High idle MITSUBISHI 3000GT 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1994, Model line: 3000GT, Model: MITSUBISHI 3000GT 1994 2.GPages: 738, PDF Size: 35.06 MB

Page 453 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-7/

L

(6) Connect a tachometer. (For the procedure for

connecting the tachometer, refer to GROUP

- On-vehicle Service.)(7)

kkconnect the negative battery cable.

(8) Leave the hood open.

(9) Start the engine.

(lO)With the engine running at 2500 rpm, turn the

headlights and other lights on and off to adjust

the generator load so that the value displayed

on the ammeter is slightly above 30A.Limit value: Max. 0.3 V

NOTE

When the generator output is high and the value

displayed on the ammeter does not decreaseto

30A, set the value to 40A. Read the value

displayed on the voltmeter at this time.

In this case the limit value becomes max. 0.4V.

Adjust the engine speed by gradually decreas-

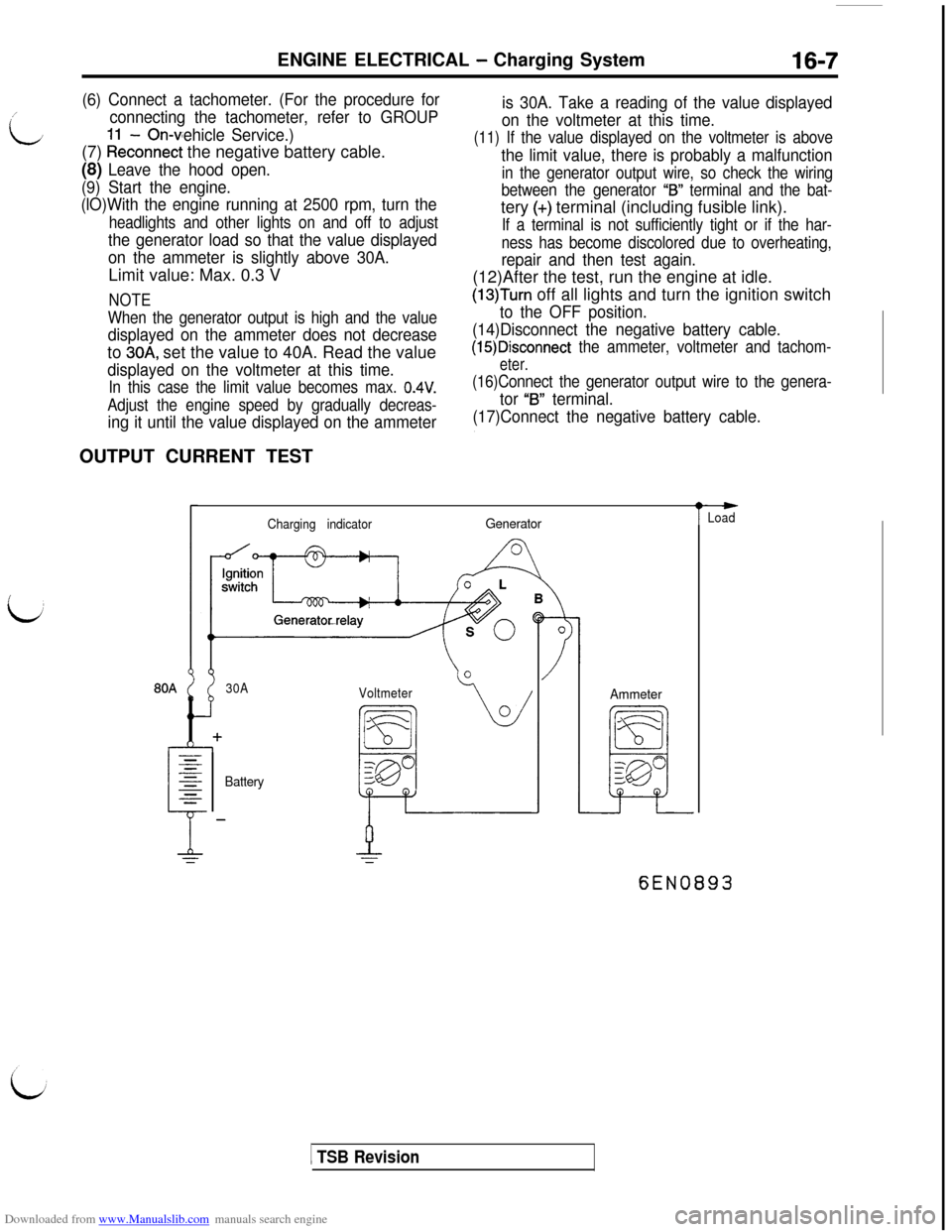

ing it until the value displayed on the ammeterOUTPUT CURRENT TEST

is 30A. Take a reading of the value displayed

on the voltmeter at this time.

(11) If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction

in the generator output wire, so check the wiring

between the generator

“IS” terminal and the bat-tery

(+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the har-

ness has become discolored due to overheating,

repair and then test again.(12)After the test, run the engine at idle.

(13)Turn off all lights and turn the ignition switch

to the OFF position.

(14)Disconnect the negative battery cable.

(15)Disconnect the ammeter, voltmeter and tachom-

eter.

(16)Connect the generator output wire to the genera-

tor “B” terminal.

(17)Connect the negative battery cable.

Charging indicatorGenerator

30A

Voltmeter

BatteryAmmeter

t

-Load

6EN0893

1 TSB Revision

Page 454 of 738

Downloaded from www.Manualslib.com manuals search engine 16-8ENGINE ELECTRICAL - Charging System

This test determines whether the generator outputs

normal current.(1) Before the test, always be sure to check the

following.l Generator installation

l

Battery (Refer to GROUP 54 - Battery.)

NOTE

The battery to be used should be slightly dis-charged. The load in a fully-charged battery

will be insufficient and the test may not be able

to be carried out correctly.l Generator drive belt tension (Refer to

