and the left and right turn-

signal lights and turn-signal indicator lights

simultaneously flash repeatedly.

NOTE

(1) The number of flashes of the hazard-warn-

ing lights does not change if there is dam-

aged or disconnected wiring of one light.

(2)The light automatic shut-OFF system is valid

for the illumination light of the hazard switch.(Refer to

P.54-37.)

TROUBLESHOOTING HINTS

1.The turn-signal lights and hazard-warning lightsdo not operate at all.

l Check the hazard switch contact (power

supply side).l Check the turn-signal and hazard flasher

unit.2. All turn-signal lights at the left (or right) side

do not function.

(1) The hazard-warning lights function normal-

ly-lCheck the hazard switch contact (turn-

signal side).l Check the turn-signal switch.

3.The number of flashes of the turn-signal lights

is excessive.l Check the bulbs.

4. The hazard-warning lights do not function.

(1) The turn-signal lights function normally.l

Check the hazard switch contact (haz-

ard-warning light side).

NOTE

For the troubleshooting hints of the automatic lightshut-OFF system, refer to

P.54-37.

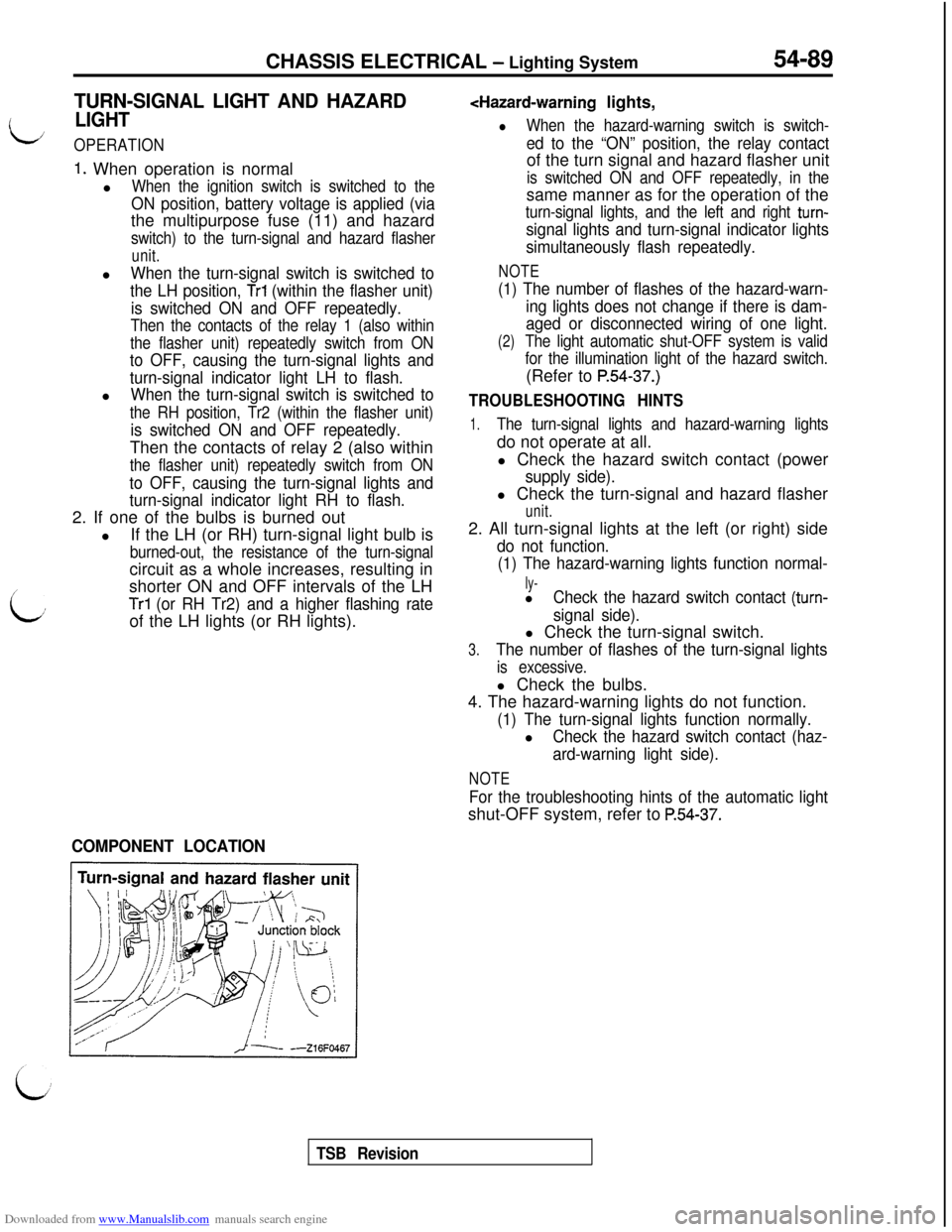

COMPONENT LOCATION

TSB Revision

