Power transistor MITSUBISHI 3000GT 1994 2.G Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1994, Model line: 3000GT, Model: MITSUBISHI 3000GT 1994 2.GPages: 738, PDF Size: 35.06 MB

Page 301 of 738

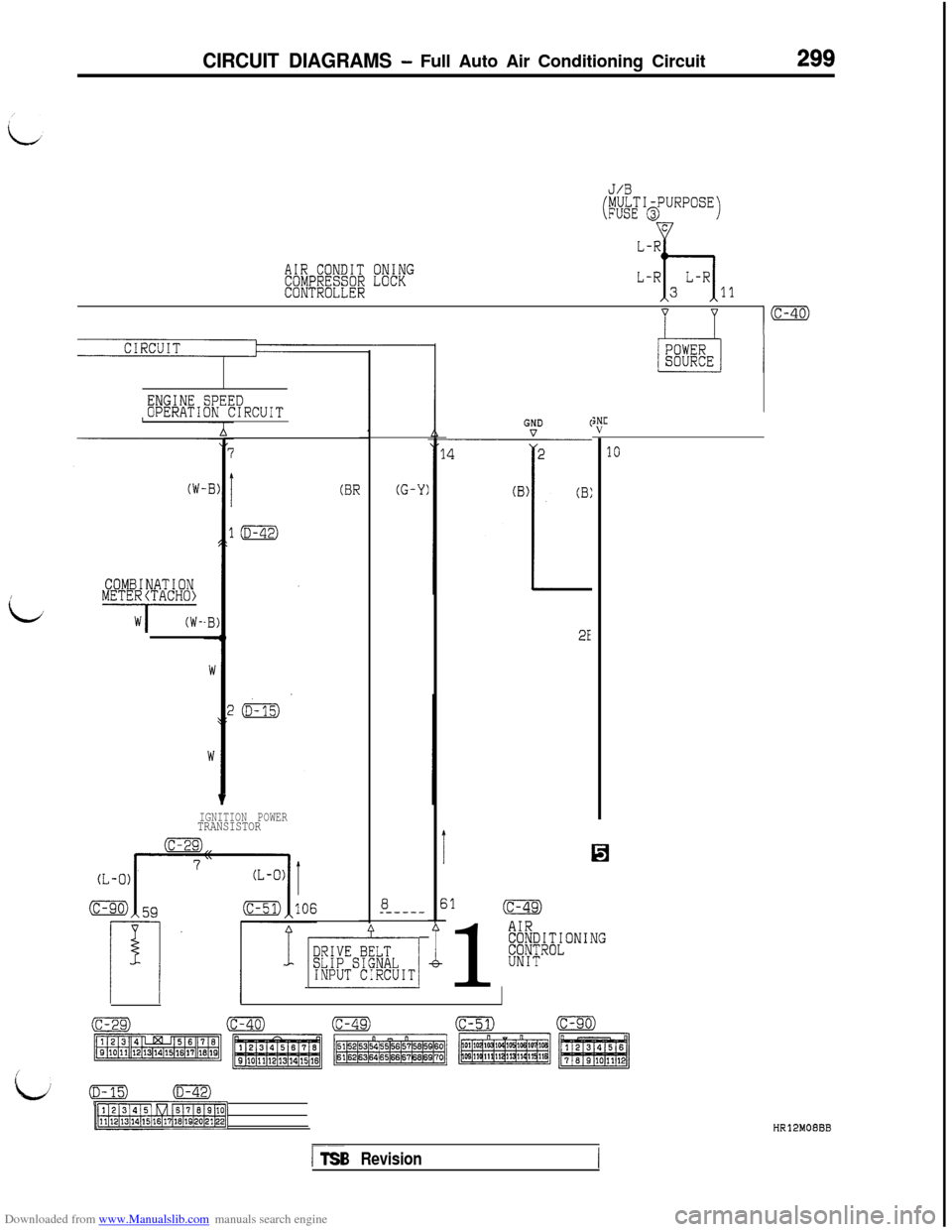

Downloaded from www.Manualslib.com manuals search engine CIRCUIT DIAGRAMS - Full Auto Air Conditioning Circuit299

AIR CONDITCOMPRESSORCONTROLLER

ONINGLOCK

J/B

(MULTI-PURPOSEFUSE @JC

L-R

h

L-RL-R311

ENGINE SPEEDOPERATION CIRCUIT

COMBINATION~METE~/TACH~~-

(BR

IGNITION POWERTRANSISTOR

8_-----

1 p&,-1

(G-Y)

I

E-

;NCV

2E%

;1(c-49)1

AIRE8/~Cl~~ONING

UNIT

10

(c-29)(c-40)(c-49)(c-51)(c-90)

pjz$zmg:,-1

/

kv/(D-15)(D-42)