GROUP 11- On-vehicle Service.)l Fusible link

l Abnormal noise from the generator while

the engine is running(2) Turn the ignition switch to the OFF position.

(3) Disconnect the negative battery cable.

(4) Disconnect the generator output wire from the

generator

“B” terminal and connect a DC testammeter with a range of O-100 A in series

between the “B” terminal and the disconnected

output wire. (Connect the

(+) lead of the amme-ter to the

“B” terminal, and then connect the(-) lead of the ammeter to the disconnected

output wire.)

Caution

Never use clips but tighten bolts and nutsto connect the line.

Otherwise loose

connections (e.g. using clips) will lead to

a serious accident because of high current.

NOTE

A clamp-type ammeter which enables measure-

ments to be taken without disconnecting the

generator output wire is recommended.(5) Connect a voltmeter with a range of 0

- 20

V between the generator “B” terminal and the

ground. (Connect the

(+) lead of the voltmeterto the “B” terminal, and then connect the (-)

lead of the voltmeter to the ground.)

(6) Connect a tachometer. (For the procedure forconnecting the tachometer, refer to GROUP

11 - On-vehicle Service.)

(7) Connect the negative battery cable.

(8) Leave the hood open.(9) Check to be sure that the reading on the

voltmeter is equal to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably an

open circuit in the wire or fusible link between

the generator “B” terminal and the battery

(+)

terminal.

(1O)After turning the light switch on and turning on

the headlights, start the engine.

(1l)lmmediately after setting the headlights to high

beam and turning the heater blower switch to

the high revolution position, increase the enginespeed to 2,500

r/min and read the maximum

current output value displayed on the ammeter.

Limit value: 70% of nominal current output

NOTEl

For the nominal current output, refer to the

Generator Specifications.l

Because the current from the battery will

soon drop after the engine is started, the

above step should be carried out as quickly

as possible in order to obtain the maximum

current output value.l The current output value will depend on

the electrical load and the temperature of

the generator body.l

If the electrical load is small while testing,the specified level of current may not be

output even though the generator is normal.

