width MITSUBISHI 3000GT 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1994, Model line: 3000GT, Model: MITSUBISHI 3000GT 1994 2.GPages: 738, PDF Size: 35.06 MB

Page 26 of 738

Downloaded from www.Manualslib.com manuals search engine 24GENERAL - Harness Connector Inspection

ess connector

contact pressure

checking harness

201 R057

Z16R1317

HARNESS CONNECTOR INSPECTION

CONNECTOR CONTINUITY AND VOLTAGE TESTWhen checking continuity and/or voltage at the waterproof

connectors, follow the steps below to avoid poor connector

contact and/or reduced waterproof performance of connectors.

(1) When checking is performed with the circuit in the stateof continuity, be sure to use the special tool (harness

connector).

Never insert a test bar from the harness side, because

to do so will reduce the waterproof performance and result

in corrosion.

(2) When the connector

JS disconnected for checking the fe-

male pin, the harness for checking the contact pressureof connector pins should be used.

Never force the insertion of a test bar, because to do

so will cause poor contact.(3) When the male pin is to be checked, apply the test bar

against the pin directly.

Care must be taken not to short-circuit the connector pins.

TERMINAL ENGAGEMENT CHECK

When the terminal stopper of connector is out of order, engage-

ment of male and female terminals becomes improper even

when the connector itself is engaged perfectly and the terminal

sometimes slips out to the rear side of connector. Ascertain,

therefore, that each terminal does not come off the connector

by pulling each harness wire.

CONNECTOR TERMINAL ENGAGEMENT AND

DISENGAGEMENTConnectors which are loose shall be rectified by removing

the female terminal from connector housing and raising its

lance to establish a more secure engagement. Removal of

connector terminal used for MFI and 4 A/l control circuit shallbe done in the following manner.