p?lRq-1HR12MOEBB

r--TSB Revision

Page 302 of 738

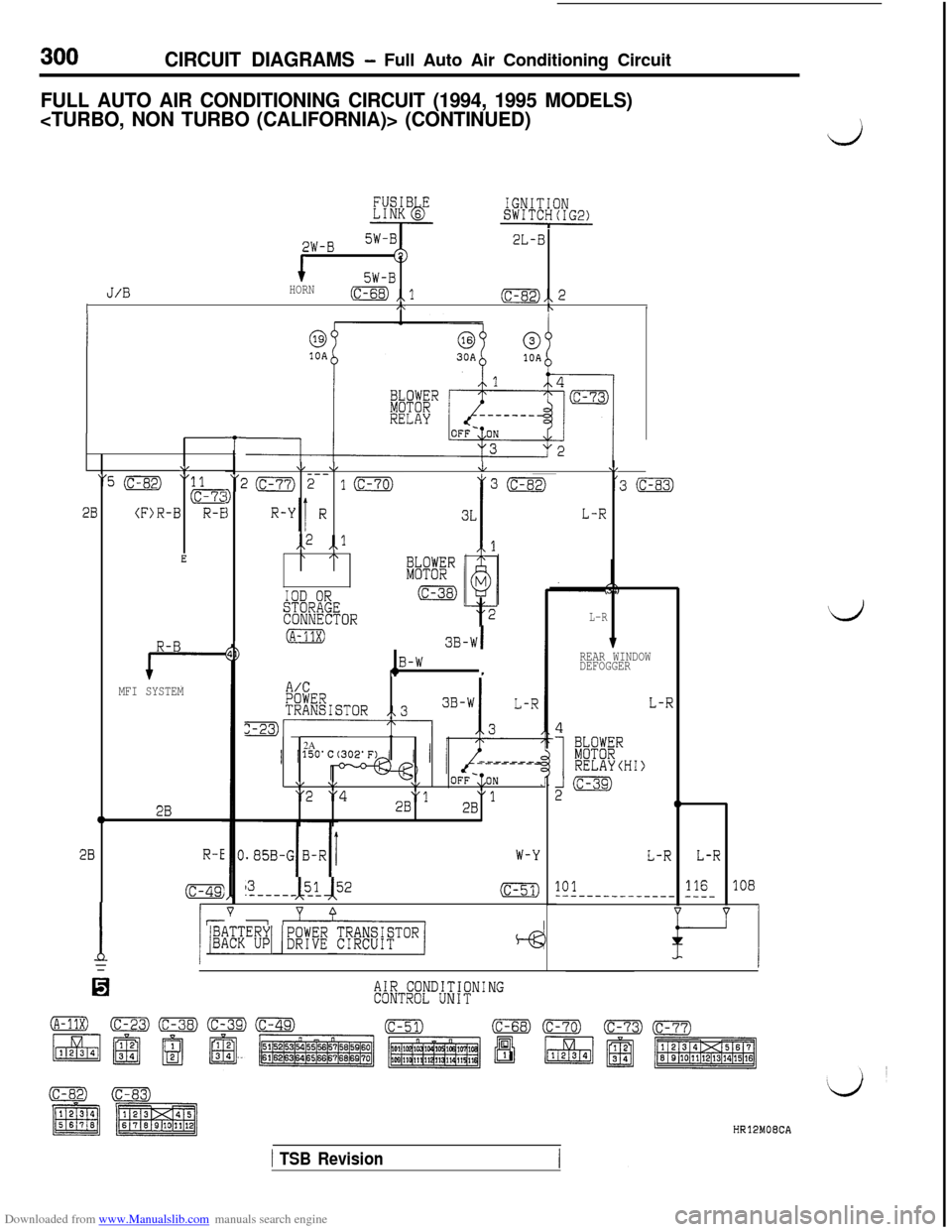

Downloaded from www.Manualslib.com manuals search engine 300CIRCUIT DIAGRAMS - Full Auto Air Conditioning Circuit

FULL AUTO AIR CONDITIONING CIRCUIT (1994, 1995 MODELS)

i

2W-B2L-B

15W-BJ/BHORN(c-68) ,,lI(c-82),, 2,\bI

\/

"5 (c-82)"

28(F)R-B

E

R-B

MFI SYSTEM

02B

28R-E

(c-49:

I15

13I, 151 52.-----_ __(c-51)

v 0--

1 /%Z”BpYI (EKE RfiF8iaToRj

T

\I \IJV

‘20 2-- 10D'3 (c-83)

jL-R

,,2 ,,l\ /\

IOD ORSTORAGECONNECTORL-R

(A-11X)3B-WI

,2B-W1

A/CPOWERTRANSISTOR,,3

m-------.-2A------__1\I \,\/OFF-,;ON"2 "428"1"12B

W-Y

TREAR WINDOW

DEFOGGER

L-R

4

I

BkPKRRELAYCHI)

