console MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 217 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-217

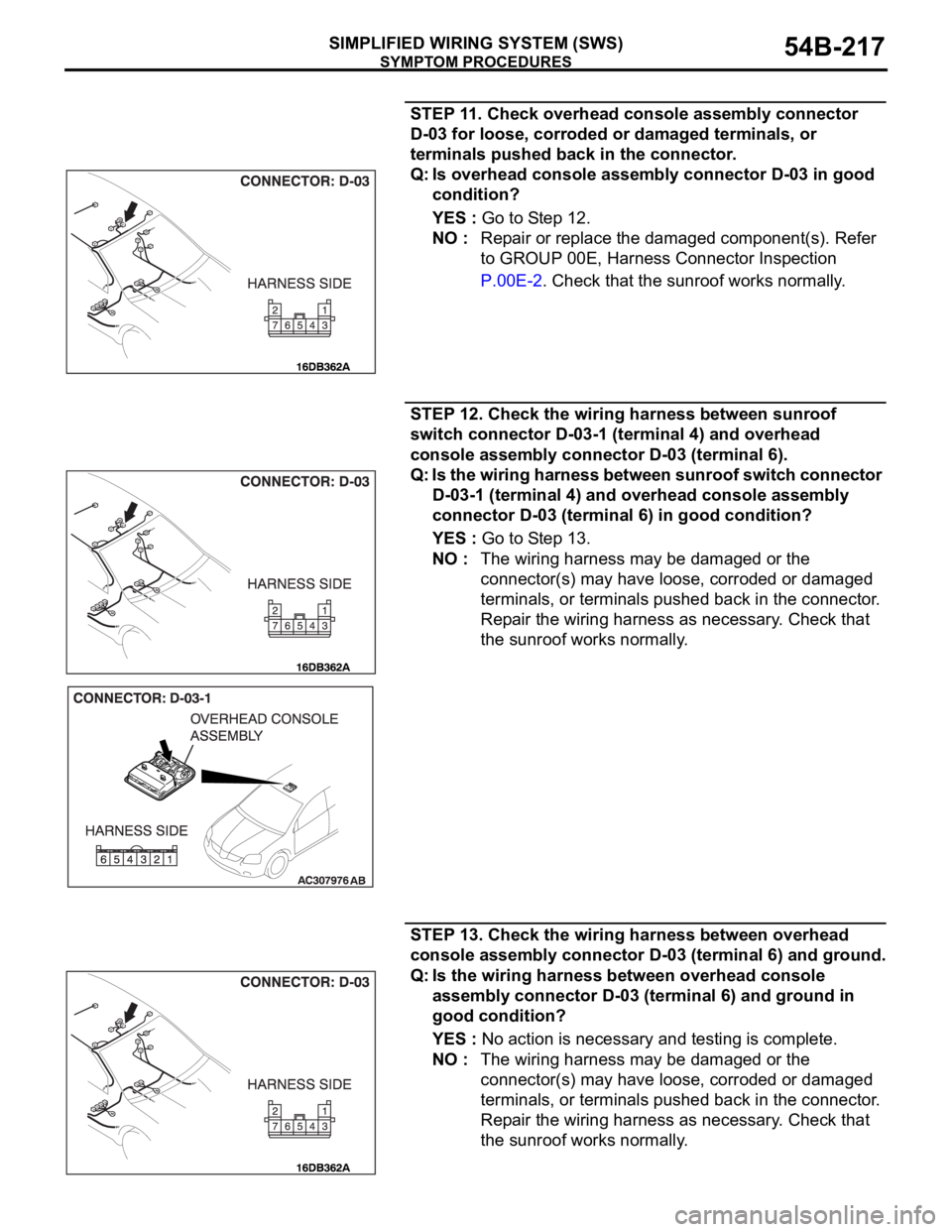

STEP 11. Check overhead console assembly connector

D-03 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is overhead console assembly connector D-03 in good

condition?

YES : Go to Step 12.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the sunroof works normally.

STEP 12. Check the wiring harness between sunroof

switch connector D-03-1 (terminal 4) and overhead

console assembly connector D-03 (terminal 6).

Q: Is the wiring harness between sunroof switch connector

D-03-1 (terminal 4) and overhead console assembly

connector D-03 (terminal 6) in good condition?

YES : Go to Step 13.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Check that

the sunroof works normally.

STEP 13. Check the wiring harness between overhead

console assembly connector D-03 (terminal 6) and ground.

