Relay wiring MITSUBISHI 380 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 783 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-82

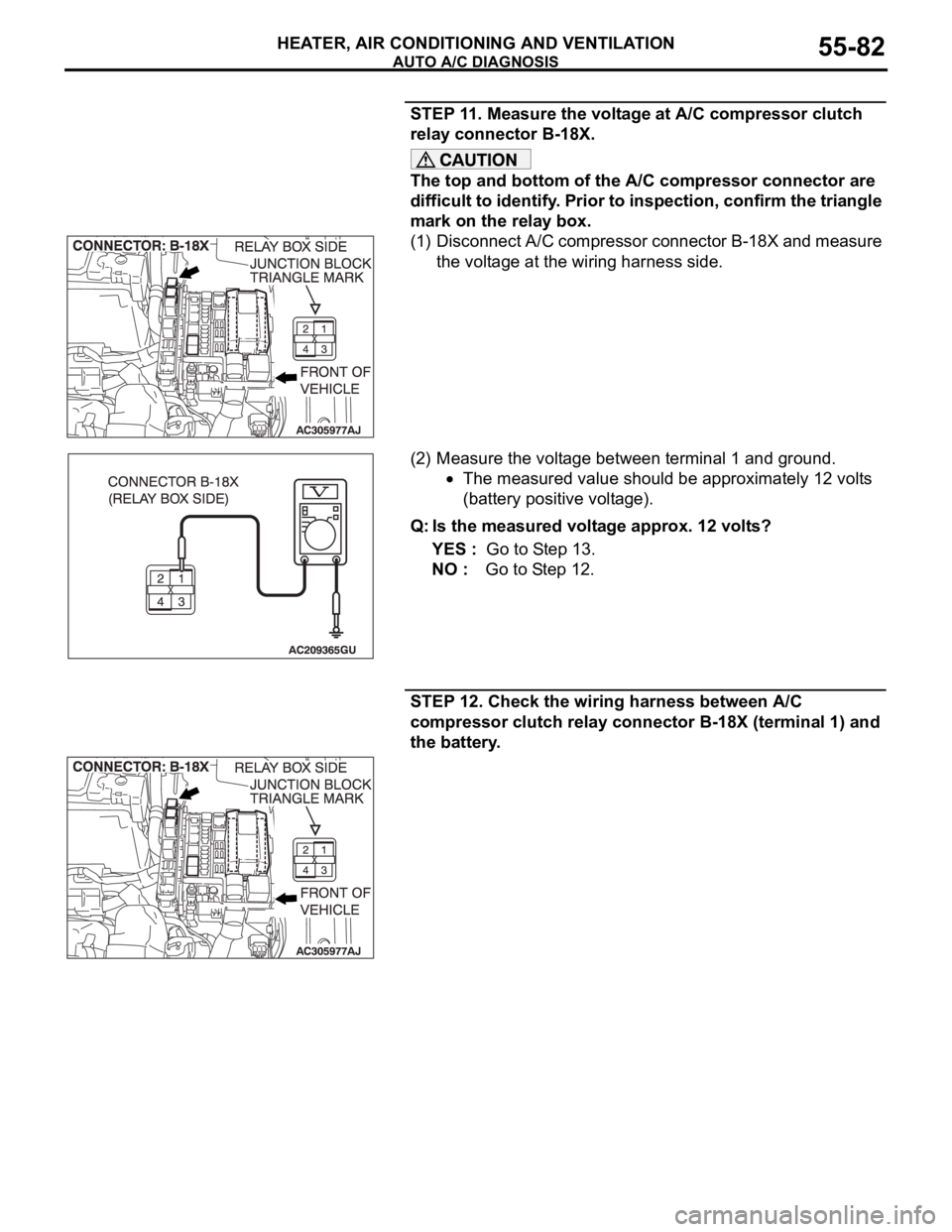

STEP 11. Measure the voltage at A/C compressor clutch

relay connector B-18X.

The top and bottom of the A/C compressor connector are

difficult to identify. Prior to inspection, confirm the triangle

mark on the relay box.

(1) Disconnect A/C compressor connector B-18X and measure

the voltage at the wiring harness side.

(2) Measure the voltage between terminal 1 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 13.

NO : Go to Step 12.

