seat MITSUBISHI 380 2005 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1210 of 1500

ON-VEHICLE SERVICE

PARKING BRAKES36-3

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Insufficient Parking Brake Function

DIAGNOSIS

STEP 1. Check the excessive parking brake lever

stroke.

Refer to P.36-3.

Q: Is the parking brake lever stroke adjusted

properly?

YES :

Go to Step 2.

NO : Adjust the parking brake lever stroke or

check the parking brake cable routing. Then

go to Step 5.

STEP 2. Check the parking brake cable for

sticking.

Q: Is the parking brake cable stuck?

YES :

Replace the cable. Then go to Step 5.

NO : Go to Step 3.

STEP 3. Check the brake lining and brake drum

for wear.

Refer to P.36-11.

Q: Is the brake lining thickness or brake drum inside

diameter outside of specification?

YES :

Replace the rear brake shoe assembly or

rear brake disc (Refer to P.36-8). Then go to

Step 5.

NO : Go to Step 4.

STEP 4. Check for oil, water, etc., on the lining

contact surfaces.

Q: Is oil, water, etc., on the lining contact surface?

YES :

Replace the part and determine and repair

source/cause of foreign material. Then go to

St e p 5.

NO : Carry out the parking brake lining seating

(Refer to P.36-5) and then go to Step 5.

STEP 5. Retest the system.

Q: Is the malfunction eliminated?

YES :

The procedure is complete.

NO : Recheck from Step 1.

ON-VEHICLE SERVICE

PARKING BRAKE LEVER STROKE CHECK AND

ADJUSTMENT

M1361000900362

1. Pull the parking brake lever with a force of approximately

200 N (45 pounds) and count the number of notches.

Standard value: 5

7 notches

2. If the parking brake lever stroke is not within the standard

value, adjust as described below.

(1) Release the parking brake.

Page 1212 of 1500

ON-VEHICLE SERVICE

PARKING BRAKES36-5

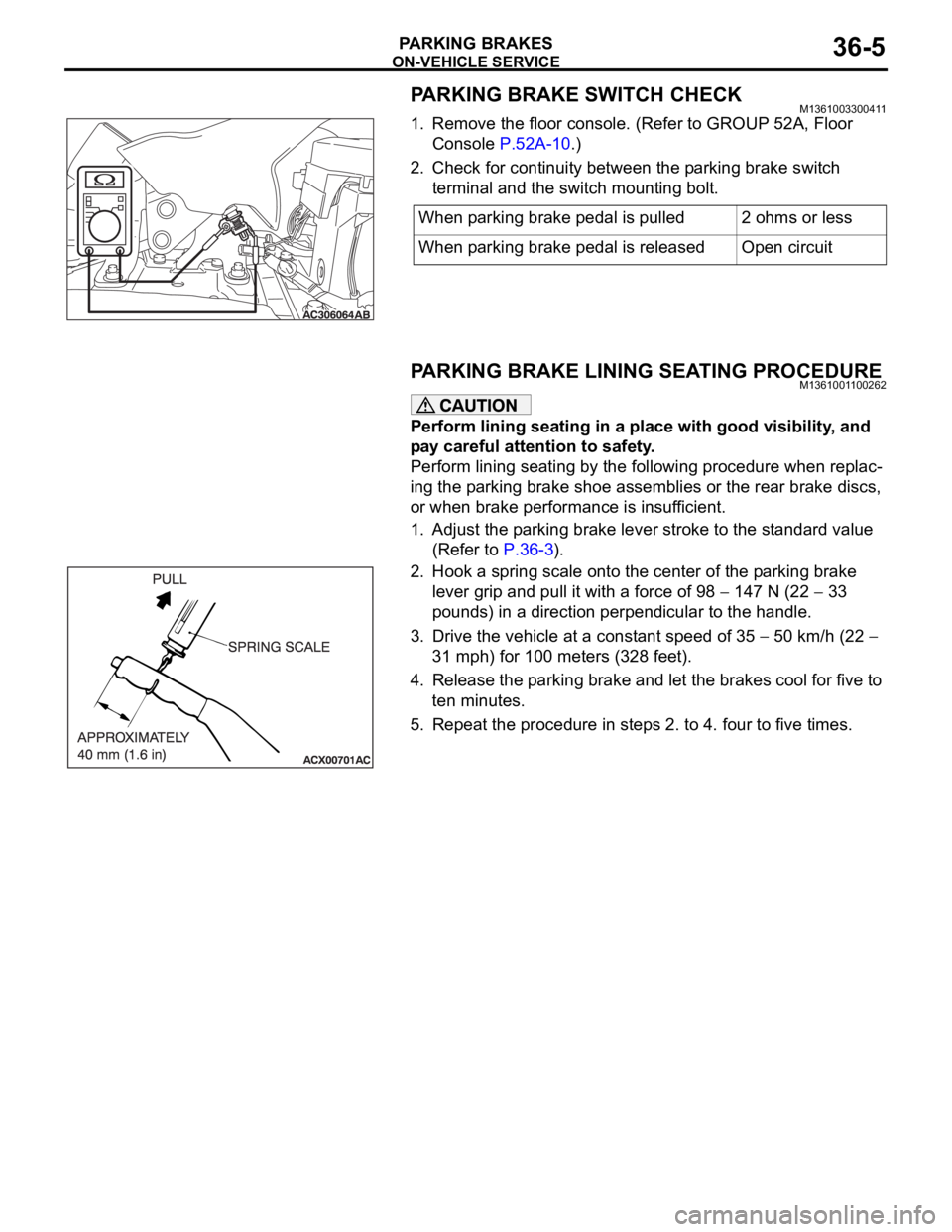

PARKING BRAKE SWITCH CHECKM1361003300411

1. Remove the floor console. (Refer to GROUP 52A, Floor

Console P.52A-10.)

