drive MITSUBISHI 3000GT 1995 2.G Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1995, Model line: 3000GT, Model: MITSUBISHI 3000GT 1995 2.GPages: 738, PDF Size: 35.06 MB

Page 460 of 738

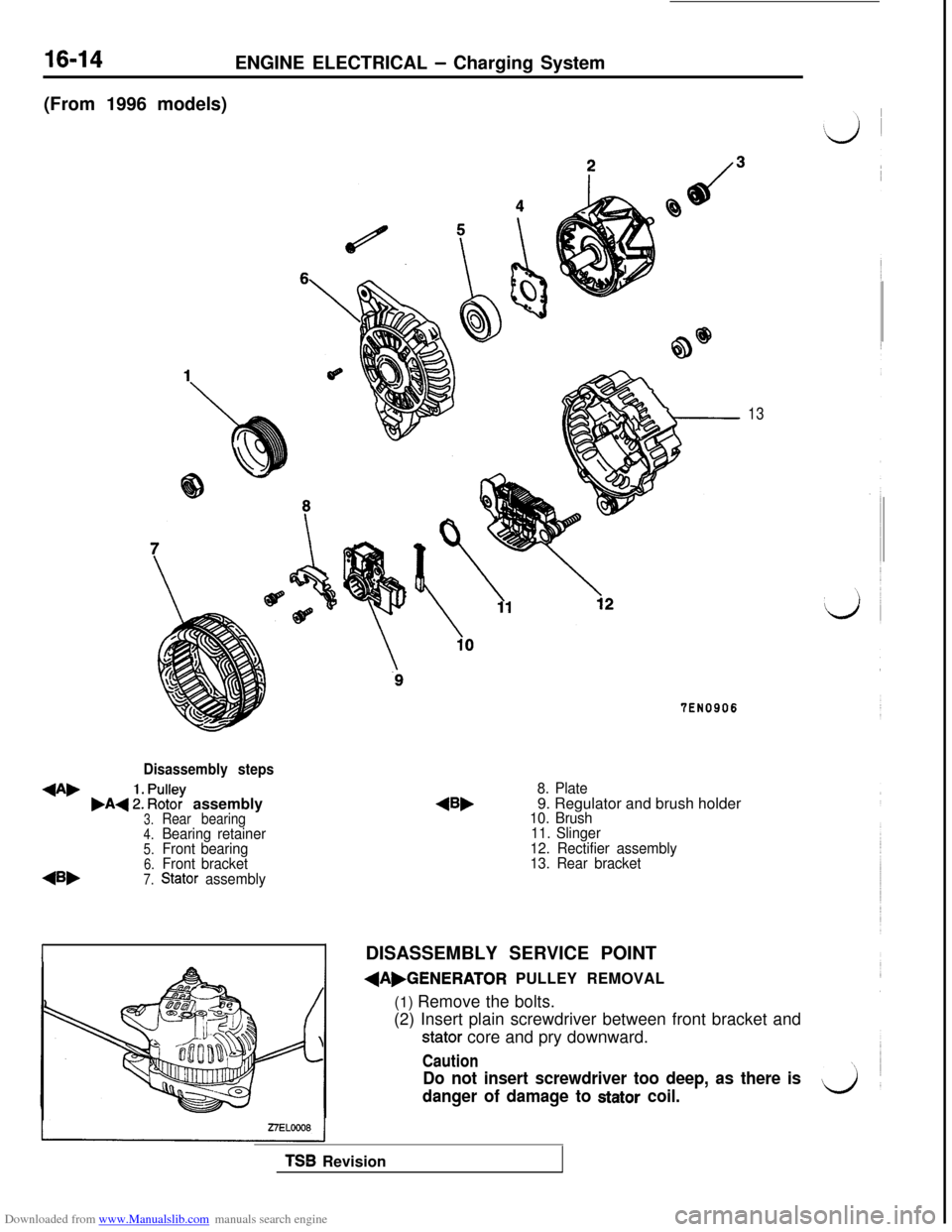

Downloaded from www.Manualslib.com manuals search engine 16-14ENGINE ELECTRICAL - Charging System

(From 1996 models)

Disassembly steps

+A,,A+ :: ~%? assembly3.Rear bearing4.Bearing retainer5.Front bearing6.Front bracket

45,7.Stator assembly

13

TEN0906

8. Plate9. Regulator and brush holder

10. Brush

11. Slinger

12. Rectifier assembly

13. Rear bracket

IDISASSEMBLY SERVICE POINT

dAbGENERATOR PULLEY REMOVAL

(1) Remove the bolts.

(2) Insert plain screwdriver between front bracket and

stator core and pry downward.

Caution

Do not insert screwdriver too deep, as there is

danger of damage to

stator coil.