Q: Is the wiring harness between overhead console

assembly connector D-03 (terminal 6) and ground in

good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Check that

the sunroof works normally.

Page 218 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-218

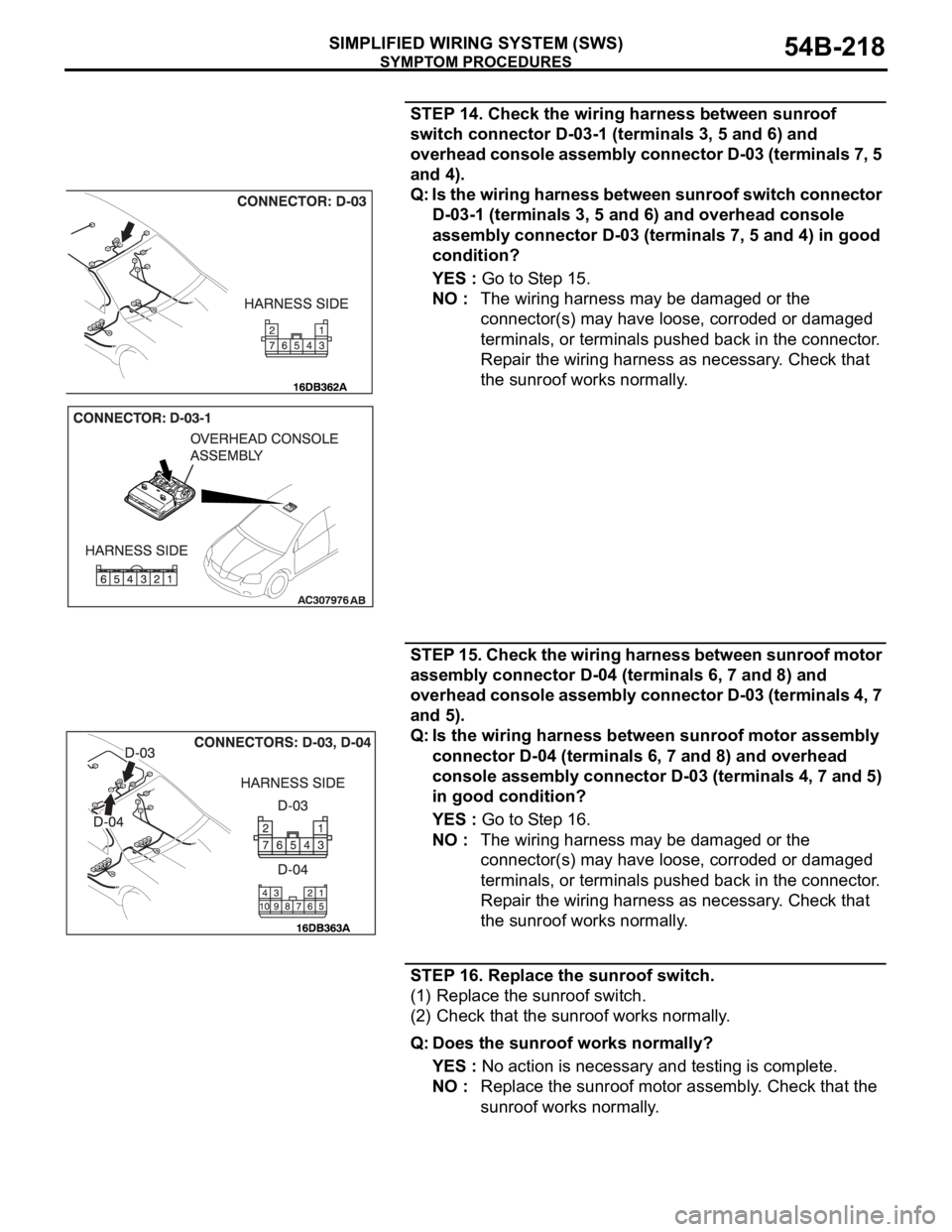

STEP 14. Check the wiring harness between sunroof

switch connector D-03-1 (terminals 3, 5 and 6) and

overhead console assembly connector D-03 (terminals 7, 5

and 4).

Q: Is the wiring harness between sunroof switch connector

D-03-1 (terminals 3, 5 and 6) and overhead console

assembly connector D-03 (terminals 7, 5 and 4) in good

condition?

YES : Go to Step 15.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Check that

the sunroof works normally.