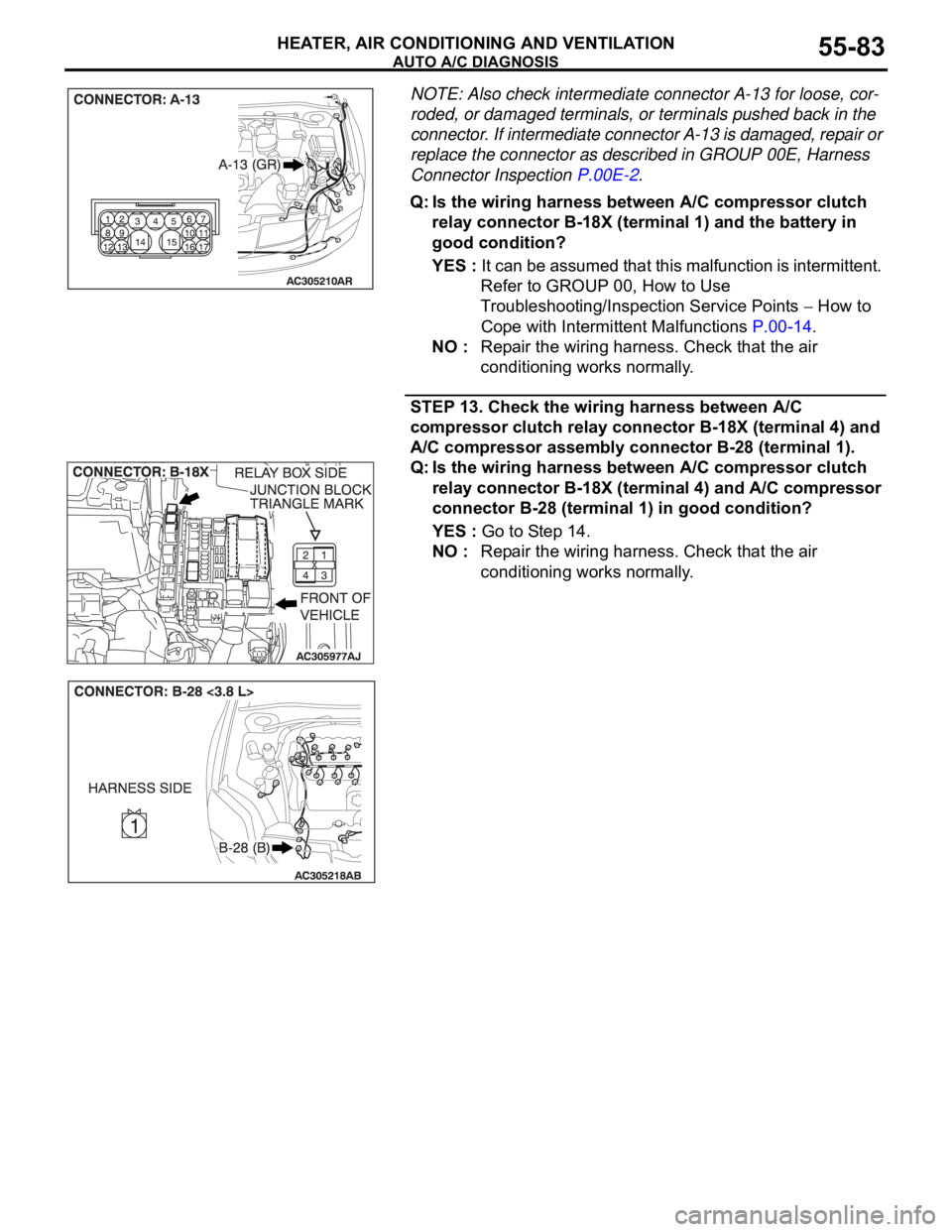

STEP 12. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 1) and

the battery.

Page 784 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-83

NOTE: Also check intermediate connector A-13 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector A-13 is damaged, repair or

replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 1) and the battery in

good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 13. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 4) and

A/C compressor assembly connector B-28 (terminal 1).

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 4) and A/C compressor

connector B-28 (terminal 1) in good condition?