TSB Revision

Page 465 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-19

L/J

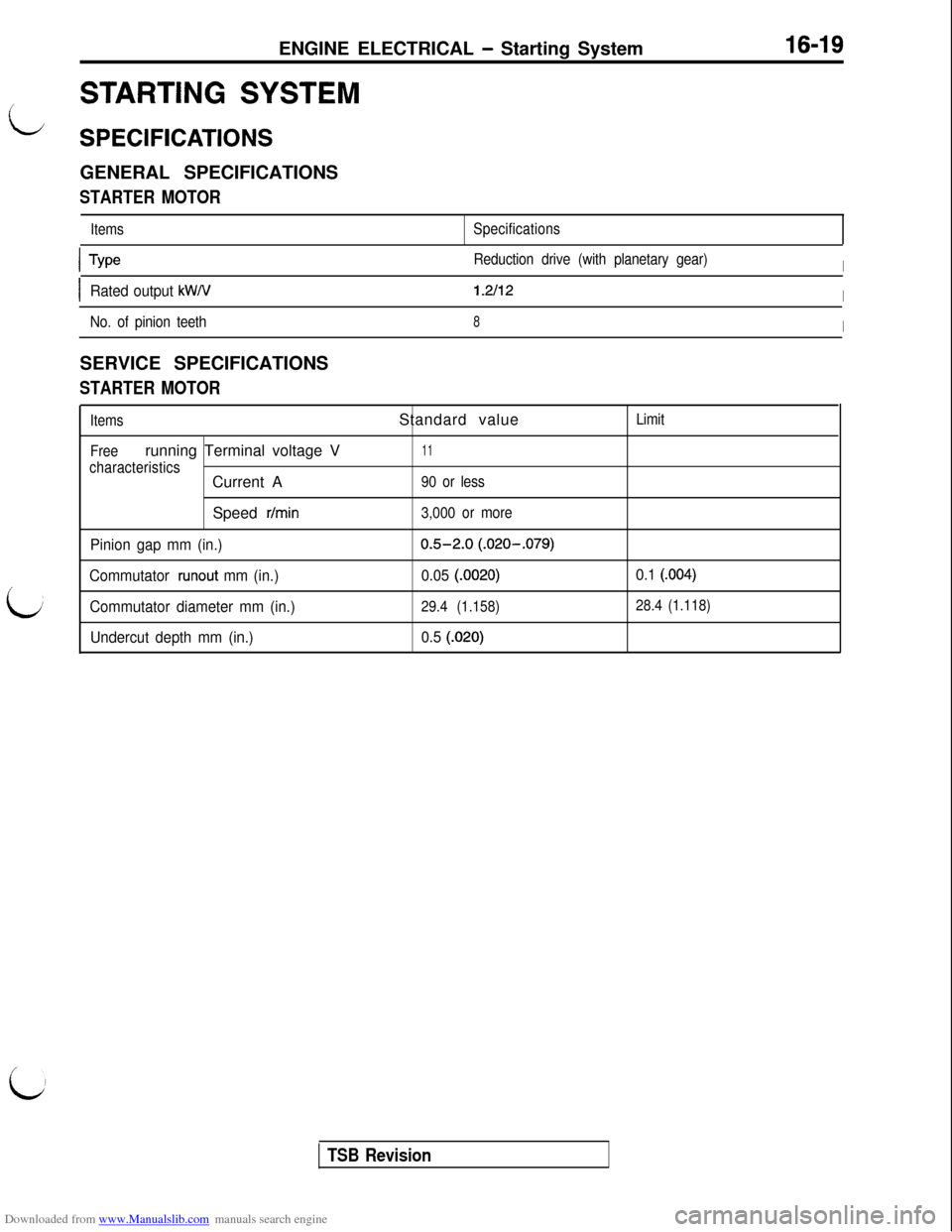

STARTING SYSTEM

SPECIFICATIONSGENERAL SPECIFICATIONS

STARTER MOTOR

ItemsSpecifications

L

ITypeReduction drive (with planetary gear)I

IRated output kW/V1.2112I

No. of pinion teeth8ISERVICE SPECIFICATIONS

STARTER MOTOR

Items

Freerunning Terminal voltage V

characteristicsCurrent A

Speed

r/min

Pinion gap mm (in.)

Commutator

runout mm (in.)

Commutator diameter mm (in.)

Undercut depth mm (in.)Standard value

11

90 or less

3,000 or more

0.5-2.0 (.020-.079)

0.05

(.0020)

29.4 (1.158)

0.5 (.020)Limit

0.1 (.004)

28.4 (1.118)

i

TSB Revision

Page 474 of 738

Downloaded from www.Manualslib.com manuals search engine 16-28ENGINE ELECTRICAL - Starting System

