Specifications MITSUBISHI 3000GT 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1994, Model line: 3000GT, Model: MITSUBISHI 3000GT 1994 2.GPages: 738, PDF Size: 35.06 MB

Page 3 of 738

Downloaded from www.Manualslib.com manuals search engine

i Service Manual

3000~l-

1992-l 996

Volume

2

Electrical

FOREWORD

i

L

This Service Manual has been prepared with the latest service information available at the time of

publication. It is subdivided into various group

categories and each section contains diagnossis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliability

designed into these outstanding vehicles.

@

A

.

.,

WESUF’FORTVOLUNTARY TECHNICIAN

CERTiFiCATlON THROUGH

National lnaltute forAUTOMOTIV ESERVICEEXCELLENC E

Mitsubishi Motors Corporation reserves the right to make changesin design or to make additions to or improvements in its products withou\

timposing any obligations upon itself to install them on its productspreviously manufactured.

L

--

GROUP / SECTION INDEX

General. . . . . . . . . . . . . . . . . . . . . . . .

Fusible Link, Fuse an d IOD or

Storage Connector Locatio n

. . . . . . . . . .w

Inspection Terminal Location . . . . . . . . .

Grounding Location . . . . . . . . . . . . . . . . . .w

m

Relay Location . . . . . . . . . . . . . . . . . . . . . -m

Sensor Locatio

n. . . . . . . . . . . . . -. . . . . . .w

Control Unit Location . . . . . . . . . . . . . . . . .m

Solenoid, Solenoid Valve Location . . . . .d

Diode Location . . . . . . . . . . . . . . -. . . . . . .w

Junction Block . . . . . . . . . . . . . . . . . . . . . . .II

Centralized Junction . . . . . . . . . #. . . . . . .w

Harness Connector Inspectio n. I . . . . . .w

How to Diagnose . . . . . . . . . . . . . -. . . . . . .

111

Configuration Diagrams . . . . . . . . . . . - . .m;

Circuit Diagrams . . . ..*.............

Engine Electrical ...............

ChassisElectrical

............ .

Alphabetical Index .............

NOTE:

For information concerning all compo-

nents other than the electrical system and

on-vehicle service procedures for engines

and transmissions, refer to Volume 1

“Chassis & Body” of this paired Service

Manual.

For overhaul procedures of engines or

transmission, refer to the separately is-

sued Engine Service Manual or Manual/

Automatic Transmission Service Manual.

@ 1995 Mitsubishi Motors CorporationReprinted in USA

Page 447 of 738

Downloaded from www.Manualslib.com manuals search engine 16-1

id

ENGINE

ELECTRICALCONTENTS

i;

CHARGING SYSTEM . . . . . . . . . . . . . . .2

GENERATOR. . . . ..*.............-.......12

ON-VEHICLE SERVICE.....................

6

Generator Output Line Voltage Drop Test.......6

Output Current Test..........................7

Regulated Voltage Test.......................9

Wave-form Check Using An Analyzer.........10

SPECIFICATIONS.........................2

General Specifications........................2

Service Specifications........................2

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . .3

IGNITION SYSTEM . . . . . . . . . . . . . . . .31

IGNITION SYSTEM . . . . . . . . . . . . . . . . . . . . . . .45

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . .36

Camshaft Position Sensor

Check. . . . . . . . . .Refer to GROUP 13A

(ON-VEHICLE INSPECTION

OF

MFI COMPONENTS)Crankshaft Position Sensor

Check. . _ . . . . . . .Refer to GROUP 13A

(ON-VEHICLE INSPECTION

OF MFI COMPONENTS)

Ignition Primary Voltage Wave-form

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Ignition Secondary Voltage Wave-form

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.37

Ignition Timing Adjustment . . . Refer to GROUP 11

Spark Plug Cable Test . . . . . . . . . . . . . . . . . . . . .36

Spark Plug Test . . . . . . . . . . . . . . . . . . . . . . . . . . .36

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . .31

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . .31

General Specifications . . . . . . . . . . . . . . . . . . . *. .31

Service Specifications . . . . . . . . . . . . . . . . . . . . . .31

TROUBLESHOOTING.....................32STARTING SYSTEM...............