YES : Go to Step 14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

Page 785 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-84

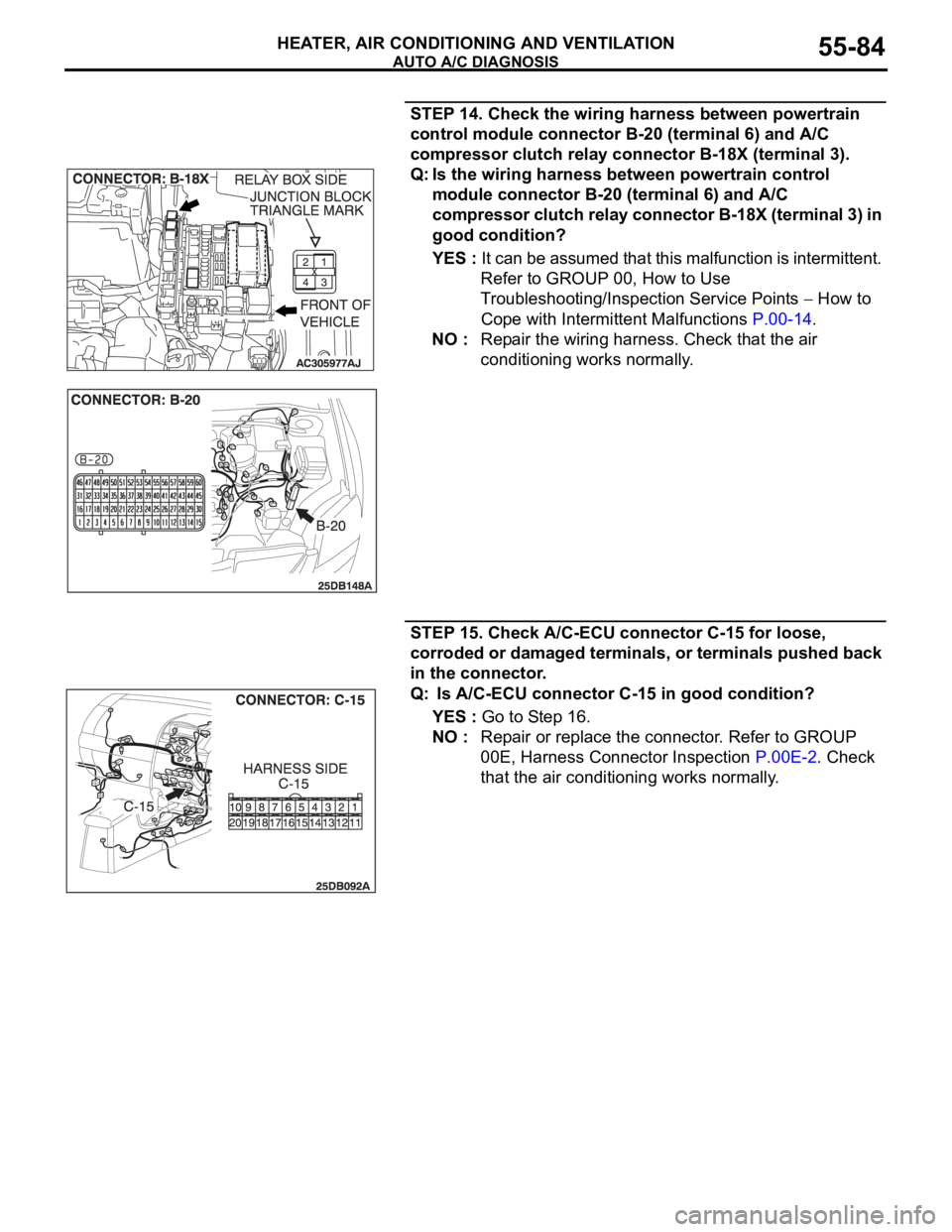

STEP 14. Check the wiring harness between powertrain

control module connector B-20 (terminal 6) and A/C

compressor clutch relay connector B-18X (terminal 3).

Q: Is the wiring harness between powertrain control

module connector B-20 (terminal 6) and A/C

compressor clutch relay connector B-18X (terminal 3) in

good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 15. Check A/C-ECU connector C-15 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is A/C-ECU connector C-15 in good condition?

YES : Go to Step 16.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. Check

that the air conditioning works normally.

Page 787 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-86

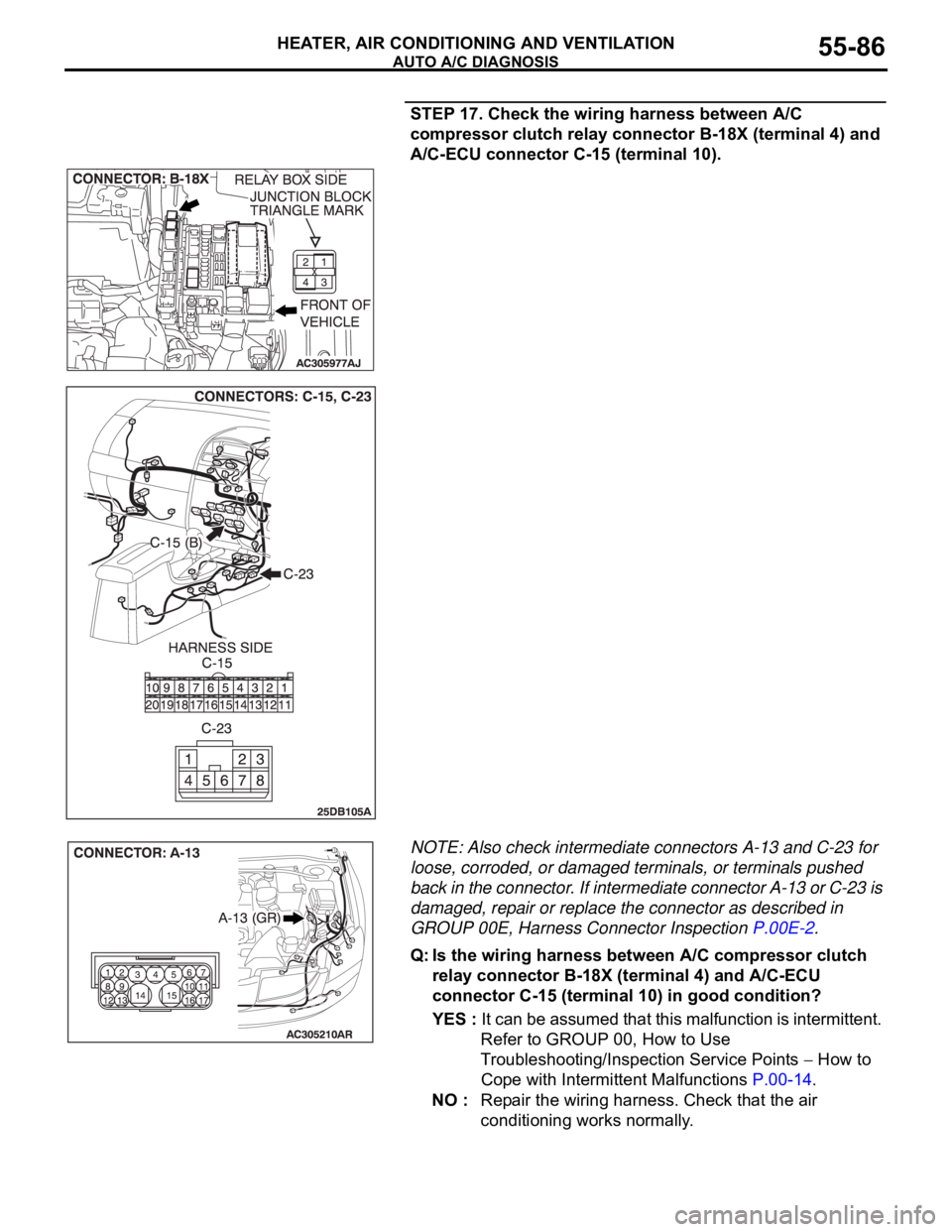

STEP 17. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 4) and

A/C-ECU connector C-15 (terminal 10).

