diagnostic MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1481 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-22

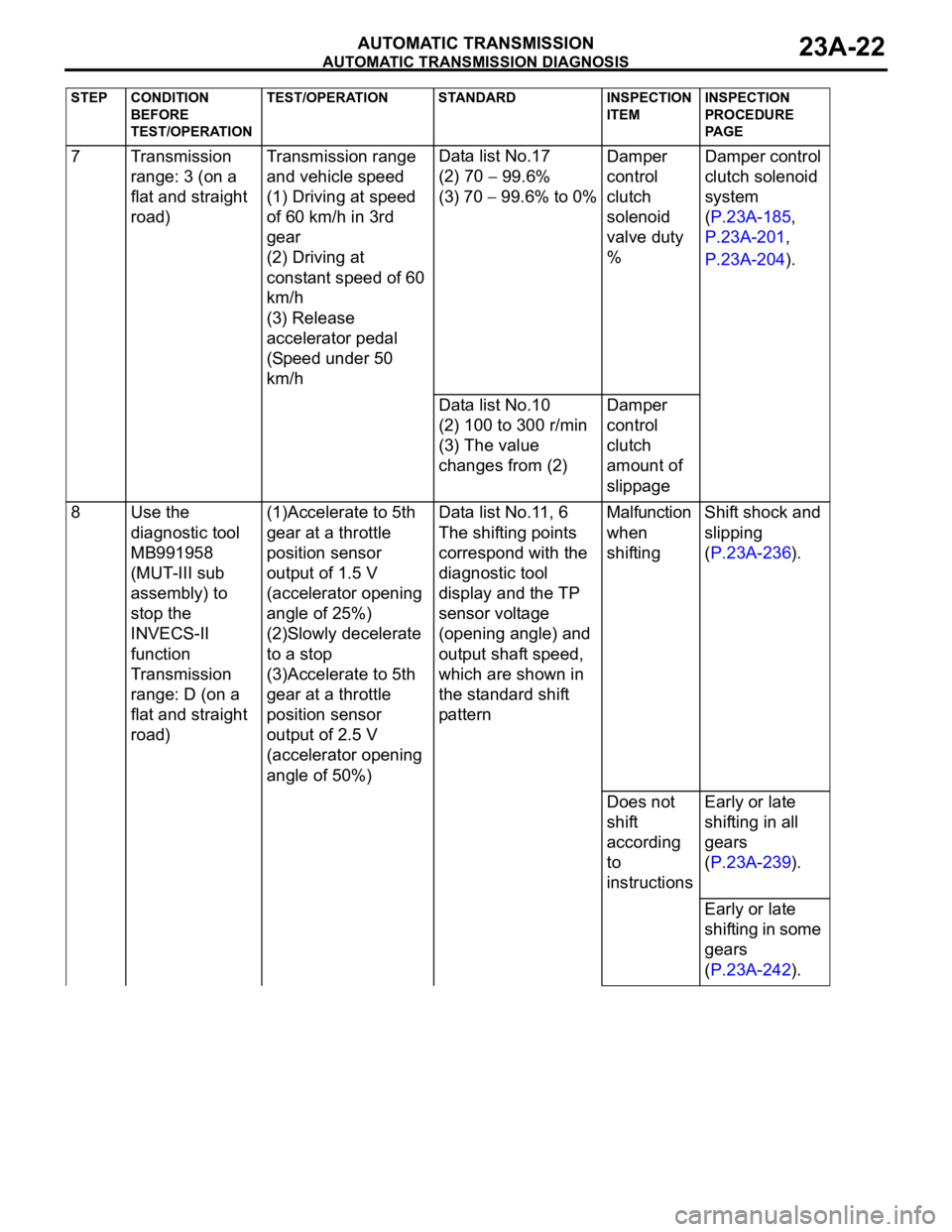

7 Transmission

range: 3 (on a

flat and straight

road)Transmission range

and vehicle speed

(1) Driving at speed

of 60 km/h in 3rd

gear

(2) Driving at

constant speed of 60

km/h

(3) Release

accelerator pedal

(Speed under 50

km/hData list No.17

(2) 70

99.6%

(3) 70

99.6% to 0%Damper

control

clutch

solenoid

valve duty

%Damper control

clutch solenoid

system

(P.23A-185,

P.23A-201,

P.23A-204).

Data list No.10

(2) 100 to 300 r/min

(3) The value

changes from (2)Damper

control

clutch

amount of

slippage

8 Use the

diagnostic tool

MB991958

(MUT-III sub

assembly) to

stop the

INVECS-II

function

Transmission

range: D (on a

flat and straight

road)(1)Accelerate to 5th

gear at a throttle

position sensor

output of 1.5 V

(accelerator opening

angle of 25%)

(2)Slowly decelerate

to a stop

(3)Accelerate to 5th

gear at a throttle

position sensor

output of 2.5 V

(accelerator opening

angle of 50%)Data list No.11, 6

The shifting points

correspond with the

diagnostic tool

display and the TP

sensor voltage

(opening angle) and

output shaft speed,

which are shown in

the standard shift

patternMalfunction

when

shiftingShift shock and

slipping

(P.23A-236).

Does not

shift

according

to

instructionsEarly or late

shifting in all

gears

(P.23A-239).

