headlamp MITSUBISHI 380 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 274 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-274

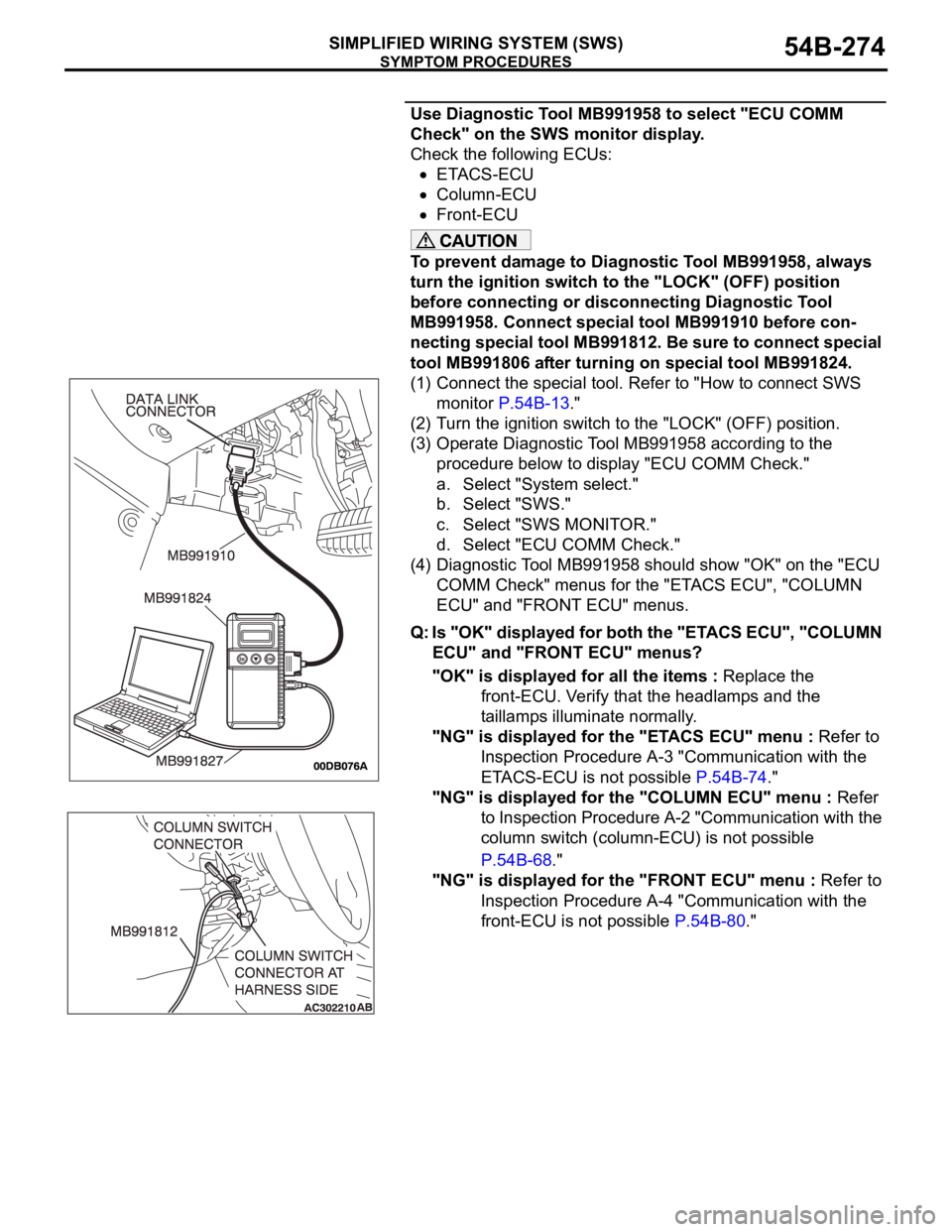

Use Diagnostic Tool MB991958 to select "ECU COMM

Check" on the SWS monitor display.

Check the following ECUs:

ETACS-ECU

Column-ECU

Front-ECU

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958. Connect special tool MB991910 before con-

necting special tool MB991812. Be sure to connect special

tool MB991806 after turning on special tool MB991824.

(1) Connect the special tool. Refer to "How to connect SWS

monitor P.54B-13."

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Operate Diagnostic Tool MB991958 according to the

procedure below to display "ECU COMM Check."

a. Select "System select."

b. Select "SWS."

c. Select "SWS MONITOR."

d. Select "ECU COMM Check."

(4) Diagnostic Tool MB991958 should show "OK" on the "ECU

COMM Check" menus for the "ETACS ECU", "COLUMN

ECU" and "FRONT ECU" menus.

Q: Is "OK" displayed for both the "ETACS ECU", "COLUMN

ECU" and "FRONT ECU" menus?

"OK" is displayed for all the items : Replace the

front-ECU. Verify that the headlamps and the

taillamps illuminate normally.

"NG" is displayed for the "ETACS ECU" menu : Refer to

Inspection Procedure A-3 "Communication with the

ETACS-ECU is not possible P.54B-74."

"NG" is displayed for the "COLUMN ECU" menu : Refer

to Inspection Procedure A-2 "Communication with the

column switch (column-ECU) is not possible

P.54B-68."

"NG" is displayed for the "FRONT ECU" menu : Refer to

Inspection Procedure A-4 "Communication with the

front-ECU is not possible P.54B-80."

