trans MITSUBISHI 3000GT 1993 2.G Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: 3000GT, Model: MITSUBISHI 3000GT 1993 2.GPages: 738, PDF Size: 35.06 MB

Page 469 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-23

OPERATION

L

0For models equipped with the M/T, the clutch

pedal position switch contact is switched OFF

when the clutch pedal is depressed; when the

ignition switch is then switched to the “ST’ posi-tion, electricity flows to the starter relay and

the starter motor, the contact (magnetic switch)of the starter is switched ON and the starter

motor is activated.

NOTEIf the ignition switch is switched to the “ST

position without the clutch pedal being de-

pressed, electricity flows to the starter relay

(coil), the clutch pedal position switch (contacts)

and to ground, with the result that the contacts

of the starter relay are switched OFF, and, be-

cause the power to the starter motor is thereby

interrupted, the starter motor is not activated.lFor models equipped with the

AIT, when the

ignition switch is switched to the “ST’ position

while the selector lever is at the “P” or “N” posi-

tion, the contact (magnetic switch) of the starter

is switched ON and the starter motor is activated.

TROUBLESHOOTING HINTSThe starter motor does not operate at all.

l Check the starter (coil).

lCheck for poor contact at the battery terminals

and starter.l Check Park/Neutral position switch.

l Check clutch pedal position switch.

l Check starter relay.

l Check theft-alarm starter relay.

l Check key reminder switch.

i

/’

L&J

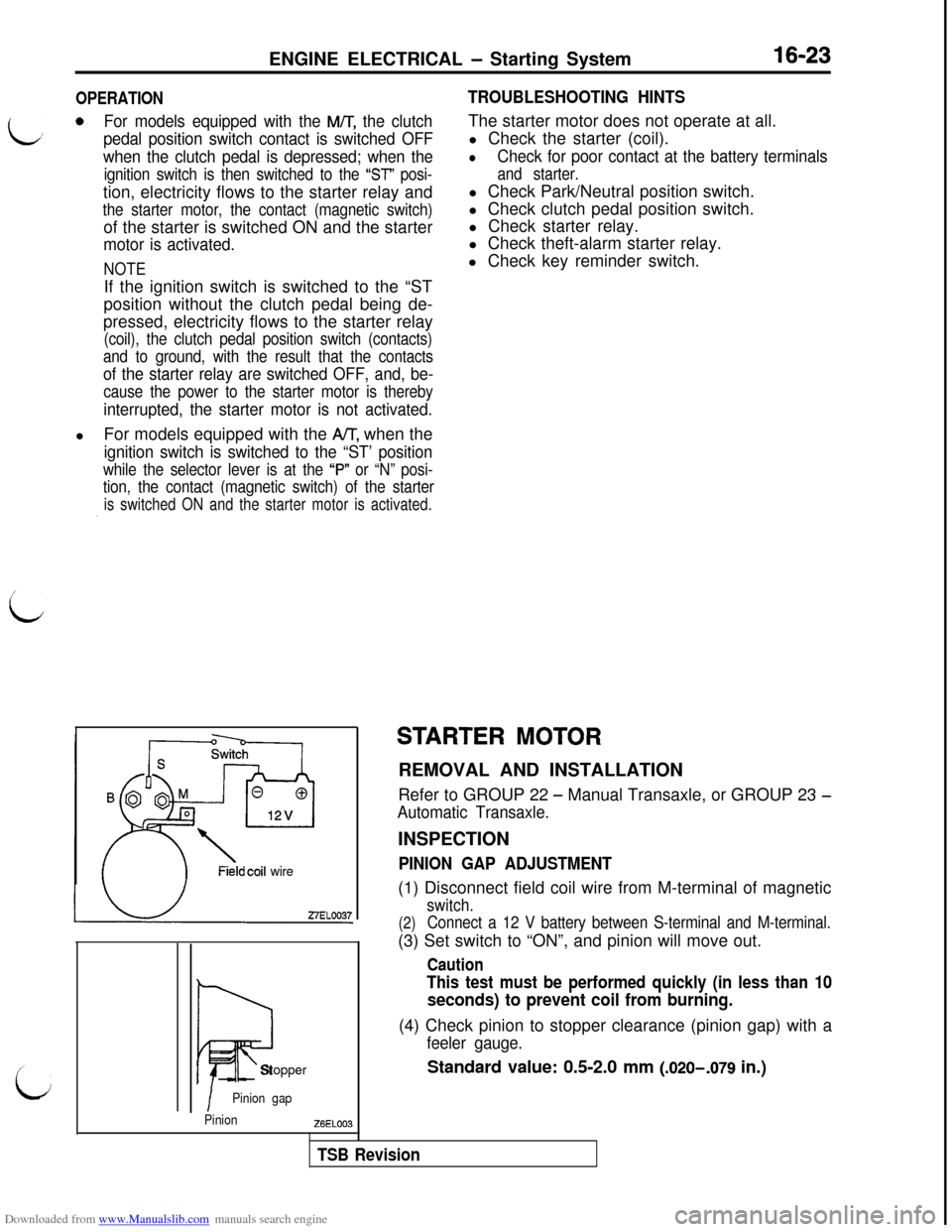

Fieldcoil wire

Iii?Stopper

IPinion gap

PinionZ6EL003

STARTER MOTORREMOVAL AND INSTALLATION

Refer to GROUP 22

- Manual Transaxle, or GROUP 23 -

Automatic Transaxle.INSPECTION

PINION GAP ADJUSTMENT(1) Disconnect field coil wire from M-terminal of magnetic

switch.

(2)Connect a 12 V battery between S-terminal and M-terminal.(3) Set switch to “ON”, and pinion will move out.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(4) Check pinion to stopper clearance (pinion gap) with a

feeler gauge.

Standard value: 0.5-2.0 mm (.020-,079 in.)