NOTE: Also check intermediate connectors A-13 and C-23 for

loose, corroded, or damaged terminals, or terminals pushed

back in the connector. If intermediate connector A-13 or C-23 is

damaged, repair or replace the connector as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 4) and A/C-ECU

connector C-15 (terminal 10) in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

Page 792 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-91

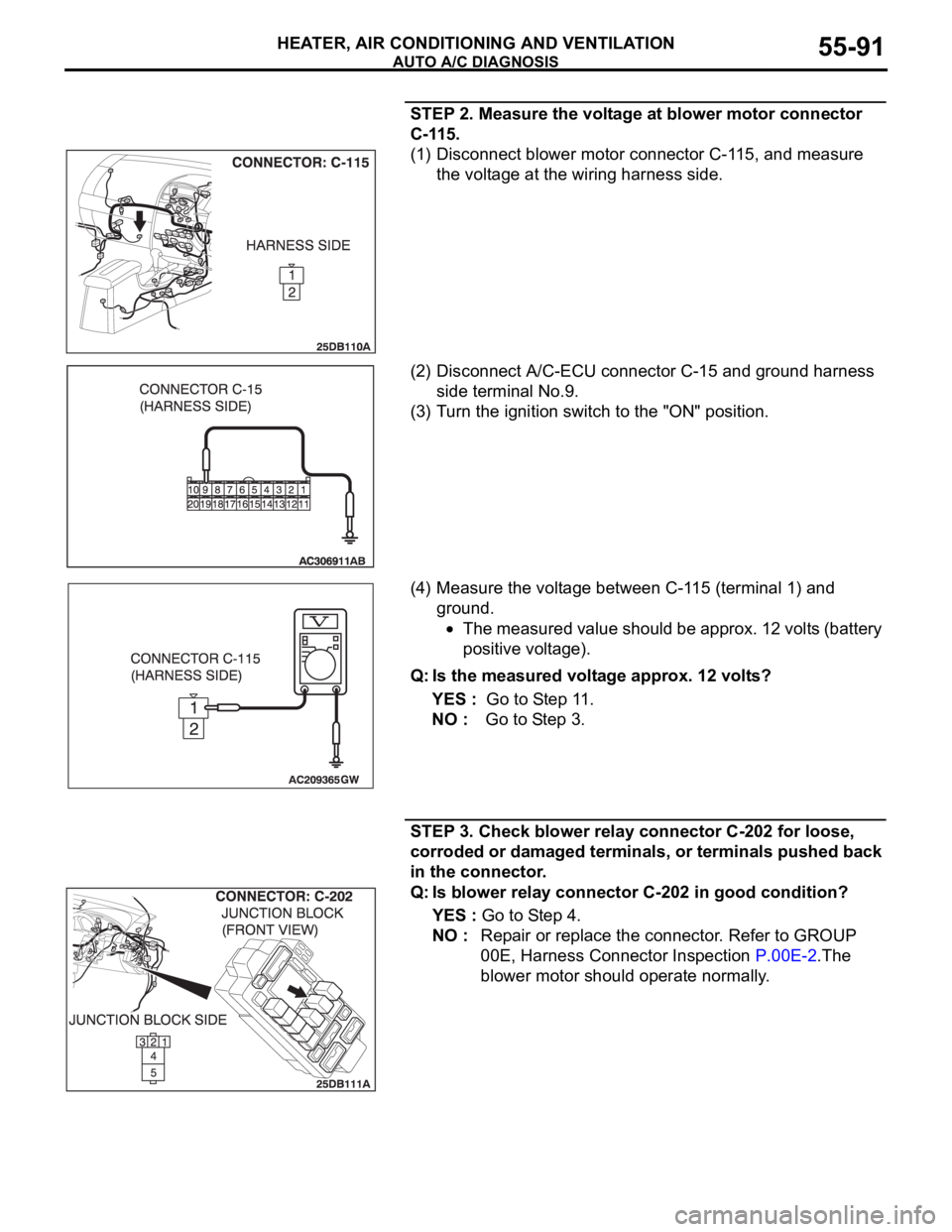

STEP 2. Measure the voltage at blower motor connector

C-115.

(1) Disconnect blower motor connector C-115, and measure

the voltage at the wiring harness side.

(2) Disconnect A/C-ECU connector C-15 and ground harness

side terminal No.9.

(3) Turn the ignition switch to the "ON" position.

(4) Measure the voltage between C-115 (terminal 1) and

ground.

The measured value should be approx. 12 volts (battery

positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 11.

NO : Go to Step 3.

STEP 3. Check blower relay connector C-202 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is blower relay connector C-202 in good condition?

YES : Go to Step 4.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2.The

blower motor should operate normally.