Early or late

shifting in some

gears

(P.23A-242).

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

Page 1482 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-23

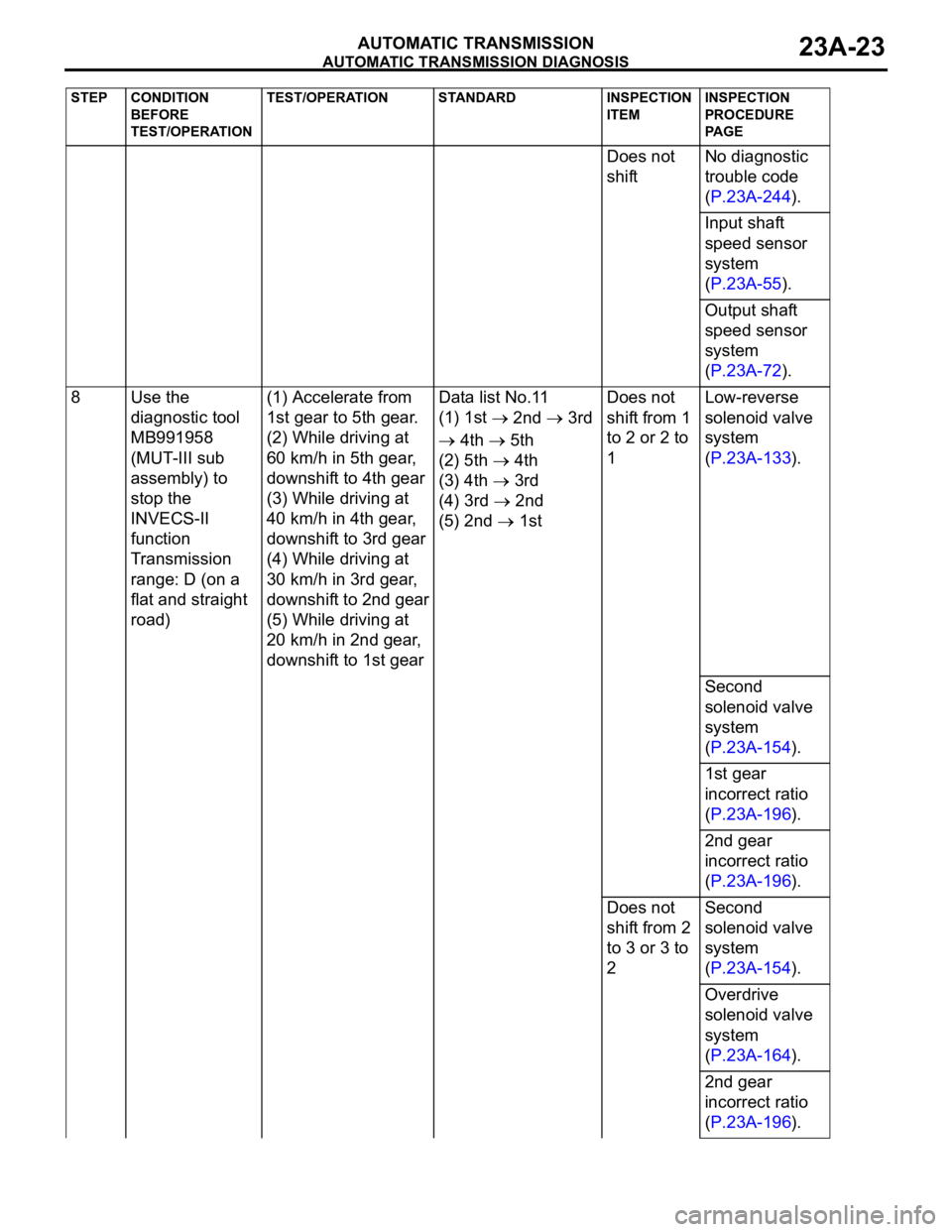

Does not

shiftNo diagnostic

trouble code

(P.23A-244).

Input shaft

speed sensor

system

(P.23A-55).

Output shaft

speed sensor

system

(P.23A-72).

8 Use the

diagnostic tool

MB991958

(MUT-III sub

assembly) to

stop the

INVECS-II

function

Transmission

range: D (on a

flat and straight

road)(1) Accelerate from

1st gear to 5th gear.

(2) While driving at

60 km/h in 5th gear,

downshift to 4th gear

(3) While driving at

40 km/h in 4th gear,

downshift to 3rd gear

(4) While driving at

30 km/h in 3rd gear,

downshift to 2nd gear

(5) While driving at

20 km/h in 2nd gear,

downshift to 1st gearData list No.11

(1) 1st

2nd 3rd

4th 5th

(2) 5th

4th

(3) 4th

3rd

(4) 3rd

2nd

(5) 2nd

1stDoes not

shift from 1

to 2 or 2 to

1Low-reverse

solenoid valve

system

(P.23A-133).

Second

solenoid valve

system

(P.23A-154).

1st gear

incorrect ratio

(P.23A-196).

2nd gear

incorrect ratio

(P.23A-196).

Does not

shift from 2

to 3 or 3 to

2Second

solenoid valve

system

(P.23A-154).

Overdrive

solenoid valve

system

(P.23A-164).