Stop ringZ6EL0097

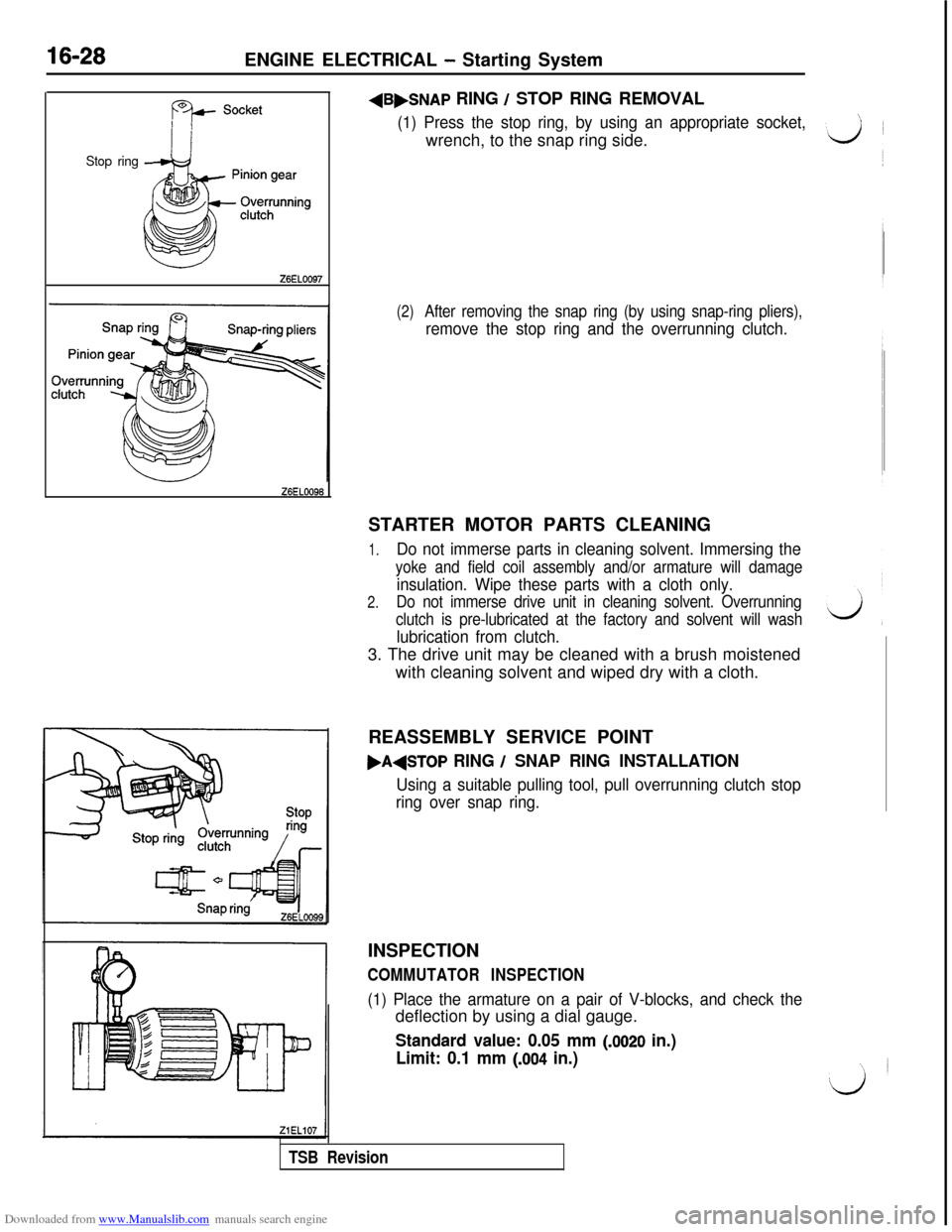

Z6ELOO96+B,SNAP

RING / STOP RING REMOVAL

(1) Press the stop ring, by using an appropriate socket,wrench, to the snap ring side.

(2)After removing the snap ring (by using snap-ring pliers),

remove the stop ring and the overrunning clutch.STARTER MOTOR PARTS CLEANING

1.Do not immerse parts in cleaning solvent. Immersing the

yoke and field coil assembly and/or armature will damage

insulation. Wipe these parts with a cloth only.

2.Do not immerse drive unit in cleaning solvent. Overrunning

clutch is pre-lubricated at the factory and solvent will wash

lubrication from clutch.3. The drive unit may be cleaned with a brush moistened

with cleaning solvent and wiped dry with a cloth.

REASSEMBLY SERVICE POINT

,A+TOP RING / SNAP RING INSTALLATION

Using a suitable pulling tool, pull overrunning clutch stop

ring over snap ring.INSPECTION

COMMUTATOR INSPECTION

(1) Place the armature on a pair of V-blocks, and check thedeflection by using a dial gauge.

Standard value: 0.05 mm (JO20 in.)

Limit: 0.1 mm

(.004 in.)