2. Check for continuity between the parking brake switch

terminal and the switch mounting bolt.

PARKING BRAKE LINING SEATING PROCEDUREM1361001100262

Perform lining seating in a place with good visibility, and

pay careful attention to safety.

Perform lining seating by the following procedure when replac-

ing the parking brake shoe assemblies or the rear brake discs,

or when brake performance is insufficient.

1. Adjust the parking brake lever stroke to the standard value

(Refer to P.36-3).

2. Hook a spring scale onto the center of the parking brake

lever grip and pull it with a force of 98

147 N (22 33

pounds) in a direction perpendicular to the handle.

3. Drive the vehicle at a constant speed of 35

50 km/h (22

31 mph) for 100 meters (328 feet).

4. Release the parking brake and let the brakes cool for five to

ten minutes.

5. Repeat the procedure in steps 2. to 4. four to five times.When parking brake pedal is pulled 2 ohms or less

When parking brake pedal is released Open circuit

Page 1215 of 1500

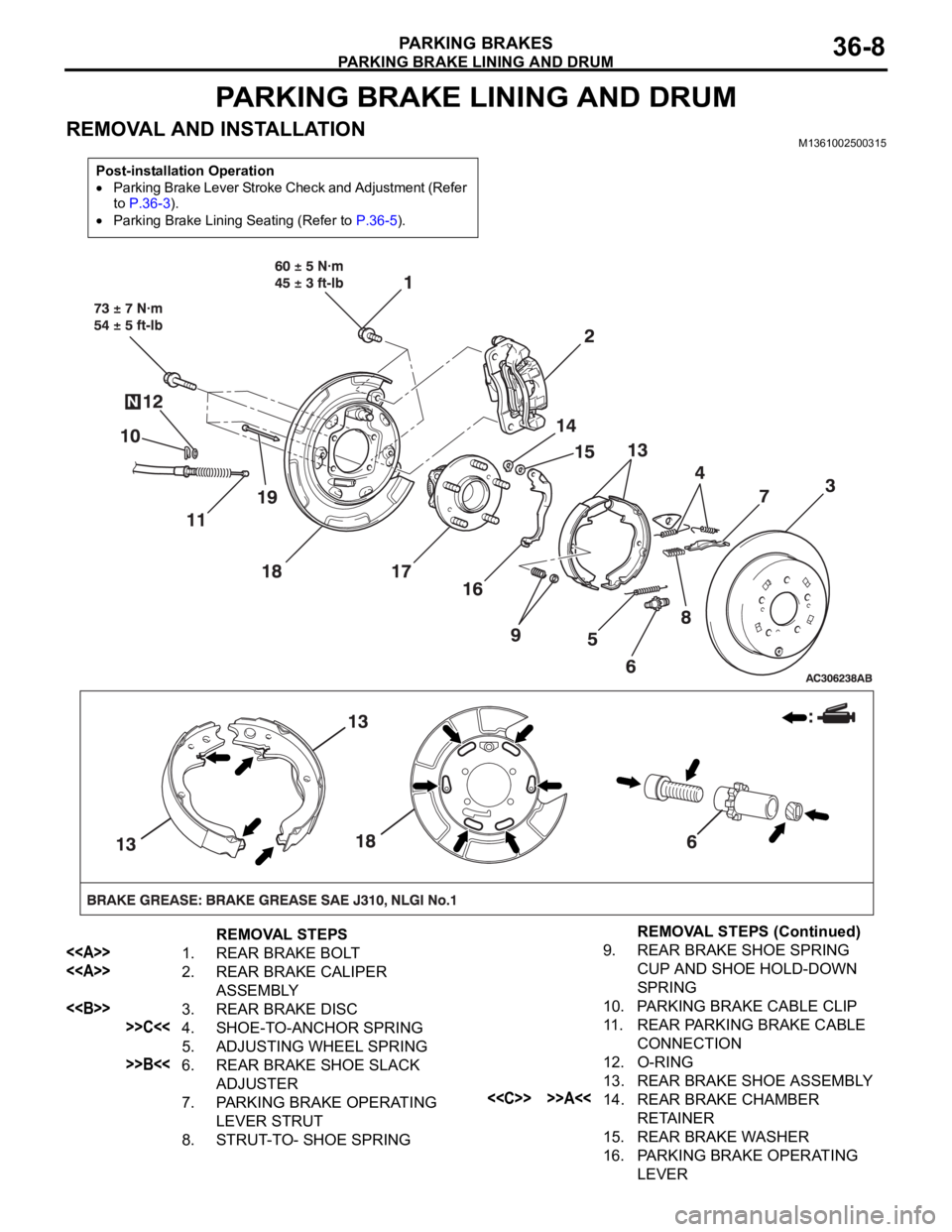

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-8

PARKING BRAKE LINING AND DRUM

REMOVAL AND INSTALLATIONM1361002500315

Post-installation Operation

Parking Brake Lever Stroke Check and Adjustment (Refer

to P.36-3).