Page 794 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-93

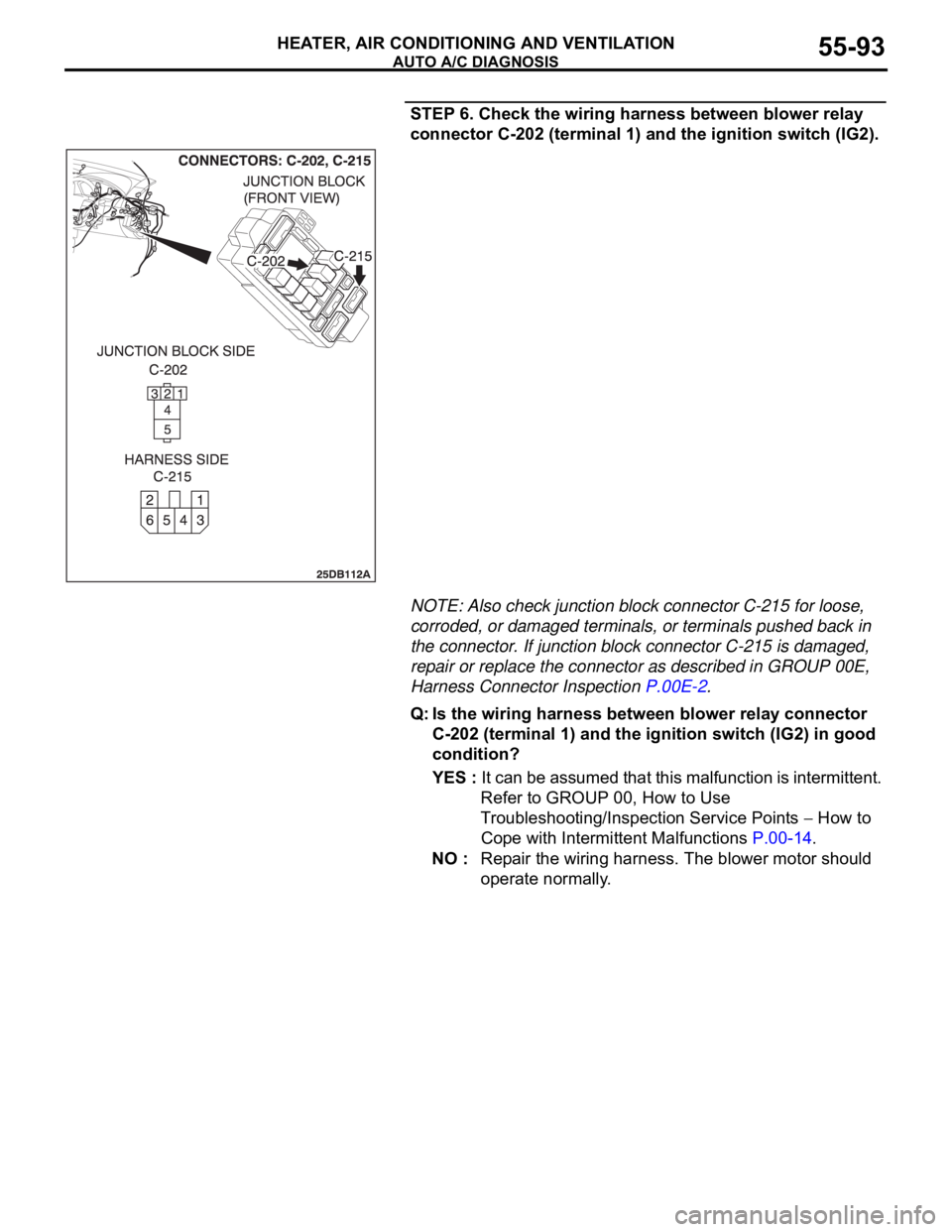

STEP 6. Check the wiring harness between blower relay

connector C-202 (terminal 1) and the ignition switch (IG2).

NOTE: Also check junction block connector C-215 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-215 is damaged,

repair or replace the connector as described in GROUP 00E,

Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between blower relay connector

C-202 (terminal 1) and the ignition switch (IG2) in good

condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. The blower motor should

operate normally.