Page 597 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System54-101

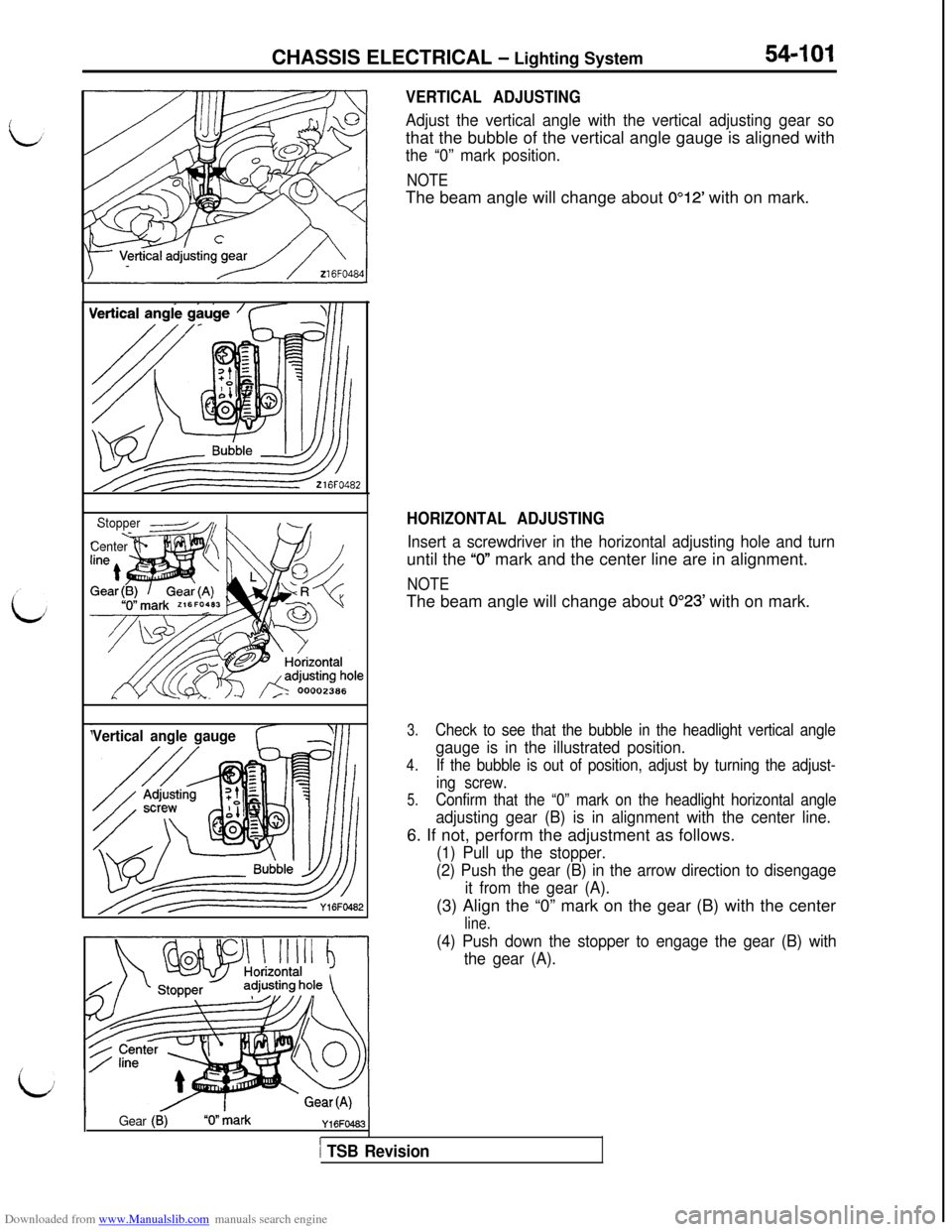

VERTICAL ADJUSTING

Adjust the vertical angle with the vertical adjusting gear sothat the bubble of the vertical angle gauge is aligned with

the “0” mark position.

NOTEThe beam angle will change about 0’12’ with on mark.

Stopper

Center bm

Vertical angle gauge

HORIZONTAL ADJUSTING

Insert a screwdriver in the horizontal adjusting hole and turnuntil the

“0” mark and the center line are in alignment.

NOTEThe beam angle will change about 0’23’ with on mark.

Gear (6)“0” hark

3.Check to see that the bubble in the headlight vertical angle

gauge is in the illustrated position.

4.If the bubble is out of position, adjust by turning the adjust-

ing screw.

5.Confirm that the “0” mark on the headlight horizontal angle

adjusting gear (B) is in alignment with the center line.6. If not, perform the adjustment as follows.

(1) Pull up the stopper.

(2) Push the gear (B) in the arrow direction to disengage

it from the gear (A).(3) Align the “0” mark on the gear (B) with the center

line.

(4) Push down the stopper to engage the gear (B) with

the gear (A).

1 TSB Revision