Parking Brake Lining Seating (Refer to P.36-5).

REMOVAL STEPS

<> 1. REAR BRAKE BOLT

<> 2. REAR BRAKE CALIPER

ASSEMBLY

<> 3. REAR BRAKE DISC

>>C<<4. SHOE-TO-ANCHOR SPRING

5. ADJUSTING WHEEL SPRING

>>B<<6. REAR BRAKE SHOE SLACK

ADJUSTER

7. PARKING BRAKE OPERATING

LEVER STRUT

8. STRUT-TO- SHOE SPRING

9. REAR BRAKE SHOE SPRING

CUP AND SHOE HOLD-DOWN

SPRING

10. PARKING BRAKE CABLE CLIP

11. REAR PARKING BRAKE CABLE

CONNECTION

12. O-RING

13. REAR BRAKE SHOE ASSEMBLY

<

RETAINER

15. REAR BRAKE WASHER

16. PARKING BRAKE OPERATING

LEVER

REMOVAL STEPS (Continued)

Page 1242 of 1500

VEHICLE IDENTIFICATION

GENERAL00-21

OPTION CODES (380 Series)

EXPORT CODES

TYRE AND LOADING INFORMATION PLACARD

The tyre and loading information placard is located on the

inside sill of the driver’s door. OPTION CODE: ITEM

G39 Sunroof

C73 Leather (380 VRX)

J40 Traction Control

W51 16" Alloy Wheels

W54 17" Alloy Wheels + Sports Suspension + Strut Tower Bar

R06 Satellite Navigation Accommodation Package

J07 LX MARK (Only in combination with G39, C78, K40, W54) on

380-LS model

G39, C73 Sunroof + Leather

J40, W51 Traction Control + 16" Alloy Wheels

C78, K40 Leather (380 LS) + Power Seats

G05, J06 ECM + Vanity Mirror Lamp

J40, W51, G39 Traction Control + 16 " Alloy Wheels + Sunroof

G39, C78, K40 Sunroof + Leather (380 LS) + Power Seats

G39, C78, K40, W54 Sunroof + Leather (380 LS) + Power Seats + 17" Alloy Wheels +

Sports Suspension + Strut Tower Bar

G39, C78, K40, W54,

J07Sunroof + Leather (380 LS) + Power Seats + 17" Alloy Wheels +

Sports Suspension + Strut Tower Bar + LX Badging

OPTION

CODE ITEM

X71 Fiji

X62 New Zealand

A18 Export Preparation (wax and brake bags)

X30 Brunei

Page 1243 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-22

ENGINE MODEL STAMPING

The engine model is stamped on the cylinder block.

The engine model number is as shown as follow.

The engine serial number is stamped near the engine model

number.

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)M1001011600056

1. Items to review when servicing SRS:

(1) Be sure to read GROUP 52B, Supplemental

Restraint System (SRS). For safe operation,

please follow the directions and heed all

warnings.

(2) Wait at least 60 seconds after disconnecting

the battery cable before doing any further

work. The SRS system is designed to retain

enough voltage to deploy the air bag even

after the battery has been disconnected.

Serious injury may result from unintended air

bag deployment if work is done on the SRS

system immediately after the battery cable is

disconnected.

(3) Warning labels must be heeded when

servicing or handling SRS components.

Warning labels can be found in the following

locations.

Front impact sensor

Hood

Sun visor

Instrument panel (passenger ’s side)

SRS-ECU

Steering wheel

Clock spring

Air bag module (Driver's or front

passenger's)

Side-airbag module (Driver's side or front

passenger's side)

Side impact sensor

Seat belt pre-tensioner

(4) Always use the designated special tools and

test equipment.(5) Store components removed from the SRS in a

clean and dry place. The air bag module

should be stored on a flat surface and placed

so that the pad surface is facing upward.

(6) Never attempt to disassemble or repair the

SRS components (SRS-ECU, air bag module

and clock spring). If there is a defect, replace

the defective part.

(7) Whenever you finish servicing the SRS, check

the SRS warning light operation to make sure

that the system functions properly.

(8) Be sure to deploy the air bag before disposing

of the air bag module or disposing of a vehicle

equipped with an air bag (Refer to GROUP

52B, Air Bag Module Disposal Procedures

P.52B-254).

2. Observe the following when carrying out

operations on places where SRS components are

installed, including operations not directly related

to the SRS air bag.

(1) When removing or installing parts, do not allow

any impact or shock to occur to the SRS

components.