In such cases, increase the electrical load

by leaving the headlights turned on for sometime to discharge the battery or by using

the lighting system in another vehicle, and

then test again.l

The specified level of current also may not

be output if the temperature of the generator

body or the ambient temperature is too high.

In such cases, cool the generator and then

test again.

(12)The reading on the ammeter should be above

the limit value. If the reading is below the limit

value and the generator output wire is normal,

remove the generator from the engine and check

the generator.(13)Run the engine at idle speed after the test.

(14)Turn the ignition switch to the OFF position.

(15)Disconnect the negative battery cable.

(16)Disconnect the ammeter, voltmeter and

tachometer.(17)Connect the generator output wire to the

generator “B” terminal.

(18)Connect the negative battery cable.

TSB Revision

Page 484 of 738

Downloaded from www.Manualslib.com manuals search engine 16-38ENGINE ELECTRICAL - Ignition System

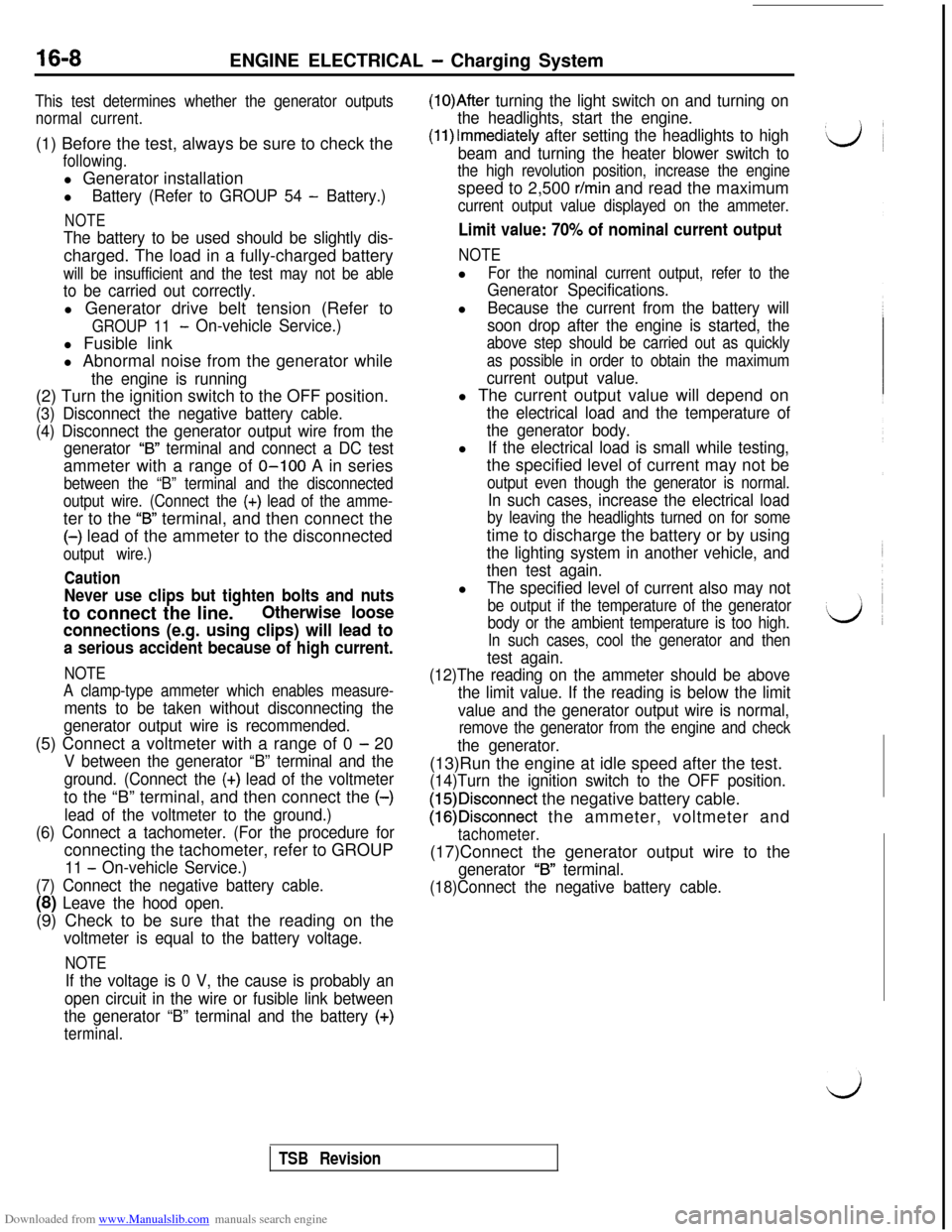

STANDARD WAVE-FORM

Observation Conditions

FUNCTIONSECONDARY

\

\j’i

IPATTERN HEIGHTHIGH (or LOW)1

PATTERN SELECTORRASTER

Engine revolutions

Curb idle speed

kV

Secondary

ignition

voltagewave-form

-6

Ignition voltage(Point D)

Dwell sectionSpark line (Point A)

/Wave damping reduction section

(Point B)

/

Time

7EL0147

Observation conditions (Only PAlTERN SELECTOR below changes from the above conditions)

PATTERN SELECTOR

DISPLAY

Secondary

ignition

voltagewave-formt

No. 1 Cylinder

No. 2 Cylinderignition noiseNo. 3 Cylinder

ignition noiseNo. 4 Cylinder

No. 5 CylinderNo. 6 Cylinder(Waveform is ignition noise ignition noise

TimeI)I7EL0148

1 TSB Revision

Page 487 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - lanition Svstem16-41