STEP 15. Check the wiring harness between sunroof motor

assembly connector D-04 (terminals 6, 7 and 8) and

overhead console assembly connector D-03 (terminals 4, 7

and 5).

Q: Is the wiring harness between sunroof motor assembly

connector D-04 (terminals 6, 7 and 8) and overhead

console assembly connector D-03 (terminals 4, 7 and 5)

in good condition?

YES : Go to Step 16.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Check that

the sunroof works normally.

STEP 16. Replace the sunroof switch.

(1) Replace the sunroof switch.

(2) Check that the sunroof works normally.

Q: Does the sunroof works normally?

YES : No action is necessary and testing is complete.

NO : Replace the sunroof motor assembly. Check that the

sunroof works normally.

Page 364 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-364

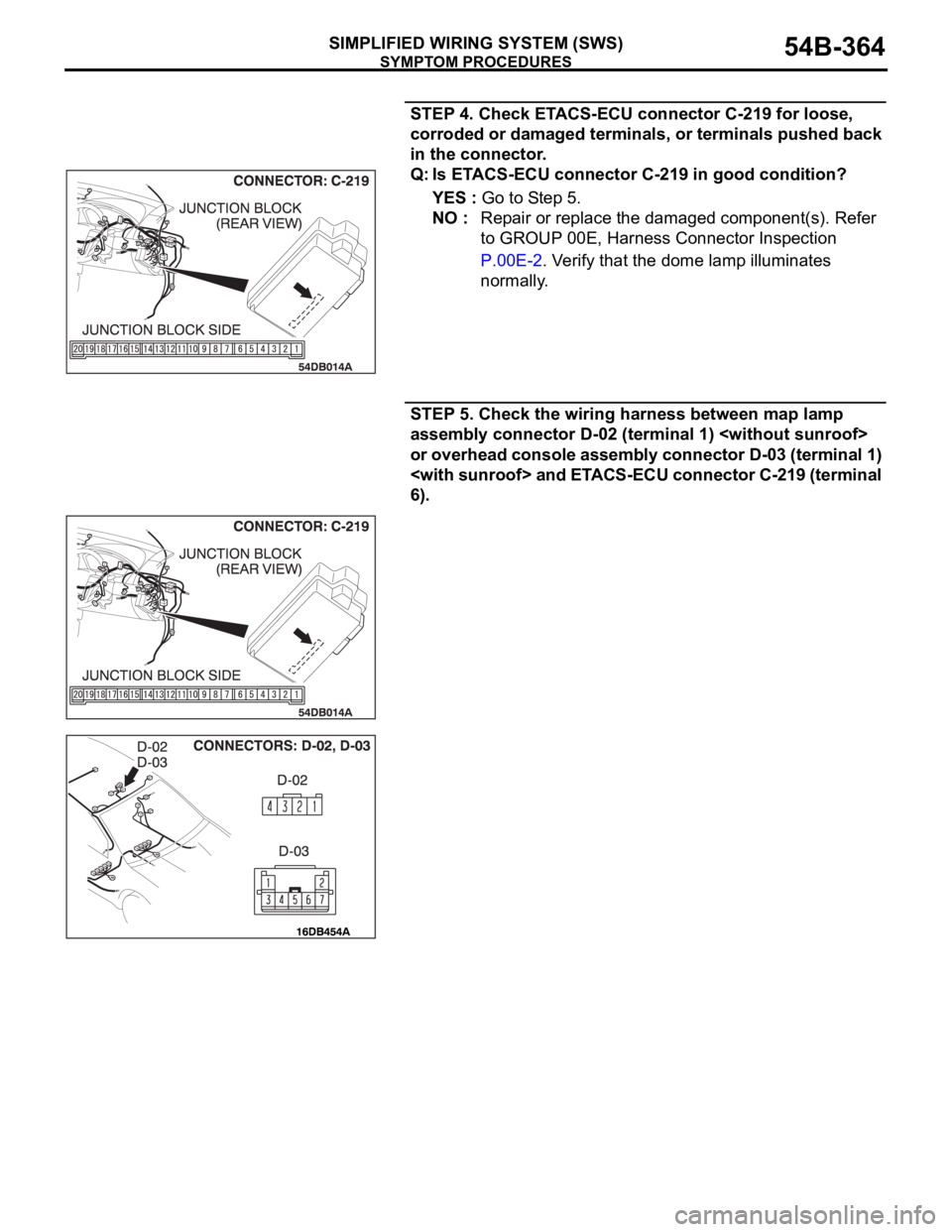

STEP 4. Check ETACS-ECU connector C-219 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-219 in good condition?