(2) If heat damage may occur during paint work,

remove the SRS-ECU, the air bag module,

clock spring, the front impact sensor, the side

impact sensor, and the seat belt pre-tensioner.

a.SRS-ECU, air bag module, clock spring,

front impact sensor, the side impact sensor:

93

C (200F) or more

b.Seat belt pre-tensioner: 90

C (194F) or

more ENGINE MODEL ENGINE DISPLACEMENT

6G75 3828cc

Page 1252 of 1500

GENERAL DATA AND SPECIFICATIONS

GENERAL00-31

GENERAL DATA AND SPECIFICATIONSM1001000900473.

GENERAL SPECIFICATIONS

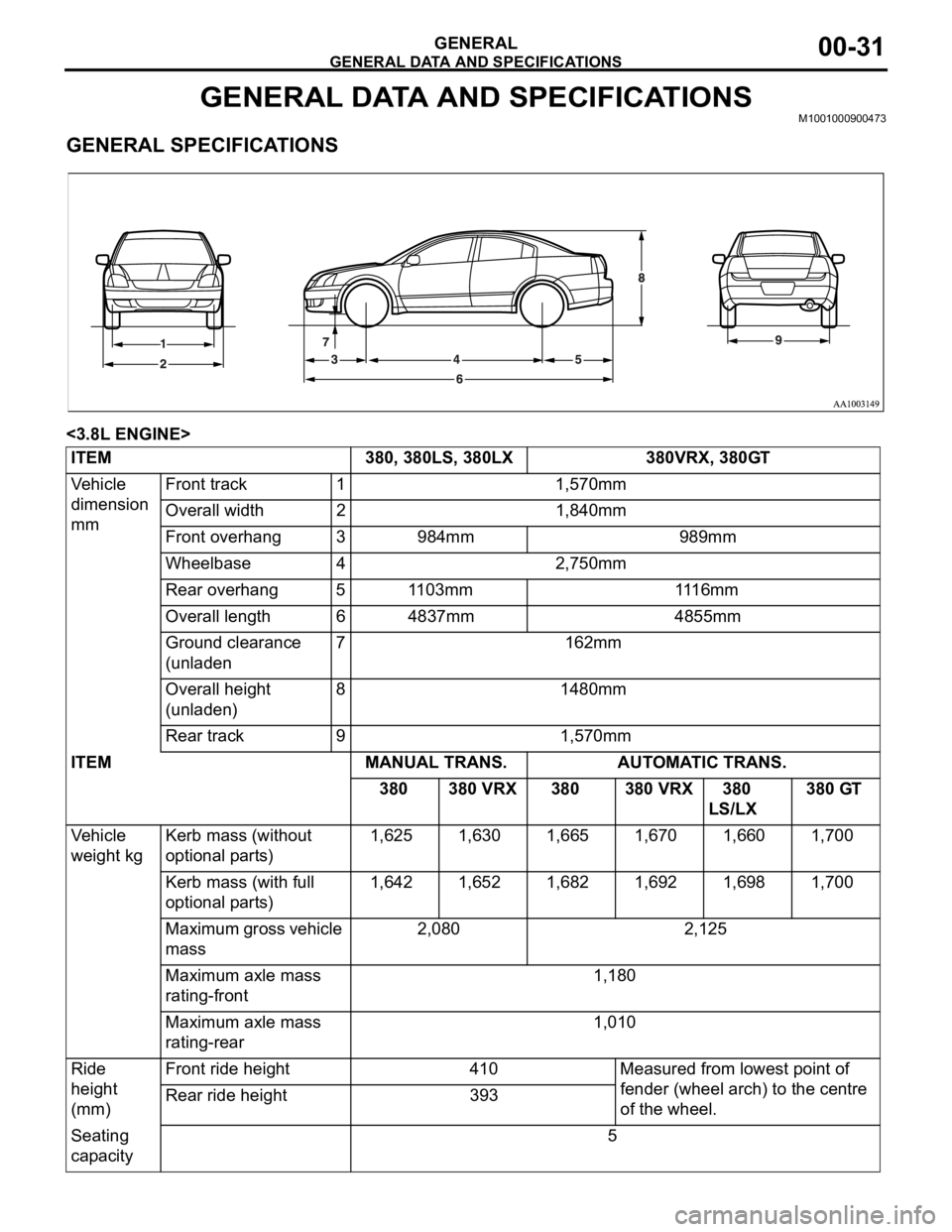

<3.8L ENGINE>

ITEM 380, 380LS, 380LX 380VRX, 380GT

Vehicle

dimension

mmFront track 1 1,570mm

Overall width 2 1,840mm

Front overhang 3 984mm 989mm

Wheelbase 4 2,750mm

Rear overhang 5 1103mm 1116mm

Overall length 6 4837mm 4855mm

Ground clearance

(unladen7 162mm

Overall height

(unladen)8 1480mm

Rear track 9 1,570mm

ITEM MANUAL TRANS. AUTOMATIC TRANS.

380 380 VRX 380 380 VRX 380

LS/LX 380 GT

Vehicle

weight kgKerb mass (without

optional parts) 1,625 1,630 1,665 1,670 1,660 1,700

Kerb mass (with full

optional parts) 1,642 1,652 1,682 1,692 1,698 1,700

Maximum gross vehicle

mass 2,080 2,125

Maximum axle mass

rating-front 1,180

Maximum axle mass

rating-rear 1,010

Ride

height

(mm)Front ride height 410 Measured from lowest point of

fender (wheel arch) to the centre

of the wheel. Rear ride height 393

Seating

capacity 5

Page 1272 of 1500

MAINTENANCE SERVICE

GENERAL00-51

18. SUSPENSION SYSTEM (INSPECT FOR

LOOSENESS AND DAMAGE)

M1001009600048

Visually inspect the front/rear suspension components for dete-

rioration and damage. Re-tighten the front/rear suspension

components retaining bolts to specified torque.