19

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . .19~

General Specifications . . . . . . . . . . . . . . . . . . . . . .19

Service Specifications . . . . . . . . . . . . . . . . . . . . . .19

STARTER MOTOR . . . . . . . . . . . . . . . . . . . . . . . 23~

TROUBLESHOOTING . . . . . .-a.. . . . . . . . . . . . .20

L

I

I

Page 448 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging Svstem

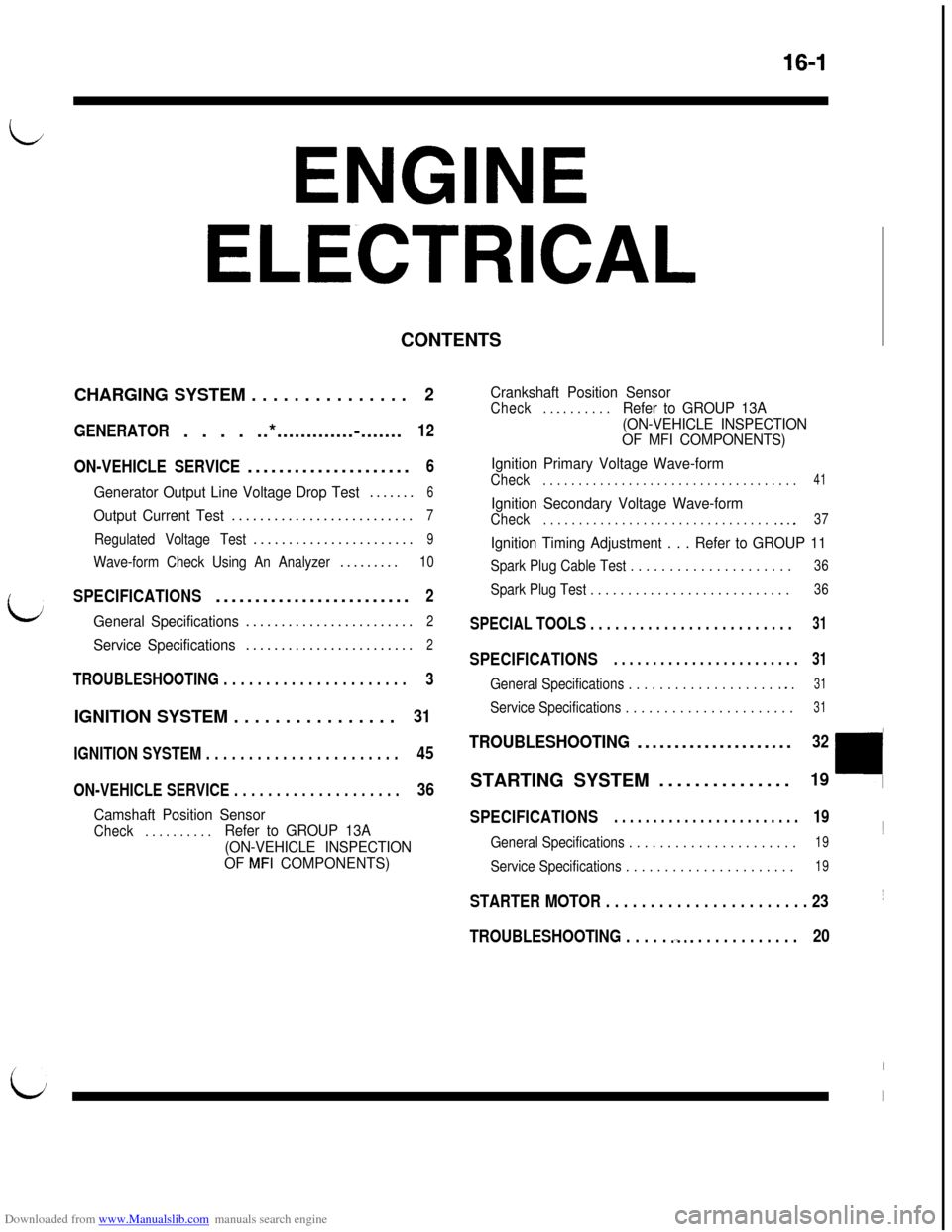

CHARGING SYSTEM

SPECIFICATIONSGENERAL SPECIFICATIONS

GENERATOR

ItemsUp to 1995 modelsFrom 1996 models

TypeBattery voltage sensingBattery voltage sensing

Rated output

VIA12fllO12l95

1 Voltage regulator1 Electronic type1 Electronic typeSERVICE SPECIFICATIONS

GENERATOR

IItems1 Standard value 1 LimitI

I Regulated voltage

Ambient temp. at voltage

rkgulator V

1 -2O’C (-4°F) ( 14.2-15.41 -I

20°C (68°F)13.9-l 4.9 -

60°C (140°F)13.4-14.6 -IIIII

1 80°C (176°F)1 13.1-14.5I-

1 Slip ring O.D.mm (in.)1 26.7 (1.05)/ 26.1 (1.03)I

IField coil resistanceQ1 Approx. 3-5

I-I

I Output currentI-/ 70% of nominal output currentI

TSB Revision

Page 454 of 738

Downloaded from www.Manualslib.com manuals search engine 16-8ENGINE ELECTRICAL - Charging System

This test determines whether the generator outputs

normal current.(1) Before the test, always be sure to check the

following.l Generator installation

l

Battery (Refer to GROUP 54 - Battery.)

NOTE

The battery to be used should be slightly dis-charged. The load in a fully-charged battery

will be insufficient and the test may not be able

to be carried out correctly.l Generator drive belt tension (Refer to

GROUP 11- On-vehicle Service.)l Fusible link

l Abnormal noise from the generator while

the engine is running(2) Turn the ignition switch to the OFF position.

(3) Disconnect the negative battery cable.

(4) Disconnect the generator output wire from the

generator

“B” terminal and connect a DC testammeter with a range of O-100 A in series

between the “B” terminal and the disconnected

output wire. (Connect the

(+) lead of the amme-ter to the

“B” terminal, and then connect the(-) lead of the ammeter to the disconnected

output wire.)

Caution

Never use clips but tighten bolts and nutsto connect the line.

Otherwise loose

connections (e.g. using clips) will lead to

a serious accident because of high current.

NOTE

A clamp-type ammeter which enables measure-

ments to be taken without disconnecting the

generator output wire is recommended.(5) Connect a voltmeter with a range of 0

- 20

V between the generator “B” terminal and the

ground. (Connect the

(+) lead of the voltmeterto the “B” terminal, and then connect the (-)

lead of the voltmeter to the ground.)

(6) Connect a tachometer. (For the procedure forconnecting the tachometer, refer to GROUP

11 - On-vehicle Service.)

(7) Connect the negative battery cable.

(8) Leave the hood open.(9) Check to be sure that the reading on the

voltmeter is equal to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably an

open circuit in the wire or fusible link between

the generator “B” terminal and the battery

(+)

terminal.