TSB Revision

Page 475 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-29

ZiELllS

UndercutI

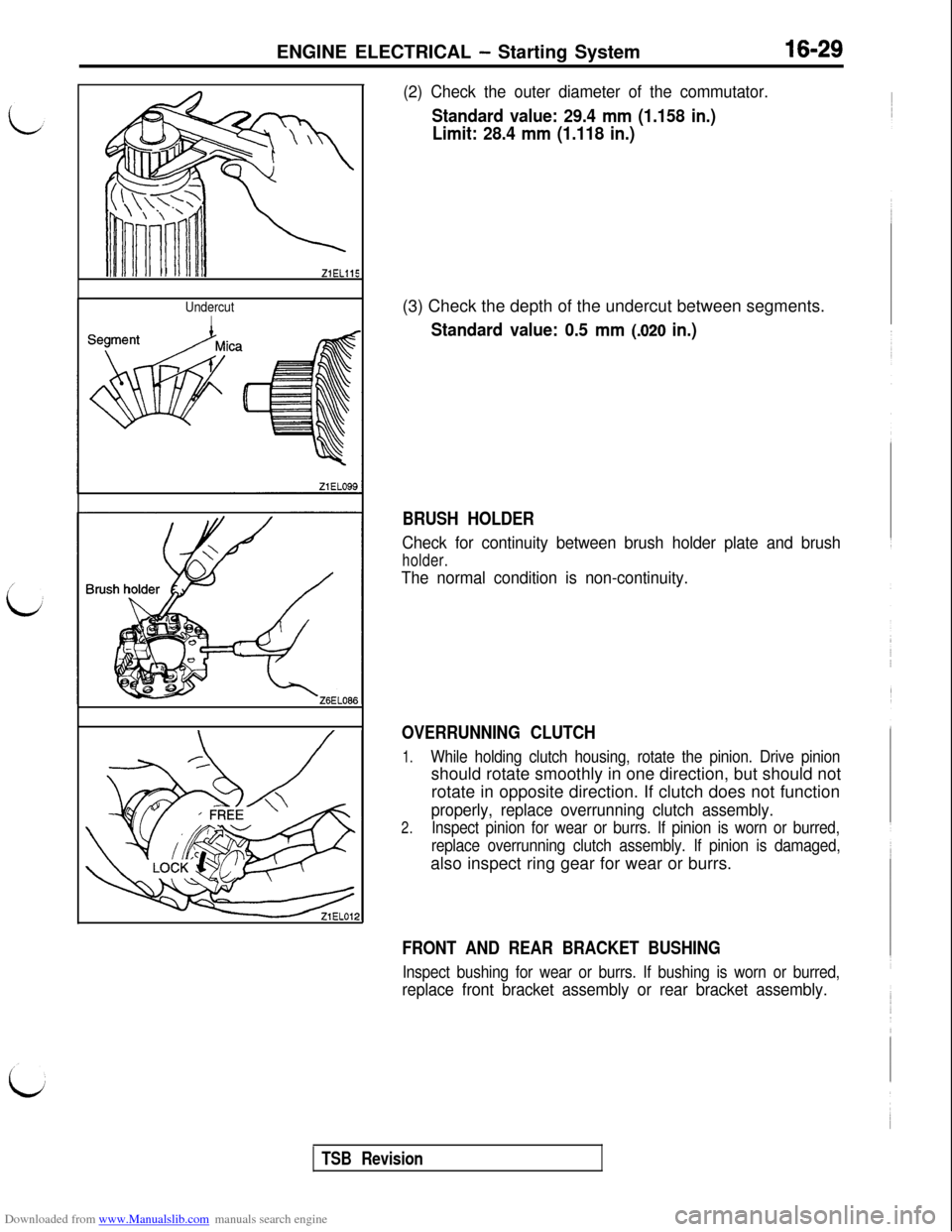

(2) Check the outer diameter of the commutator.

Standard value: 29.4 mm (1.158 in.)

Limit: 28.4 mm (1.118 in.)(3) Check the depth of the undercut between segments.

Standard value: 0.5 mm (.020 in.)

BRUSH HOLDER

Check for continuity between brush holder plate and brush

holder.

The normal condition is non-continuity.

OVERRUNNING CLUTCH

1.While holding clutch housing, rotate the pinion. Drive pinionshould rotate smoothly in one direction, but should not

rotate in opposite direction. If clutch does not function

properly, replace overrunning clutch assembly.

2.Inspect pinion for wear or burrs. If pinion is worn or burred,

replace overrunning clutch assembly. If pinion is damaged,also inspect ring gear for wear or burrs.

FRONT AND REAR BRACKET BUSHING

Inspect bushing for wear or burrs. If bushing is worn or burred,

replace front bracket assembly or rear bracket assembly.

TSB Revision

Page 497 of 738

Downloaded from www.Manualslib.com manuals search engine 54-1

CHASSIS

ELECTRICAL

CONTENTS

AERO PARTS (ACTIVE AERO).....Refer to GROUP 51

ANTI-LOCK BRAKING SYSTEM....

Refer to GROUP 35

BATTERY...........................................-3

ON-VEHICLE SERVICE............................3

Battery Charging.................................4Battery Inspection................................3Battery Testing Procedure........................5

SPECIFICATIONS................................-3

General Specifications............................3

CIGARETTE LIGHTER.............................119

CIGARETTE LIGHTER..........................123

SPECIFICATIONS..............................

119

General Specifications............I...........119

TROUBLESHOOTING............................120

COLUMN SWITCH.................................

.lll

COLUMN SWITCH*............................112

SPECIAL TOOL.................................111

SPECIFICATIONS...............................111

General Specifications..........................111

CRUISE CONTROL SYSTEM . . . . . . . Refer to GROUP 17

DOOR GLASS AND REGULATOR

(POWER WINDOWS) . . . . . . . . . . . . . .Refer to GROUP 42

DOOR HANDLE AND LATCH

(CENTRAL DOOR LOCKING) . . . . . . Refer to GROUP 42

DOOR MIRROR (ELECTRONIC

CONTROLLED MIRROR). . . . . . . . . . .Refer to GROUP 51

ELECTRONIC CONTROL

SUSPENSION . . . . . . . . . . . . . . . . . . . . Refer to GROUP

338

FRONT SEAT (POWER SEAT) . . . . Refer to GROUP 52A

HEATER AND AIR CONDITIONING . Refer to GROUP 55

HORN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

HORN SWITCH* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

RELAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

118

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

General Specifications . . . . . . . . . . . . . . . . . . . . . . . .115

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .115

KEYLESS ENTRY SYSTEM

(CENTRAL DOOR LOCKING) . . . . . . Refer to GROUP 42

CONTINUED ON NEXT PAGE

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the

SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from render-

ing the SRS inoperative).

(2) Service or maintenance of any SRS component or

SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3)MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

TSupplemental Re-

straint System (SRS) and GROUP 00 -Maintenance Service before beginning any service or maintenance of any com-

ponent of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: impact sensors, SRS diagnosis unit, SRS warning light, air bag module, clock spring

and interconnecting wiring. Other SRS-related components (that may

h,a”” to be removed/installed in connection with SRS serviceor maintenance) are indicated in the table of contents by an asterisk ( ).