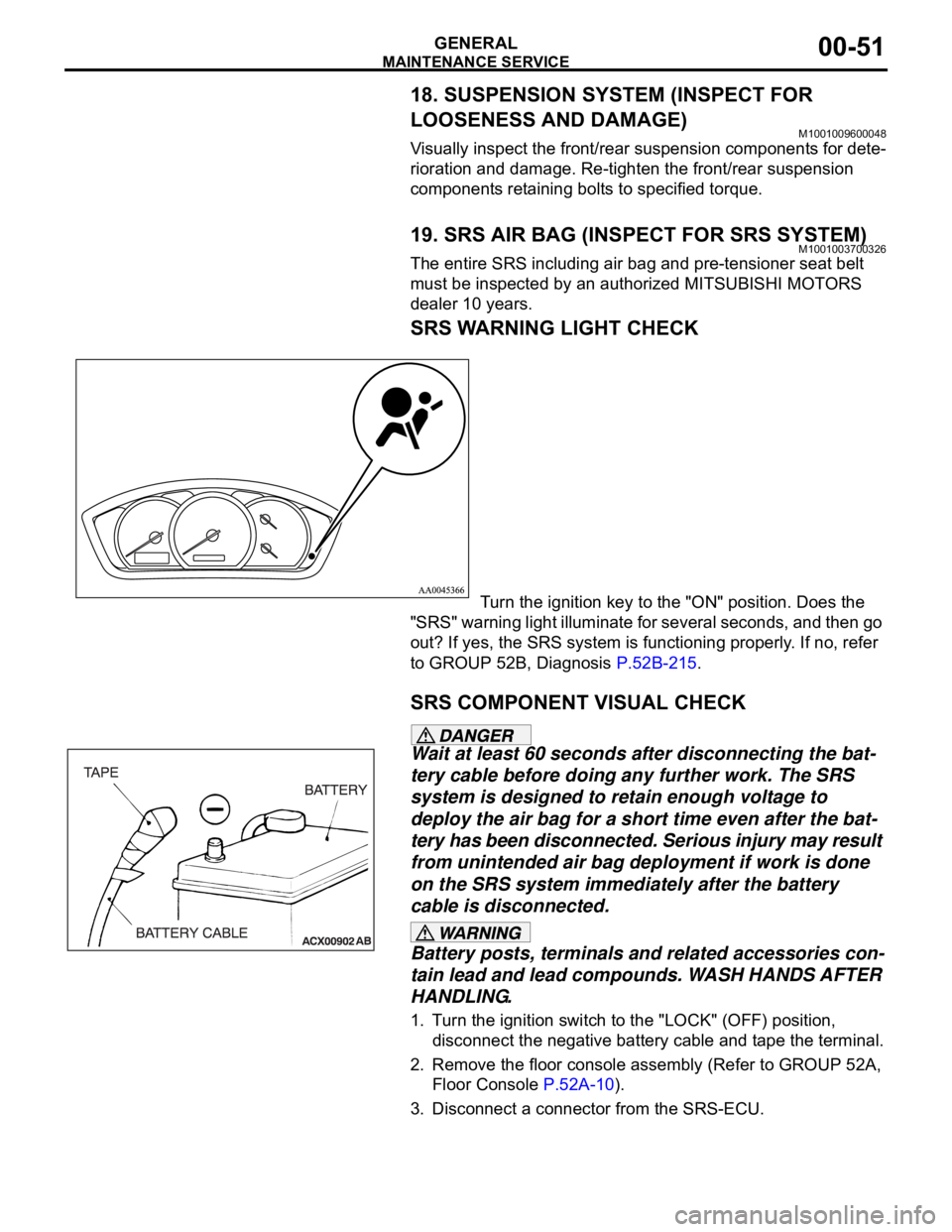

19. SRS AIR BAG (INSPECT FOR SRS SYSTEM)M1001003700326

The entire SRS including air bag and pre-tensioner seat belt

must be inspected by an authorized MITSUBISHI MOTORS

dealer 10 years.

SRS WARNING LIGHT CHECK

Turn the ignition key to the "ON" position. Does the

"SRS" warning light illuminate for several seconds, and then go

out? If yes, the SRS system is functioning properly. If no, refer

to GROUP 52B, Diagnosis P.52B-215.

SRS COMPONENT VISUAL CHECK

Wait at least 60 seconds after disconnecting the bat-

tery cable before doing any further work. The SRS

system is designed to retain enough voltage to

deploy the air bag for a short time even after the bat-

tery has been disconnected. Serious injury may result

from unintended air bag deployment if work is done

on the SRS system immediately after the battery

cable is disconnected.

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

1. Turn the ignition switch to the "LOCK" (OFF) position,

disconnect the negative battery cable and tape the terminal.