2nd gear

incorrect ratio

(P.23A-196).

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

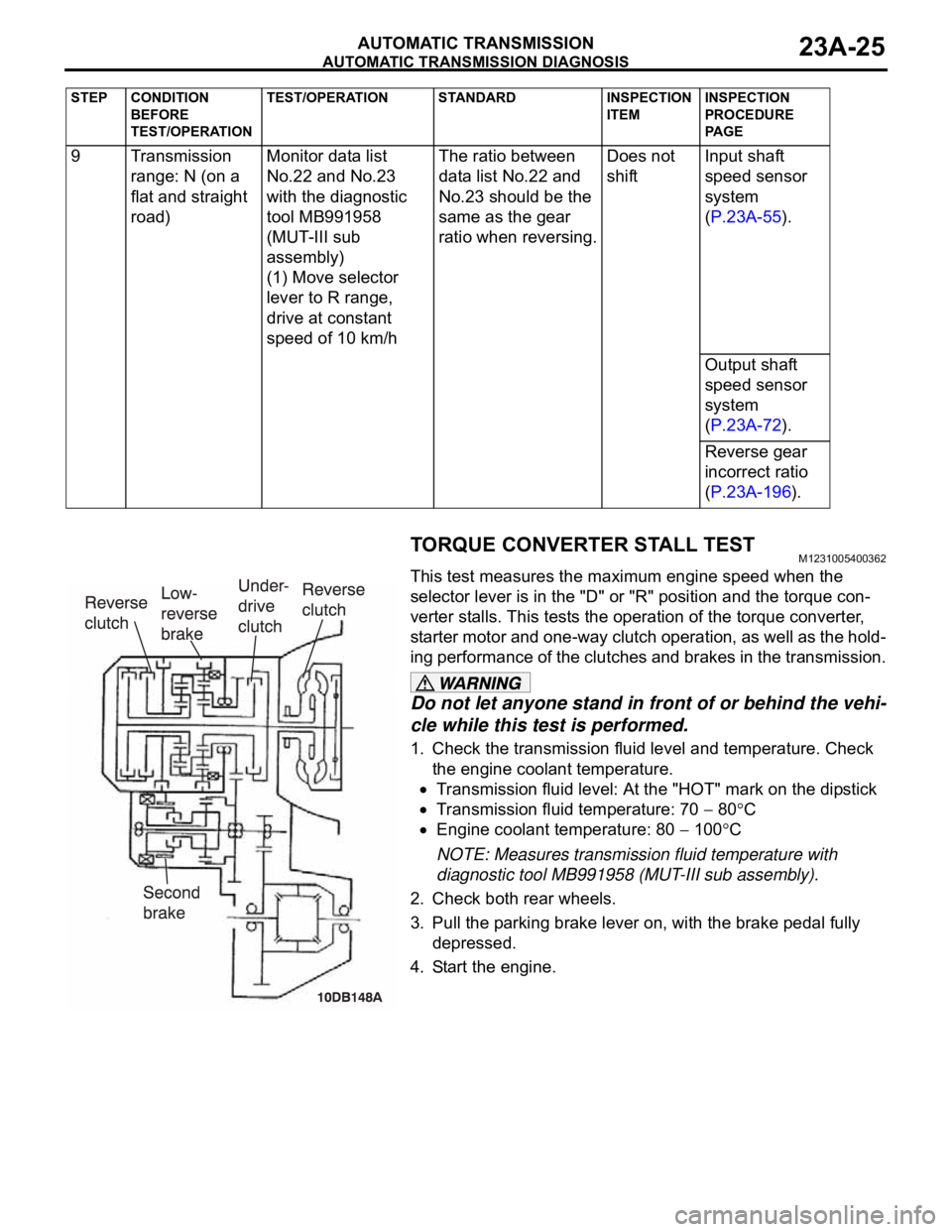

Page 1484 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-25

TORQUE CONVERTER STALL TESTM1231005400362

This test measures the maximum engine speed when the

selector lever is in the "D" or "R" position and the torque con-

verter stalls. This tests the operation of the torque converter,

starter motor and one-way clutch operation, as well as the hold-

ing performance of the clutches and brakes in the transmission.

Do not let anyone stand in front of or behind the vehi-

cle while this test is performed.

1. Check the transmission fluid level and temperature. Check

the engine coolant temperature.

Transmission fluid level: At the "HOT" mark on the dipstick

Transmission fluid temperature: 70 80C

Engine coolant temperature: 80 100C

NOTE: Measures transmission fluid temperature with

diagnostic tool MB991958 (MUT-III sub assembly).

2. Check both rear wheels.

3. Pull the parking brake lever on, with the brake pedal fully

depressed.

4. Start the engine. 9 Transmission

range: N (on a

flat and straight

road)Monitor data list

No.22 and No.23

with the diagnostic

tool MB991958

(MUT-III sub

assembly)

(1) Move selector

lever to R range,

drive at constant

speed of 10 km/hThe ratio between

data list No.22 and

No.23 should be the

same as the gear

ratio when reversing.Does not

shiftInput shaft

speed sensor

system

(P.23A-55).

Output shaft

speed sensor

system

(P.23A-72).

Reverse gear

incorrect ratio

(P.23A-196).