/

L

i

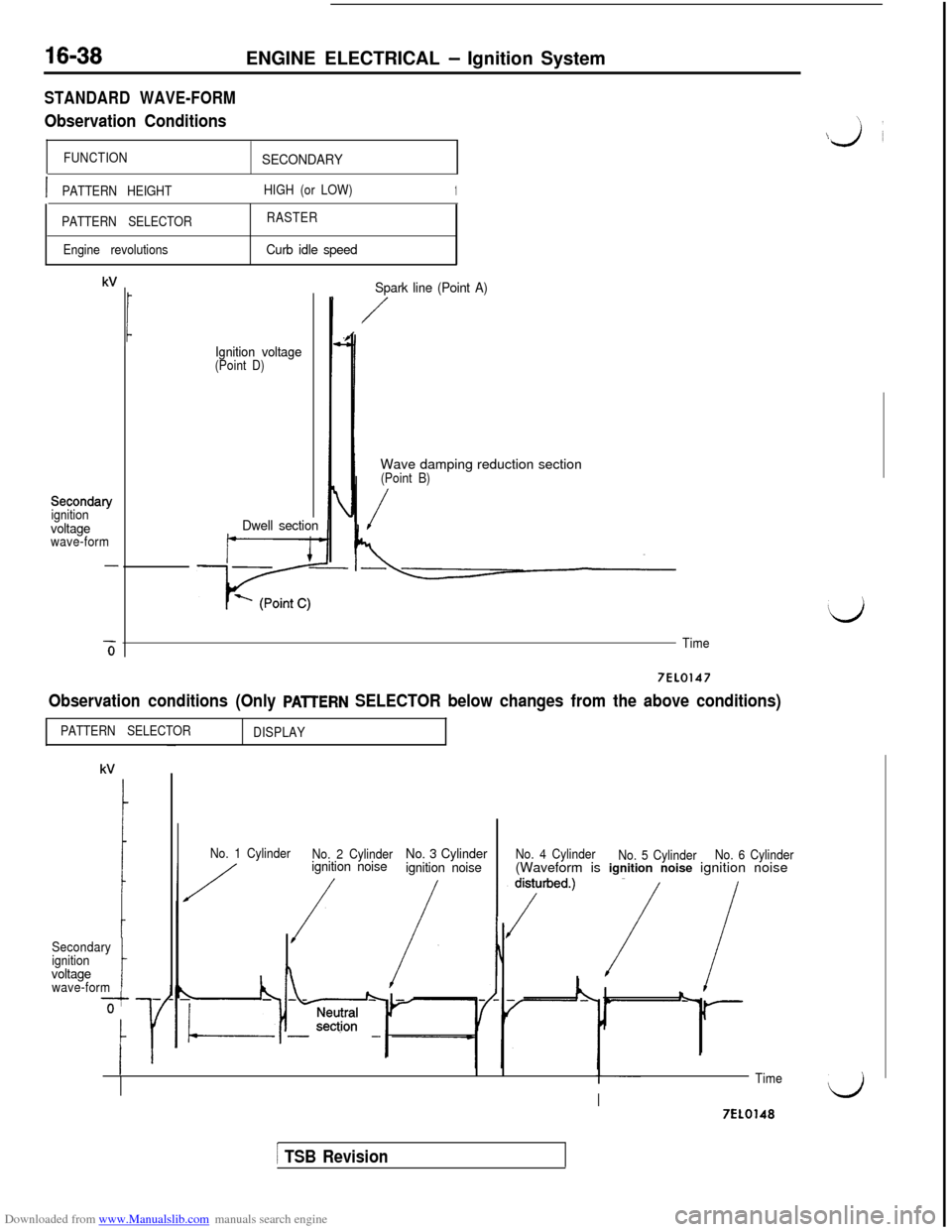

Analyzer

GroundL

01L1008

STANDARD WAVE-FORM

Observation ConditionsIGNITION PRIMARY VOLTAGE WAVE-FORM

CHECK

MEASUREMENT METHOD

(1)Remove the ignition coil connector and connect the special

tool (harness connector: MD998464) in between.

(2) When observing the No. 1 - No. 4 cylinder group, connectthe primary pickup of the analyzer probe to the ignition

coil side connector terminal No. 2 (black clip on the special

tool).

For the No. 2 - No. 5 cylinder group, connect to terminal

No. 1 (red clip), and for the No. 3

- No. 6 cylinder group,connect to terminal No. 4 (white clip).

(3) Ground the primary pickup ground terminal.

(4) Clamp the spark plug cable with the trigger pickup.

NOTE(1) Clamp the spark plug cable of cylinder No. 1, No.

2 or No. 3 which belongs to the same group of the

cylinder to which the primary pickup is connected.

(2) The wave-form of any cylinder in the same group

is displayed on the left side of the screen.

FUNCTION

PRIMARY

PATTERN HEIGHTHIGH (or LOW)

PAVERN SELECTOR

Engine revolutionsRASTER

Curb idle speed

(V)

100

Primary Primary*ignition ignition

voltage voltage

wave-form

owave-formkr

0

Zener

voltage

(Point C)

Dwell

section

b

Spark line (Point A)

/b-4

Wave damping reduction section (Point B)