2. Remove the floor console assembly (Refer to GROUP 52A,

Floor Console P.52A-10).

3. Disconnect a connector from the SRS-ECU.

Page 1276 of 1500

MAINTENANCE SERVICE

GENERAL00-55

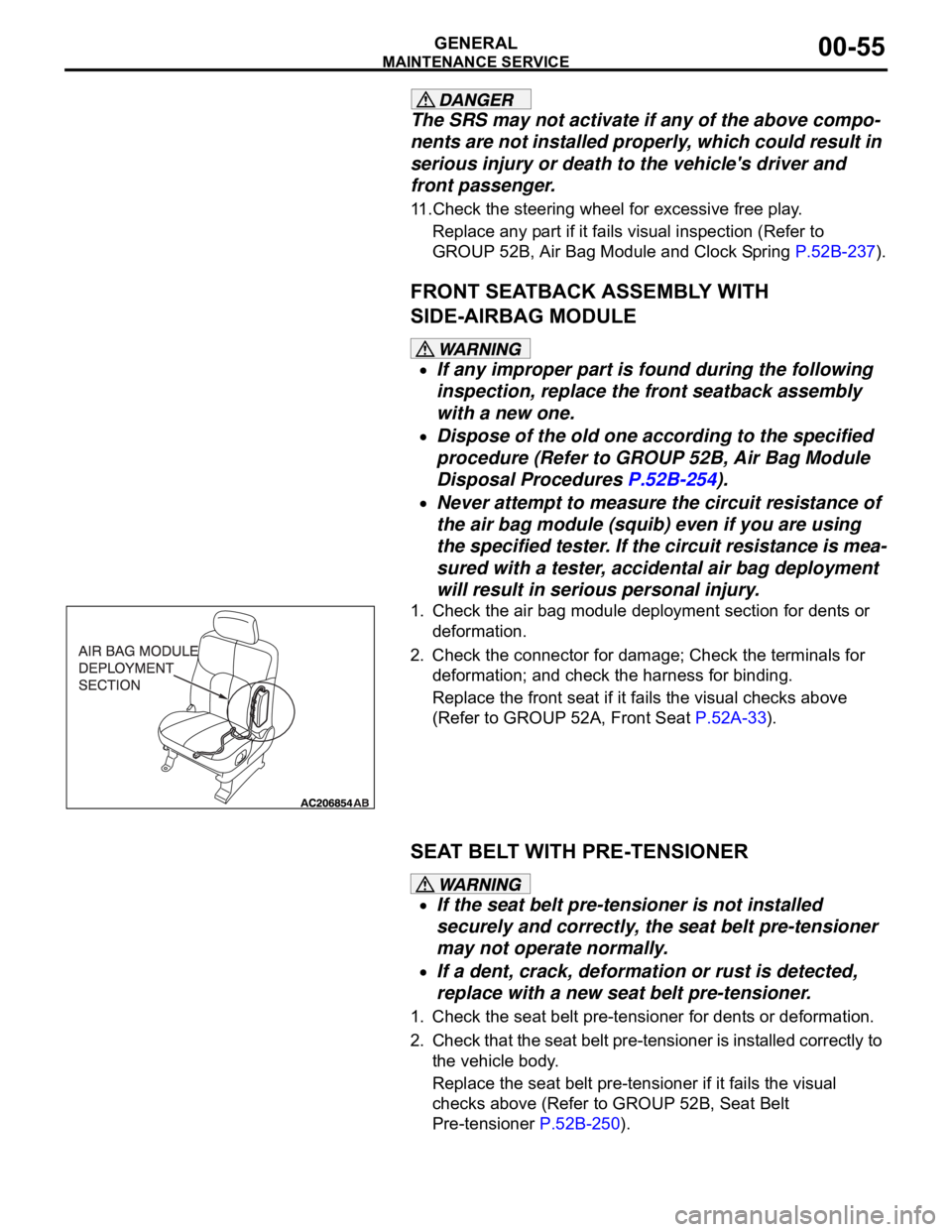

The SRS may not activate if any of the above compo-

nents are not installed properly, which could result in

serious injury or death to the vehicle's driver and

front passenger.

11.Check the steering wheel for excessive free play.

Replace any part if it fails visual inspection (Refer to

GROUP 52B, Air Bag Module and Clock Spring P.52B-237).

FRONT SEATBACK ASSEMBLY WITH

SIDE-AIRBAG MODULE

If any improper part is found during the following

inspection, replace the front seatback assembly

with a new one.

Dispose of the old one according to the specified

procedure (Refer to GROUP 52B, Air Bag Module

Disposal Procedures P.52B-254).

Never attempt to measure the circuit resistance of

the air bag module (squib) even if you are using

the specified tester. If the circuit resistance is mea-

sured with a tester, accidental air bag deployment

will result in serious personal injury.

1. Check the air bag module deployment section for dents or

deformation.

2. Check the connector for damage; Check the terminals for

deformation; and check the harness for binding.

Replace the front seat if it fails the visual checks above

(Refer to GROUP 52A, Front Seat P.52A-33).

SEAT BELT WITH PRE-TENSIONER

If the seat belt pre-tensioner is not installed

securely and correctly, the seat belt pre-tensioner

may not operate normally.