STEP CONDITION

BEFORE

TEST/OPERATIONTEST/OPERATION STANDARD INSPECTION

ITEMINSPECTION

PROCEDURE

PA G E

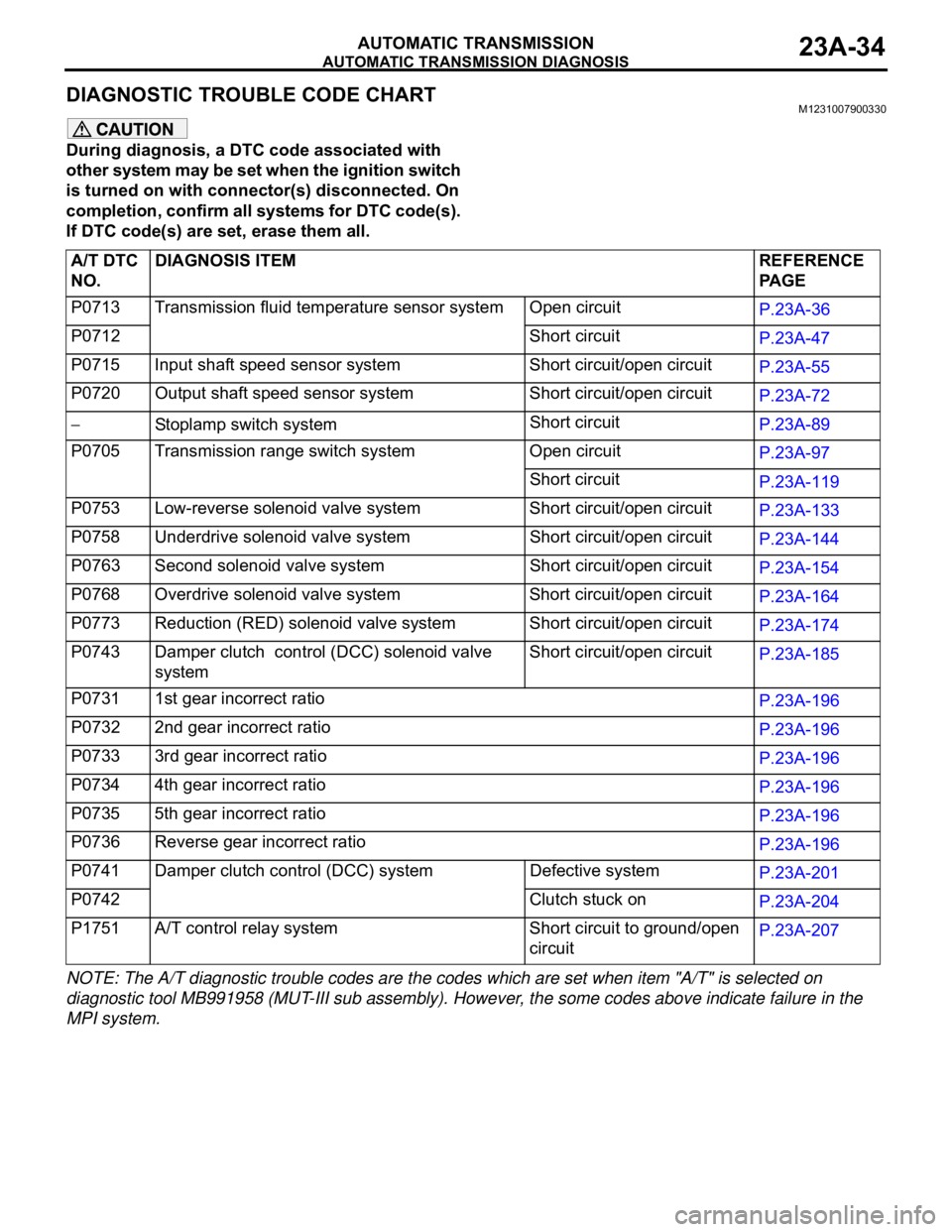

Page 1493 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-34

DIAGNOSTIC TROUBLE CODE CHARTM1231007900330

During diagnosis, a DTC code associated with

other system may be set when the ignition switch

is turned on with connector(s) disconnected. On

completion, confirm all systems for DTC code(s).

If DTC code(s) are set, erase them all.

NOTE: The A/T diagnostic trouble codes are the codes which are set when item "A/T" is selected on

diagnostic tool MB991958 (MUT-III sub assembly). However, the some codes above indicate failure in the