/

Time

7EL0149

/ TSB Revision

Page 733 of 738

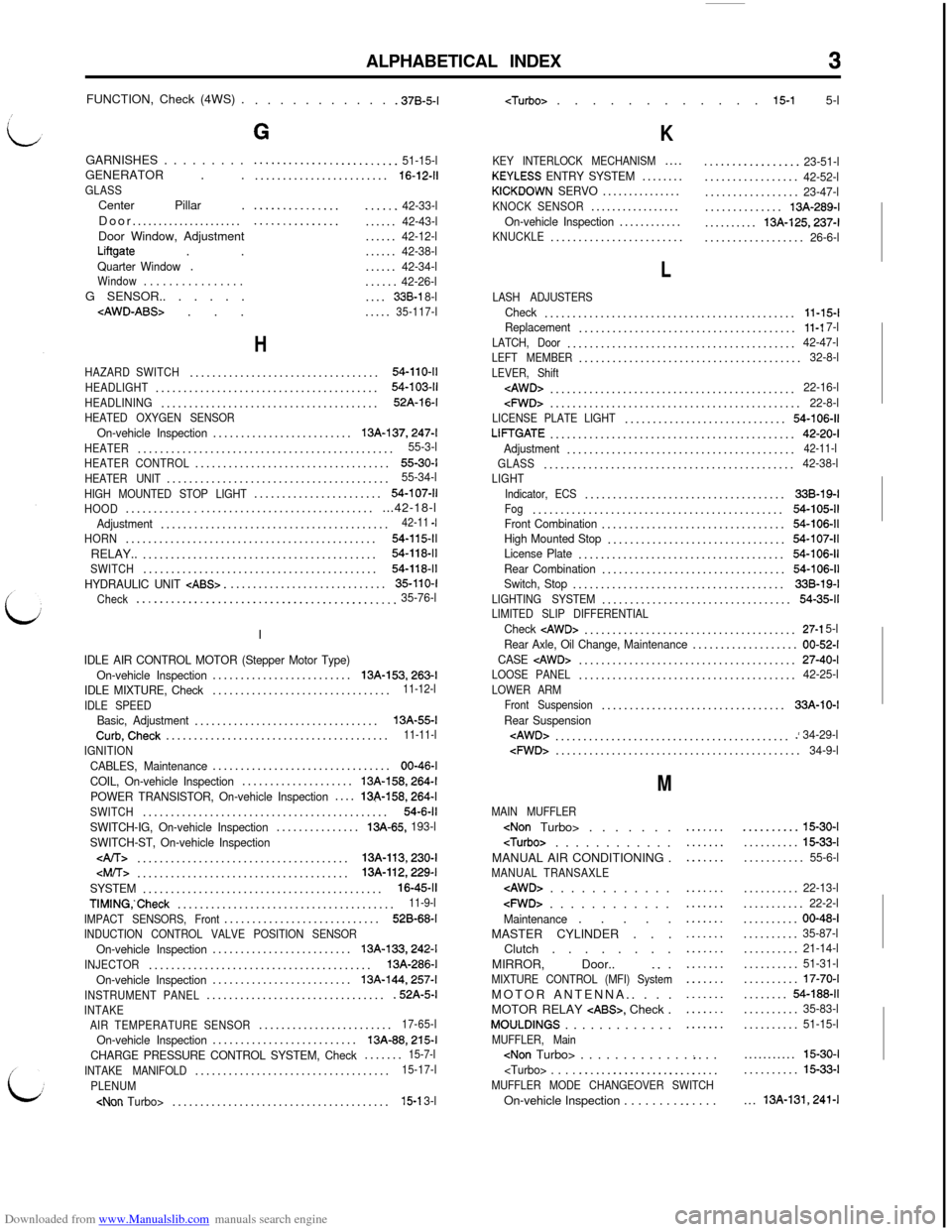

Downloaded from www.Manualslib.com manuals search engine ALPHABETICAL INDEX3FUNCTION, Check (4WS) .

. . . . . . . . . . . .37B-5-l

GARNISHES . . . . . . . . .

GENERATOR . .

GLASSCenter Pillar .

Door.....................

Door Window, Adjustment

Liftgate . .Quarter Window.Window. . . . . . . . . . . . . . . .G SENSOR.. . . . . .

G

.........................51-15-l........................16-12-11

.....................42-33-l.....................42-43-l......42-12-l......42-38-l......42-34-l......42-26-l....338-l 8-l.....35-117-l

H

HAZARD SWITCH..................................54-110-11

HEADLIGHT........................................54-103-11

HEADLINING.......................................52A-16-l

HEATED OXYGEN SENSOROn-vehicle Inspection.........................13A-137,247-l

HEATER..............................................55-3-l

HEATER CONTROL...................................55-30-I

HEATER UNIT........................................55-34-l

HIGH MOUNTED STOP LIGHT.......................54-107-11

HOOD...............................................42-18-lAdjustment.........................................42-11 -I

HORN.............................................54-115-11RELAY..