Page 275 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-275

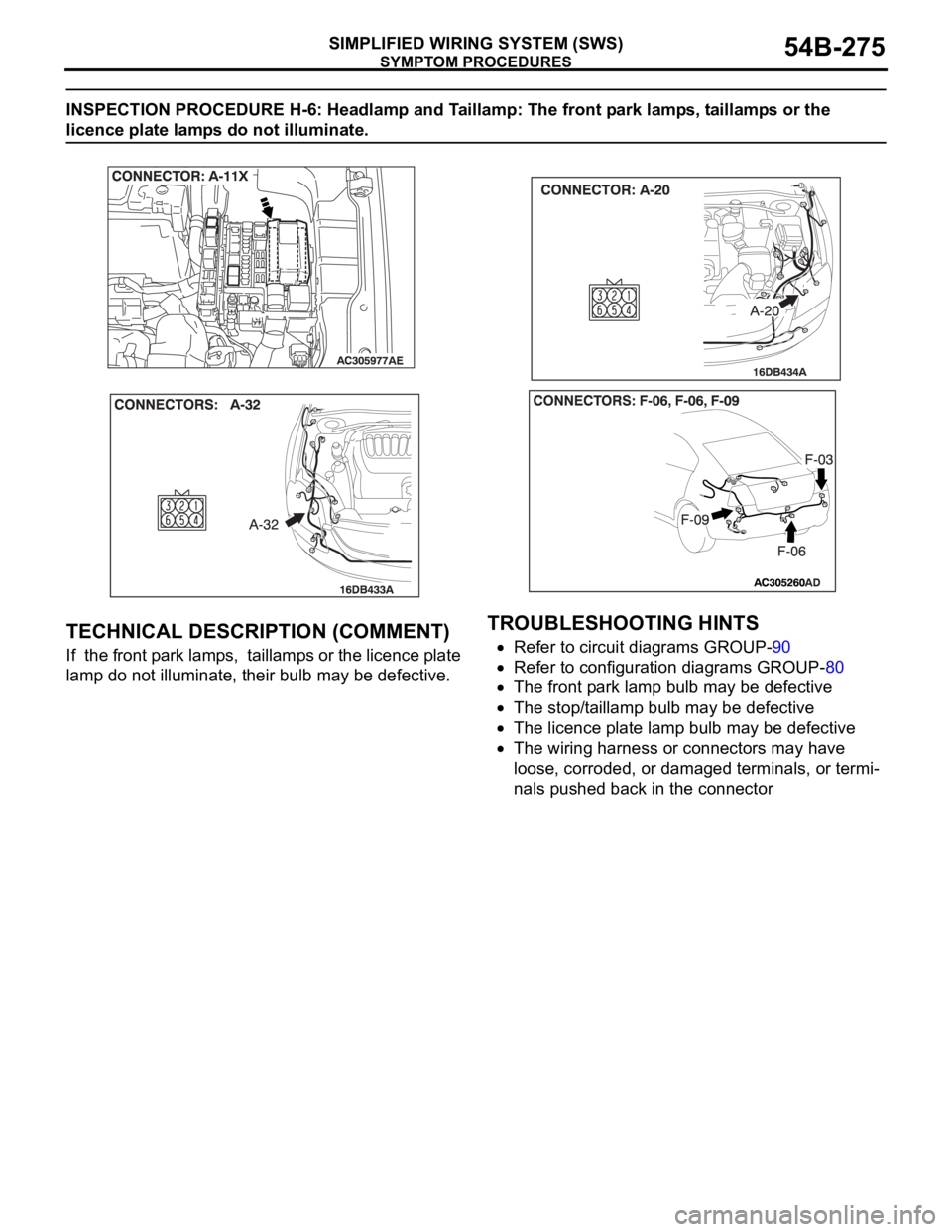

INSPECTION PROCEDURE H-6: Headlamp and Taillamp: The front park lamps, taillamps or the

licence plate lamps do not illuminate.

.

TECHNICAL DESCRIPTION (COMMENT)

If the front park lamps, taillamps or the licence plate

lamp do not illuminate, their bulb may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The front park lamp bulb may be defective

The stop/taillamp bulb may be defective

The licence plate lamp bulb may be defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

.