MPI system.A/T DTC

NO.DIAGNOSIS ITEM REFERENCE

PA G E

P0713 Transmission fluid temperature sensor system Open circuit

P.23A-36

P0712 Short circuit

P.23A-47

P0715 Input shaft speed sensor system Short circuit/open circuit

P.23A-55

P0720 Output shaft speed sensor system Short circuit/open circuit

P.23A-72

Stoplamp switch systemShort circuit

P.23A-89

P0705 Transmission range switch system Open circuit

P.23A-97

Short circuit

P.23A-119

P0753 Low-reverse solenoid valve system Short circuit/open circuit

P.23A-133

P0758 Underdrive solenoid valve system Short circuit/open circuit

P.23A-144

P0763 Second solenoid valve system Short circuit/open circuit

P.23A-154

P0768 Overdrive solenoid valve system Short circuit/open circuit

P.23A-164

P0773 Reduction (RED) solenoid valve system Short circuit/open circuit

P.23A-174

P0743 Damper clutch control (DCC) solenoid valve

systemShort circuit/open circuit

P.23A-185

P0731 1st gear incorrect ratio

P.23A-196

P0732 2nd gear incorrect ratio

P.23A-196

P0733 3rd gear incorrect ratio

P.23A-196

P0734 4th gear incorrect ratio

P.23A-196

P0735 5th gear incorrect ratio

P.23A-196

P0736 Reverse gear incorrect ratio

P.23A-196

P0741 Damper clutch control (DCC) system Defective system

P.23A-201

P0742 Clutch stuck on

P.23A-204

P1751 A/T control relay system Short circuit to ground/open

circuitP.23A-207

Page 1494 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-35

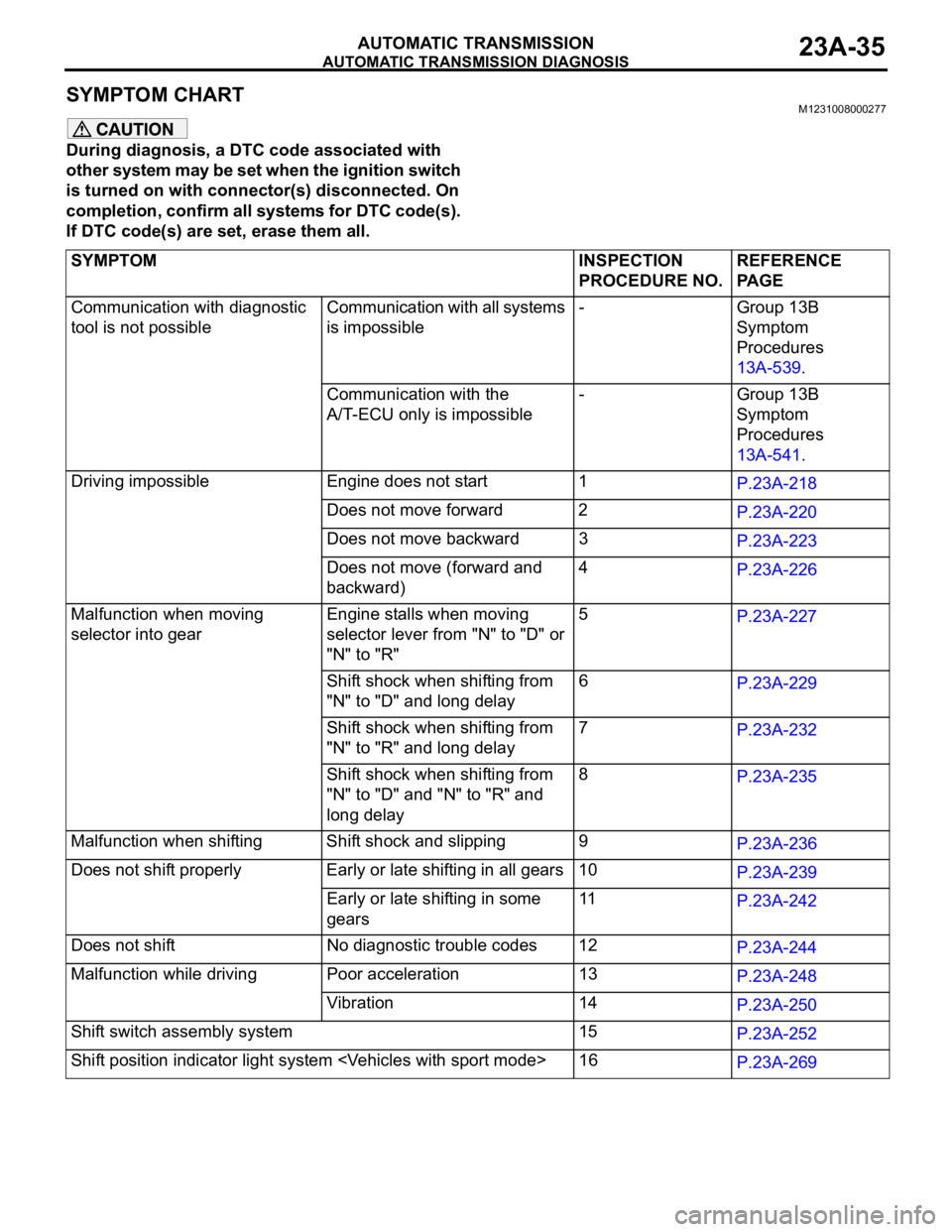

SYMPTOM CHART M1231008000277

During diagnosis, a DTC code associated with

other system may be set when the ignition switch

is turned on with connector(s) disconnected. On

completion, confirm all systems for DTC code(s).

If DTC code(s) are set, erase them all.

SYMPTOM INSPECTION

PROCEDURE NO.REFERENCE

PA G E

Communication with diagnostic

tool is not possibleCommunication with all systems

is impossible- Group 13B

Symptom

Procedures

13A-539.

Communication with the

A/T-ECU only is impossible- Group 13B

Symptom

Procedures

13A-541.