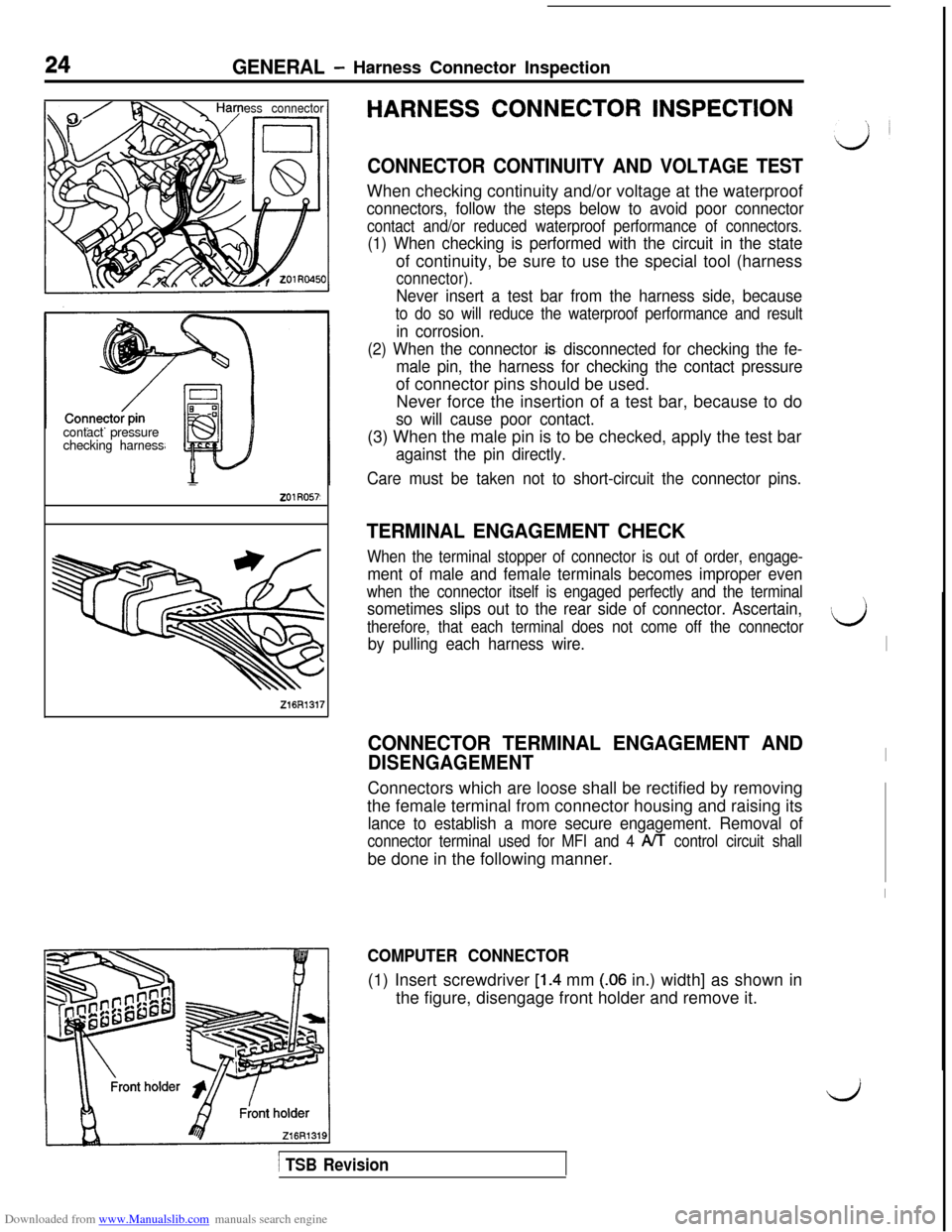

COMPUTER CONNECTOR(1) Insert screwdriver

[1.4 mm (.06 in.) width] as shown in

the figure, disengage front holder and remove it.

1 TSB Revision

IJ

I

I

I

Page 27 of 738

Downloaded from www.Manualslib.com manuals search engine GENERAL - Harness Connector Inspection25 ~