Page 290 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-290

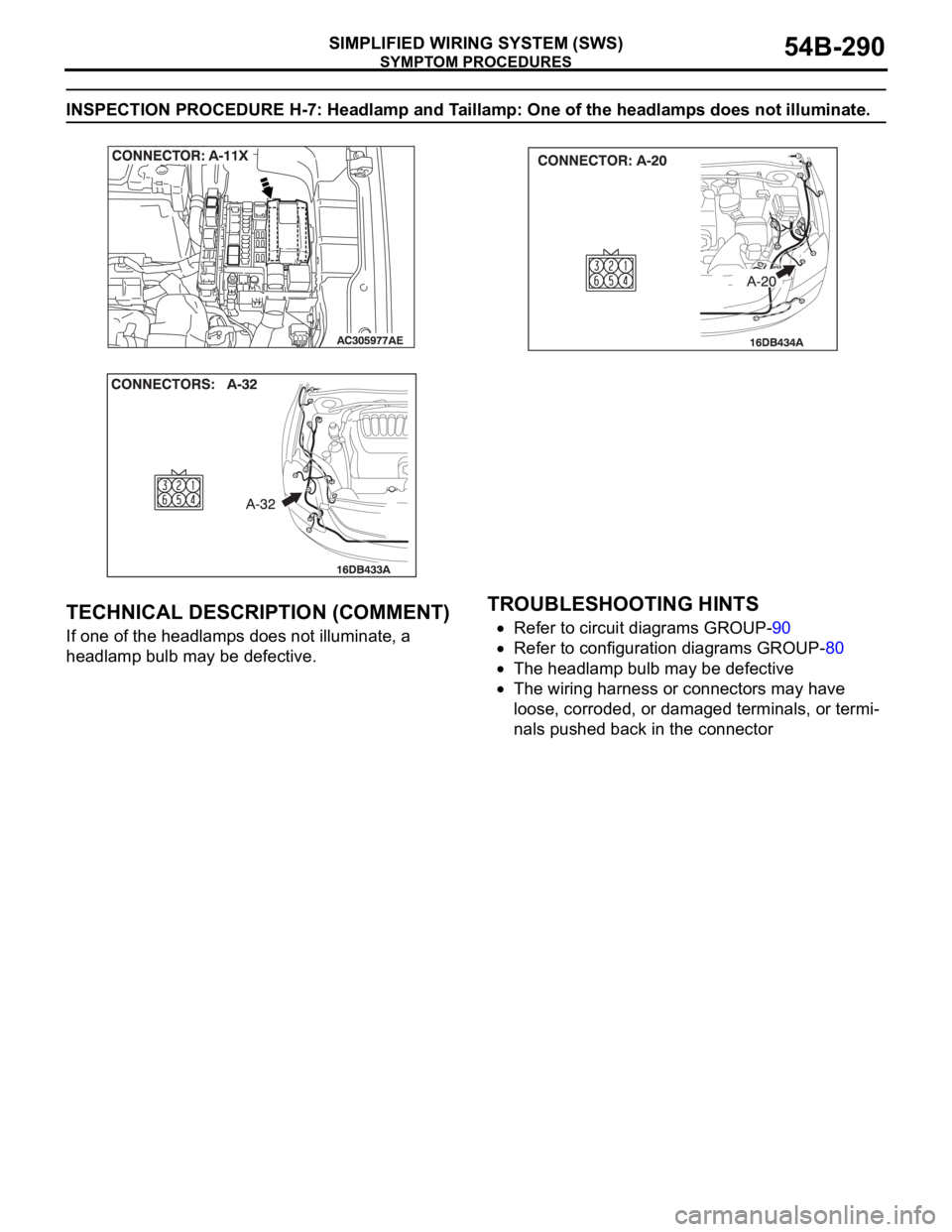

INSPECTION PROCEDURE H-7: Headlamp and Taillamp: One of the headlamps does not illuminate.

.

TECHNICAL DESCRIPTION (COMMENT)

If one of the headlamps does not illuminate, a

headlamp bulb may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The headlamp bulb may be defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

.

Page 291 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-291

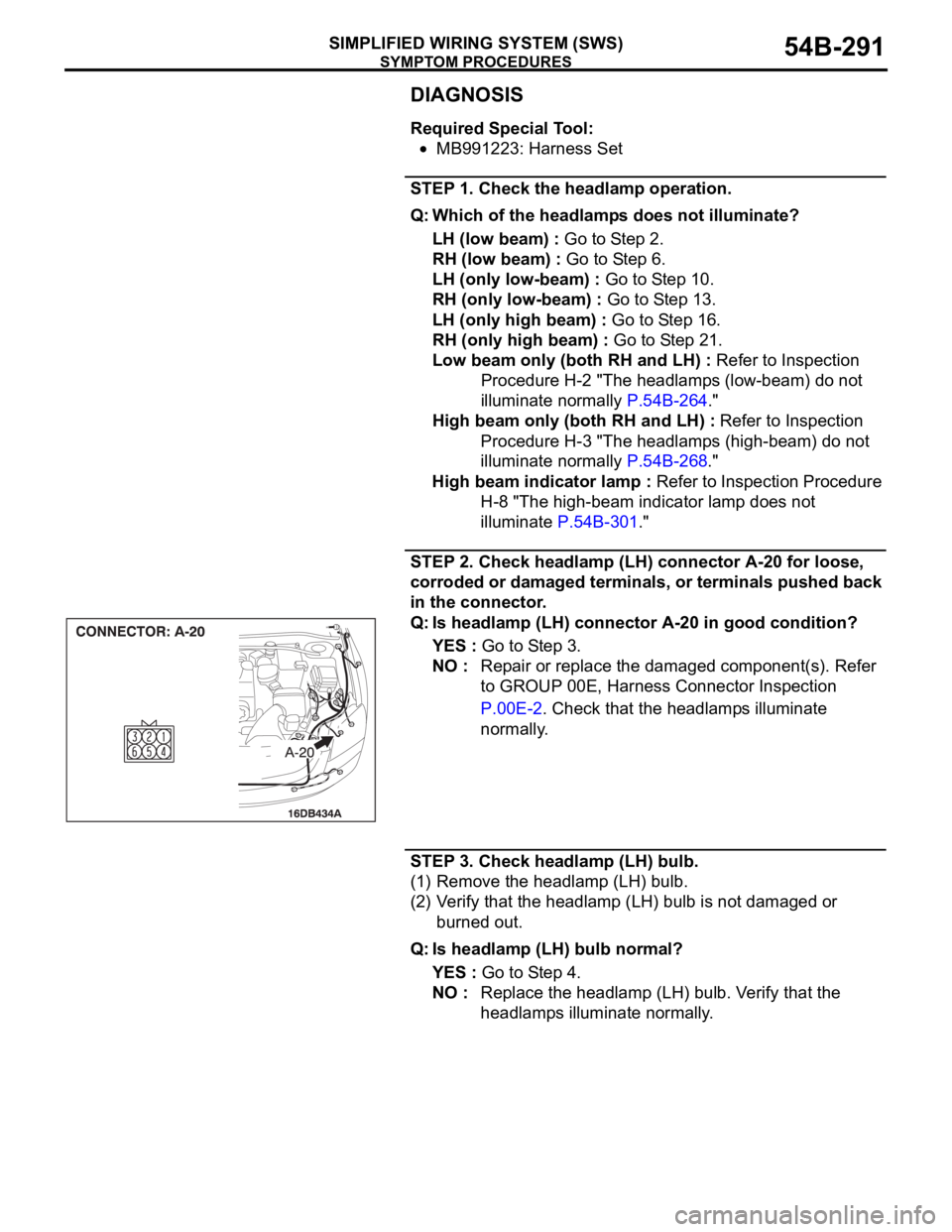

DIAGNOSIS

Required Special Tool:

MB991223: Harness Set

STEP 1. Check the headlamp operation.