Page 796 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-95

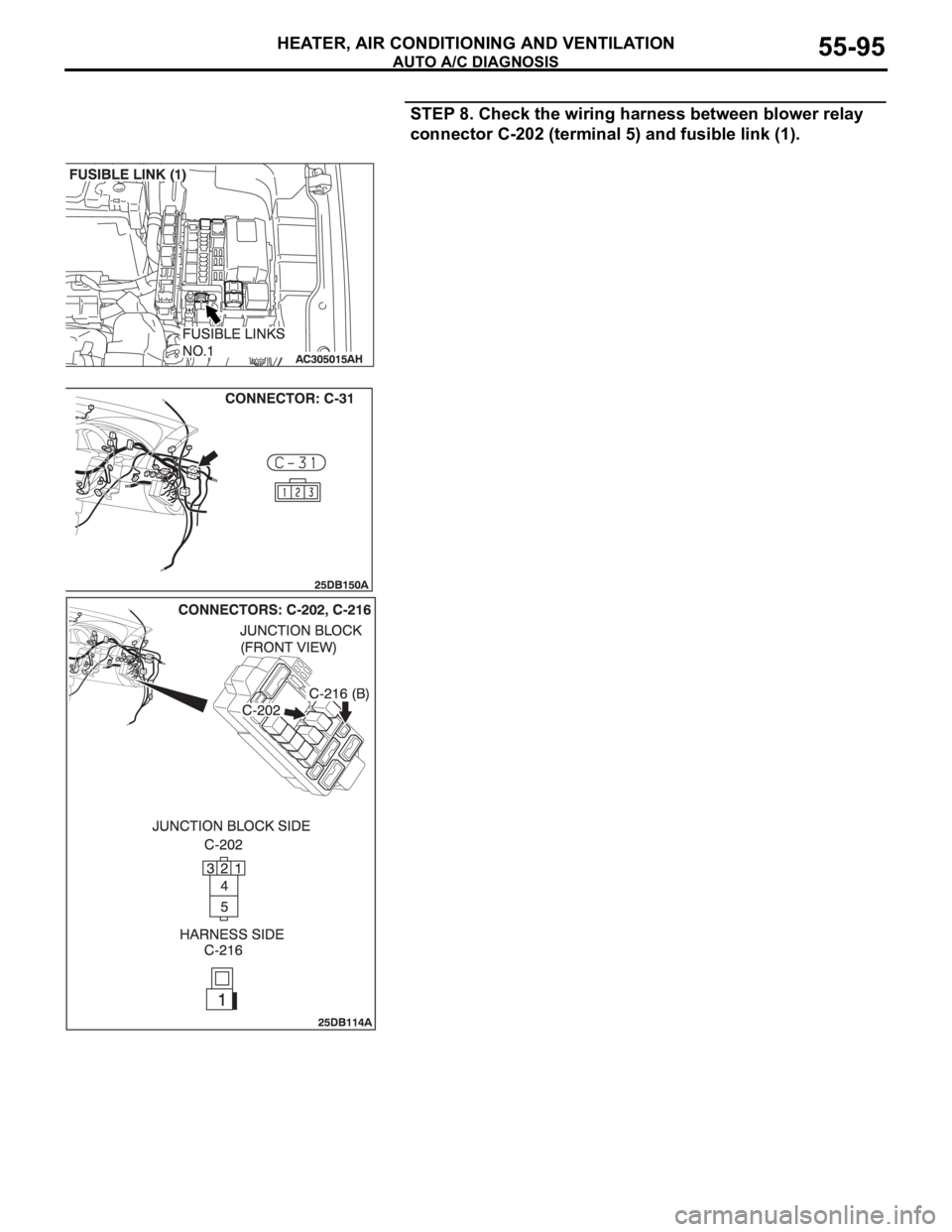

STEP 8. Check the wiring harness between blower relay

connector C-202 (terminal 5) and fusible link (1).

Page 797 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-96

NOTE: Also check intermediate connector C-31 and junction

block connector C-216 for loose, corroded, or damaged termi-

nals, or terminals pushed back in the connector. If intermediate

connector C-31, junction block connector C-216 is damaged,

repair or replace the connector as described in GROUP 00E,

Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between blower relay connector

C-202 (terminal 5) and fusible link (1) in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. The blower motor should

operate normally.