2m

0

L-RL-R

101116108------___------ -___

Lj

AIR CONDITIONINGCONTROL UNIT

HR12MOECA

1 TSB Revision

Page 309 of 738

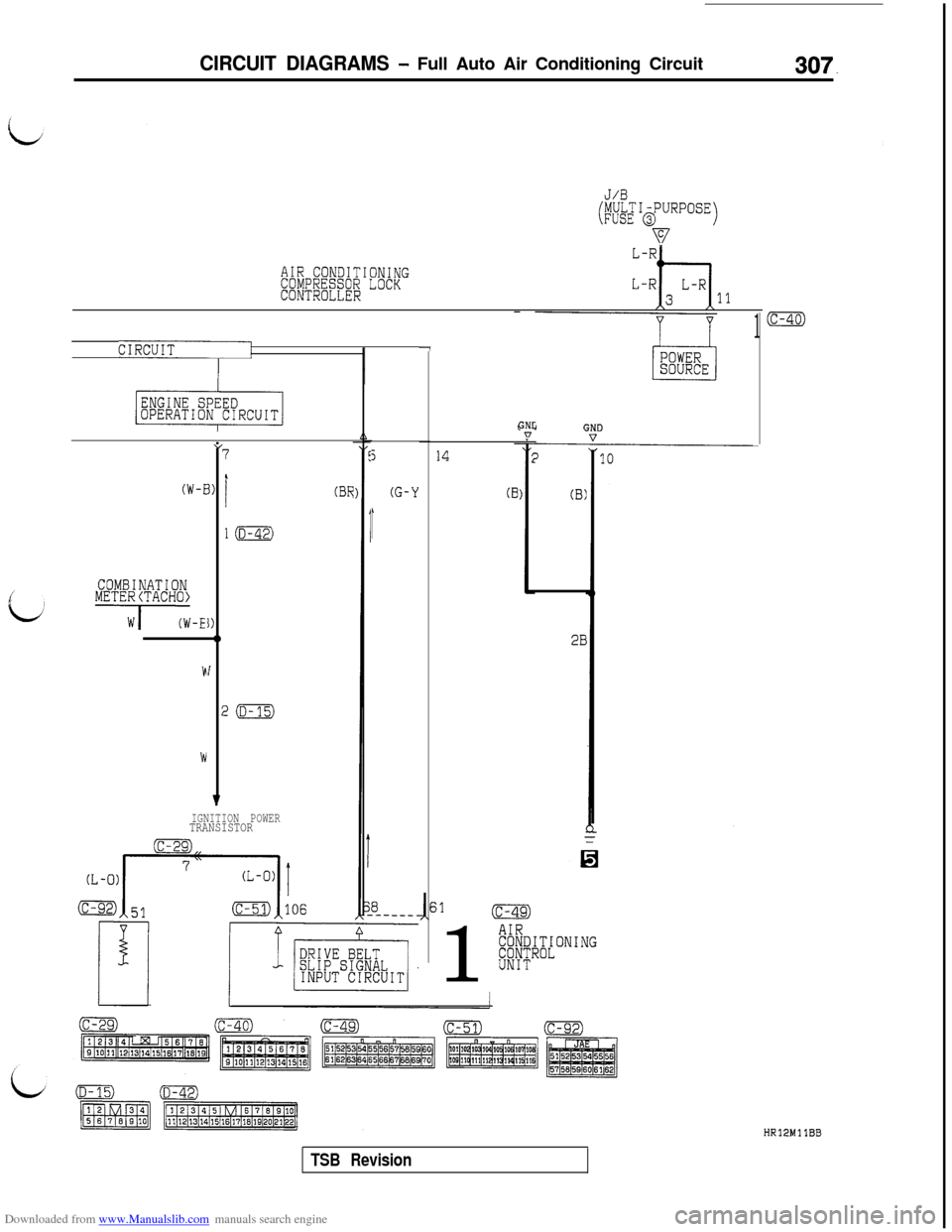

Downloaded from www.Manualslib.com manuals search engine CIRCUIT DIAGRAMS - Full Auto Air Conditioning Circuit307.

J/B

(MULTI-PURPOSEFUSE @)

v

AIR CONDITIONINGCOMPRESSOR LOCKCONTROLLER11

1

CIRCUITpj-7

(W-E

cvCOMBINATIONMETE~iTACH~~-I”

r

1)

I)-lb

I

;

v

7

I

l(D-42)

!m

IGNITION POWERTRANSISTOR

(BR

5

(G-Y

,

14

(B

GNL:n

(B)

2B1

AIR#/;~;[ONING

UNIT

(c-40)

HR12MllBB

TSB Revision

Page 310 of 738

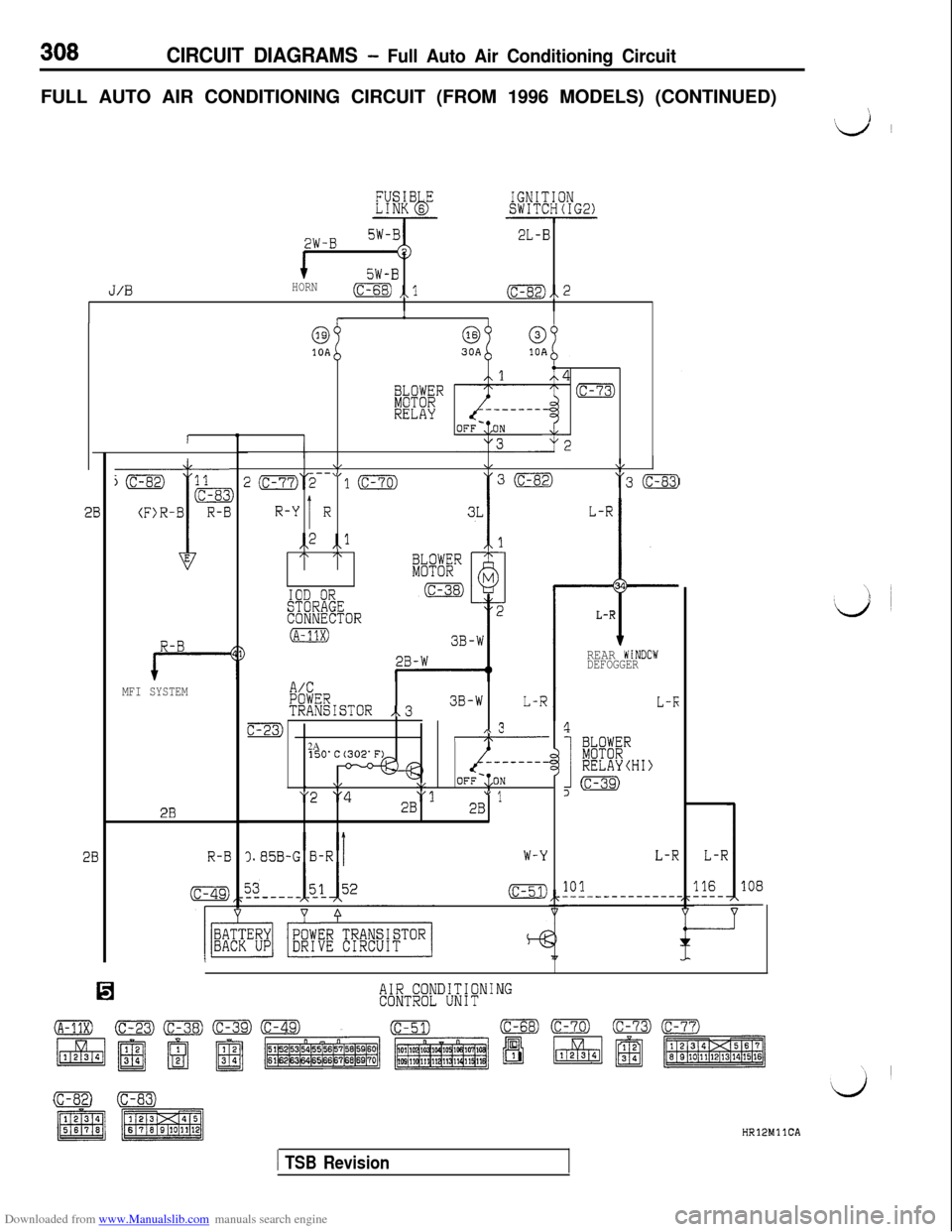

Downloaded from www.Manualslib.com manuals search engine CIRCUIT DIAGRAMS - Full Auto Air Conditioning CircuitFULL AUTO AIR CONDITIONING CIRCUIT (FROM 1996 MODELS) (CONTINUED)

\

‘d ~

2W-B2L-B

5W-B

J/0HORN(c-68) ,,l(c-82),, 2

R-B

MFI SYSTEM

2B

R-E

1

6310A

4

iFBR(c-73)

RELAY

\,&\/T- \I

J2(c-77)2-- 10"3 (c-83)

IR-Y Ri,2 ,,lI\ /\

IOD ORSTORAGECONNECTOR

(A-11X)