YES : Go to Step 5.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the dome lamp illuminates

normally.

STEP 5. Check the wiring harness between map lamp

assembly connector D-02 (terminal 1)

or overhead console assembly connector D-03 (terminal 1)

6).

Page 365 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-365

NOTE: Also check junction block connector C-205 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-205 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between map lamp assembly

connector D-02 (terminal 1)

overhead console assembly connector D-03 (terminal 1)

(terminal 6) in good condition?

YES : Replace the ETACS-ECU. Verify that the dome lamp

illuminates normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the dome lamp illuminates normally.

Page 368 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-368

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

STEP 1. Check which of the front dome lamp, rear dome

lamp or trunk lamp do not illuminate normally.

Q: Which of the front dome lamp, rear dome lamp or trunk

lamp fail to illuminate normally?

Front dome lamp and rear dome lamp : Go to Step 2.

Front dome lamp : Go to Step 4.

Rear dome lamp : Go to Step 9.

Tru n k l am p : Go to Step 14.

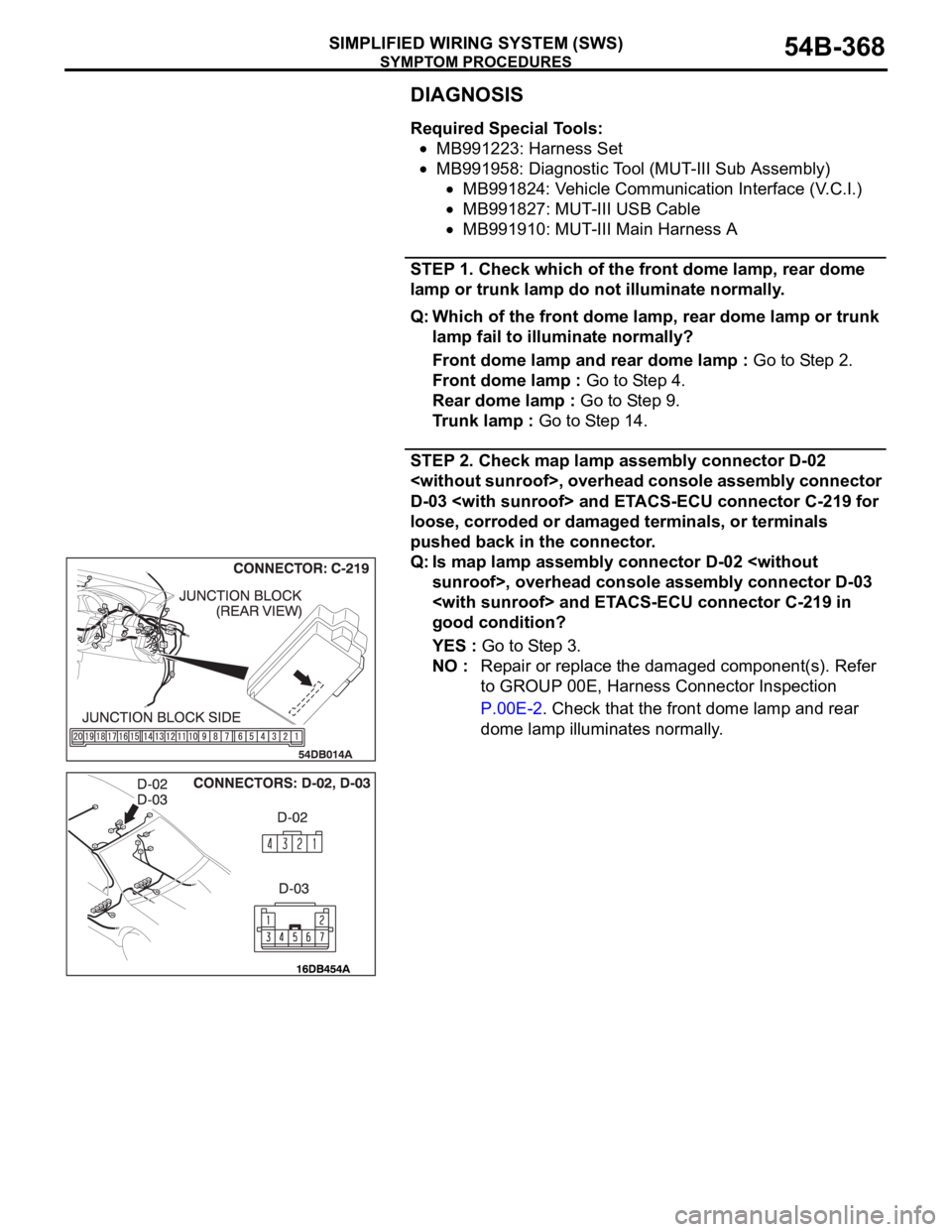

STEP 2. Check map lamp assembly connector D-02

D-03

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is map lamp assembly connector D-02

good condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the front dome lamp and rear

dome lamp illuminates normally.