TSB Revision

Page 478 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - lanition Svstem

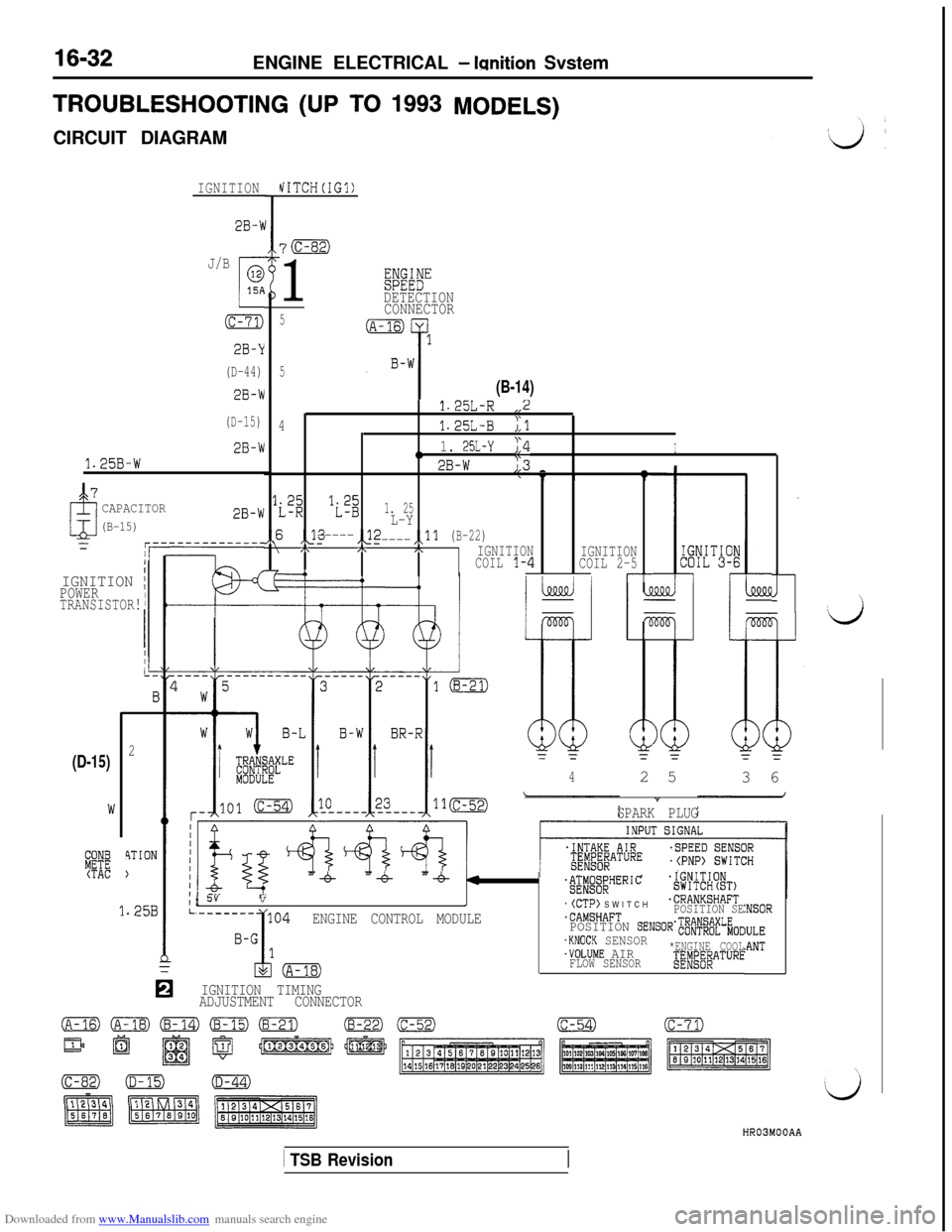

TROUBLESHOOTING (UP TO 1993MODELS)CIRCUIT DIAGRAM

IGNITIONhiITCH(IG1)

2B-X

7m

1

J/B

c

015A

(c-71)

2B-Y

(D-44)

2B-W

(D-15)

2B-W

1.25B-W

@%t”DETECTION

CONNECTOR

5

5

(B-14)

1.25L-R,,2

41.25L-B;,l

,,1. 25L-Y;,4I

2B-W23_

y;'$1. 25L-Y

A6 ,P-----,\22-----,,ll(B-22) /\,h,\IGNITION

IGNITIONCOIL1-4COIL2-5-r--

CAPACITOR

(B-15)2B-W

1/IGNITION IPOWERTRANSISTOR!rl

2

4TION

)

(D-15)

3%(TAC

42 5

3 6

”