(1O)After turning the light switch on and turning on

the headlights, start the engine.

(1l)lmmediately after setting the headlights to high

beam and turning the heater blower switch to

the high revolution position, increase the enginespeed to 2,500

r/min and read the maximum

current output value displayed on the ammeter.

Limit value: 70% of nominal current output

NOTEl

For the nominal current output, refer to the

Generator Specifications.l

Because the current from the battery will

soon drop after the engine is started, the

above step should be carried out as quickly

as possible in order to obtain the maximum

current output value.l The current output value will depend on

the electrical load and the temperature of

the generator body.l

If the electrical load is small while testing,the specified level of current may not be

output even though the generator is normal.

In such cases, increase the electrical load

by leaving the headlights turned on for sometime to discharge the battery or by using

the lighting system in another vehicle, and

then test again.l

The specified level of current also may not

be output if the temperature of the generator

body or the ambient temperature is too high.

In such cases, cool the generator and then

test again.

(12)The reading on the ammeter should be above

the limit value. If the reading is below the limit

value and the generator output wire is normal,

remove the generator from the engine and check

the generator.(13)Run the engine at idle speed after the test.

(14)Turn the ignition switch to the OFF position.

(15)Disconnect the negative battery cable.

(16)Disconnect the ammeter, voltmeter and

tachometer.(17)Connect the generator output wire to the

generator “B” terminal.

(18)Connect the negative battery cable.