Page 369 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-369

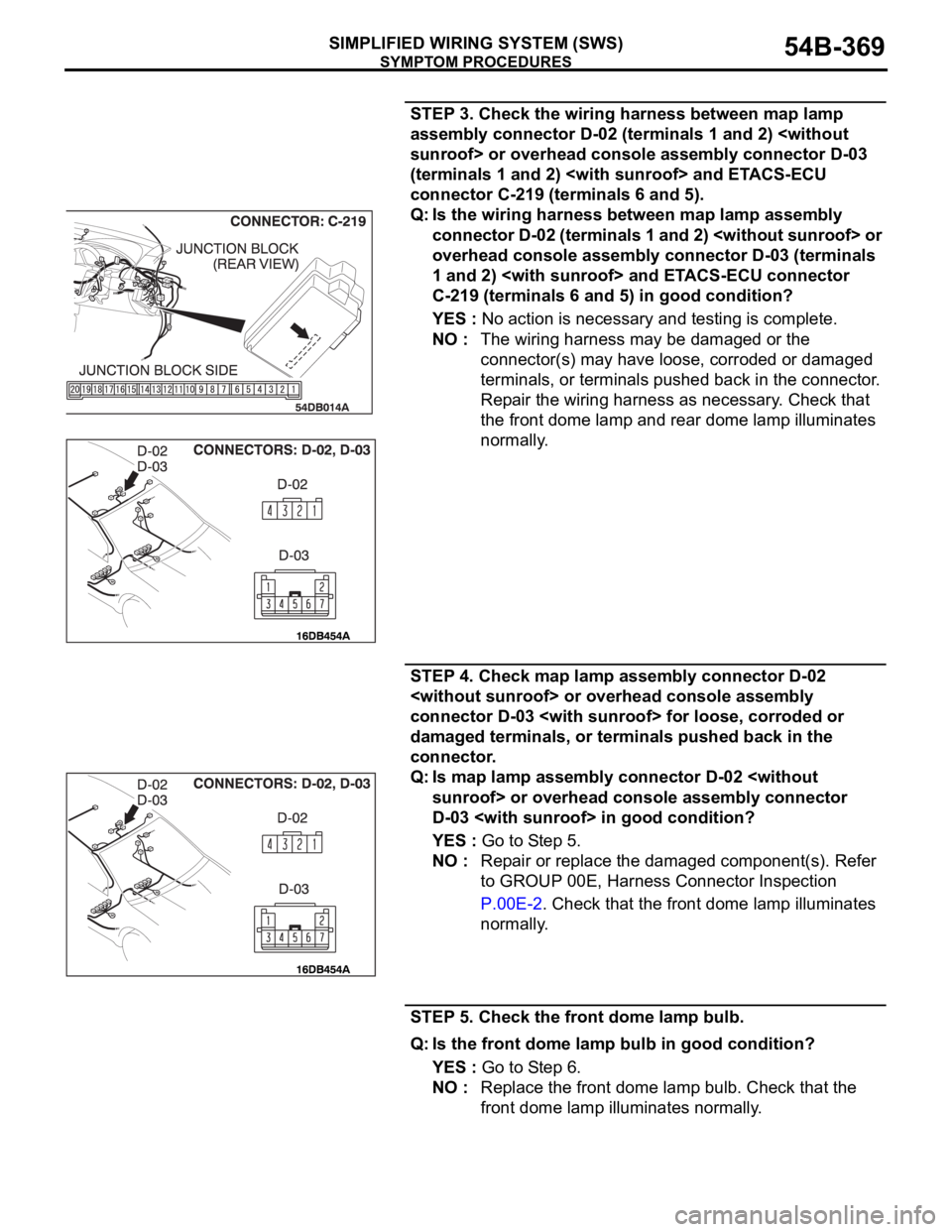

STEP 3. Check the wiring harness between map lamp

assembly connector D-02 (terminals 1 and 2)

(terminals 1 and 2)

connector C-219 (terminals 6 and 5).