..........................................54-118-11

SWITCH..........................................54-118-11

HYDRAULIC UNIT CABS>.............................35-110-I

Check

.............................................35-76-lI

IDLE AIR CONTROL MOTOR (Stepper Motor Type)

On-vehicle Inspection.........................13A-153,263-l

IDLE MIXTURE, Check................................11-12-l

IDLE SPEED

Basic, Adjustment.................................13A-55-lCurb,Check........................................11-11-l

IGNITION

CABLES, Maintenance................................00-46-l

COIL, On-vehicle Inspection....................

13A-158,264-l

POWER TRANSISTOR, On-vehicle Inspection....13&158,264-l

SWITCH............................................54-6-11

SWITCH-IG, On-vehicle Inspection...............13A-65, 193-l

SWITCH-ST, On-vehicle Inspection

......................................13A-113,230-l

SYSTEM...........................................16-45-11

TIMING,‘Check.......................................11-9-l

IMPACT SENSORS, Front............................528-68-I

INDUCTION CONTROL VALVE POSITION SENSOROn-vehicle Inspection.........................13A-133,242-l

INJECTOR........................................13A-286-l

On-vehicle Inspection.........................

13A-144,257-l

INSTRUMENT PANEL.................................52A-5-lINTAKE

AIR TEMPERATURE SENSOR........................17-65-l

On-vehicle Inspection..........................13A-88,215-l

CHARGE PRESSURE CONTROL SYSTEM, Check.......15-7-l

INTAKE MANIFOLD...................................15-17-l

PLENUM

K

KEY INTERLOCK MECHANISM....KEYLESS ENTRY SYSTEM........KICKDOWN SERVO...............KNOCK SENSOR.................On-vehicle Inspection............KNUCKLE........................

.................23-51-l.................42-52-l.................23-47-l..............13A-289-l..........

13A-125,237-l..................26-6-l

L

LASH ADJUSTERSCheck.............................................11-15-lReplacement.......................................11-l 7-l

LATCH, Door.........................................42-47-lLEFT MEMBER........................................32-8-l

LEVER, Shift

cFWD>.............................................22-8-lLICENSE PLATE LIGHT.............................54-106-11

LIFTGATE............................................42-20-I

Adjustment.........................................42-11-l

GLASS.............................................42-38-lLIGHT

Indicator, ECS....................................338-19-IFog.............................................54-105-11Front Combination.................................54-106-11High Mounted Stop................................54-107-11License Plate.....................................54-106-11

Rear Combination.................................54-106-11Switch, Stop......................................33B-19-l

LIGHTING SYSTEM..................................54-35-11LIMITED SLIP DIFFERENTIALCheck cAWD>......................................27-l 5-l

Rear Axle, Oil Change, Maintenance...................00-52-I

CASE

LOOSE PANEL.......................................42-25-l

LOWER ARM

Front Suspension.................................33A-10-I

Rear Suspension

M

MAIN MUFFLER

MANUAL AIR CONDITIONING .

MANUAL TRANSAXLE

cFWD> . . . . . . . . . . . .Maintenance. . . . .

MASTER CYLINDER . . .

Clutch . . . . . . . .

MIRROR, Door..

_. .MIXTURE CONTROL (MFI) SystemMOTOR ANTENNA.. . . .

MOTOR RELAY

CABS>, Check .MOULDINGS . . . . . . . . . . . . .MUFFLER, Main

.....................

.......

...............................................................

..........15-30-I..........

15-33-l...........55-6-l..........

22-13-l...........22-2-l..........00-48-I..........35-87-l..........21-14-l..........51-31-l..........17-70-I........54-188-11..........35-83-l..........51-15-l...........

15-30-I..........15-33-l...

13A-131,241-l