SPARK PLUG

1.25B

IIIIIIII1IL

“-6% “-6 “-4%4;ig;f;HERIC.IGNITIONSWITCHtST)/ 5vv.(CTP) SWITCH.CRANKSHAFT

.CAMSHAFTPOSITION SEENGINE CONTROL MODULEPOSITION SENSOR';#$;~L;oc.KNOCK SENSOR.VOLUME AIR*ENGINE COOL

FLOW SENSOR;ED&f$AT"RE

:NSOR

IULE:ANT

IGNITION TIMING

ADJUSTMENT CONNECTOR

HR03MOOAA

1 TSB Revision

Page 479 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition Svstem

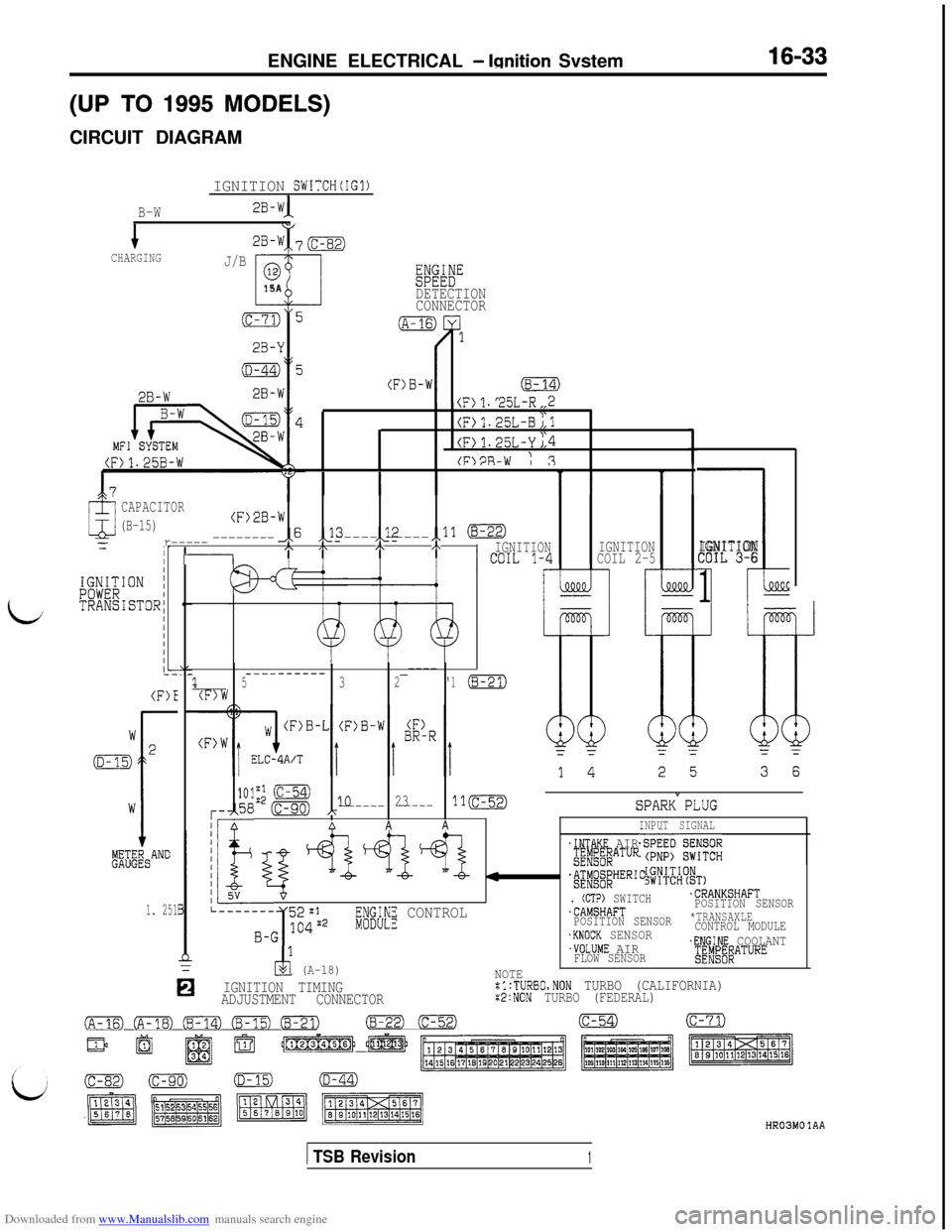

(UP TO 1995 MODELS)CIRCUIT DIAGRAM

IGNITION SWITCH(IG1)

B-W

1CHARGING33-W 70

J/B0

t15A

(c-71)5

2B-Y

2B-W

WEDETECTION

CONNECTOR

\I/1. c5L-R,,2

(F)1.25L-B;,lI'(F>1.25L-Y J,4

(FlPR-W : 3

CAPACITOR

(B-15)(F)2B-W

,x6 ,J3,_12=r------------------ -----,,ll (B-22)

iI -,\ I\,\,\IGNITION' ""TL 1-4IGNITION

COIL 2-5

i

IGNITION

COIL 3-6

1

(F)E_________-----------_----1532'1(8-21)(F)W

101;; (C-54)

r-,58 (c-90) A

1o23-----------ll(c-52)

I/ AAAA

SPARK"PLUG

INPUT SIGNAL

&i&AND

1. 251

!I

~~$yqppQ.INTAKE AIRgE;g;EATUREsiKz&G

'&$AT~~;HER'C

k-_""_---- 52~1. (CTP) SWITCH.CRANKSHAFT

3.CAMSHAFTPOSITION SENSOR

B-G 104g2

I

if;INE CONTROLPOSITION SENSOR*TRANSAXLE

.KNOCK SENSORCONTROL MODULE

2 (A-18)

.VOLUME AIR.ENGINE COOLANT

FLOW SENSOR$~~~~~ATURE

0

NOTEIGNITION TIMING:l:TURBO,NON TURBO (CALIFORNIA)ADJUSTMENT CONNECTORx2:NON TURBO (FEDERAL)

FE) CFm) (B-14) Em3 EFZTJ(B-22)-(c-54)(c-71)

/$J$mb @f-@

ok4 Oh,

( TSB Revision1

HR03MO 1AA

Page 480 of 738

Downloaded from www.Manualslib.com manuals search engine 16-34ENGINE ELECTRICAL - Ignition System