Q: Is the wiring harness between map lamp assembly

connector D-02 (terminals 1 and 2)

overhead console assembly connector D-03 (terminals

1 and 2)

C-219 (terminals 6 and 5) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Check that

the front dome lamp and rear dome lamp illuminates

normally.

STEP 4. Check map lamp assembly connector D-02

connector D-03

damaged terminals, or terminals pushed back in the

connector.

Q: Is map lamp assembly connector D-02

D-03

YES : Go to Step 5.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the front dome lamp illuminates

normally.

STEP 5. Check the front dome lamp bulb.

Q: Is the front dome lamp bulb in good condition?

YES : Go to Step 6.

NO : Replace the front dome lamp bulb. Check that the

front dome lamp illuminates normally.

Page 370 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-370

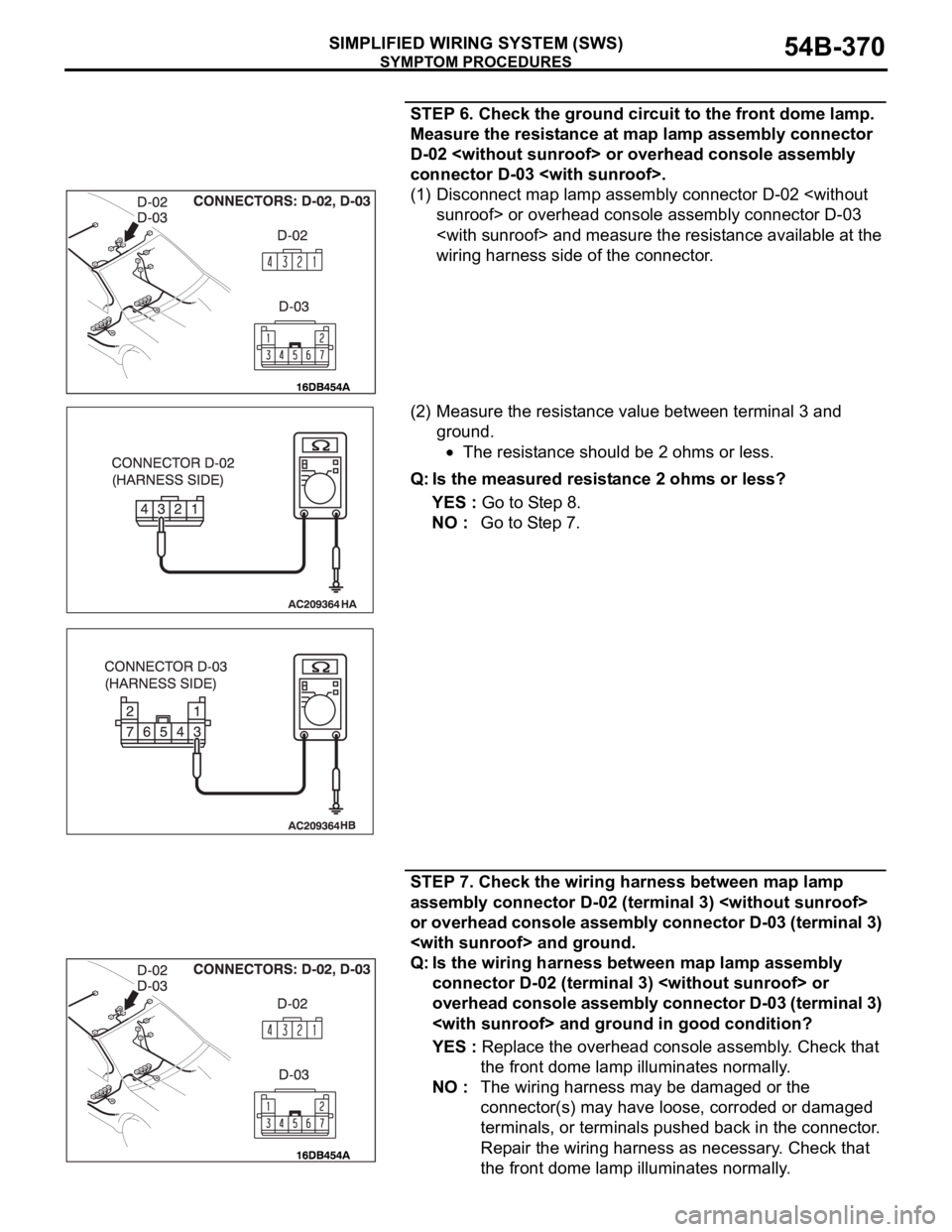

STEP 6. Check the ground circuit to the front dome lamp.