L-R

t

34

L-R

A/CPOWERTRANSISTOR ,.33B-WL-R

c-23),\ 3I\2A- - - - - - - -,

\,\/OFF-:,ON

"2 "4"12B" 12B

).85B-G B-RW-Y

(c-51)

REAR WiNDOWDEFOGGER

L-K

4

I

k%"RELAYCHI)

,m

L-RL-R

101116108-

AIR CONDITIONINGCONTROL UNIT

(c-se)0HRlPMllCA

1 TSB Revision

Page 478 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - lanition Svstem

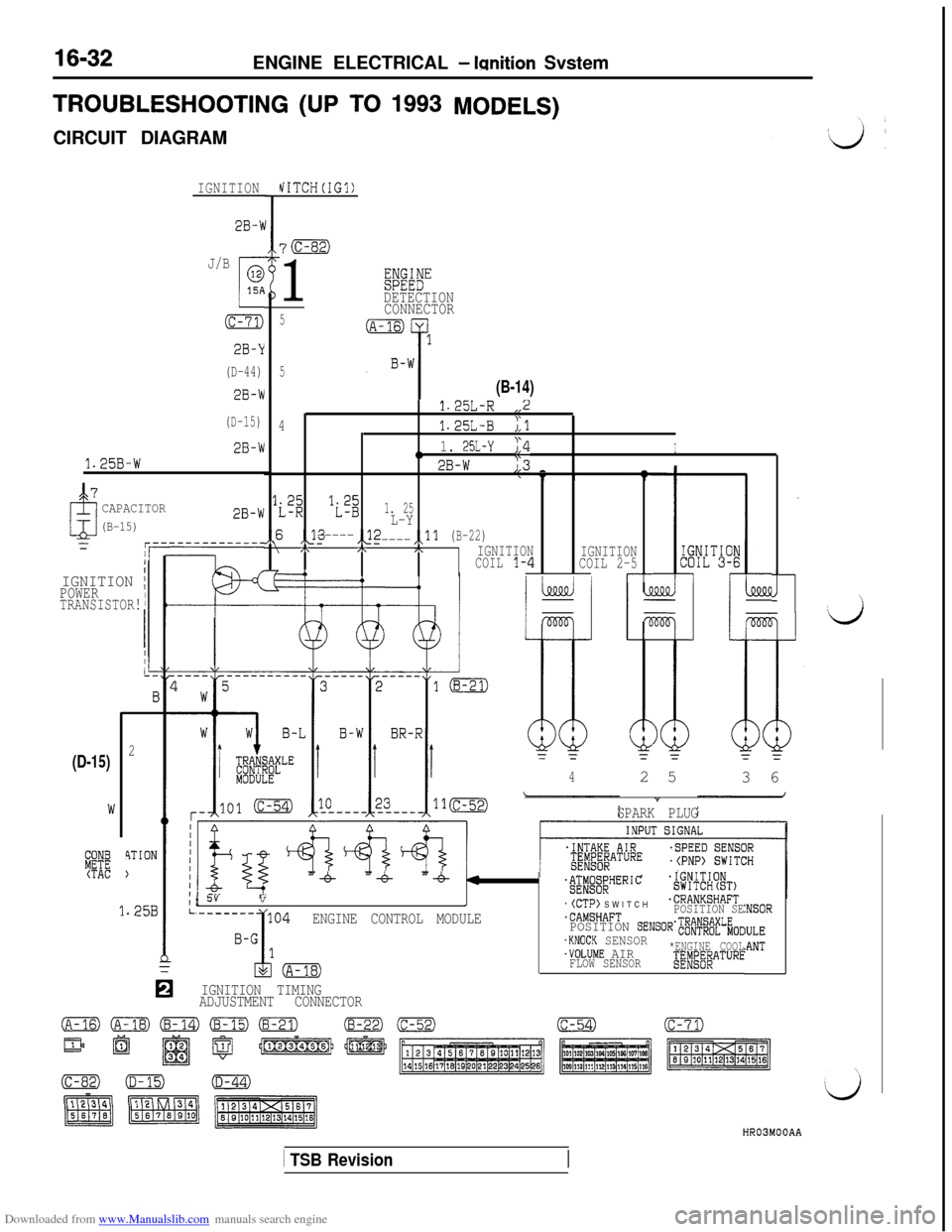

TROUBLESHOOTING (UP TO 1993MODELS)CIRCUIT DIAGRAM

IGNITIONhiITCH(IG1)

2B-X

7m

1

J/B

c

015A

(c-71)

2B-Y

(D-44)

2B-W

(D-15)

2B-W

1.25B-W

@%t”DETECTION

CONNECTOR

5

5

(B-14)

1.25L-R,,2

41.25L-B;,l

,,1. 25L-Y;,4I

2B-W23_

y;'$1. 25L-Y

A6 ,P-----,\22-----,,ll(B-22) /\,h,\IGNITION

IGNITIONCOIL1-4COIL2-5-r--

CAPACITOR

(B-15)2B-W

1/IGNITION IPOWERTRANSISTOR!rl

2

4TION

)

(D-15)

3%(TAC

42 5

3 6

”

SPARK PLUG

1.25B

IIIIIIII1IL

“-6% “-6 “-4%4;ig;f;HERIC.IGNITIONSWITCHtST)/ 5vv.(CTP) SWITCH.CRANKSHAFT

.CAMSHAFTPOSITION SEENGINE CONTROL MODULEPOSITION SENSOR';#$;~L;oc.KNOCK SENSOR.VOLUME AIR*ENGINE COOL

FLOW SENSOR;ED&f$AT"RE

:NSOR

IULE:ANT

IGNITION TIMING

ADJUSTMENT CONNECTOR

HR03MOOAA

1 TSB Revision

Page 480 of 738

Downloaded from www.Manualslib.com manuals search engine 16-34ENGINE ELECTRICAL - Ignition System