Page 533 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System54-37

i

TROUBLESHOOTING

LHEADLIGHT

OPERATION

lTurn the lighting switch to “HEAD”, and the con-

tact point of the headlight relay will be closedto turn “ON” the headlight relay.

lWhen the dimmer switch is placed in the LO

position, the headlight low-beams go on. On

vehicles up to 1993 model, when the switch

is placed in the HI position, the headlight high-

beams go on. On vehicles from 1994 model,when the switch is placed in the HI position,

the headlight high-beams and low-beams go

on.

When the high-beam is lit or when the passing

switch is activated, the high-beam indicator lightwill be lit.

If the driver’s door is opened after the ignition

switch is turned to “OFF” or the ignition switchis turned to “OFF” after the driver’s door is

opened when the headlights are lit, the currentwhich flows to the coil side of the headlight

relay will be cut off by the light automatic shut-OFF unit opening the contact point, and the

headlight relay will be turned “OFF” to automati-

cally shut off the headlights.l

To turn the headlights on again after they are

automatically shut off, turn the lighting switchto “OFF” once and then back to “HEAD”, or

turn the ignition switch to “ACC” or “ON”, and

the

aut0mati.c shut-OFF will be cancelled andthe current will flow from the light automatic

shut-OFF unit to the coil side of the headlightrelay again to close the contact point. Thus,

the headlight relay will be turned “ON” to turnon the headlights.

NOTEWhen the lighting switch is at “HEAD”, the light

automatic shut-OFF system is valid for tail lights,

parking and side marker lights, license plate light,

illumination light, etc.(Refer to

P.54-70.)

l

When the lighting switch is placed in the HEAD

position, current flows through multi-purpose

fuse (6) to the lighting switch, and the ETACScontrol unit. Then the UP timer circuit in the

LETACS control unit is operated, and currentflows from the ETACS control unit to the U con-tact of the pop-up motor U/D (UP/DOWN)

switch, the coil of the pop-up motor relay and

ground, causing the contacts of the pop-up mo-

tor relay to close.

When the contacts of the pop-up motor relay

close, current flows through the contacts of the

pop-up motor relay to the pop-up motor and

ground, causing the pop-up motor to rotate,

which brings the headlights to the UP position.

The pop-up motor rotates until the automatic

UP stop position is reached, then the contactsof the interlocked U/D (UP/DOWN) switch

change from the U to D contacts. As a result,

the contacts of the pop-up motor relay opento cut off the current supplied to the pop-up

motor. Then the pop-up motor ceases to rotate,

holding the headlights in the UP position.l

When the lighting switch is placed in the TAIL

or OFF position, current flows through the multi-

purpose fuse (6) to the lighting switch, and the

ETACS control unit. Then the DOWN timer cir-

cuit in the ETACS control unit is operated and

current flows from the ETACS control unit to

the DOWN contacts of the pop-up motor U/D

(UP/DOWN) switch, the coil of the pop-up motor

relay and ground, causing the contacts of the

pop-up motor relay to close.

When the contacts of the pop-up motor relay

close, current flows through the contacts of the

pop-up motor relay to the pop-up motor andground, causing the pop-up motor to rotate,

which brings the headlights to the DOWN posi-

tion.

The pop-up motor rotates until the automatic

DOWN stop position is reached, then the con-

tacts of the interlocked U/D (UP/DOWN) switch

change from the D to U contacts. As a result,

the contacts of the pop-up motor relay open

to cut off current supply to the pop-up motor.

Then the pop-up motor ceases to rotate, holding

the headlights in the DOWN position.

When the pop-up switch is placed in the UP

position, current flows through multi-purpose

fuse (6) to the lighting switch, the pop-up switch

and the ETACS control unit, which brings the

headlights to the UP position and holds them

in the UP position just like when they are oper-

ated by the lighting switch.l

When the pop-up switch is placed in the DOWN

position, current flows through the multi-purpose

fuse (6) to the lighting switch, the pop-up switch

and the ETACS control unit, which brings the

headlights to the DOWN position and holds them

in the DOWN position just like when they are

operated by the lighting switch.