Measure the resistance at map lamp assembly connector

D-02

connector D-03

(1) Disconnect map lamp assembly connector D-02

wiring harness side of the connector.

(2) Measure the resistance value between terminal 3 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 8.

NO : Go to Step 7.

STEP 7. Check the wiring harness between map lamp

assembly connector D-02 (terminal 3)

or overhead console assembly connector D-03 (terminal 3)

Q: Is the wiring harness between map lamp assembly

connector D-02 (terminal 3)

overhead console assembly connector D-03 (terminal 3)

YES : Replace the overhead console assembly. Check that

the front dome lamp illuminates normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Check that

the front dome lamp illuminates normally.

Page 371 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-371

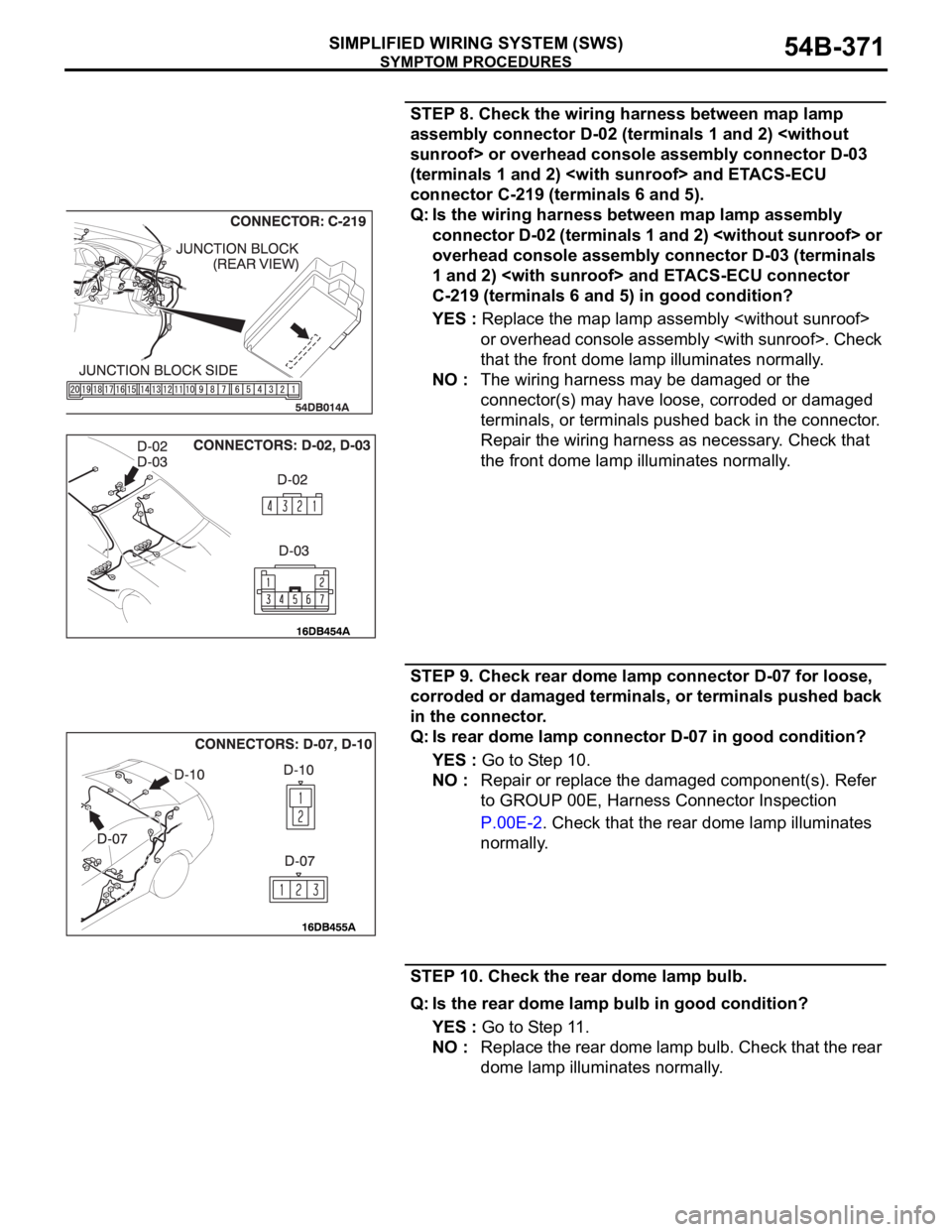

STEP 8. Check the wiring harness between map lamp

assembly connector D-02 (terminals 1 and 2)

(terminals 1 and 2)

connector C-219 (terminals 6 and 5).