TSB Revision

Page 465 of 738

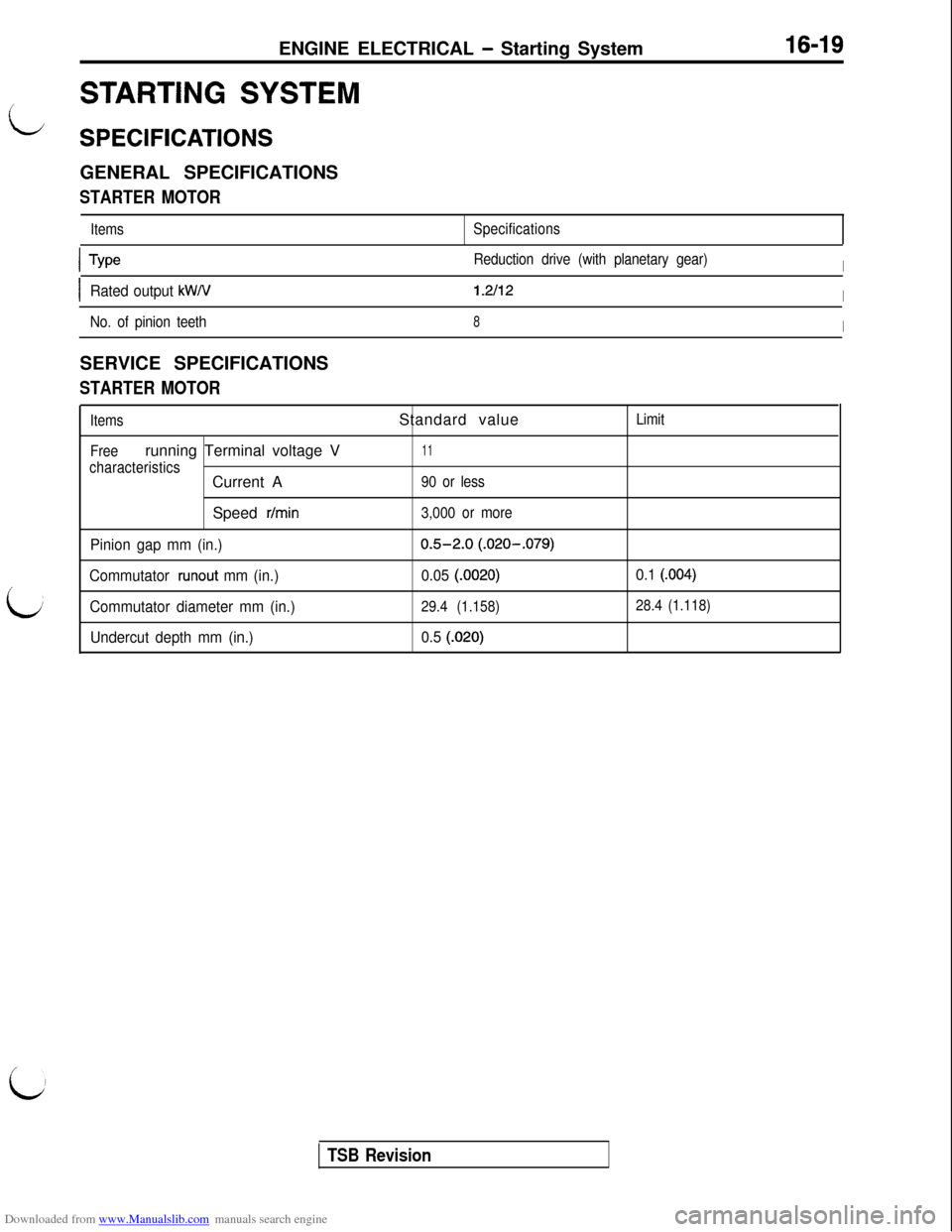

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-19

L/J

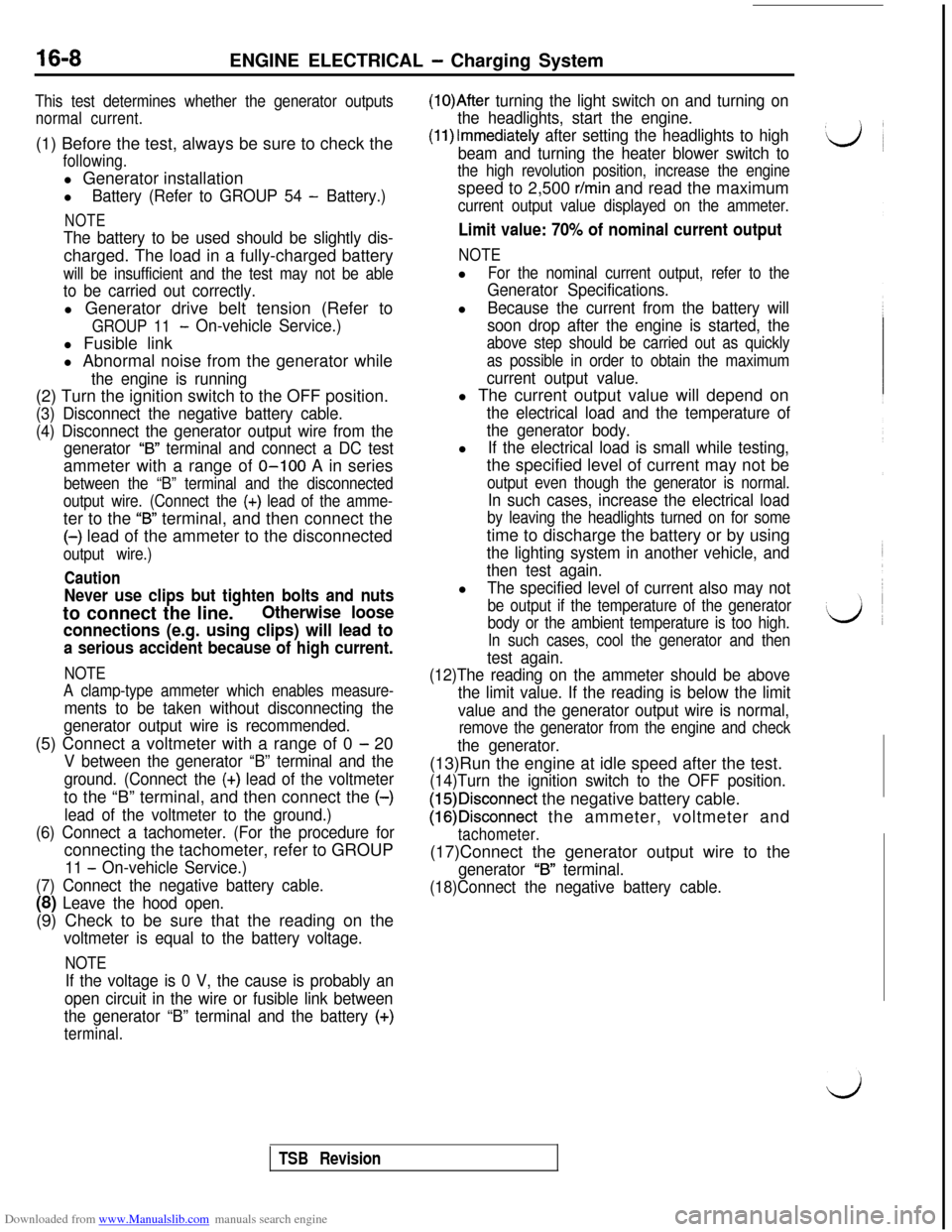

STARTING SYSTEM

SPECIFICATIONSGENERAL SPECIFICATIONS

STARTER MOTOR

ItemsSpecifications

L

ITypeReduction drive (with planetary gear)I

IRated output kW/V1.2112I

No. of pinion teeth8ISERVICE SPECIFICATIONS

STARTER MOTOR

Items

Freerunning Terminal voltage V

characteristicsCurrent A

Speed

r/min

Pinion gap mm (in.)

Commutator

runout mm (in.)

Commutator diameter mm (in.)

Undercut depth mm (in.)Standard value

11

90 or less

3,000 or more

0.5-2.0 (.020-.079)

0.05

(.0020)

29.4 (1.158)

0.5 (.020)Limit

0.1 (.004)

28.4 (1.118)