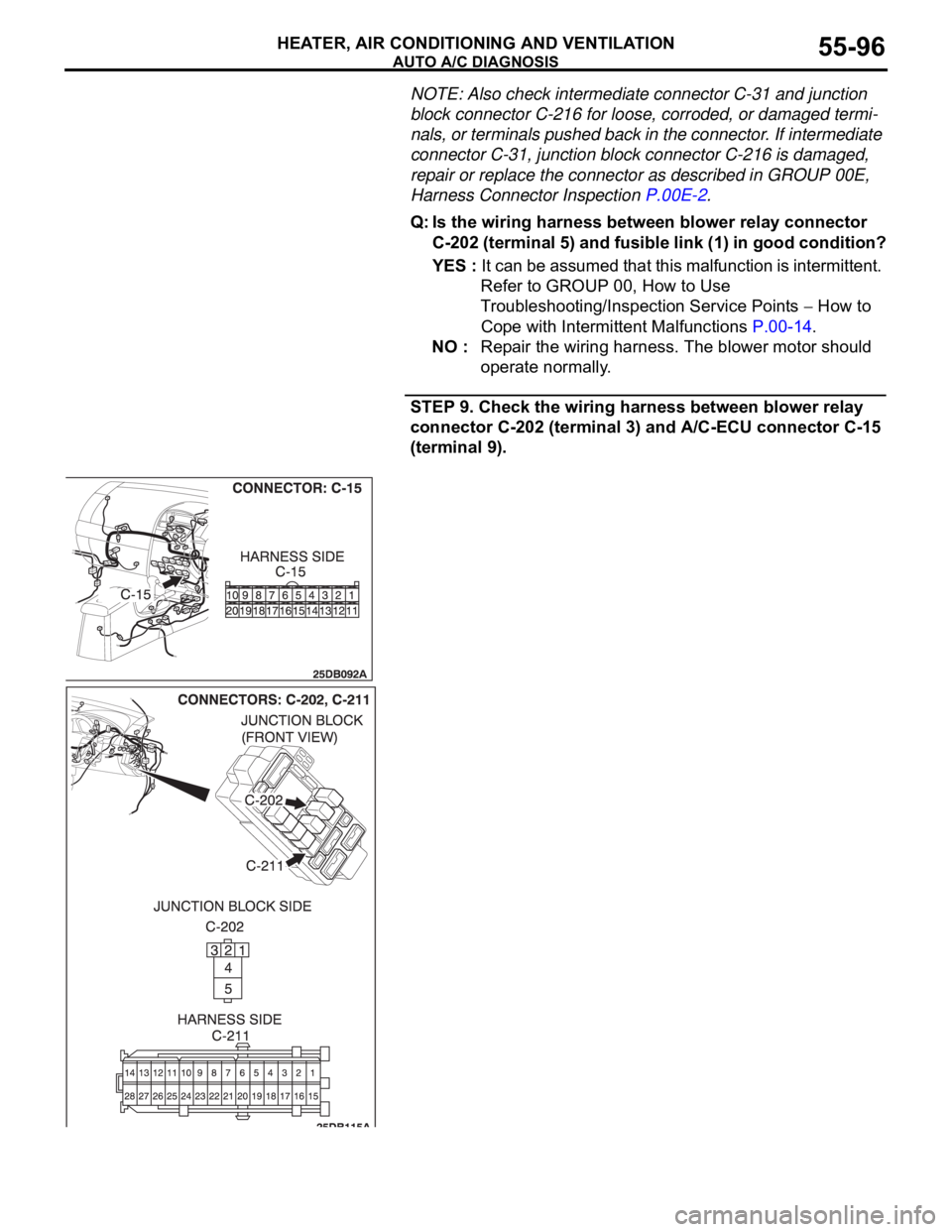

STEP 9. Check the wiring harness between blower relay

connector C-202 (terminal 3) and A/C-ECU connector C-15

(terminal 9).

Page 798 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-97

NOTE: Also check junction block connector C-211 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-211 is damaged,

repair or replace the connector as described in GROUP 00E,

Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between blower relay connector

C-202 (terminal 3) and A/C-ECU connector C-15

(terminal 9) in good condition?

YES : Go to Step 10.

NO : Repair the wiring harness. The blower motor should

operate normally.

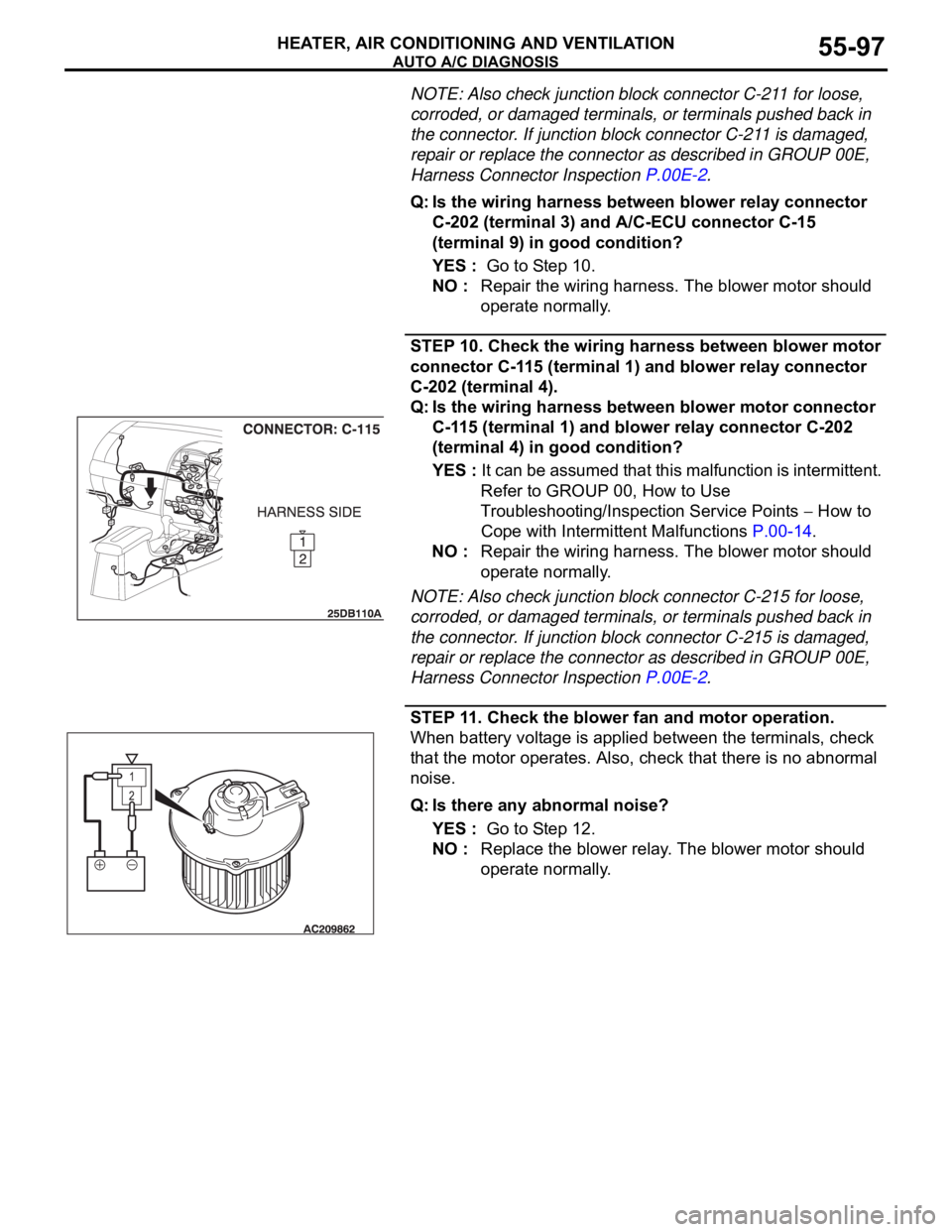

STEP 10. Check the wiring harness between blower motor

connector C-115 (terminal 1) and blower relay connector

C-202 (terminal 4).