Q: Is the wiring harness between map lamp assembly

connector D-02 (terminals 1 and 2)

overhead console assembly connector D-03 (terminals

1 and 2)

C-219 (terminals 6 and 5) in good condition?

YES : Replace the map lamp assembly

or overhead console assembly

that the front dome lamp illuminates normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Check that

the front dome lamp illuminates normally.

STEP 9. Check rear dome lamp connector D-07 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is rear dome lamp connector D-07 in good condition?

YES : Go to Step 10.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the rear dome lamp illuminates

normally.

STEP 10. Check the rear dome lamp bulb.

Q: Is the rear dome lamp bulb in good condition?

YES : Go to Step 11.

NO : Replace the rear dome lamp bulb. Check that the rear

dome lamp illuminates normally.

Page 490 of 1500

52A-1

GROUP 52A

INTERIOR

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .52A-3

SEAT BELT DIAGNOSIS. . . . . . . . . .52A-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .52A-3

INSTRUMENT PANEL ASSEMBLY*.52A-4

REMOVAL AND INSTALLATION . . . . . . . . 52A-4

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-9

FLOOR CONSOLE ASSEMBLY . . . .52A-10

REMOVAL AND INSTALLATION . . . . . . . . 52A-10

TRIMS . . . . . . . . . . . . . . . . . . . . . . . . .52A-11

REMOVAL AND INSTALLATION . . . . . . . . 52A-11

DOOR TRIM . . . . . . . . . . . . . . . . . . . .52A-14

REMOVAL AND INSTALLATION . . . . . . . . 52A-14

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-17

HEADLINING . . . . . . . . . . . . . . . . . . .52A-19

REMOVAL AND INSTALLATION . . . . . . . . 52A-19

INSIDE REAR VIEW MIRROR . . . . . .52A-20

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

Page 495 of 1500

INSTRUMENT PANEL ASSEMBLY

INTERIOR52A-6

6. RADIO AND CD PLAYER,

ASSEMBLY

7. RADIO, CD PLAYER AND CD

CHANGER ASSEMBLY

8. CONSOLE METER HOOD

11. MULTI-CENTER DISPLAY

ASSEMBLY

12. INSTRUMENT DIGITAL CLOCK

ASSEMBLY

13. CENTER CONSOLE ASSEMBLY

14. INSTURMENT PANEL GARNISH

15. COMBINATION METER

ASSEMBLY

FRONT PILLAR TRIM (REFER TO

P.52A-11.)

16. FRONT SPEAKER GARNISH

17. TWEETER

18. INSTRUMENT PANEL SIDE

COVER

19. INSTRUMETN PANEL SIDE AIR

OUTLET

AIR BAG MODULE ASSEMBLY

(DRIVER’S SIDE) (REFER TO

GROUP 52B, AIR BAG MODULE

AND CLOCK SPRING P.52B-237.)

STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37,

STEERING WHEEL P.37-23.)

20. STEERING COLUMN COVERREMOVAL STEPS (Continued)

<>CLOCK SPRING CONNECTOR

<>COLUMN SWITHC CONNECTOR

CLOCK SPRING AND COLUMN

SWITCH ASSEMBLY (REFER TO

GROUP 37, STEERING SHAFT

P.37-25.)

21. INTERIOR TEMPERATURE

SENSOR (GROUP 55B,

SENSORS 55-160.)

22. INSTRUMENT PANEL FRONT

END GARNISH

23. PHOTO SENSOR (GROUP 55B,

SENSORS 55-160.) AND

SECURITY LED.

FLOOR CONSOLE ASSEMBLY

(REFER TO P.52A-10.)

COWL SIDE TRIM (REFER TO

P.52A-11.)

<>AIR BAG MODULE CONNECTOR

(PASSENGER’S SIDE) (REFER

TO GROUP 52B, AIR BAG

MODULE AND CLOCK SPRING

P.52B-237.)

25. INSTRUMENT PANEL ASSEMBLYREMOVAL STEPS (Continued)