Q: Which of the headlamps does not illuminate?

LH (low beam) : Go to Step 2.

RH (low beam) : Go to Step 6.

LH (only low-beam) : Go to Step 10.

RH (only low-beam) : Go to Step 13.

LH (only high beam) : Go to Step 16.

RH (only high beam) : Go to Step 21.

Low beam only (both RH and LH) : Refer to Inspection

Procedure H-2 "The headlamps (low-beam) do not

illuminate normally P.54B-264."

High beam only (both RH and LH) : Refer to Inspection

Procedure H-3 "The headlamps (high-beam) do not

illuminate normally P.54B-268."

High beam indicator lamp : Refer to Inspection Procedure

H-8 "The high-beam indicator lamp does not

illuminate P.54B-301."

STEP 2. Check headlamp (LH) connector A-20 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is headlamp (LH) connector A-20 in good condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the headlamps illuminate

normally.

STEP 3. Check headlamp (LH) bulb.

(1) Remove the headlamp (LH) bulb.

(2) Verify that the headlamp (LH) bulb is not damaged or

burned out.

Q: Is headlamp (LH) bulb normal?

YES : Go to Step 4.

NO : Replace the headlamp (LH) bulb. Verify that the

headlamps illuminate normally.

Page 292 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-292

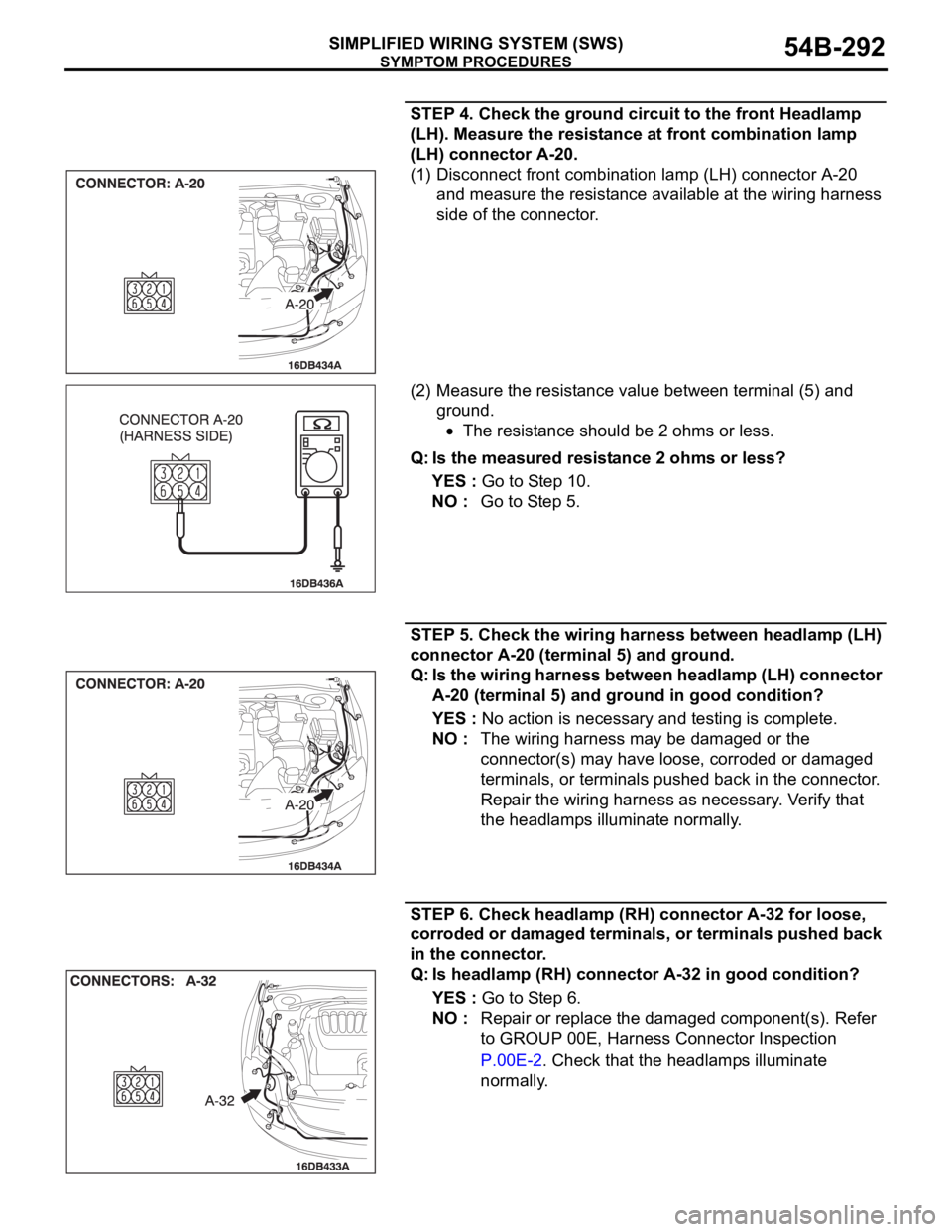

STEP 4. Check the ground circuit to the front Headlamp

(LH). Measure the resistance at front combination lamp

(LH) connector A-20.