TSB Revision

Page 534 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Liahting System

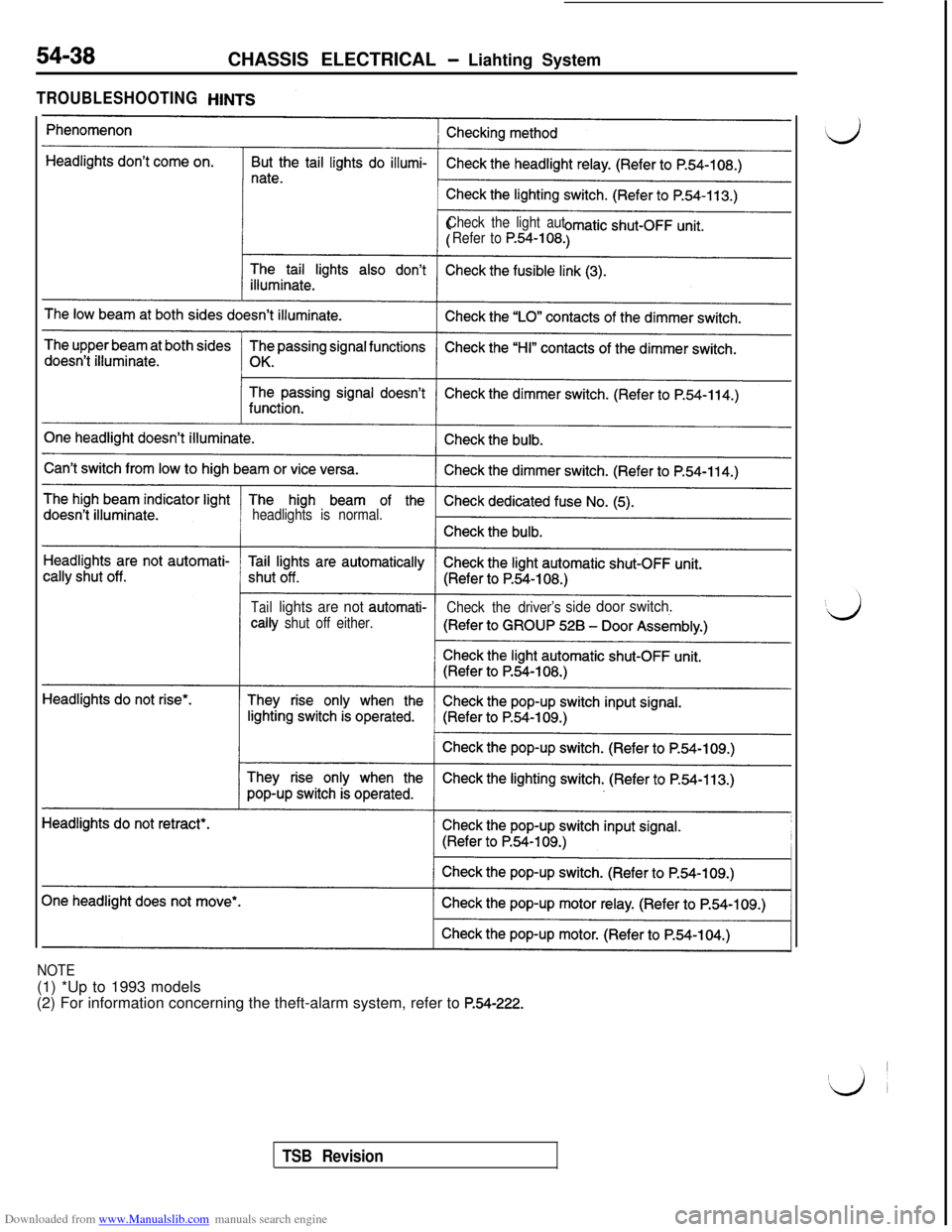

TROUBLESHOOTING

Check the light aut

Refer to

P.54-108.

headlights is normal.

Taillights are not automati-

Check the driver’ssidedoor switch.tally

shut off either.

NOTE(1) *Up to 1993 models

(2) For information concerning the theft-alarm system, refer to

P.54-222.

TSB Revision

Page 566 of 738

Downloaded from www.Manualslib.com manuals search engine 54-70CHASSIS ELECTRICAL - Lighting System

OPERATION

0When the lighting switch is placed in the TAILor HEAD position, current flows through the

coil of the tail light relay to the lighting switchand ground, causing the contacts of the tail

light relay to close.

Then current flows through the contacts of thetail light relay to the dedicated fuse

(2) the

individual lights and ground, causing the tail

lights, parking/side marker lights and licenseplate lights to go ON.

lIf the driver’s door is opened after the ignition

switch is turned to “OFF” or the ignition switchis turned to “OFF” after the driver’s door is

opened when the tail lights are lit, the current

which flows to the coil side of the tail light relaywill be cut off by the light automatic shut-off

unit opening the contact point, and the tail light

relay will be turned “OFF’ to automatically shut

off the tail lights, parking and front side marker

lights and license plate light.

lTo turn on the tail lights, parking and front side

marker lights and license plate light again after

they are automatically shut off, turn the lightingswitch to “OFF” once and to “HEAD” again,

or turn the ignition switch to “ACC” or “ON”,

and the automatic shut-OFF will be cancelled

and the current will flow from the light automaticshut-OFF unit to the coil side of the tail light

relay to close the contact point. Thus, the taillight relay will be turned “ON” to turn on the

tail lights, parking and front marker lights and

license plate light.

NOTE

When the lighting switch is at the “HEAD” position,

the light automatic shut-OFF system will be also

activated for the headlights. (Refer to P.54-37.) The

same system will also be activated for the illumina-

tion lights, etc.

TROUBLESHOOTING HINTS1. All lights don’t illuminate.

(1) The headlights don’t illuminate, either.l Check the fusible link (3).

(2) The headlights illuminate.l Check the tail light relay. (Refer to

P.54-108.)l Check the dedicated fuse (2).

l Check the lighting switch. (Refer to

P.54-113.)l Check the light automatic shut-OFF

unit. (Refer to

P.54-108.)2. Some light does not come on.

l Check the bulb.

l Check the grounding circuit.

3. Some light is not automatically shut off.

lCheck the driver’s side door switch.

(Refer to GROUP 42- Door Assembly.)l Check the automatic shut-OFF unit.

(Refer to

P.54-108.)