Q: Is the wiring harness between blower motor connector

C-115 (terminal 1) and blower relay connector C-202

(terminal 4) in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. The blower motor should

operate normally.

NOTE: Also check junction block connector C-215 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-215 is damaged,

repair or replace the connector as described in GROUP 00E,

Harness Connector Inspection P.00E-2.

STEP 11. Check the blower fan and motor operation.

When battery voltage is applied between the terminals, check

that the motor operates. Also, check that there is no abnormal

noise.

Q: Is there any abnormal noise?

YES : Go to Step 12.

NO : Replace the blower relay. The blower motor should

operate normally.

Page 816 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-115

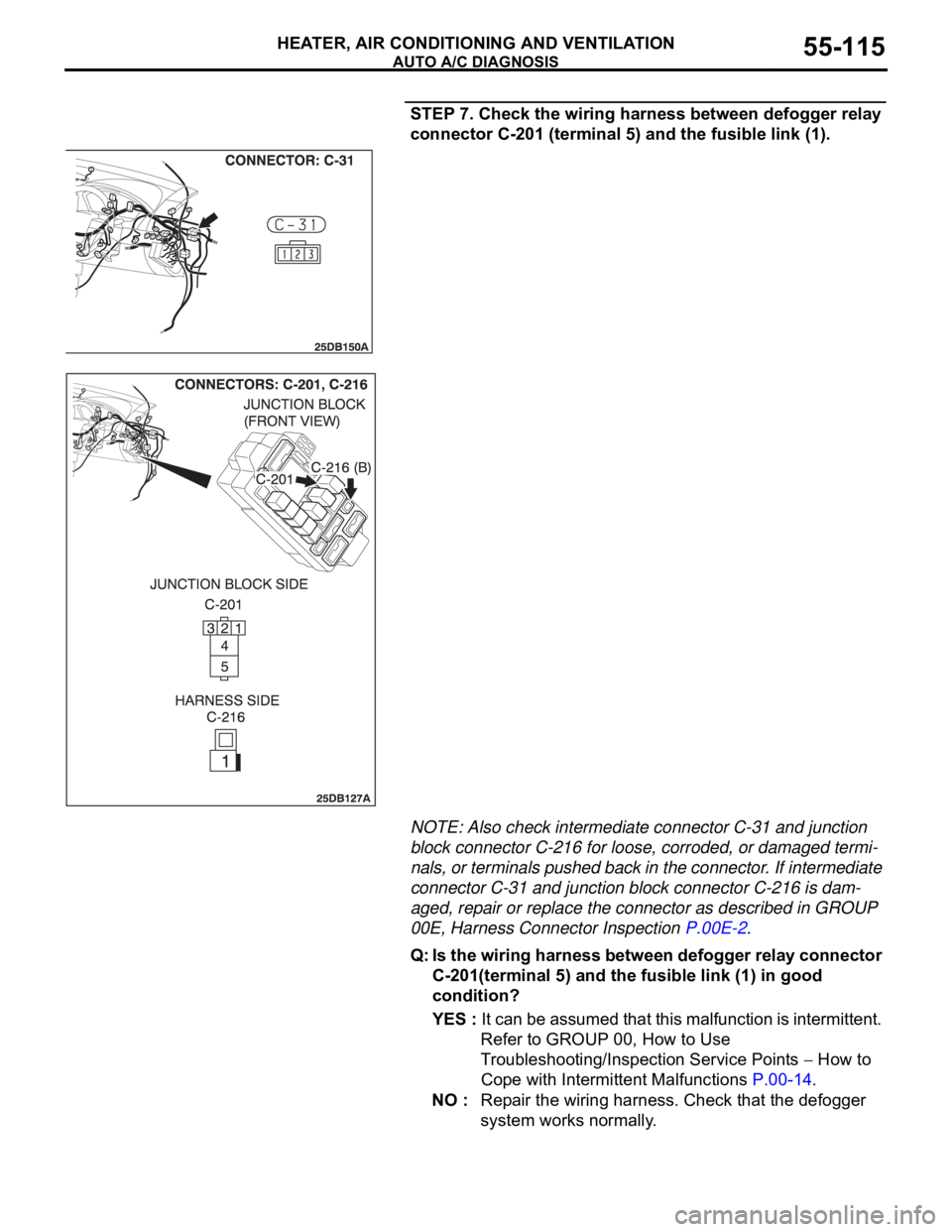

STEP 7. Check the wiring harness between defogger relay

connector C-201 (terminal 5) and the fusible link (1).

NOTE: Also check intermediate connector C-31 and junction

block connector C-216 for loose, corroded, or damaged termi-

nals, or terminals pushed back in the connector. If intermediate

connector C-31 and junction block connector C-216 is dam-

aged, repair or replace the connector as described in GROUP

00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between defogger relay connector

C-201(terminal 5) and the fusible link (1) in good

condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the defogger

system works normally.