(1) Disconnect front combination lamp (LH) connector A-20

and measure the resistance available at the wiring harness

side of the connector.

(2) Measure the resistance value between terminal (5) and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 10.

NO : Go to Step 5.

STEP 5. Check the wiring harness between headlamp (LH)

connector A-20 (terminal 5) and ground.

Q: Is the wiring harness between headlamp (LH) connector

A-20 (terminal 5) and ground in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

STEP 6. Check headlamp (RH) connector A-32 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is headlamp (RH) connector A-32 in good condition?

YES : Go to Step 6.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the headlamps illuminate

normally.

Page 293 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-293

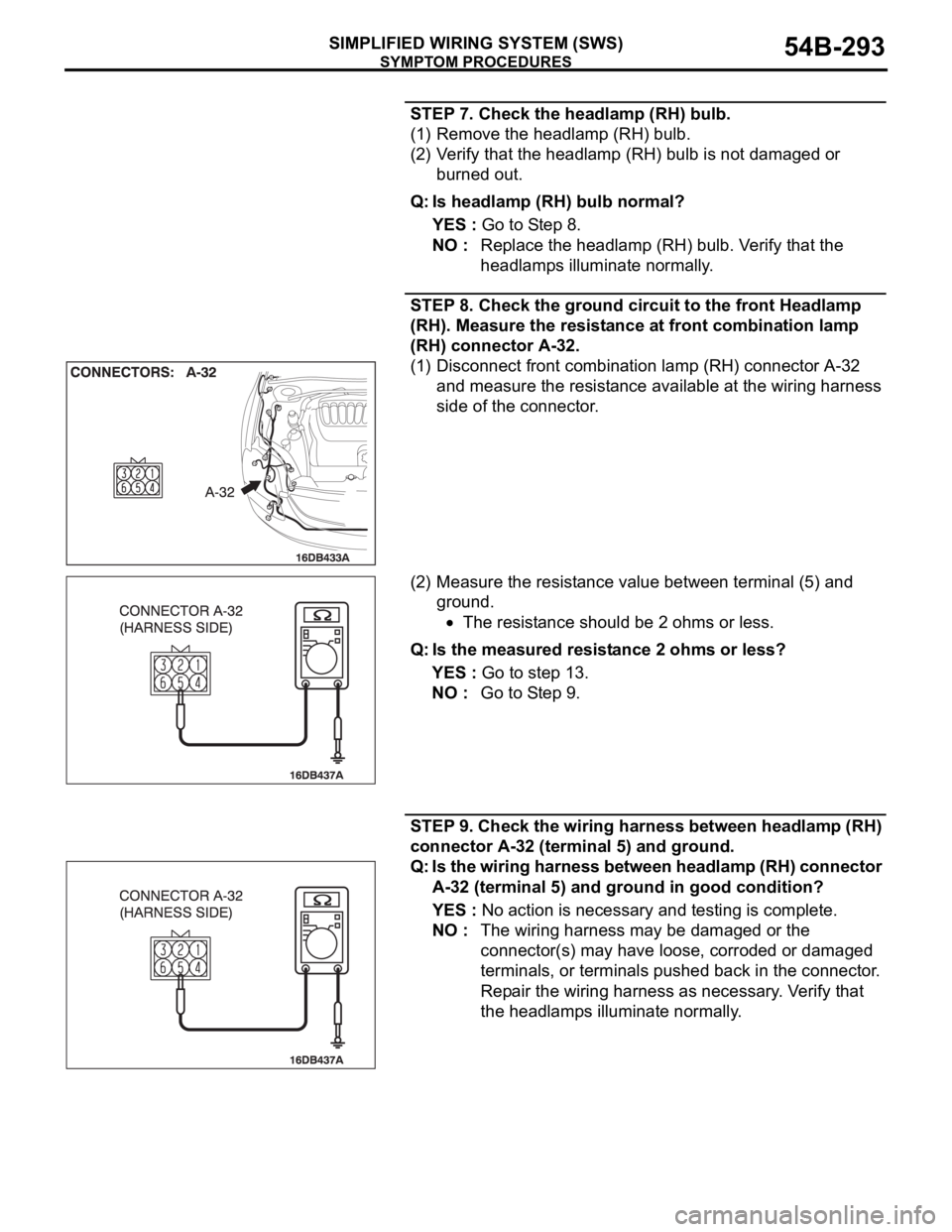

STEP 7. Check the headlamp (RH) bulb.

(1) Remove the headlamp (RH) bulb.

(2) Verify that the headlamp (RH) bulb is not damaged or

burned out.

Q: Is headlamp (RH) bulb normal?

YES : Go to Step 8.

NO : Replace the headlamp (RH) bulb. Verify that the

headlamps illuminate normally.

STEP 8. Check the ground circuit to the front Headlamp

(RH). Measure the resistance at front combination lamp

(RH) connector A-32.

(1) Disconnect front combination lamp (RH) connector A-32

and measure the resistance available at the wiring harness

side of the connector.

(2) Measure the resistance value between terminal (5) and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to step 13.

NO : Go to Step 9.

STEP 9. Check the wiring harness between headlamp (RH)

connector A-32 (terminal 5) and ground.