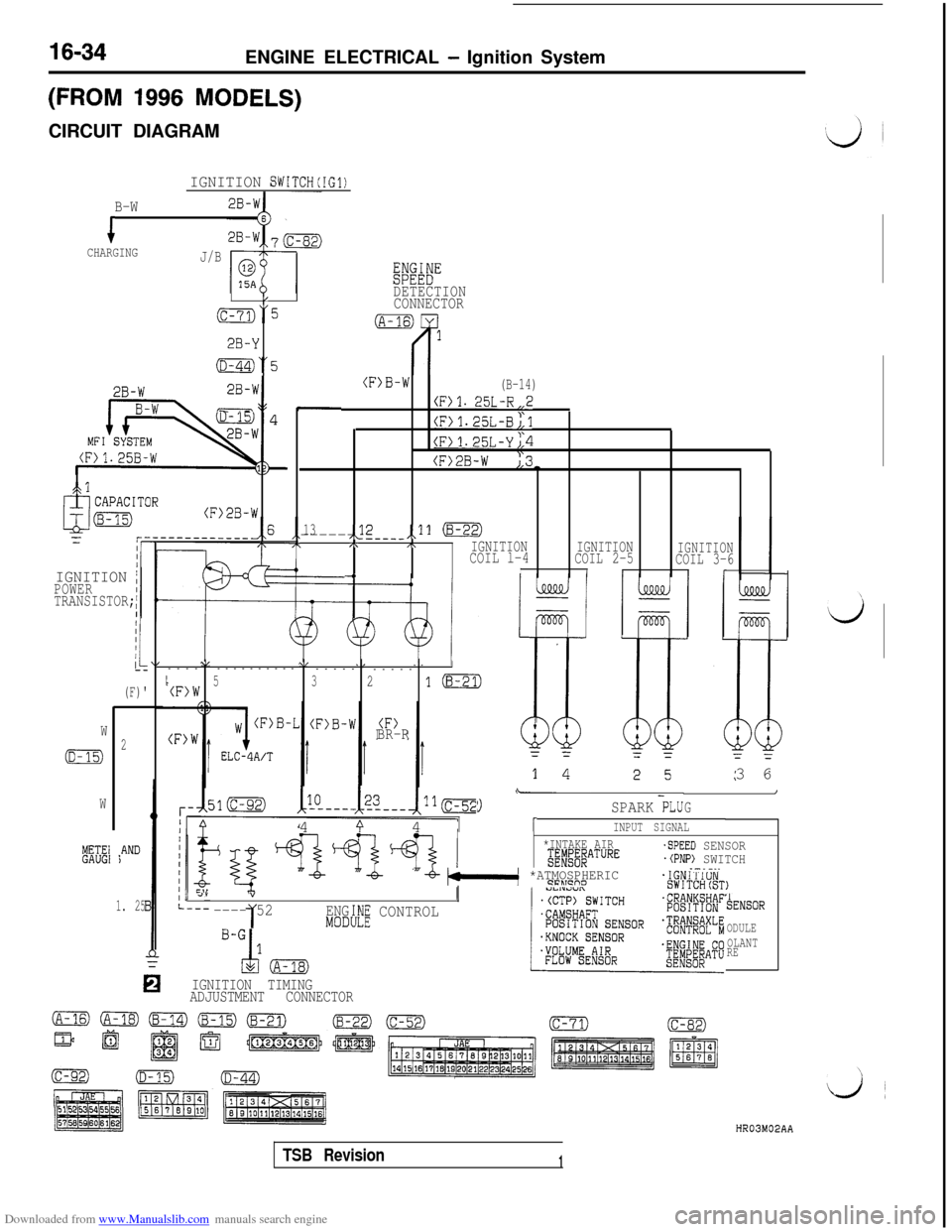

(FROM 1996 MODELS)CIRCUIT DIAGRAM

IGNITION SWITCH(IG1)

B-W

iCHARGINGJ/B

Eiwi"

/DETECTION

(c-73)“5CONNECTOR

2B-Y

(D-44)“5

2B-W-I

2B-W

MFILS - --

(F>B-W(B-14)

(F)l. 25L-R,,2

(F)1.25L-B;,l

(F>1.25L-Yj,4

(F>2B-W ),3-

.

13,<2------ ---__,,11 (8-22),\,\IGNITIONCOIL l-4IGNITION

COIL 2-5IGNITIONCOIL 3-6-4III(r

,cl

(F>2B-W

IGNITION /POWER

TRANSISTOR;

I

(F)'

\I\/,I--------------

-----

-----

I5(F)W321m

BR-RW

(D-15)2

W

METE1GAUGI*AND)3 6

\-I

G9SPARK PLU4

9 41INPUT SIGNAL

*INTAKE AIRg;#j#ATURE

"-b- bkl *ATMOSPHERIC9FLTcno

-SPEED SENSOR.(PNP) SWITCH.-.-..

, 4””

---- 521ENG:h!E CONTROLMODI

TENSOR

ODULE

OLANT

RE

IGNITION TIMING

ADJUSTMENT CONNECTOR

1. 25

HR03M02AA

TSB Revision1

Page 481 of 738

Downloaded from www.Manualslib.com manuals search engine i;ENGINE ELECTRICAL

- Ignition System16-35

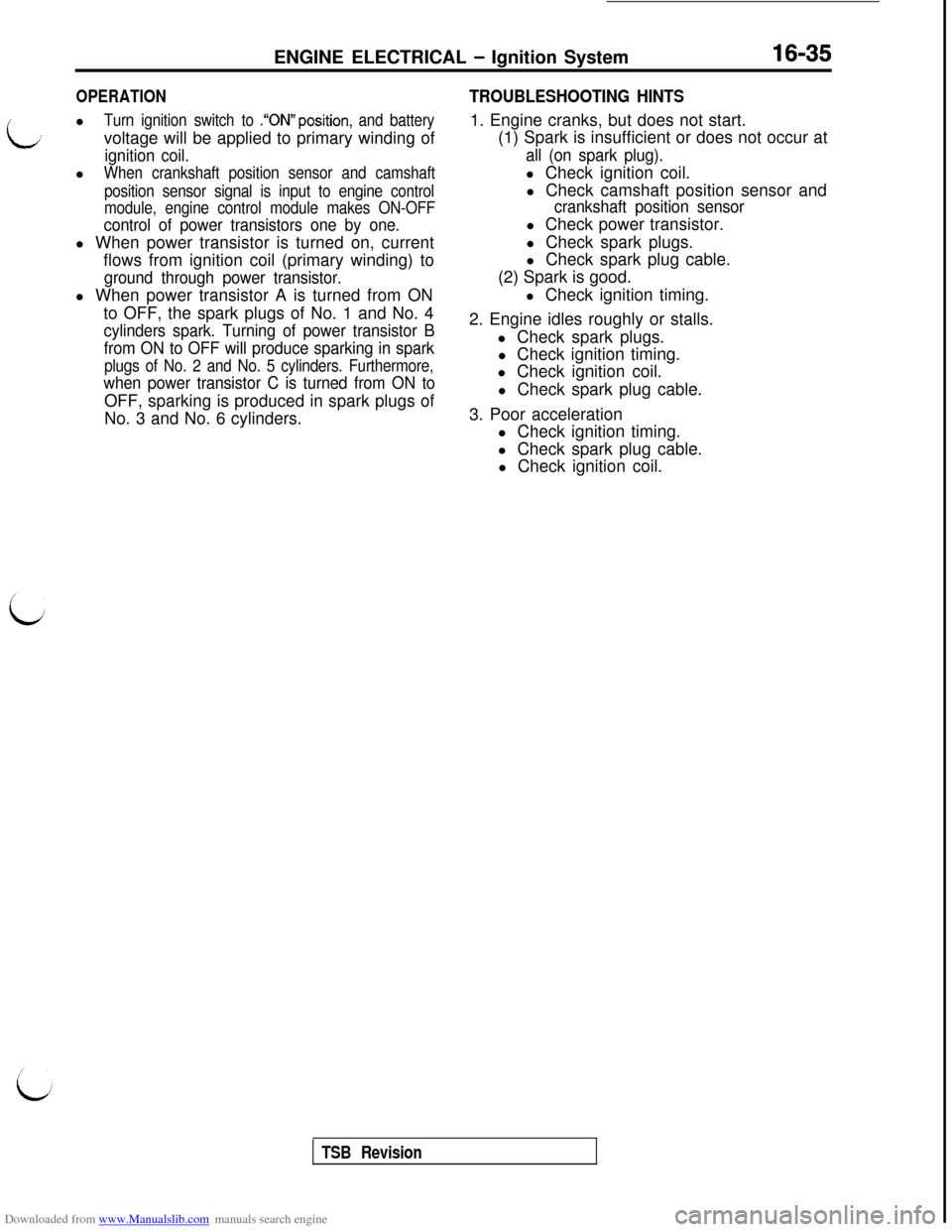

OPERATIONl

Turn ignition switch to .“ON”position, and batteryvoltage will be applied to primary winding of

ignition coil.l

When crankshaft position sensor and camshaft

position sensor signal is input to engine control

module, engine control module makes ON-OFF

control of power transistors one by one.l When power transistor is turned on, current

flows from ignition coil (primary winding) to

ground through power transistor.l When power transistor A is turned from ON

to OFF, the spark plugs of No. 1 and No. 4

cylinders spark. Turning of power transistor B

from ON to OFF will produce sparking in spark

plugs of No. 2 and No. 5 cylinders. Furthermore,

when power transistor C is turned from ON toOFF, sparking is produced in spark plugs of

No. 3 and No. 6 cylinders.