If a dent, crack, deformation or rust is detected,

replace with a new seat belt pre-tensioner.

1. Check the seat belt pre-tensioner for dents or deformation.

2. Check that the seat belt pre-tensioner is installed correctly to

the vehicle body.

Replace the seat belt pre-tensioner if it fails the visual

checks above (Refer to GROUP 52B, Seat Belt

Pre-tensioner P.52B-250).

Page 1322 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-43

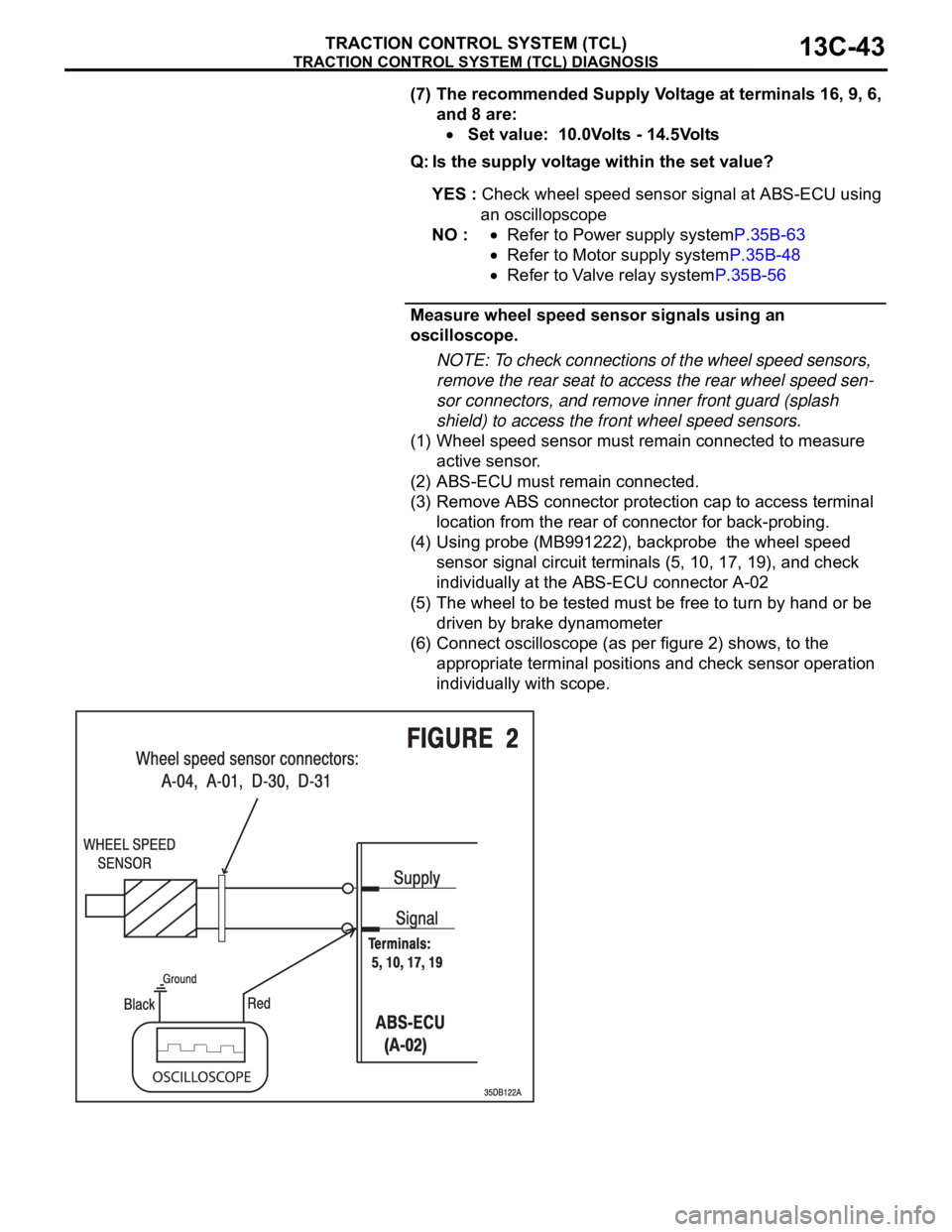

(7) The recommended Supply Voltage at terminals 16, 9, 6,

and 8 are:

Set value: 10.0Volts - 14.5Volts

Q: Is the supply voltage within the set value?

YES : Check wheel speed sensor signal at ABS-ECU using

an oscillopscope

NO :

Refer to Power supply systemP.35B-63

Refer to Motor supply systemP.35B-48

Refer to Valve relay systemP.35B-56

Measure wheel speed sensor signals using an

oscilloscope.

NOTE: To check connections of the wheel speed sensors,

remove the rear seat to access the rear wheel speed sen-

sor connectors, and remove inner front guard (splash

shield) to access the front wheel speed sensors.

(1) Wheel speed sensor must remain connected to measure

active sensor.

(2) ABS-ECU must remain connected.

(3) Remove ABS connector protection cap to access terminal

location from the rear of connector for back-probing.