Driving impossible Engine does not start 1

P.23A-218

Does not move forward 2

P.23A-220

Does not move backward 3

P.23A-223

Does not move (forward and

backward)4

P.23A-226

Malfunction when moving

selector into gearEngine stalls when moving

selector lever from "N" to "D" or

"N" to "R"5

P.23A-227

Shift shock when shifting from

"N" to "D" and long delay6

P.23A-229

Shift shock when shifting from

"N" to "R" and long delay 7

P.23A-232

Shift shock when shifting from

"N" to "D" and "N" to "R" and

long delay 8

P.23A-235

Malfunction when shifting Shift shock and slipping 9

P.23A-236

Does not shift properly Early or late shifting in all gears 10

P.23A-239

Early or late shifting in some

gears11

P.23A-242

Does not shift No diagnostic trouble codes 12

P.23A-244

Malfunction while driving Poor acceleration 13

P.23A-248

Vibration 14

P.23A-250

Shift switch assembly system 15

P.23A-252

Shift position indicator light system

P.23A-269

Page 1495 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-36

DIAGNOSTIC TROUBLE CODE PROCEDURES

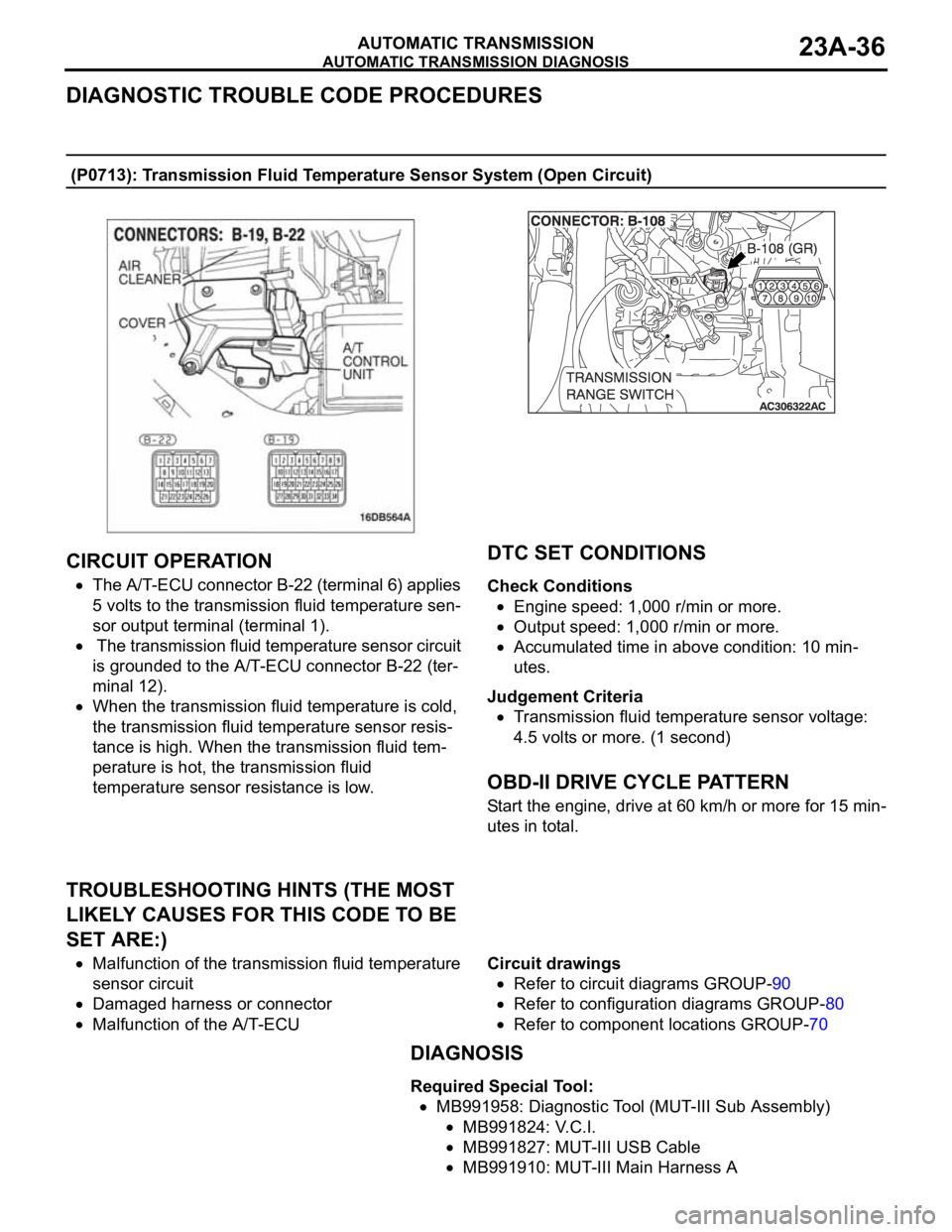

(P0713): Transmission Fluid Temperature Sensor System (Open Circuit)

.

CIRCUIT OPERATION

The A/T-ECU connector B-22 (terminal 6) applies

5 volts to the transmission fluid temperature sen-

sor output terminal (terminal 1).

The transmission fluid temperature sensor circuit

is grounded to the A/T-ECU connector B-22 (ter-

minal 12).