TROUBLESHOOTING HINTS1. Engine cranks, but does not start.

(1) Spark is insufficient or does not occur at

all (on spark plug).l Check ignition coil.

l Check camshaft position sensor and

crankshaft position sensorl Check power transistor.

l Check spark plugs.

l Check spark plug cable.

(2) Spark is good.

l Check ignition timing.

2. Engine idles roughly or stalls.

l Check spark plugs.

l Check ignition timing.

l Check ignition coil.

l Check spark plug cable.

3. Poor acceleration

l Check ignition timing.

l Check spark plug cable.

l Check ignition coil.

TSB Revision

Page 491 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-45 l

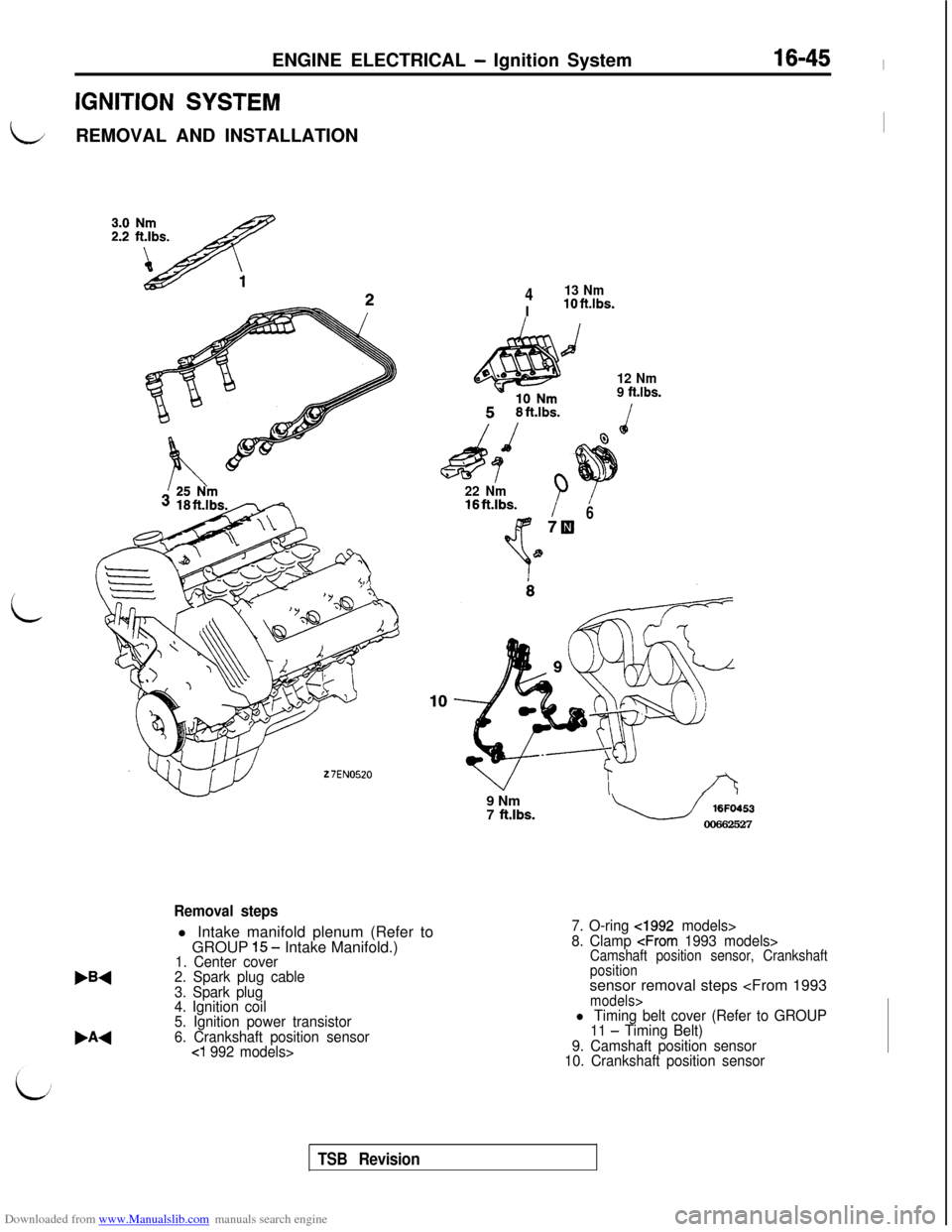

IGNITION SYSTEM

LREMOVAL AND INSTALLATIONI

i

27EN0520

413 NmIlOft.lbs.

d

12 Nm

9 ft.lbs.

22 Nm16ftAbs.B678

W1

,A4

Removal stepsl Intake manifold plenum (Refer to

GROUP

1.5 - Intake Manifold.)1. Center cover

2. Spark plug cable

3. Spark plug

4. Ignition coil

5. Ignition power transistor

6. Crankshaft position sensor

cl 992 models>9 Nm

7

ft.lbs.u 16FO453

00662527

7. O-ring cl992 models>

8. Clamp

positionsensor removal steps

11 - Timing Belt)

9. Camshaft position sensor

10. Crankshaft position sensor

TSB Revision

Page 494 of 738

Downloaded from www.Manualslib.com manuals search engine 16-48ENGINE ELECTRICAL - lanition Svstem