Q: Is the wiring harness between headlamp (RH) connector

A-32 (terminal 5) and ground in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

Page 294 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-294

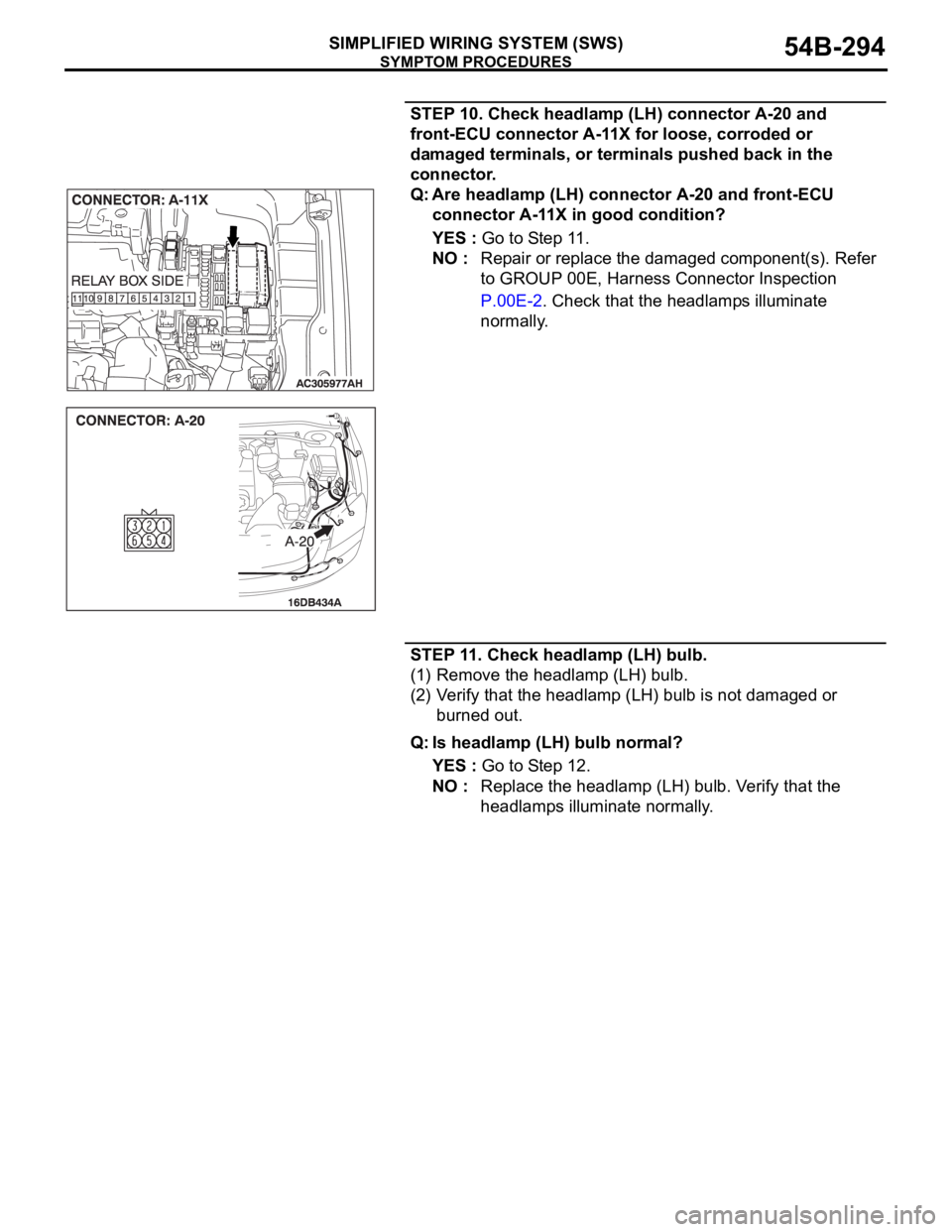

STEP 10. Check headlamp (LH) connector A-20 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (LH) connector A-20 and front-ECU

connector A-11X in good condition?

YES : Go to Step 11.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the headlamps illuminate

normally.

STEP 11. Check headlamp (LH) bulb.

(1) Remove the headlamp (LH) bulb.

(2) Verify that the headlamp (LH) bulb is not damaged or

burned out.

Q: Is headlamp (LH) bulb normal?

YES : Go to Step 12.

NO : Replace the headlamp (LH) bulb. Verify that the

headlamps illuminate normally.