i

TSB Revision

Page 477 of 738

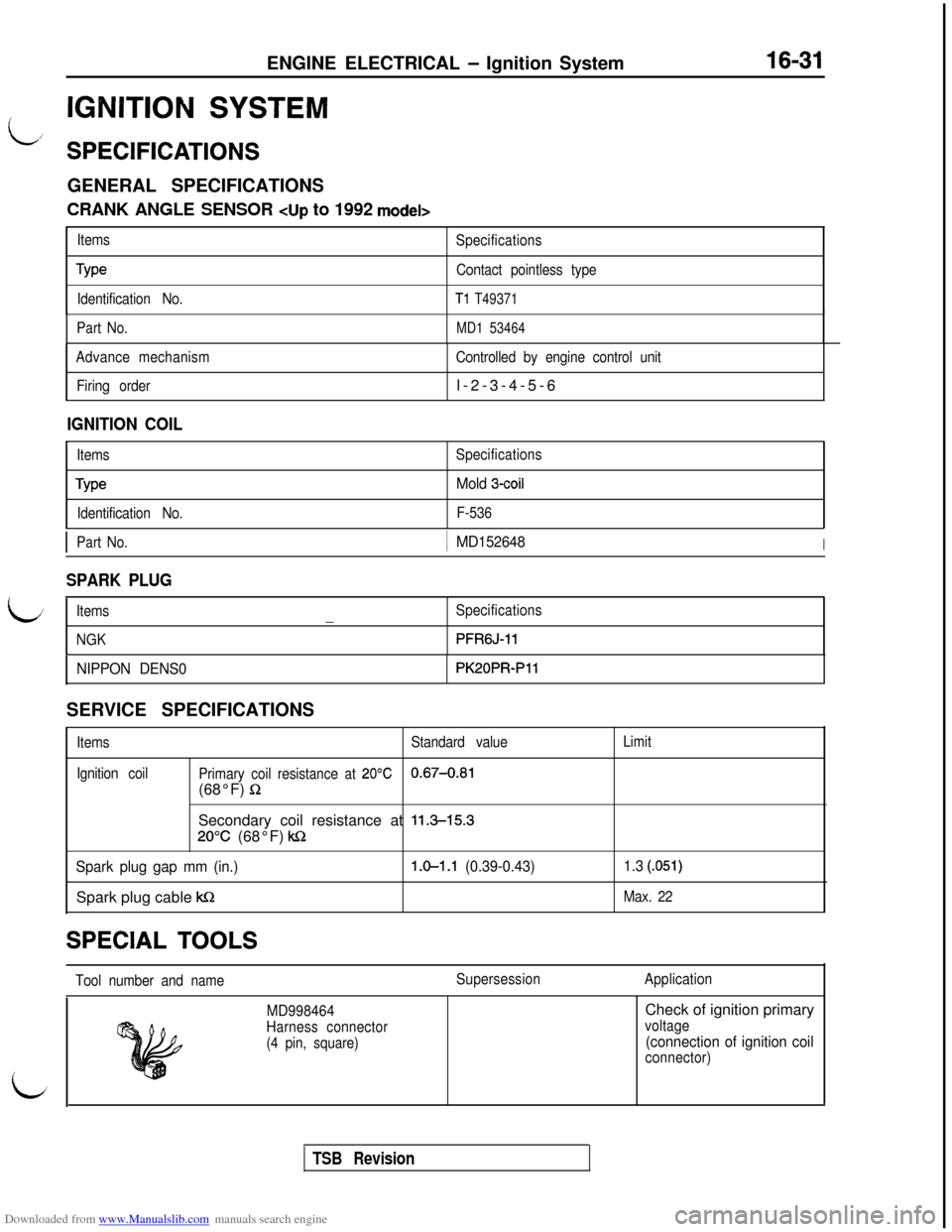

Downloaded from www.Manualslib.com manuals search engine i/ENGINE ELECTRICAL

- Ignition System

IGNITION SYSTEM

16-31

SPECIFICATIONSGENERAL SPECIFICATIONS

CRANK ANGLE SENSOR cup to 1992 model>

Items

Specifications

TypeContact pointless type

Identification No.

Tl T49371

Part No.MD1 53464

Advance mechanism

Firing orderControlled by engine control unitl-2-3-4-5-6

IGNITION COILrItems

Type

Identification No.SpecificationsMold 3-coil

F-536

L

IPart No.j MD152648I

SPARK PLUG

Items

NGK-Specifications

PFRGJ-11

NIPPON DENS0PK20PRPllSERVICE SPECIFICATIONS

Items

Ignition coilStandard valueLimit

Primary coil resistance at

20°C0.67-0.81(68°F)

RSecondary coil resistance at

11.3-15.3

20°C (68°F) kc2

Spark plug gap mm (in.)1.0-l .l (0.39-0.43)Spark plug cable

kQ

1.3 (.051)

Max. 22SPECIAL

TOOLS

Tool number and nameSupersessionApplication

i

MD998464

Harness connector

(4 pin, square)Check of ignition primaryvoltage

(connection of ignition coil

connector)