\/27EL0086

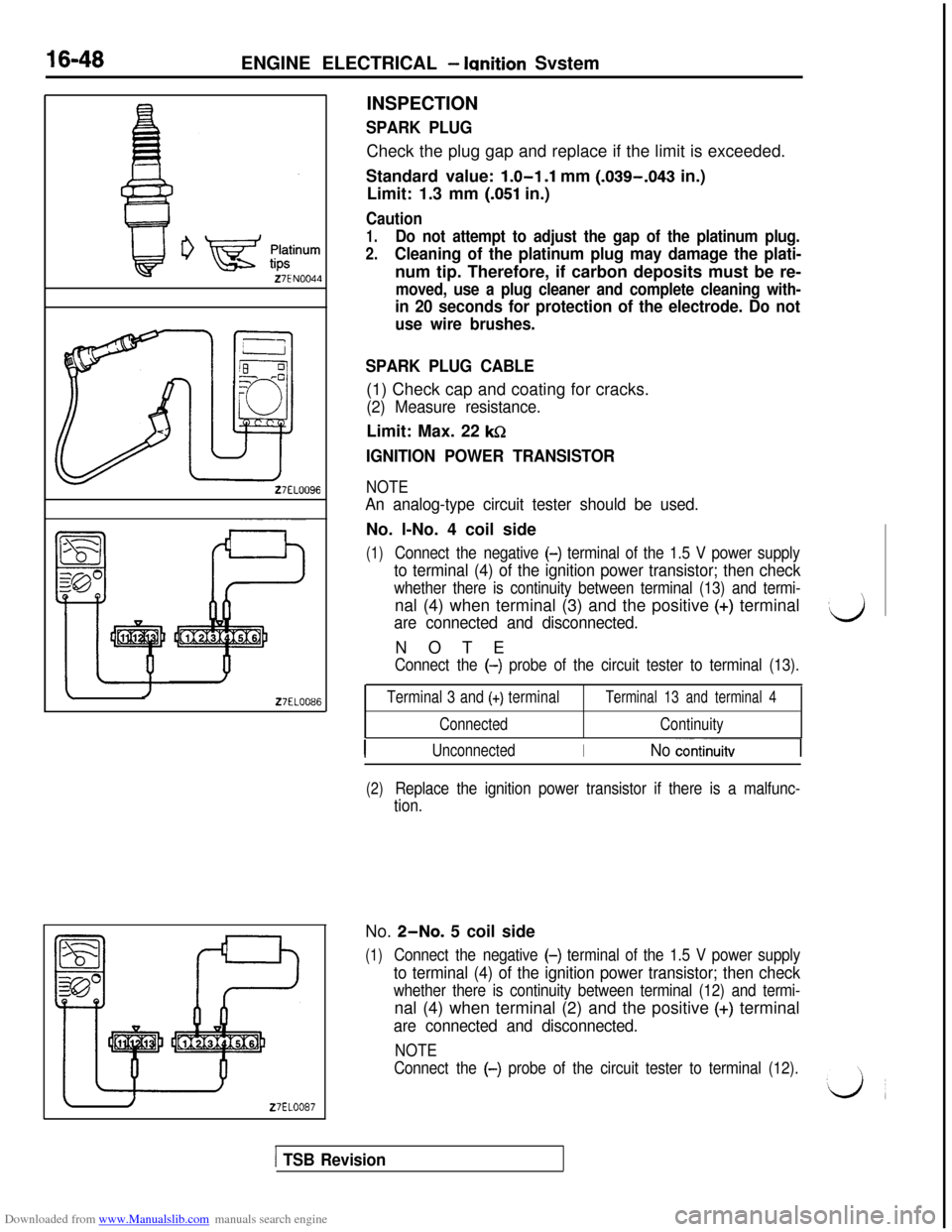

/DEL0087INSPECTION

SPARK PLUGCheck the plug gap and replace if the limit is exceeded.

Standard value:

1.0-l .l mm (.039-.043 in.)

Limit: 1.3 mm

(.051 in.)

Caution

1.Do not attempt to adjust the gap of the platinum plug.

2.Cleaning of the platinum plug may damage the plati-num tip. Therefore, if carbon deposits must be re-

moved, use a plug cleaner and complete cleaning with-

in 20 seconds for protection of the electrode. Do not

use wire brushes.

SPARK PLUG CABLE(1) Check cap and coating for cracks.

(2) Measure resistance.Limit: Max. 22

ksZ

IGNITION POWER TRANSISTOR

NOTE

An analog-type circuit tester should be used.No. l-No. 4 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (13) and termi-nal (4) when terminal (3) and the positive

(+) terminal

are connected and disconnected.NOTE

Connect the (-) probe of the circuit tester to terminal (13).

Terminal 3 and (+) terminal

ConnectedTerminal 13 and terminal 4

Continuity

IUnconnectedINo continuitv

(2)Replace the ignition power transistor if there is a malfunc-

tion.No. ~-NO. 5 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (12) and termi-nal (4) when terminal (2) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-)

probe of the circuit tester to terminal (12).

[ TSB Revision

Page 495 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL b Ignition System16-49