Page 295 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-295

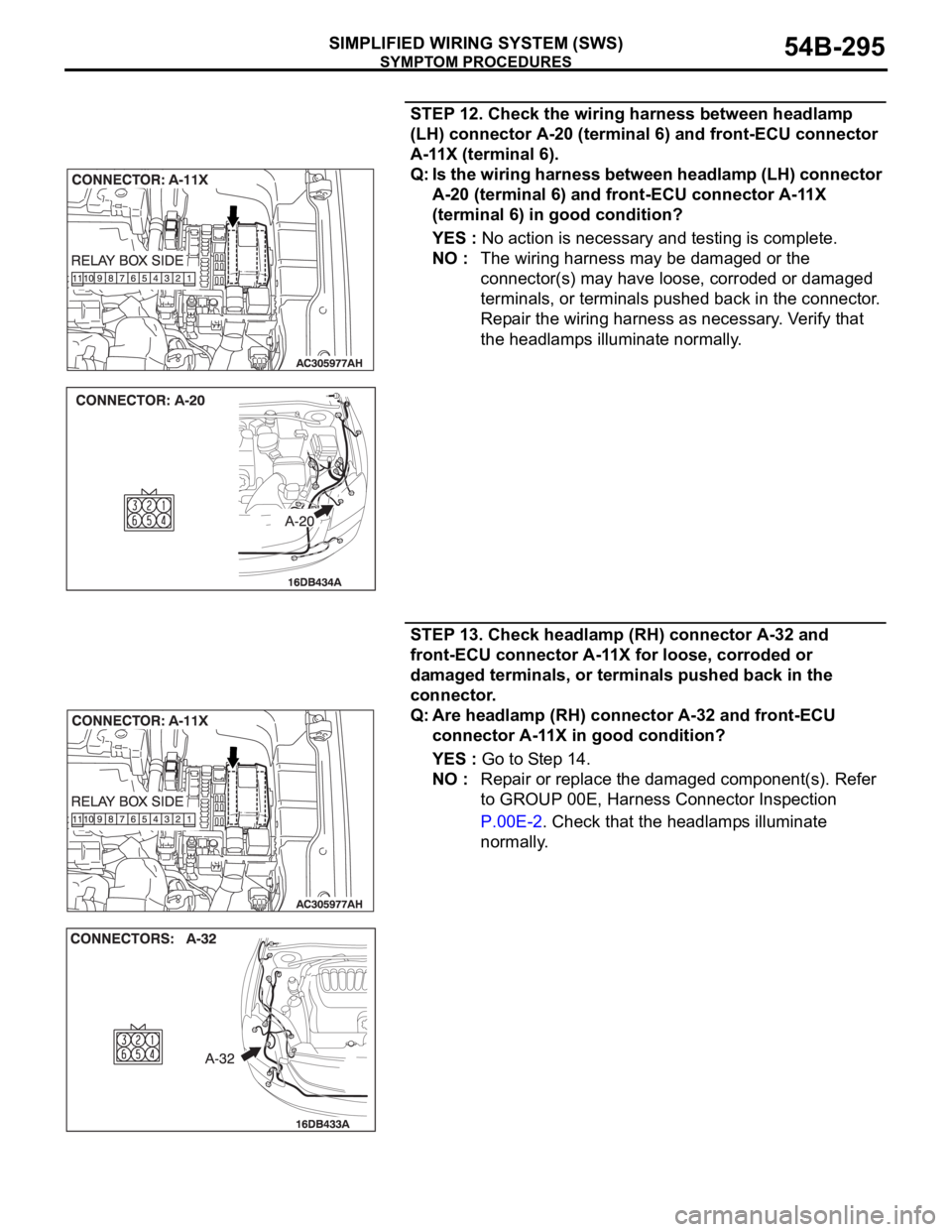

STEP 12. Check the wiring harness between headlamp

(LH) connector A-20 (terminal 6) and front-ECU connector

A-11X (terminal 6).

Q: Is the wiring harness between headlamp (LH) connector

A-20 (terminal 6) and front-ECU connector A-11X

(terminal 6) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

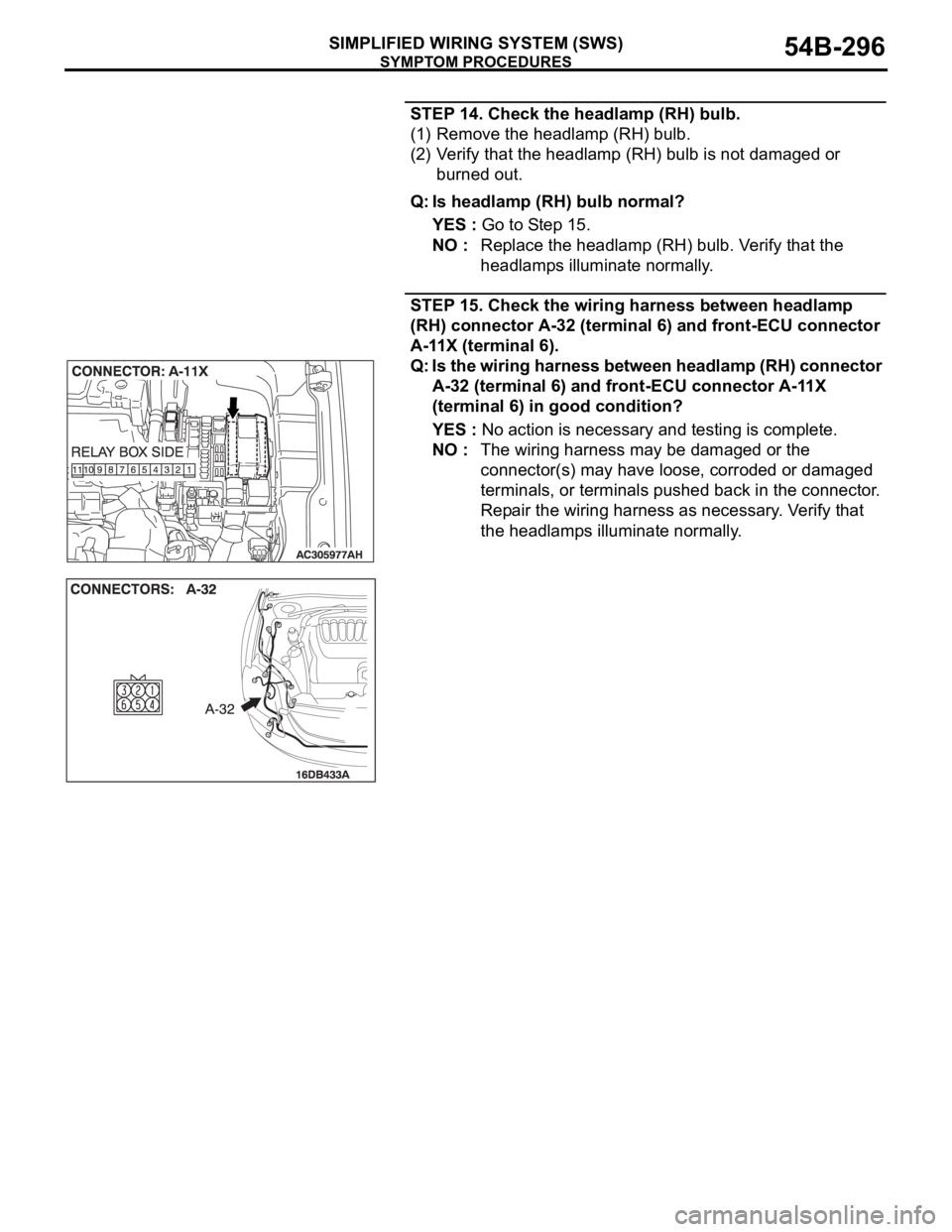

STEP 13. Check headlamp (RH) connector A-32 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (RH) connector A-32 and front-ECU

connector A-11X in good condition?