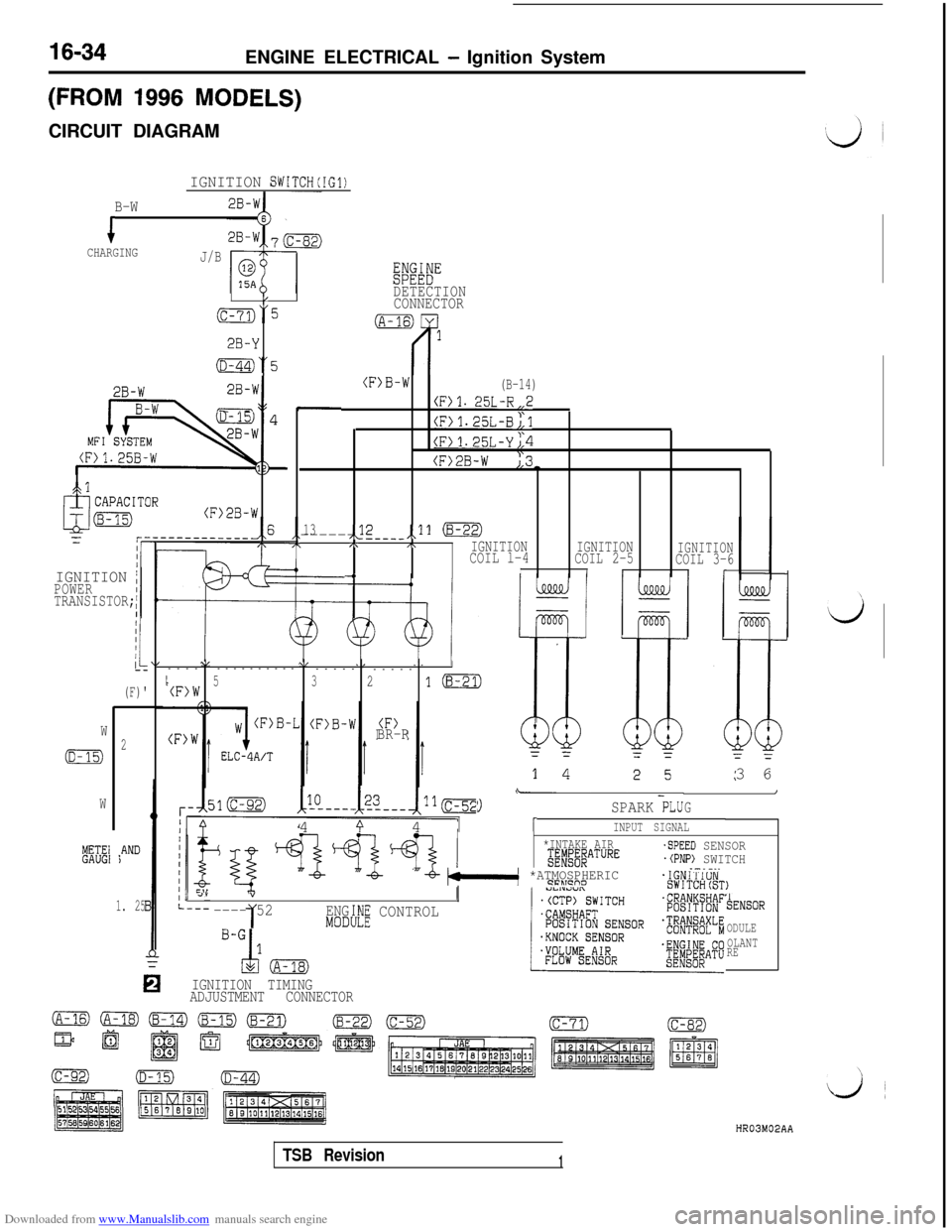

(FROM 1996 MODELS)CIRCUIT DIAGRAM

IGNITION SWITCH(IG1)

B-W

iCHARGINGJ/B

Eiwi"

/DETECTION

(c-73)“5CONNECTOR

2B-Y

(D-44)“5

2B-W-I

2B-W

MFILS - --

(F>B-W(B-14)

(F)l. 25L-R,,2

(F)1.25L-B;,l

(F>1.25L-Yj,4

(F>2B-W ),3-

.

13,<2------ ---__,,11 (8-22),\,\IGNITIONCOIL l-4IGNITION

COIL 2-5IGNITIONCOIL 3-6-4III(r

,cl

(F>2B-W

IGNITION /POWER

TRANSISTOR;

I

(F)'

\I\/,I--------------

-----

-----

I5(F)W321m

BR-RW

(D-15)2

W

METE1GAUGI*AND)3 6

\-I

G9SPARK PLU4

9 41INPUT SIGNAL

*INTAKE AIRg;#j#ATURE

"-b- bkl *ATMOSPHERIC9FLTcno

-SPEED SENSOR.(PNP) SWITCH.-.-..

, 4””