Z16R1320

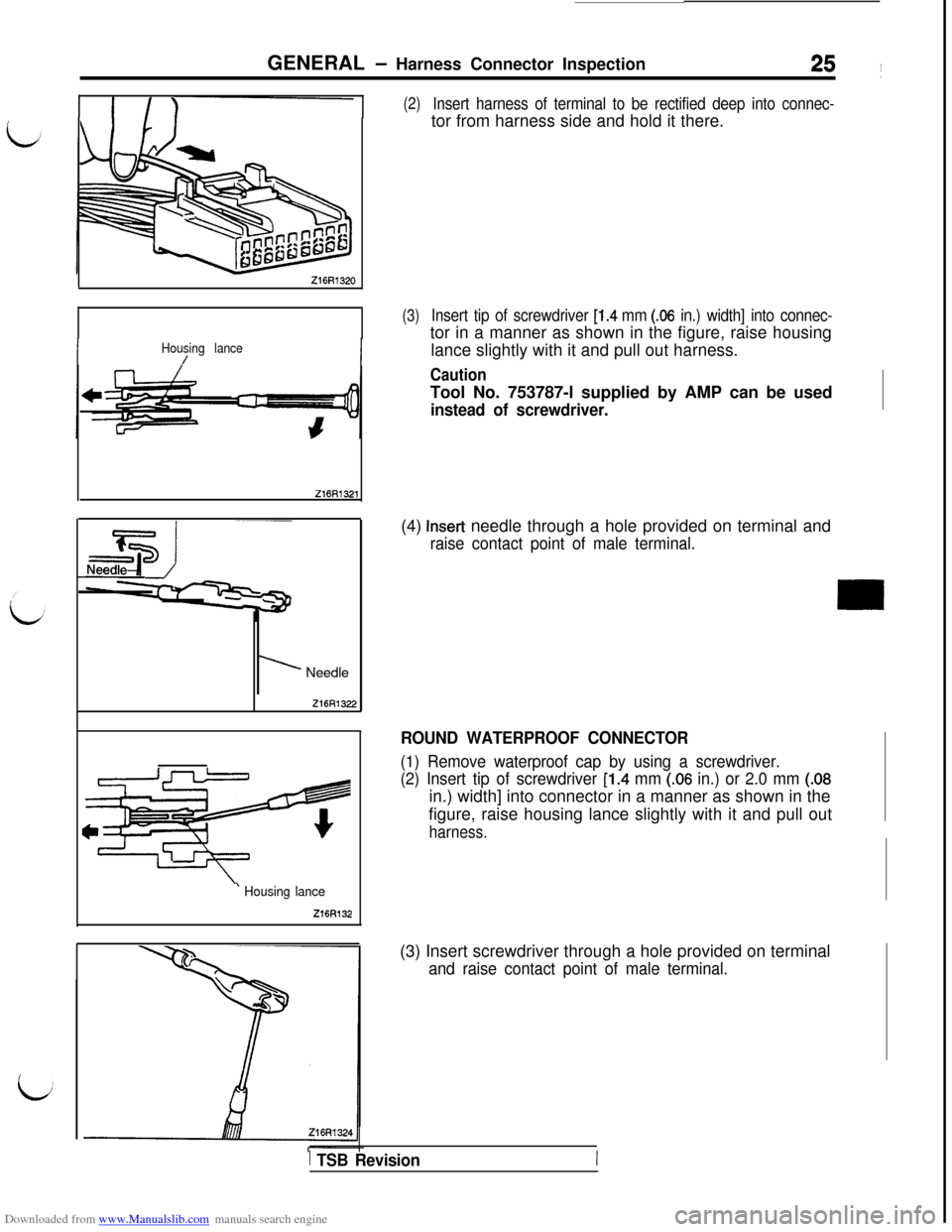

(2)Insert harness of terminal to be rectified deep into connec-tor from harness side and hold it there.

Housing lance/

’ Needle

’ Housing lance

Z16R132

(3)Insert tip of screwdriver [1.4 mm (.06 in.) width] into connec-tor in a manner as shown in the figure, raise housing

lance slightly with it and pull out harness.

CautionTool No. 753787-l supplied by AMP can be used

instead of screwdriver.(4)

insert needle through a hole provided on terminal and

raise contact point of male terminal.

ROUND WATERPROOF CONNECTOR

(1) Remove waterproof cap by using a screwdriver.

(2) Insert tip of screwdriver

[I.4 mm (.06 in.) or 2.0 mm (.08in.) width] into connector in a manner as shown in the

figure, raise housing lance slightly with it and pull out

harness.(3) Insert screwdriver through a hole provided on terminal

and raise contact point of male terminal.

1 TSB Revision

Page 28 of 738

![MITSUBISHI 3000GT 1994 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 26GENERAL - Harness Connector Inspection

Front holder

\\Z16R1325]

Housing lance7,fiEL,

c

Terminal lance00000400\

RECTANGULAR WATERPROOF CONNECT MITSUBISHI 3000GT 1994 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 26GENERAL - Harness Connector Inspection

Front holder

\\Z16R1325]

Housing lance7,fiEL,

c

Terminal lance00000400\

RECTANGULAR WATERPROOF CONNECT](/img/19/7561/w960_7561-27.png)

Downloaded from www.Manualslib.com manuals search engine 26GENERAL - Harness Connector Inspection

Front holder

\\Z16R1325]

Housing lance7,fiEL,

c

Terminal lance00000400\

RECTANGULAR WATERPROOF CONNECTOR

(1)Disengage front holder by using a screwdriver and remove

it.

(2) Inset-t tip of screwdriver [*0.8 mm (.03 in.) width] into con-

nector in a manner as shown in the figure, push it lightly

to raise housing lance and pull out harness.

*If right size screwdriver is not available, convert a conven-

tional driver to suit the size.

(3) Press contact point of male terminal down by holding a

screwdriver [1.4 mm (.06 in.) width] in a manner as shown

in the figure.

INJECTOR CONNECTOR

(1) Remove waterproof cap.

(2)Insert tip of screwdriver [1.4 mm (.06 in.) width] into connec-

tor in a manner as shown in the figure, press in terminal

lance and pull out harness.

(3) Press contact point of male terminal down by holding a

screwdriver [1.4 mm (.06 in.) width] in a manner as shown

in the figure.

CautionMake sure that lance is in proper condition before

terminal is inserted into connector.

1 TSB Revision