1 TSB Revision

Page 596 of 738

Downloaded from www.Manualslib.com manuals search engine 54-100CHASSIS ELECTRICAL - Lighting System

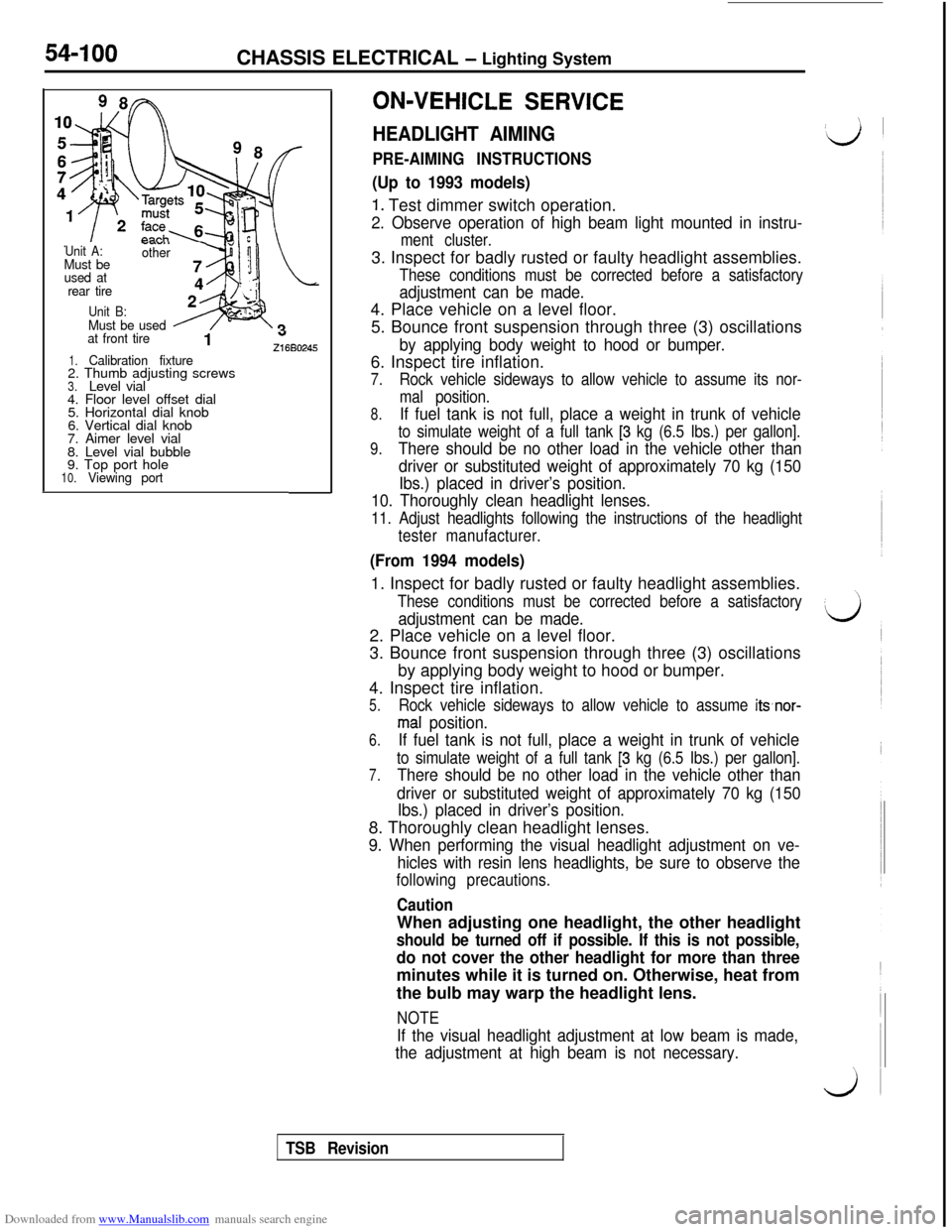

Unit A:Must be

used at

rear tire

“..“I. .other

Unit B:Must be used

at front tire1 -216802451.Calibration fixture2. Thumb adjusting screws

3.Level vial

4. Floor level offset dial

5. Horizontal dial knob

6. Vertical dial knob

7. Aimer level vial

8. Level vial bubble

9. Top port hole

10.Viewing portON-VEHICLE

SERVICE

HEADLIGHT AIMING

PRE-AIMING INSTRUCTIONS

(Up to 1993 models)

1. Test dimmer switch operation.

2. Observe operation of high beam light mounted in instru-

ment cluster.3. Inspect for badly rusted or faulty headlight assemblies.

These conditions must be corrected before a satisfactory

adjustment can be made.4. Place vehicle on a level floor.

5. Bounce front suspension through three (3) oscillations

by applying body weight to hood or bumper.6. Inspect tire inflation.

7.Rock vehicle sideways to allow vehicle to assume its nor-

mal position.

8.If fuel tank is not full, place a weight in trunk of vehicle

9.

to simulate weight of a full tank [3 kg (6.5 Ibs.) per gallon].

There should be no other load in the vehicle other than

driver or substituted weight of approximately 70 kg (150

Ibs.) placed in driver’s position.

10. Thoroughly clean headlight lenses.

11. Adjust headlights following the instructions of the headlight

tester manufacturer.

(From 1994 models)1. Inspect for badly rusted or faulty headlight assemblies.

These conditions must be corrected before a satisfactory

adjustment can be made.2. Place vehicle on a level floor.

3. Bounce front suspension through three (3) oscillations

by applying body weight to hood or bumper.

4. Inspect tire inflation.

5.Rock vehicle sideways to allow vehicle to assume it.snor-

mal position.

6.If fuel tank is not full, place a weight in trunk of vehicle

7.

to simulate weight of a full tank [3 kg (6.5 Ibs.) per gallon].