---- 521ENG:h!E CONTROLMODI

TENSOR

ODULE

OLANT

RE

IGNITION TIMING

ADJUSTMENT CONNECTOR

1. 25

HR03M02AA

TSB Revision1

Page 481 of 738

Downloaded from www.Manualslib.com manuals search engine i;ENGINE ELECTRICAL

- Ignition System16-35

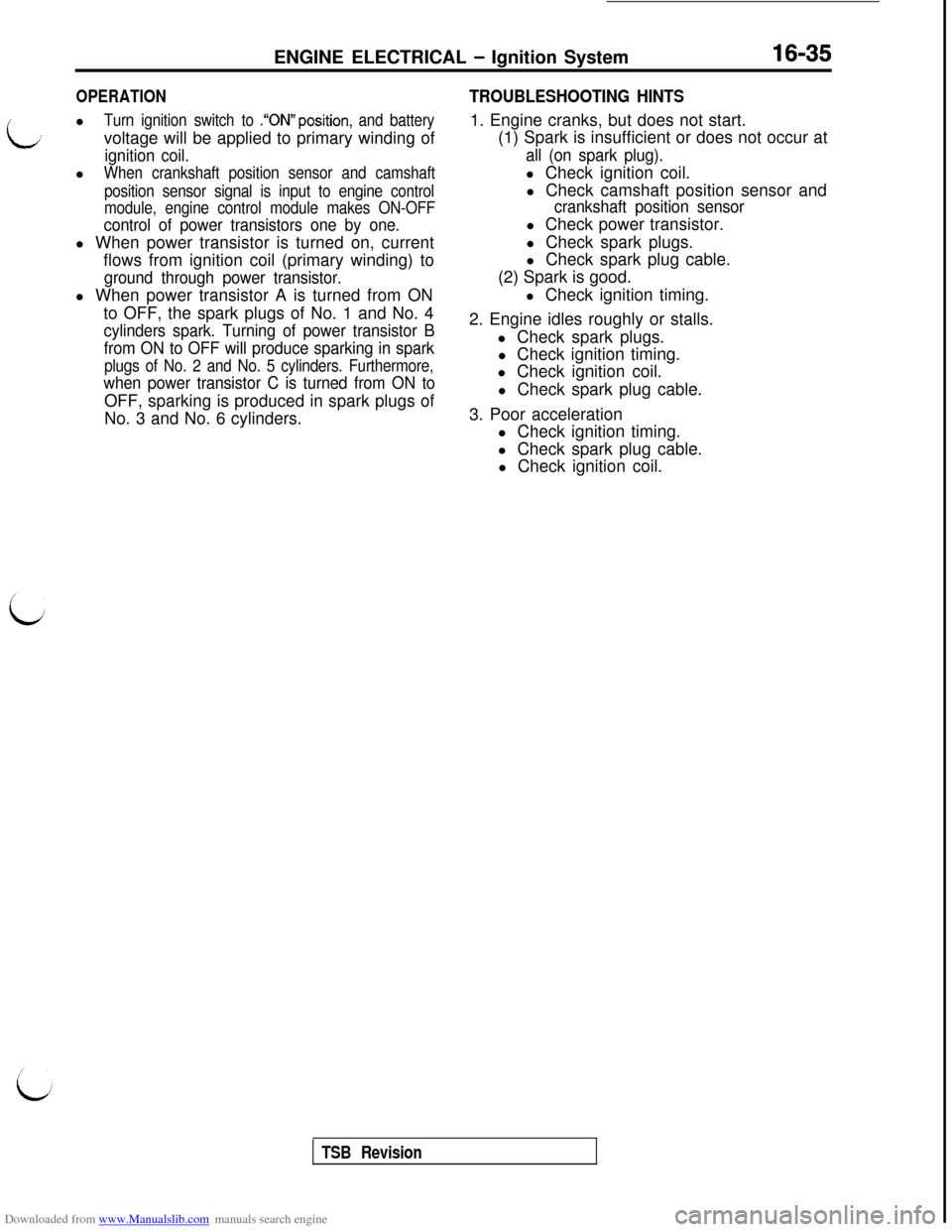

OPERATIONl

Turn ignition switch to .“ON”position, and batteryvoltage will be applied to primary winding of

ignition coil.l

When crankshaft position sensor and camshaft

position sensor signal is input to engine control

module, engine control module makes ON-OFF

control of power transistors one by one.l When power transistor is turned on, current

flows from ignition coil (primary winding) to

ground through power transistor.l When power transistor A is turned from ON

to OFF, the spark plugs of No. 1 and No. 4

cylinders spark. Turning of power transistor B

from ON to OFF will produce sparking in spark

plugs of No. 2 and No. 5 cylinders. Furthermore,

when power transistor C is turned from ON toOFF, sparking is produced in spark plugs of

No. 3 and No. 6 cylinders.

TROUBLESHOOTING HINTS1. Engine cranks, but does not start.

(1) Spark is insufficient or does not occur at

all (on spark plug).l Check ignition coil.

l Check camshaft position sensor and

crankshaft position sensorl Check power transistor.

l Check spark plugs.

l Check spark plug cable.

(2) Spark is good.

l Check ignition timing.

2. Engine idles roughly or stalls.

l Check spark plugs.

l Check ignition timing.

l Check ignition coil.

l Check spark plug cable.

3. Poor acceleration

l Check ignition timing.

l Check spark plug cable.

l Check ignition coil.