i

TSB Revision

Page 497 of 738

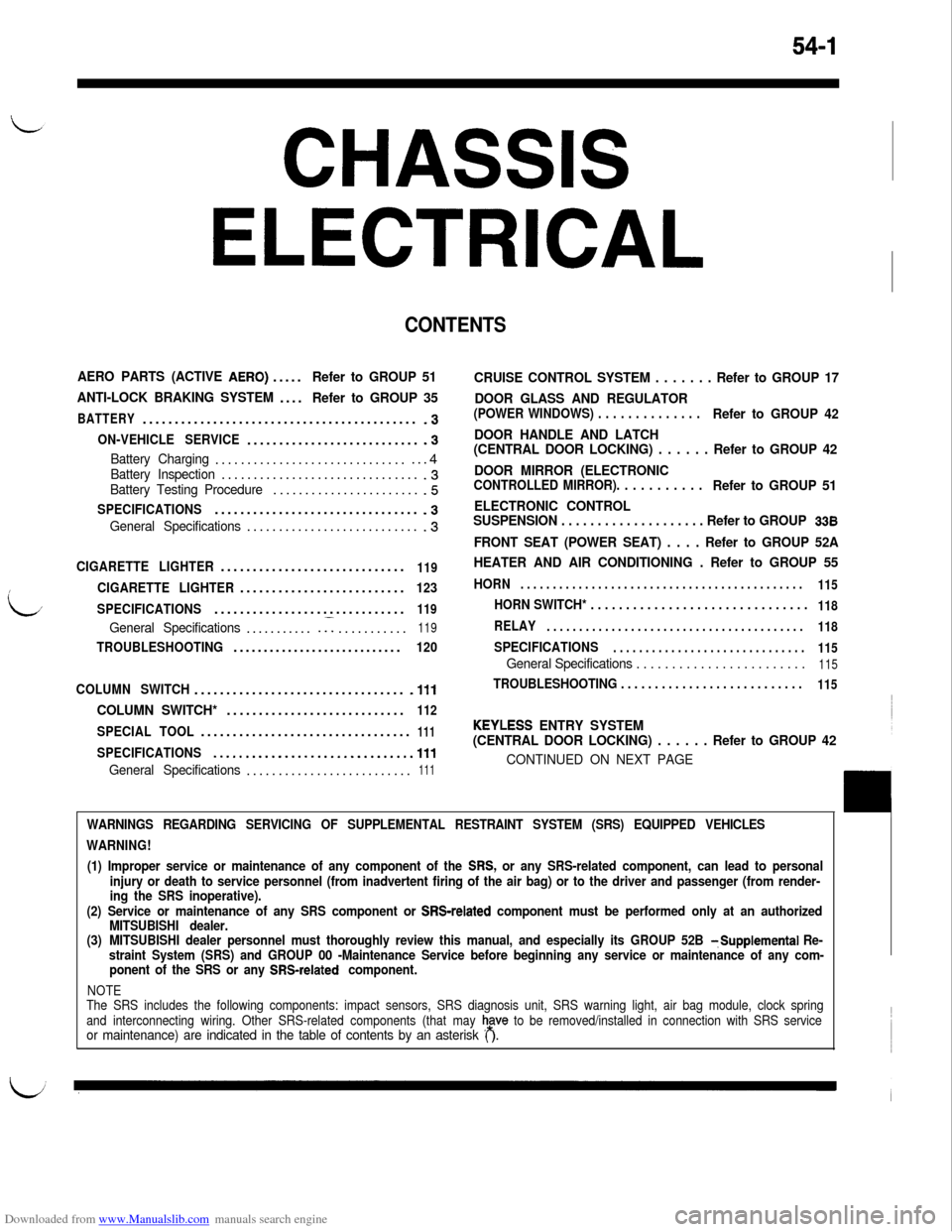

Downloaded from www.Manualslib.com manuals search engine 54-1

CHASSIS

ELECTRICAL

CONTENTS

AERO PARTS (ACTIVE AERO).....Refer to GROUP 51

ANTI-LOCK BRAKING SYSTEM....

Refer to GROUP 35

BATTERY...........................................-3

ON-VEHICLE SERVICE............................3

Battery Charging.................................4Battery Inspection................................3Battery Testing Procedure........................5

SPECIFICATIONS................................-3

General Specifications............................3

CIGARETTE LIGHTER.............................119

CIGARETTE LIGHTER..........................123

SPECIFICATIONS..............................

119

General Specifications............I...........119

TROUBLESHOOTING............................120

COLUMN SWITCH.................................

.lll

COLUMN SWITCH*............................112

SPECIAL TOOL.................................111

SPECIFICATIONS...............................111

General Specifications..........................111

CRUISE CONTROL SYSTEM . . . . . . . Refer to GROUP 17

DOOR GLASS AND REGULATOR

(POWER WINDOWS) . . . . . . . . . . . . . .Refer to GROUP 42

DOOR HANDLE AND LATCH

(CENTRAL DOOR LOCKING) . . . . . . Refer to GROUP 42

DOOR MIRROR (ELECTRONIC

CONTROLLED MIRROR). . . . . . . . . . .Refer to GROUP 51

ELECTRONIC CONTROL

SUSPENSION . . . . . . . . . . . . . . . . . . . . Refer to GROUP

338

FRONT SEAT (POWER SEAT) . . . . Refer to GROUP 52A

HEATER AND AIR CONDITIONING . Refer to GROUP 55

HORN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

HORN SWITCH* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

RELAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

118

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

General Specifications . . . . . . . . . . . . . . . . . . . . . . . .115

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .115

KEYLESS ENTRY SYSTEM

(CENTRAL DOOR LOCKING) . . . . . . Refer to GROUP 42

CONTINUED ON NEXT PAGE

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the

SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from render-

ing the SRS inoperative).

(2) Service or maintenance of any SRS component or

SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3)MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

TSupplemental Re-

straint System (SRS) and GROUP 00 -Maintenance Service before beginning any service or maintenance of any com-

ponent of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: impact sensors, SRS diagnosis unit, SRS warning light, air bag module, clock spring

and interconnecting wiring. Other SRS-related components (that may

h,a”” to be removed/installed in connection with SRS serviceor maintenance) are indicated in the table of contents by an asterisk ( ).