27EL0089

Z7ELOOQO

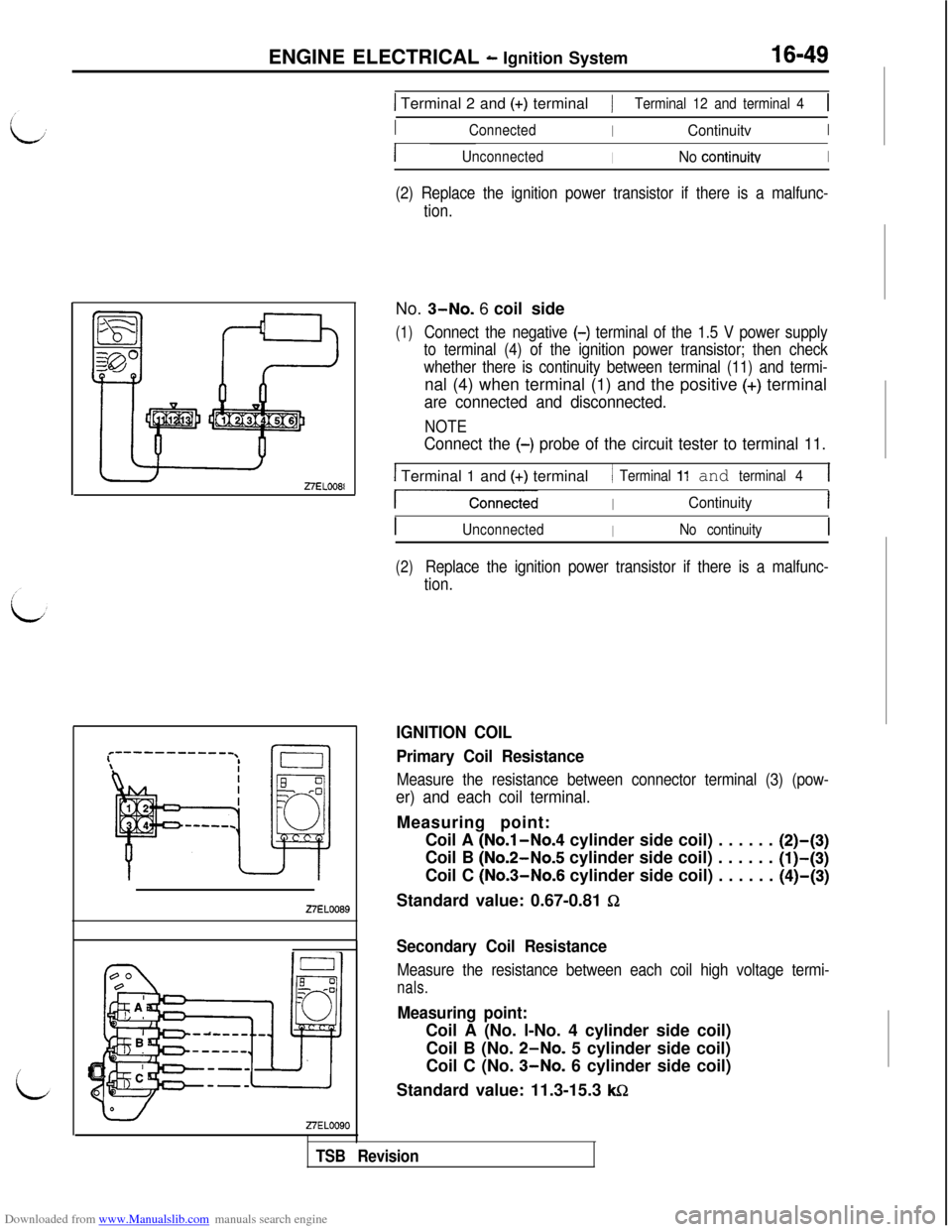

1 Terminal 2 and (+) terminal/Terminal 12 and terminal 41

IConnectedIContinuitvI

IUnconnectedINo continuitvI

(2) Replace the ignition power transistor if there is a malfunc-

tion.No. ~-NO. 6 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (11) and termi-nal (4) when terminal (1) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-) probe of the circuit tester to terminal 11.

I Terminal 1 and (+) terminal/ Terminal 11 and terminal 41

-ConnectedIContinuityI

IUnconnectedINo continuityI

(2)Replace the ignition power transistor if there is a malfunc-

tion.

IGNITION COIL

Primary Coil Resistance

Measure the resistance between connector terminal (3) (pow-

er) and each coil terminal.Measuring point:

Coil A

(No.l-No.4 cylinder side coil) . . . . . . (2)-(3)Coil B (No.2-No.5 cylinder side coil) . . . . . .

(l)-(3)Coil C (No.3-No.6 cylinder side coil) . . . . . .

(4)-(3)Standard value: 0.67-0.81

Sz

TSB Revision

Secondary Coil Resistance

Measure the resistance between each coil high voltage termi-

nals.

Measuring point:Coil A (No. l-No. 4 cylinder side coil)

Coil B (No. ~-NO. 5 cylinder side coil)

Coil C (No. ~-NO. 6 cylinder side coil)

Standard value: 11.3-15.3

Wz

Page 523 of 738

Downloaded from www.Manualslib.com manuals search engine I,;CHASSIS ELECTRICAL

- Meters and Gauges54-27

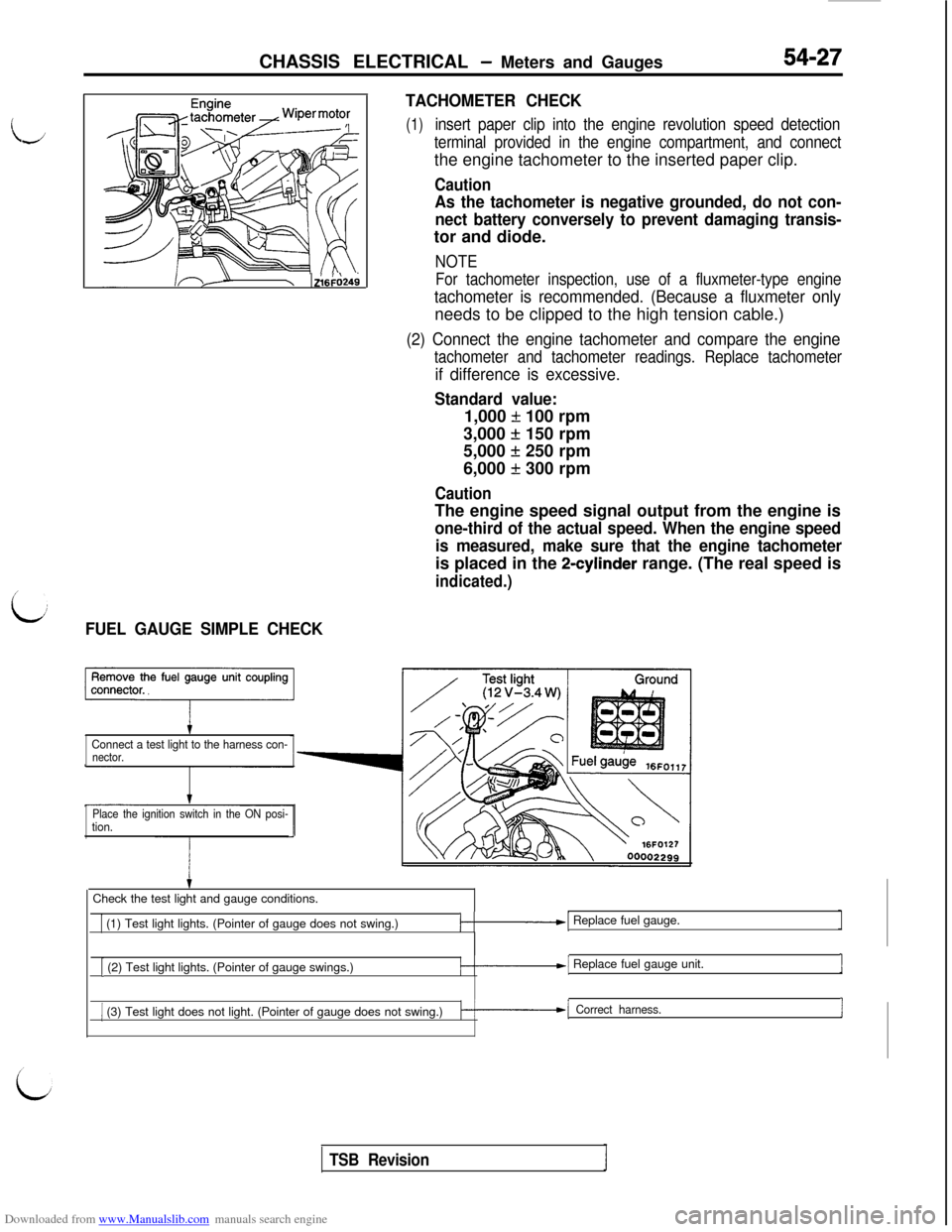

c I\\ zl6F024;

L:FUEL GAUGE SIMPLE CHECKTACHOMETER CHECK

(1)insert paper clip into the engine revolution speed detection

terminal provided in the engine compartment, and connectthe engine tachometer to the inserted paper clip.