TSB Revision

Page 491 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-45 l

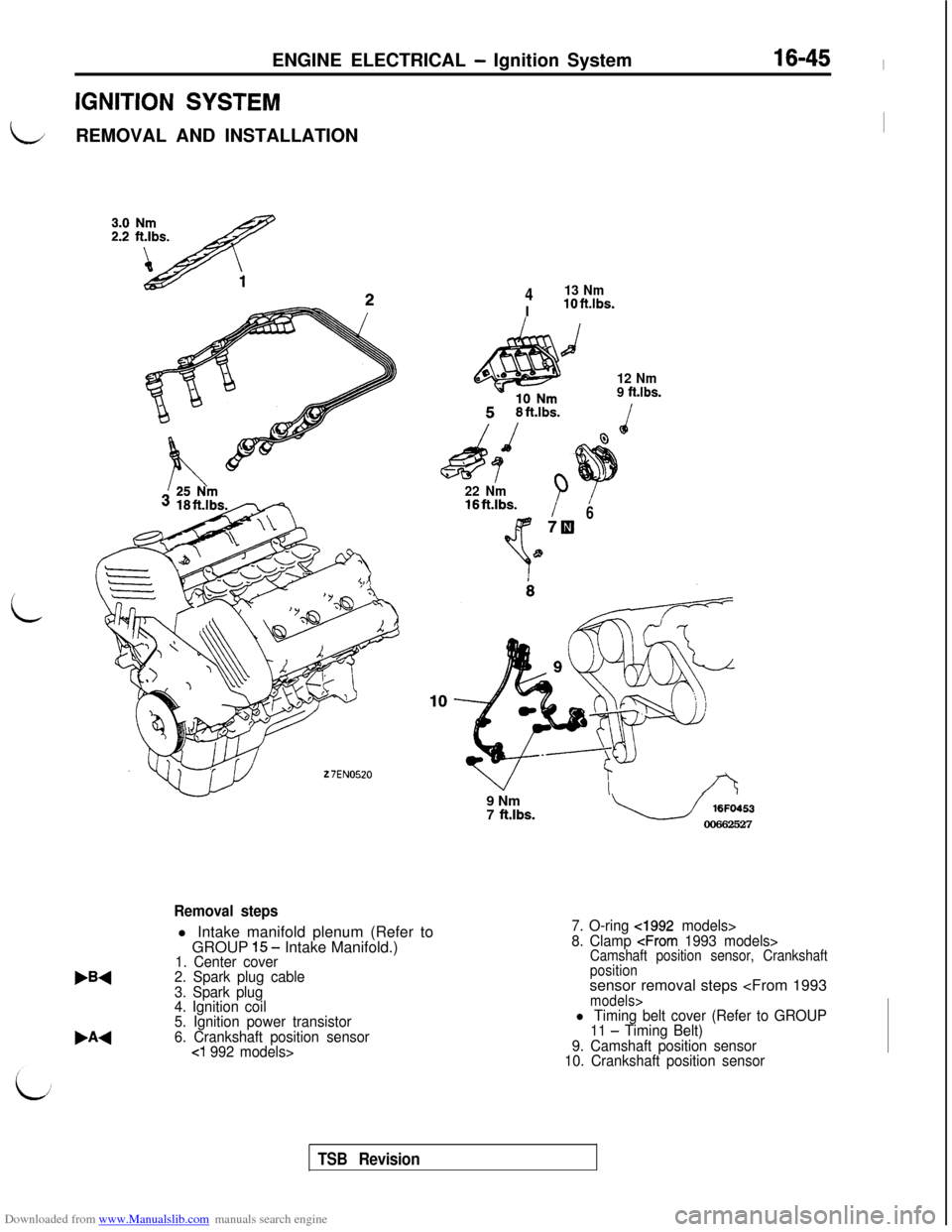

IGNITION SYSTEM

LREMOVAL AND INSTALLATIONI

i

27EN0520

413 NmIlOft.lbs.

d

12 Nm

9 ft.lbs.

22 Nm16ftAbs.B678

W1

,A4

Removal stepsl Intake manifold plenum (Refer to

GROUP

1.5 - Intake Manifold.)1. Center cover

2. Spark plug cable

3. Spark plug

4. Ignition coil

5. Ignition power transistor

6. Crankshaft position sensor

cl 992 models>9 Nm

7

ft.lbs.u 16FO453

00662527

7. O-ring cl992 models>

8. Clamp

positionsensor removal steps

11 - Timing Belt)

9. Camshaft position sensor

10. Crankshaft position sensor

TSB Revision

Page 494 of 738

Downloaded from www.Manualslib.com manuals search engine 16-48ENGINE ELECTRICAL - lanition Svstem

\/27EL0086

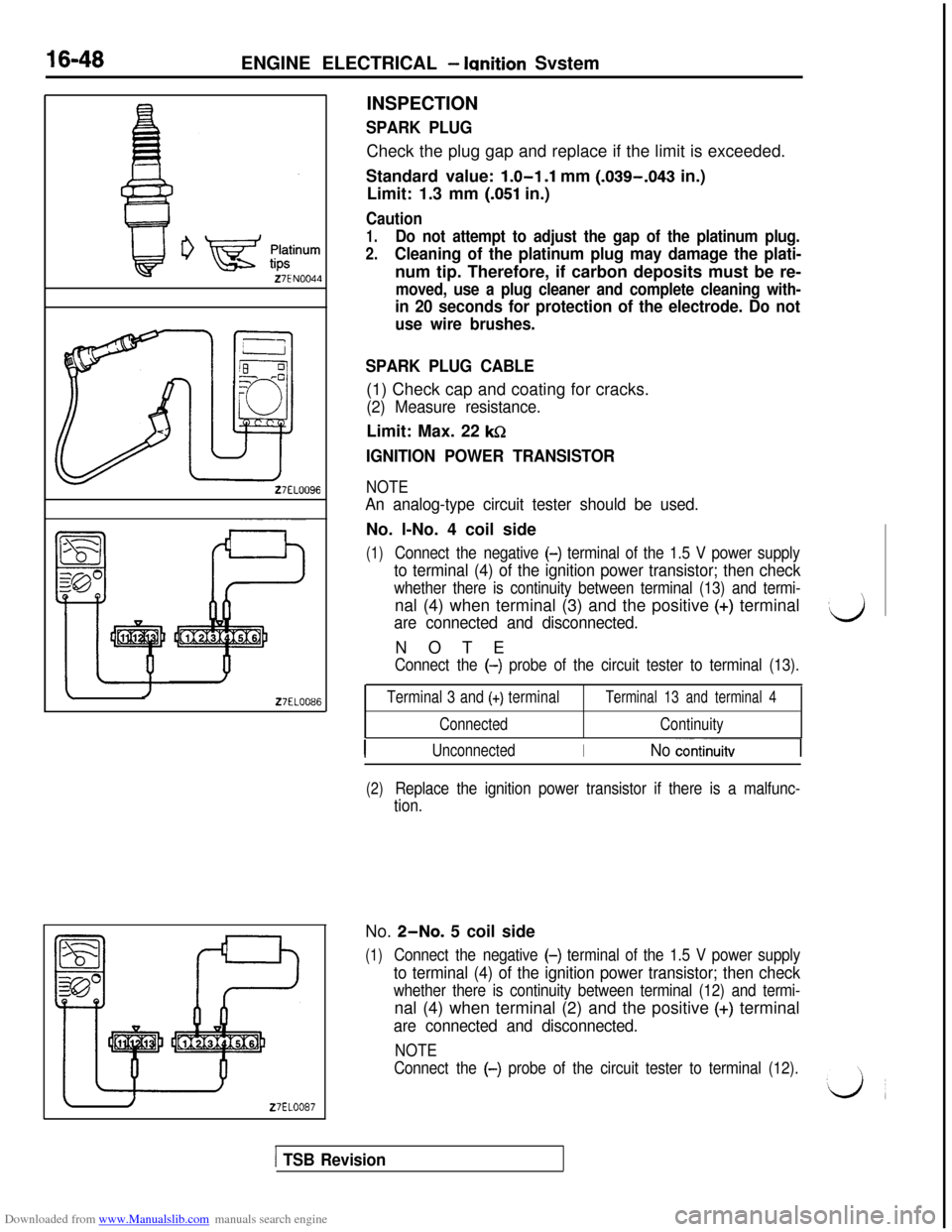

/DEL0087INSPECTION

SPARK PLUGCheck the plug gap and replace if the limit is exceeded.

Standard value:

1.0-l .l mm (.039-.043 in.)

Limit: 1.3 mm

(.051 in.)

Caution

1.Do not attempt to adjust the gap of the platinum plug.

2.Cleaning of the platinum plug may damage the plati-num tip. Therefore, if carbon deposits must be re-

moved, use a plug cleaner and complete cleaning with-

in 20 seconds for protection of the electrode. Do not

use wire brushes.