(4) Using probe (MB991222), backprobe the wheel speed

sensor signal circuit terminals (5, 10, 17, 19), and check

individually at the ABS-ECU connector A-02

(5) The wheel to be tested must be free to turn by hand or be

driven by brake dynamometer

(6) Connect oscilloscope (as per figure 2) shows, to the

appropriate terminal positions and check sensor operation

individually with scope.

Page 1429 of 1500

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-12

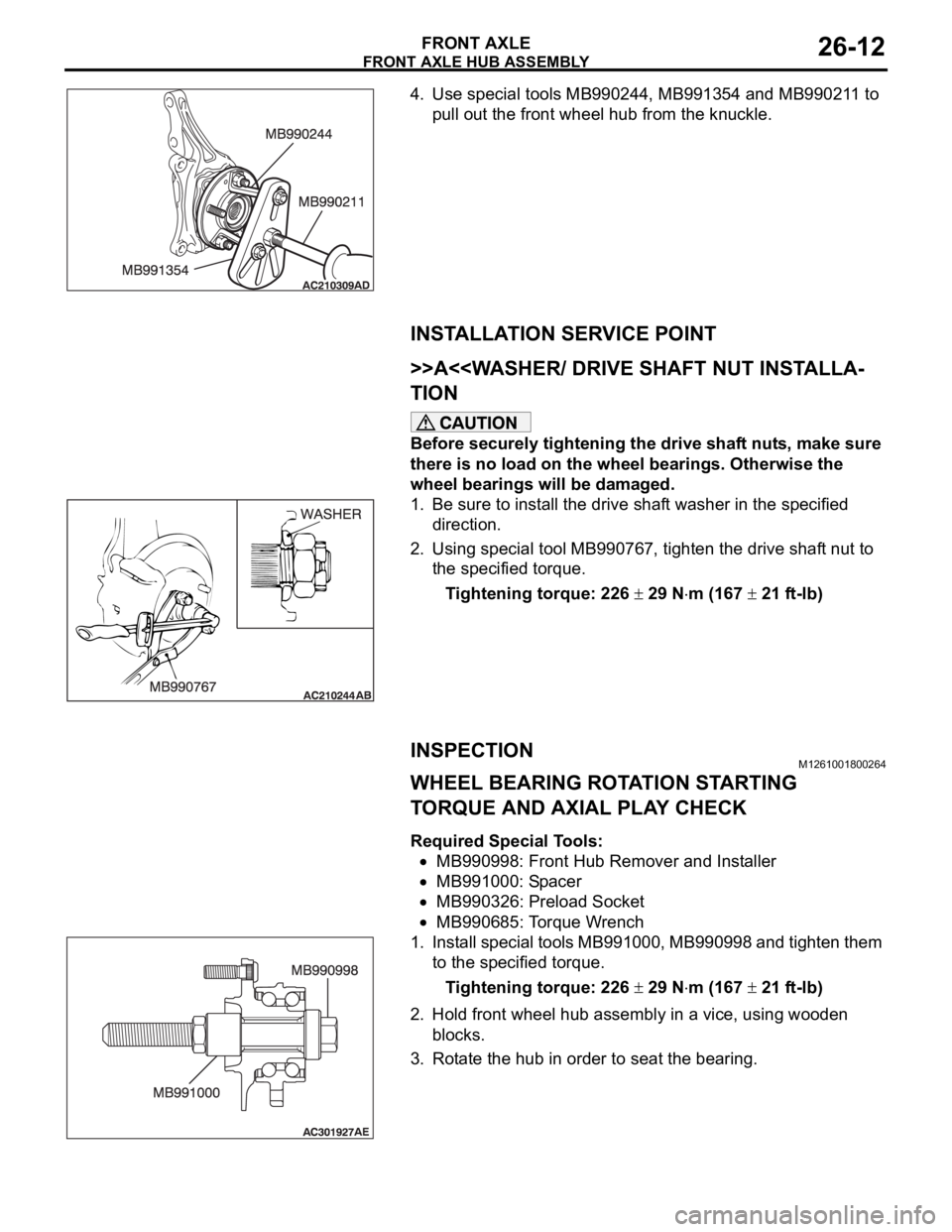

4. Use special tools MB990244, MB991354 and MB990211 to

pull out the front wheel hub from the knuckle.

INSTALLATION SERVICE POINT

.

>>A<

Before securely tightening the drive shaft nuts, make sure

there is no load on the wheel bearings. Otherwise the

wheel bearings will be damaged.

1. Be sure to install the drive shaft washer in the specified

direction.

2. Using special tool MB990767, tighten the drive shaft nut to

the specified torque.

Tightening torque: 226

29 Nm (167 21 ft-lb)

INSPECTIONM1261001800264

WHEEL BEARING ROTATION STARTING

TORQUE AND AXIAL PLAY CHECK

Required Special Tools:

MB990998: Front Hub Remover and Installer

MB991000: Spacer

MB990326: Preload Socket

MB990685: Torque Wrench

1. Install special tools MB991000, MB990998 and tighten them

to the specified torque.

Tightening torque: 226

29 Nm (167 21 ft-lb)

2. Hold front wheel hub assembly in a vice, using wooden

blocks.

3. Rotate the hub in order to seat the bearing.