When the transmission fluid temperature is cold,

the transmission fluid temperature sensor resis-

tance is high. When the transmission fluid tem-

perature is hot, the transmission fluid

temperature sensor resistance is low.

.

DTC SET CONDITIONS

Check Conditions

Engine speed: 1,000 r/min or more.

Output speed: 1,000 r/min or more.

Accumulated time in above condition: 10 min-

utes.

Judgement Criteria

Transmission fluid temperature sensor voltage:

4.5 volts or more. (1 second)

.

OBD-II DRIVE CYCLE PATTERN

Start the engine, drive at 60 km/h or more for 15 min-

utes in total.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CODE TO BE

SET ARE:)

Malfunction of the transmission fluid temperature

sensor circuit

Damaged harness or connector

Malfunction of the A/T-ECUCircuit drawings

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Refer to component locations GROUP-70

DIAGNOSIS

Required Special Tool:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 1496 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-37

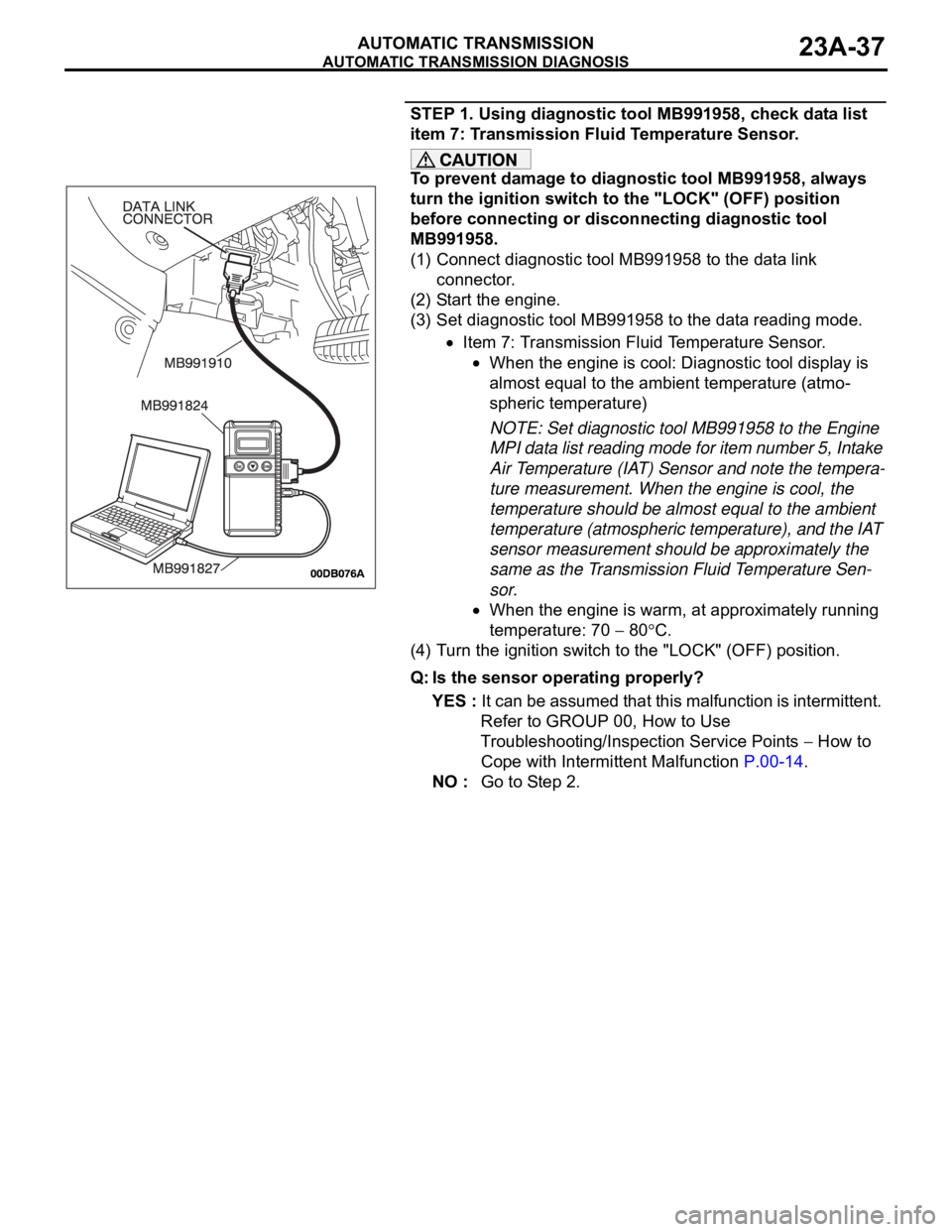

STEP 1. Using diagnostic tool MB991958, check data list

item 7: Transmission Fluid Temperature Sensor.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector.

(2) Start the engine.

(3) Set diagnostic tool MB991958 to the data reading mode.

Item 7: Transmission Fluid Temperature Sensor.

When the engine is cool: Diagnostic tool display is

almost equal to the ambient temperature (atmo-

spheric temperature)

NOTE: Set diagnostic tool MB991958 to the Engine

MPI data list reading mode for item number 5, Intake

Air Temperature (IAT) Sensor and note the tempera-

ture measurement. When the engine is cool, the

temperature should be almost equal to the ambient

temperature (atmospheric temperature), and the IAT

sensor measurement should be approximately the

same as the Transmission Fluid Temperature Sen-

sor.