SPARK PLUG CABLE(1) Check cap and coating for cracks.

(2) Measure resistance.Limit: Max. 22

ksZ

IGNITION POWER TRANSISTOR

NOTE

An analog-type circuit tester should be used.No. l-No. 4 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (13) and termi-nal (4) when terminal (3) and the positive

(+) terminal

are connected and disconnected.NOTE

Connect the (-) probe of the circuit tester to terminal (13).

Terminal 3 and (+) terminal

ConnectedTerminal 13 and terminal 4

Continuity

IUnconnectedINo continuitv

(2)Replace the ignition power transistor if there is a malfunc-

tion.No. ~-NO. 5 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (12) and termi-nal (4) when terminal (2) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-)

probe of the circuit tester to terminal (12).

[ TSB Revision

Page 495 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL b Ignition System16-49

27EL0089

Z7ELOOQO

1 Terminal 2 and (+) terminal/Terminal 12 and terminal 41

IConnectedIContinuitvI

IUnconnectedINo continuitvI

(2) Replace the ignition power transistor if there is a malfunc-

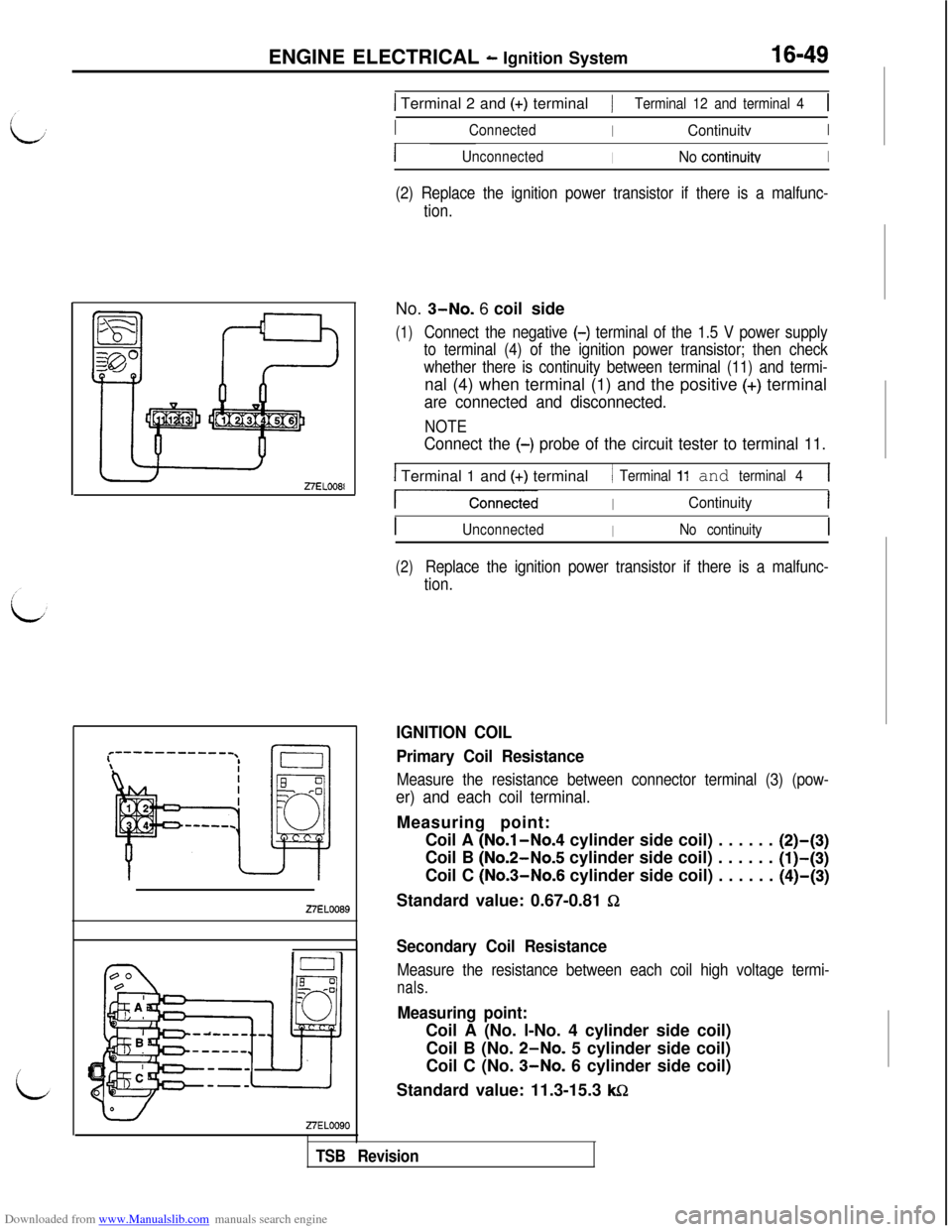

tion.No. ~-NO. 6 coil side

(1)Connect the negative (-) terminal of the 1.5 V power supply

to terminal (4) of the ignition power transistor; then check

whether there is continuity between terminal (11) and termi-nal (4) when terminal (1) and the positive

(+) terminal

are connected and disconnected.

NOTE

Connect the (-) probe of the circuit tester to terminal 11.

I Terminal 1 and (+) terminal/ Terminal 11 and terminal 41

-ConnectedIContinuityI

IUnconnectedINo continuityI

(2)Replace the ignition power transistor if there is a malfunc-

tion.

IGNITION COIL

Primary Coil Resistance

Measure the resistance between connector terminal (3) (pow-

er) and each coil terminal.Measuring point:

Coil A

(No.l-No.4 cylinder side coil) . . . . . . (2)-(3)Coil B (No.2-No.5 cylinder side coil) . . . . . .

(l)-(3)Coil C (No.3-No.6 cylinder side coil) . . . . . .

(4)-(3)Standard value: 0.67-0.81

Sz

TSB Revision

Secondary Coil Resistance

Measure the resistance between each coil high voltage termi-

nals.

Measuring point:Coil A (No. l-No. 4 cylinder side coil)

Coil B (No. ~-NO. 5 cylinder side coil)

Coil C (No. ~-NO. 6 cylinder side coil)

Standard value: 11.3-15.3

Wz