Caution

As the tachometer is negative grounded, do not con-

nect battery conversely to prevent damaging transis-tor and diode.

NOTE

For tachometer inspection, use of a fluxmeter-type engine

tachometer is recommended. (Because a fluxmeter onlyneeds to be clipped to the high tension cable.)

(2) Connect the engine tachometer and compare the engine

tachometer and tachometer readings. Replace tachometer

if difference is excessive.

Standard value:1,000

f 100 rpm

3,000

+ 150 rpm

5,000

f 250 rpm

6,000

f 300 rpm

CautionThe engine speed signal output from the engine is

one-third of the actual speed. When the engine speed

is measured, make sure that the engine tachometeris placed in the

2-cylinder range. (The real speed is

indicated.)

Connect a test light to the harness con-nector.

Place the ignition switch in the ON posi-

tion.Check the test light and gauge conditions.

1 (1) Test light lights. (Pointer of gauge does not swing.)/-.-I Replace fuel gauge.

[ (2) Test light lights. (Pointer of gauge swings.)/-.--I Replace fuel gauge unit.1

1 (3) Test light does not light. (Pointer of gauge does not swing.)k-1 Correct harness.I

TSB Revision

Page 527 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauges54-31

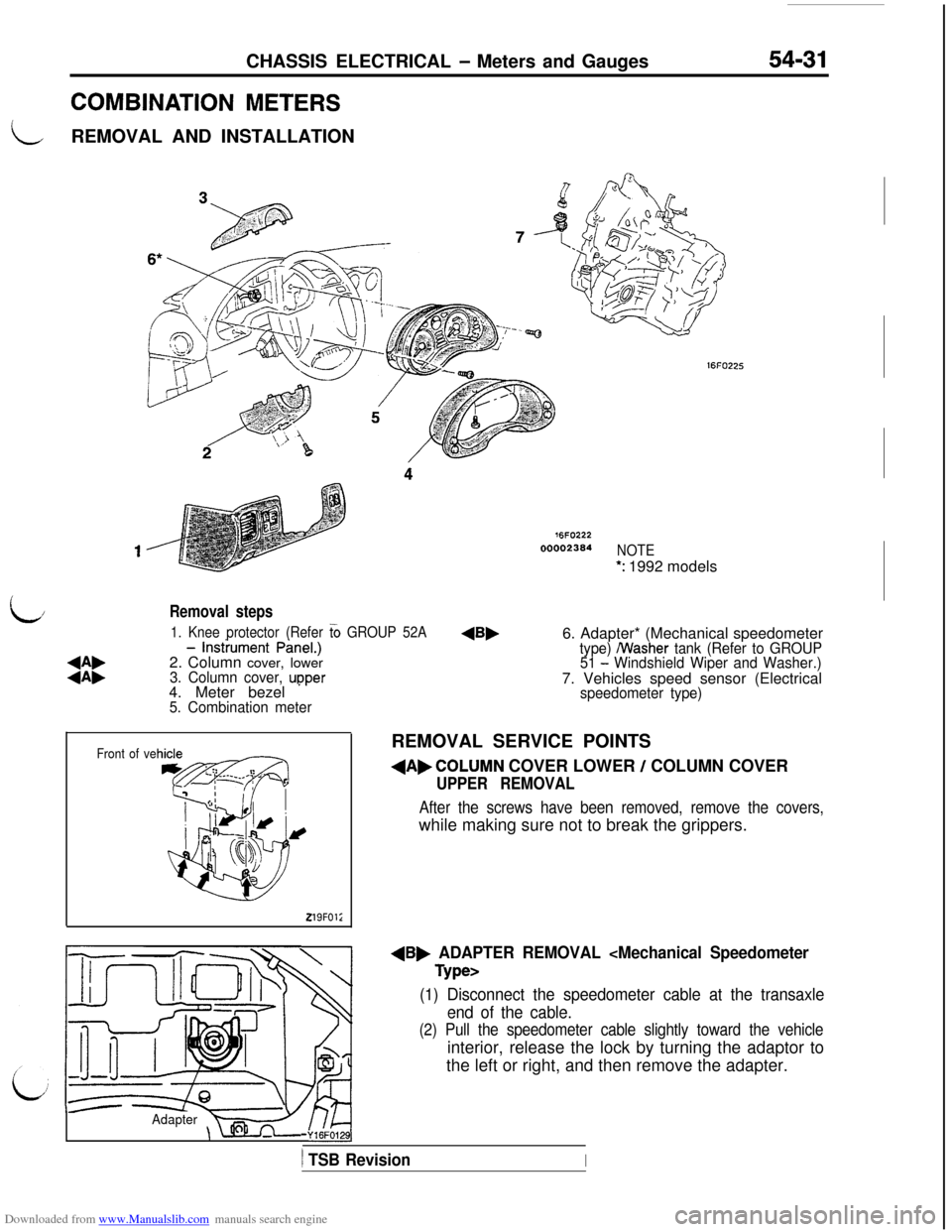

COMBINATION METERS

LREMOVAL AND INSTALLATION

76FO22200002364

NOTE

*: 1992 models

L/

:i:

- lnstiument PineI.)

2. Column cover, lower

3. Column cover, upper 1. Knee protector (Refer

G GROUP 52A4. Meter bezel

* ’5. Combination meter

Removal steps6. Adapter* (Mechanical speedometer

type) /Washer tank (Refer to GROUP

51 - Windshield Wiper and Washer.)7. Vehicles speed sensor (Electrical

Front of ve

219FOl;

speedometer type)REMOVAL SERVICE POINTS

dAbCOLUMN COVER LOWER / COLUMN COVER

UPPER REMOVAL

After the screws have been removed, remove the covers,while making sure not to break the grippers.

dB, ADAPTER REMOVAL

(1) Disconnect the speedometer cable at the transaxle

end of the cable.

(2) Pull the speedometer cable slightly toward the vehicleinterior, release the lock by turning the adaptor to

the left or right, and then remove the adapter.

Adapter-Y16FO129],

) TSB RevisionI