Page 498 of 738

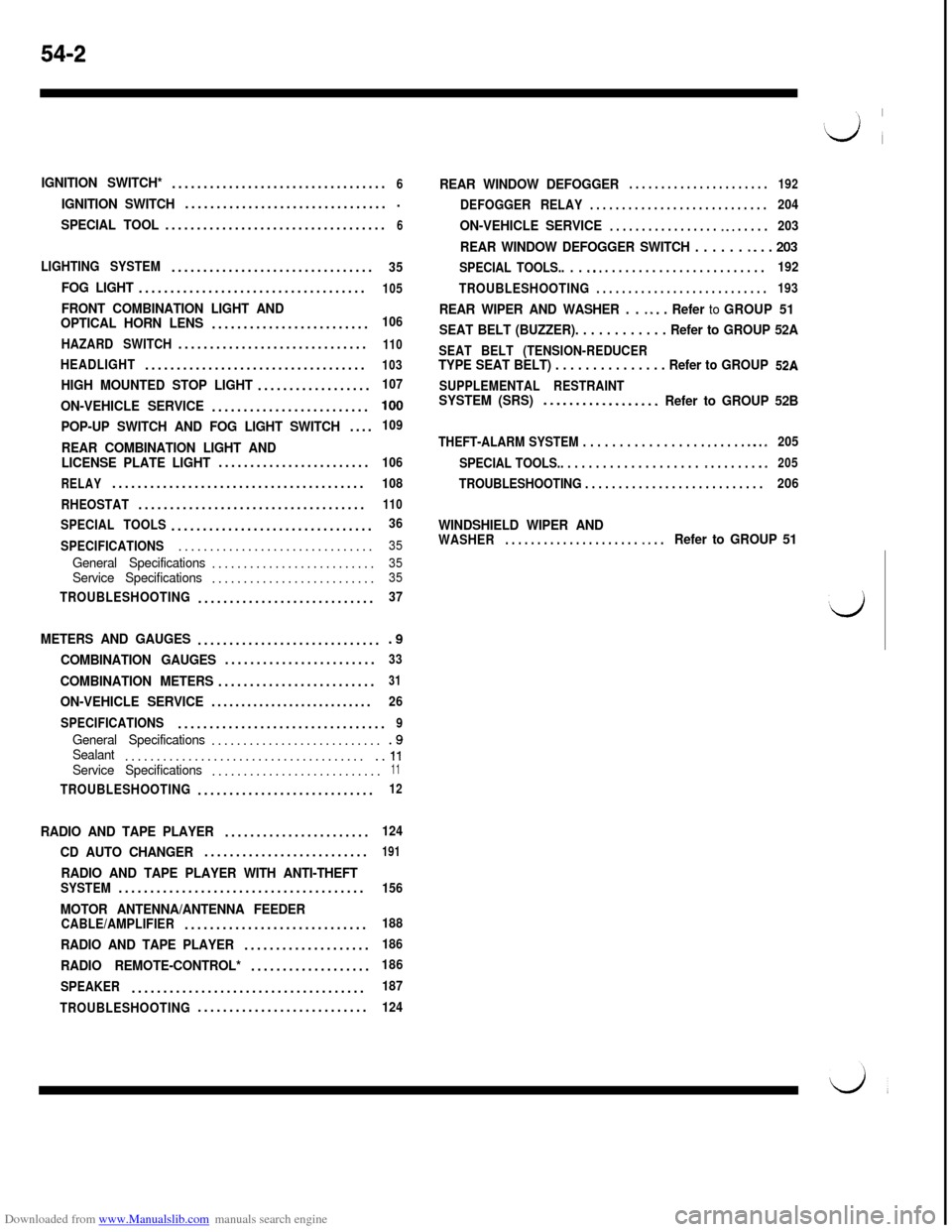

Downloaded from www.Manualslib.com manuals search engine 54-2

IGNITION SWITCH*..................................6

IGNITION SWITCH.................................

SPECIAL TOOL...................................6

LIGHTING SYSTEM................................35

FOG LIGHT....................................105

FRONT COMBINATION LIGHT AND

OPTICAL HORN LENS.........................106

HAZARD SWITCH..............................

110

HEADLIGHT...................................103

HIGH MOUNTED STOP LIGHT..................107

ON-VEHICLE SERVICE.........................100

POP-UP SWITCH AND FOG LIGHT SWITCH....109

REAR COMBINATION LIGHT AND

LICENSE PLATE LIGHT........................106

RELAY........................................108

RHEOSTAT....................................

110

SPECIAL TOOLS................................36

SPECIFICATIONS...............................

35

General Specifications..........................35Service Specifications..........................35

TROUBLESHOOTING............................37

METERS AND GAUGES..............................9

COMBINATION GAUGES........................33

COMBINATION METERS.........................31

ON-VEHICLE SERVICE...........................26

SPECIFICATIONS.................................

9

General Specifications............................9Sealant........................................ll

Service Specifications...........................11

TROUBLESHOOTING............................12

RADIO AND TAPE PLAYER.......................124

CD AUTO CHANGER..........................191

RADIO AND TAPE PLAYER WITH ANTI-THEFTSYSTEM.......................................156

MOTOR ANTENNA/ANTENNA FEEDERCABLE/AMPLIFIER.............................188

RADIO AND TAPE PLAYER....................186

RADIO REMOTE-CONTROL*...................186

SPEAKER.....................................

187

TROUBLESHOOTING...........................

124

REAR WINDOW DEFOGGER. . . . . . . . . . . . . . . . . . . . . .192

DEFOGGER RELAY. . . . . . . . . . . . . . . . . . . . . . . . . . . .204

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . . ~ ~. . . . . .203

REAR WINDOW DEFOGGER SWITCH . . . . . . -. . . 203

SPECIAL TOOLS.. . . s.. . . . . . . . . . . . . . . . . . . . . . . . .192

TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . .193

REAR WIPER AND WASHER . . ~ *. . Refer to GROUP 51

SEAT BELT (BUZZER). . . . . . . . . . . . Refer to GROUP 52A

SEAT BELT (TENSION-REDUCERTYPE SEAT BELT) . . . . . . . . . . . . . . . Refer to GROUP 52A

SUPPLEMENTAL RESTRAINTSYSTEM (SRS)..-...............Refer to GROUP 52B

THEFT-ALARM SYSTEM . . . . . . . . . . . . . . . . . e . . . . . m.. s205

SPECIAL TOOLS.. . . . . . . . . . . . . . . . . . . .

m . . . . . . . .e205

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .206

WINDSHIELD WIPER ANDWASHER. . . . . . . . . . . . . . . . . . . . . ~. . .Refer to GROUP 51

Page 499 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Battery54-3

BATTERY

LSPECIFICATIONSGENERAL SPECIFICATIONS

ItemsUp to 1993 modelsFrom 1994 models

Type75D26R-MF75D23R-MF

Ampere hours

(5HR) Ah5252

Cranking rating [at -18°C (O’F)] A490520

Reserve capacity min.123118

NOTES

1.CRANKING RATING is the current a battery can deliver for 30 seconds and maintain a terminal voltage of

7.2 volts or greater at a specified temperature.