There should be no other load in the vehicle other than

driver or substituted weight of approximately 70 kg (150

Ibs.) placed in driver’s position.8. Thoroughly clean headlight lenses.

9. When performing the visual headlight adjustment on ve-

hicles with resin lens headlights, be sure to observe the

following precautions.

CautionWhen adjusting one headlight, the other headlight

should be turned off if possible. If this is not possible,

do not cover the other headlight for more than threeminutes while it is turned on. Otherwise, heat from

the bulb may warp the headlight lens.

NOTE

If the visual headlight adjustment at low beam is made,

the adjustment at high beam is not necessary.

TSB Revision

Page 597 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System54-101

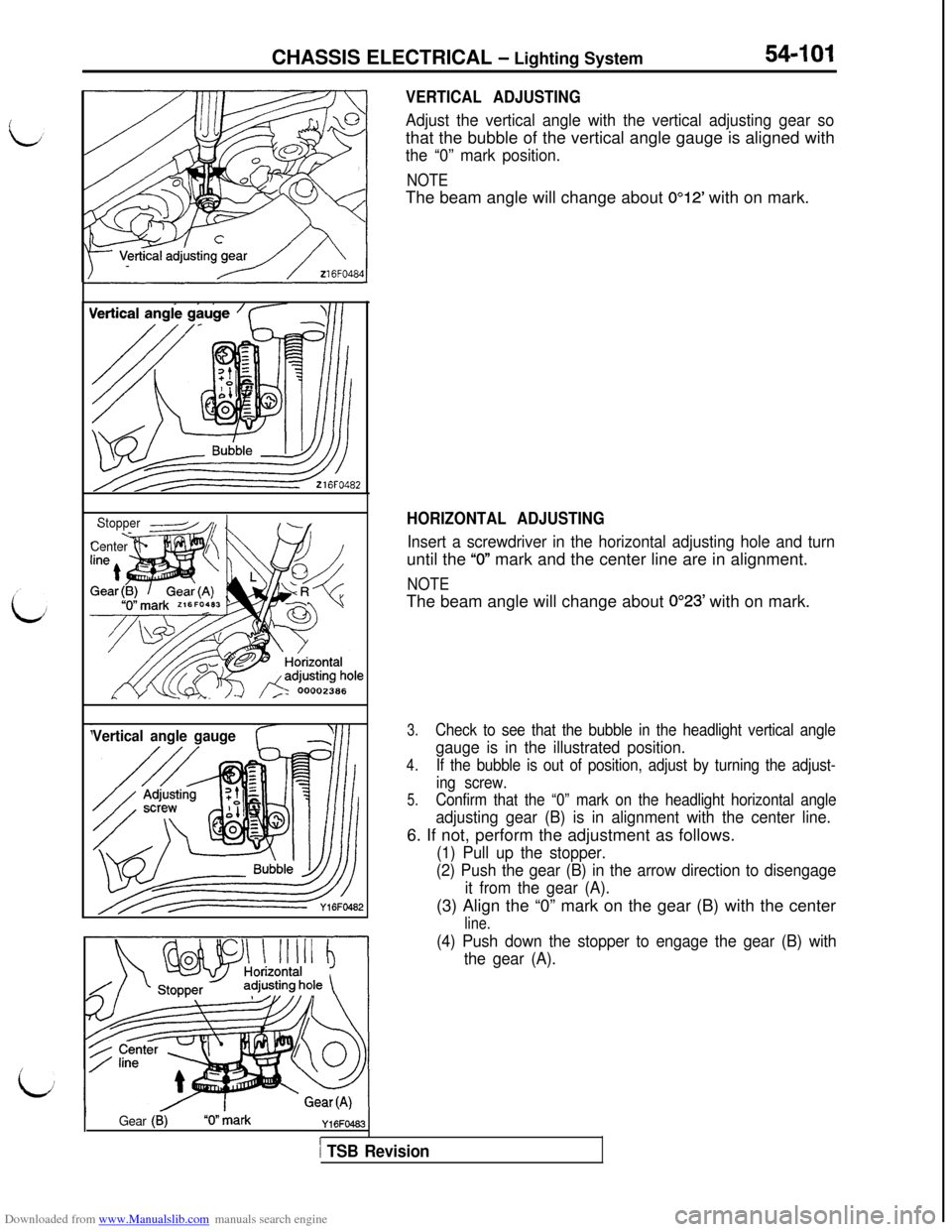

VERTICAL ADJUSTING

Adjust the vertical angle with the vertical adjusting gear sothat the bubble of the vertical angle gauge is aligned with

the “0” mark position.

NOTEThe beam angle will change about 0’12’ with on mark.

Stopper

Center bm

Vertical angle gauge

HORIZONTAL ADJUSTING

Insert a screwdriver in the horizontal adjusting hole and turnuntil the

“0” mark and the center line are in alignment.

NOTEThe beam angle will change about 0’23’ with on mark.

Gear (6)“0” hark

3.Check to see that the bubble in the headlight vertical angle

gauge is in the illustrated position.

4.If the bubble is out of position, adjust by turning the adjust-

ing screw.

5.Confirm that the “0” mark on the headlight horizontal angle

adjusting gear (B) is in alignment with the center line.6. If not, perform the adjustment as follows.

(1) Pull up the stopper.

(2) Push the gear (B) in the arrow direction to disengage

it from the gear (A).(3) Align the “0” mark on the gear (B) with the center

line.

(4) Push down the stopper to engage the gear (B) with

the gear (A).

1 TSB Revision