YES : Go to Step 14.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the headlamps illuminate

normally.

Page 296 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-296

STEP 14. Check the headlamp (RH) bulb.

(1) Remove the headlamp (RH) bulb.

(2) Verify that the headlamp (RH) bulb is not damaged or

burned out.

Q: Is headlamp (RH) bulb normal?

YES : Go to Step 15.

NO : Replace the headlamp (RH) bulb. Verify that the

headlamps illuminate normally.

STEP 15. Check the wiring harness between headlamp

(RH) connector A-32 (terminal 6) and front-ECU connector

A-11X (terminal 6).

Q: Is the wiring harness between headlamp (RH) connector

A-32 (terminal 6) and front-ECU connector A-11X

(terminal 6) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

Page 297 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-297

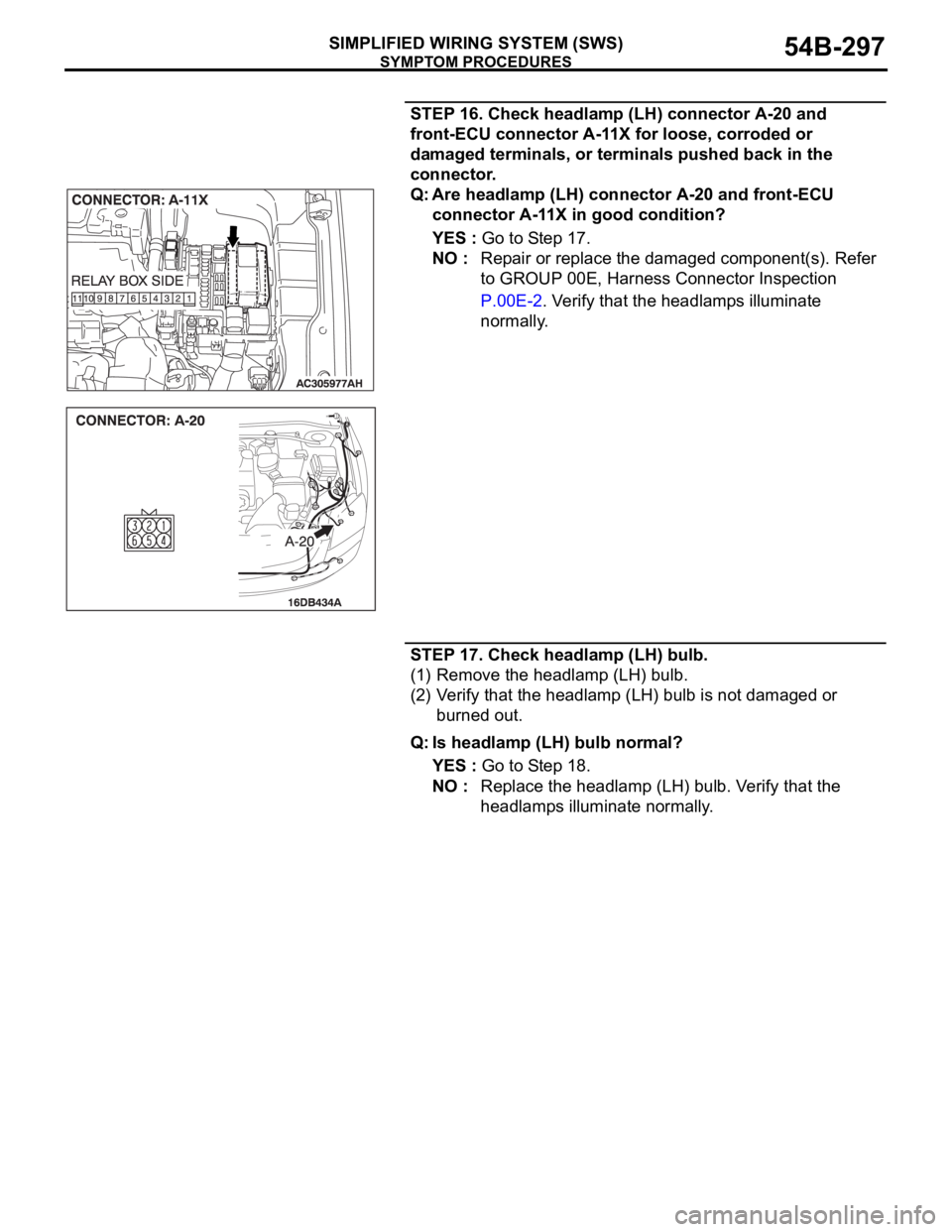

STEP 16. Check headlamp (LH) connector A-20 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (LH) connector A-20 and front-ECU

connector A-11X in good condition?

YES : Go to Step 17.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the headlamps illuminate

normally.

STEP 17. Check headlamp (LH) bulb.

(1) Remove the headlamp (LH) bulb.

(2) Verify that the headlamp (LH) bulb is not damaged or

burned out.

Q: Is headlamp (LH) bulb normal?

YES : Go to Step 18.

NO : Replace the headlamp (LH) bulb. Verify that the

headlamps illuminate normally.