2.RESERVE CAPACITY RATING is the amount of time a battery can deliver 25A and maintain a minimum terminal

voltage of 10.5 at

27% (80°F).

L

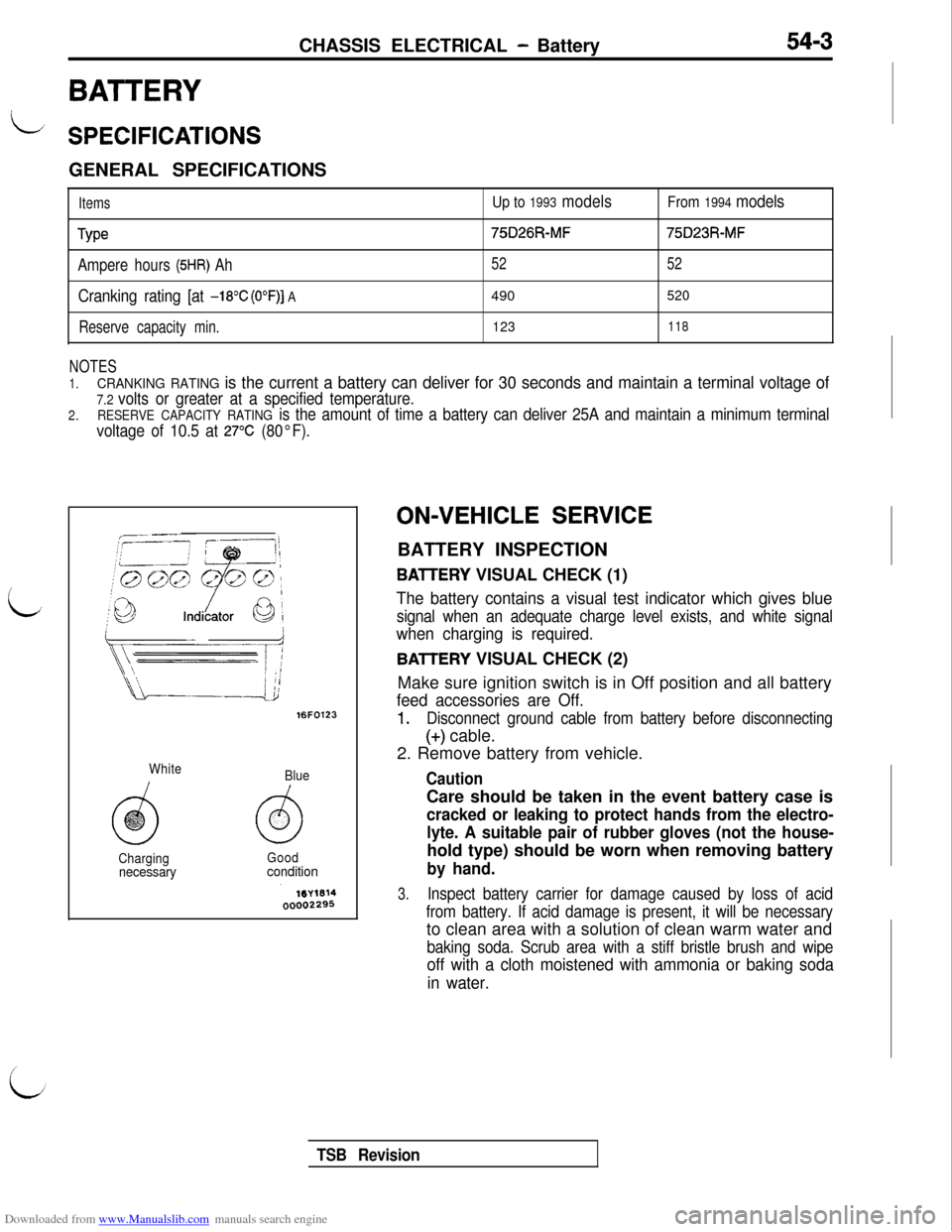

16FO123

White

Blue

ChargingGood

necessaryconditionON-VEHICLE

SERVICE

BATTERY INSPECTION

BAlTERY VISUAL CHECK (1)

The battery contains a visual test indicator which gives blue

signal when an adequate charge level exists, and white signal

when charging is required.

BAlTERY VISUAL CHECK (2)

Make sure ignition switch is in Off position and all battery

feed accessories are Off.

1.Disconnect ground cable from battery before disconnecting

(+) cable.

2. Remove battery from vehicle.

CautionCare should be taken in the event battery case is

cracked or leaking to protect hands from the electro-

lyte. A suitable pair of rubber gloves (not the house-hold type) should be worn when removing battery

by hand.

3.Inspect battery carrier for damage caused by loss of acid

from battery. If acid damage is present, it will be necessaryto clean area with a solution of clean warm water and

baking soda. Scrub area with a stiff bristle brush and wipe

off with a cloth moistened with ammonia or baking soda

in water.

TSB Revision

Page 505 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauaes

(/

METERS AND GAUGES

SPECIFICATIONSGENERAL SPECIFICATIONS

METERS AND GAUGES

LNOTE*’ 1992

models

*z 1992 models

TSB Revision