When the engine is warm, at approximately running

temperature: 70

80C.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor operating properly?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14.

NO : Go to Step 2.

Page 1500 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-41

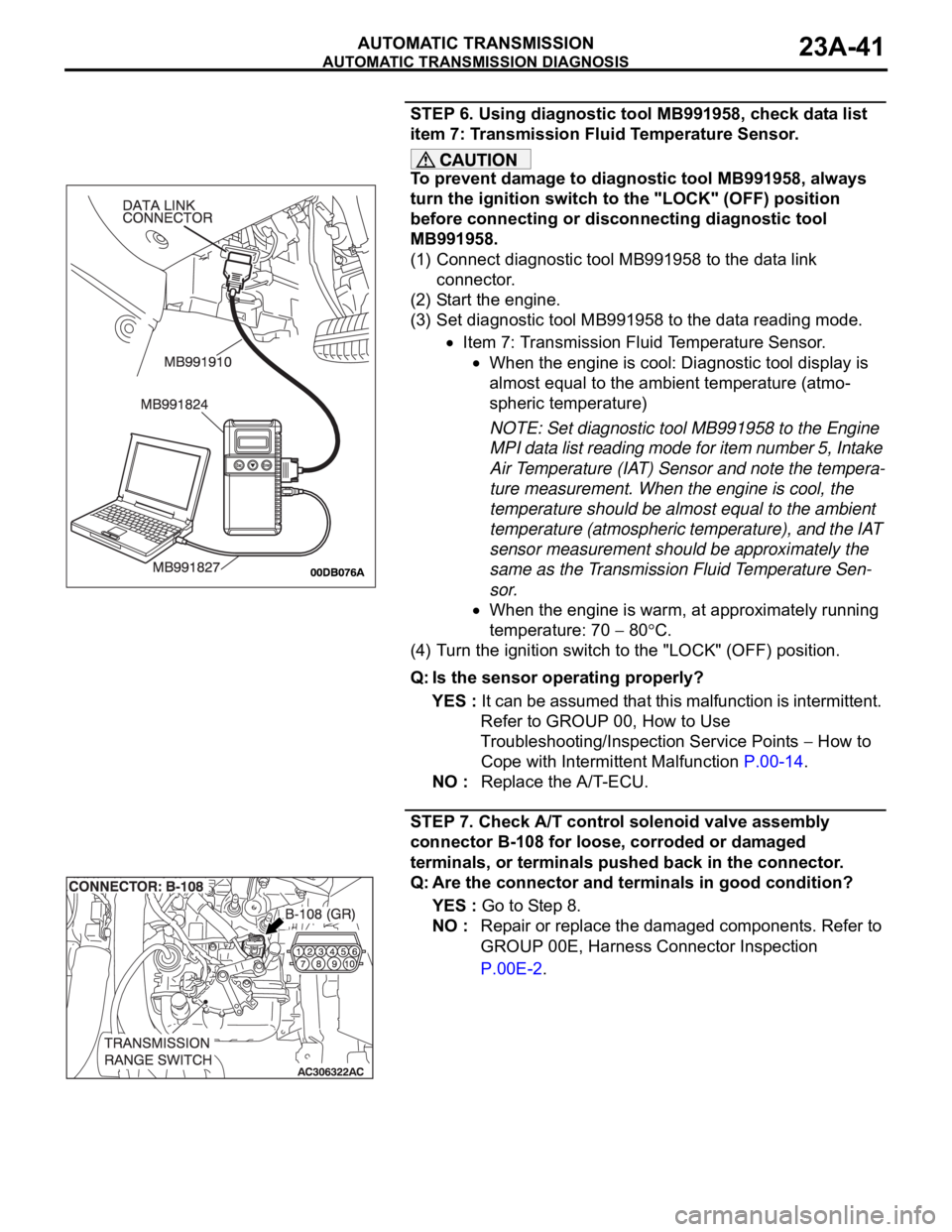

STEP 6. Using diagnostic tool MB991958, check data list

item 7: Transmission Fluid Temperature Sensor.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector.

(2) Start the engine.

(3) Set diagnostic tool MB991958 to the data reading mode.

Item 7: Transmission Fluid Temperature Sensor.

When the engine is cool: Diagnostic tool display is

almost equal to the ambient temperature (atmo-

spheric temperature)

NOTE: Set diagnostic tool MB991958 to the Engine

MPI data list reading mode for item number 5, Intake

Air Temperature (IAT) Sensor and note the tempera-

ture measurement. When the engine is cool, the

temperature should be almost equal to the ambient

temperature (atmospheric temperature), and the IAT

sensor measurement should be approximately the

same as the Transmission Fluid Temperature Sen-

sor.

When the engine is warm, at approximately running

temperature: 70

80C.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor operating properly?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14.

NO : Replace the A/T-ECU.

STEP 7. Check A/T control solenoid valve assembly

connector B-108 for loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Q: Are the connector and terminals in good condition?

YES : Go to Step 8.

NO : Repair or replace the damaged components. Refer to

GROUP 00E, Harness Connector Inspection

P.00E-2.