fuses MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 10 of 1500

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-10

SWS DIAGNOSIS

GENERAL DESCRIPTION

BEFORE CARRYING OUT TROUBLESHOOTINGM1549014700710

Before carrying out troubleshooting, check the fol-

lowing two items.

Make sure that the ETACS-ECU, the junction

block (J/B), the front-ECU and the engine com-

partment relay box are connected securely.

Make sure that fuses and fusible links related to

relevant systems are not blown.

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

DIAGNOSTIC FUNCTIONM1549028900245

ON-BOARD DIAGNOSTICS

If an error occurs in the ECU or the SWS or CAN

communication line which performs the SWS or CAN

communication, the DTC is memorized in

ETACS-ECU. The DTCs have 11 items. The DTCs

are checked to connect diagnostic tool MB991958

(MUT-III sub assembly). The memorised DTCs are

not erased even if the ignition switch is turned to the

LOCK (OFF) position. The DTCs are erased to oper-

ate diagnostic tool MB991958 (MUT-III sub assem-

bly).NOTE:

*1: For vehicles that do not have a sunroof,

the diagnosis code is always sent but it does not indi-

cate a problem.

NOTE:

*2: The diagnosis code for the current prob-

lem is not sent.

NOTE:

*3: For vehicles that do not have a multi cen-

ter display (middle grade type), the diagnosis code is

always sent but it does not indicate a problem.

HOW TO CONNECT THE DIAGNOSTIC TOOL

(MUT-III)

Required Special Tools:

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

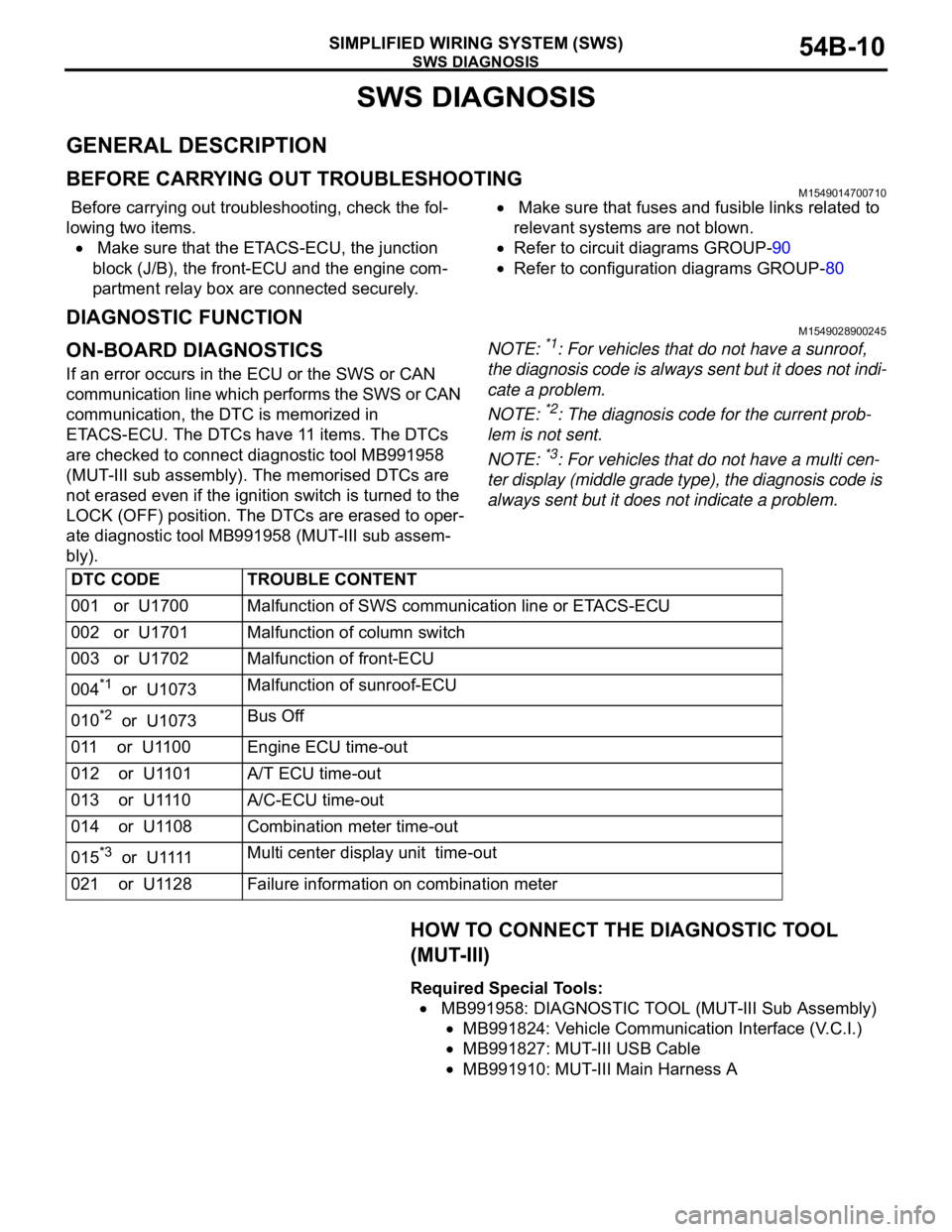

MB991910: MUT-III Main Harness A DTC CODE TROUBLE CONTENT

001 or U1700 Malfunction of SWS communication line or ETACS-ECU

002 or U1701 Malfunction of column switch

003 or U1702 Malfunction of front-ECU

004

*1 or U1073Malfunction of sunroof-ECU

010

*2 or U1073Bus Off

011 or U1100 Engine ECU time-out

012 or U1101 A/T ECU time-out

013 or U1110 A/C-ECU time-out

014 or U1108 Combination meter time-out

015

*3 or U1111Multi center display unit time-out

021 or U1128 Failure information on combination meter

Page 881 of 1500

FUSIBLE LINK, FUSE AND IOD OR STORAGE CONNECTOR

COMPONENT LOCATIONS70-2

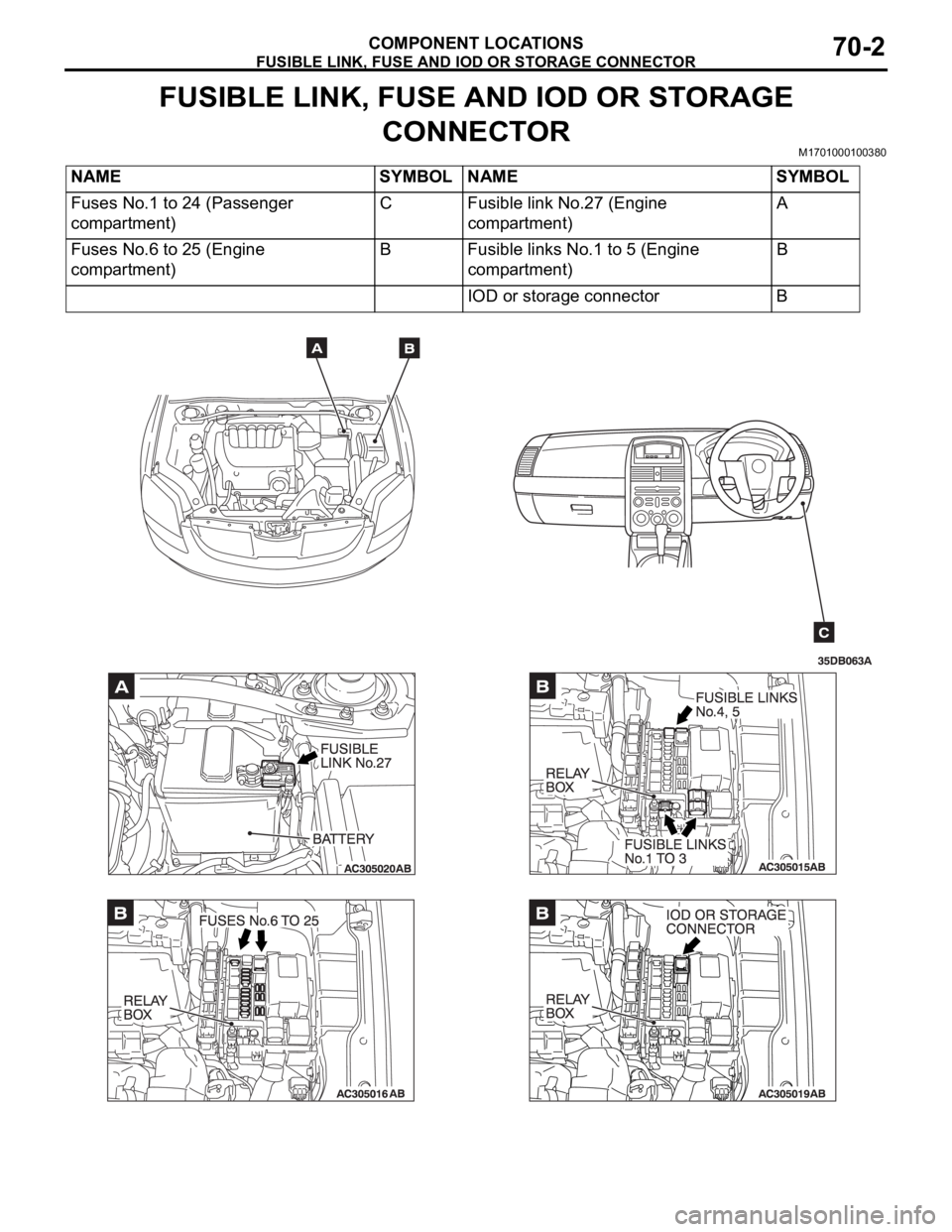

FUSIBLE LINK, FUSE AND IOD OR STORAGE

CONNECTOR

M1701000100380

NAME SYMBOL NAME SYMBOL

Fuses No.1 to 24 (Passenger

compartment)C Fusible link No.27 (Engine

compartment)A

Fuses No.6 to 25 (Engine

compartment)B Fusible links No.1 to 5 (Engine

compartment)B

IOD or storage connector B

Page 902 of 1500

00E-1

GROUP 00E

GENERAL

CONTENTS

HARNESS CONNECTOR

INSPECTION . . . . . . . . . . . . . . . . . . .00E-2

HOW TO DIAGNOSE . . . . . . . . . . . . .00E-2

HOW TO DIAGNOSE . . . . . . . . . . . . . . . . . 00E-2

TROUBLESHOOTING STEPS . . . . . . . . . . 00E-3

INFORMATION FOR DIAGNOSIS . . . . . . . 00E-3

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 00E-4INSPECTION INSTRUMENTS . . . . . . . . . . 00E-5

CHECKING FUSES . . . . . . . . . . . . . . . . . . . 00E-6

CHECKING SWITCHES . . . . . . . . . . . . . . . 00E-7

CHECKING RELAYS . . . . . . . . . . . . . . . . . 00E-8

CABLES AND WIRES CHECK . . . . . . . . . . 00E-9

BATTERY HANDLING . . . . . . . . . . . . . . . . 00E-9

GENERAL ELECTRICAL SYSTEM CHECK00E-9

Page 907 of 1500

HOW TO DIAGNOSE

GENERAL

5. Ohmmeter

An ohmmeter is used to check continuity or measure

resistance of a switch or coil. If the measuring range has

been changed, the zero point must be adjusted before

measurement.

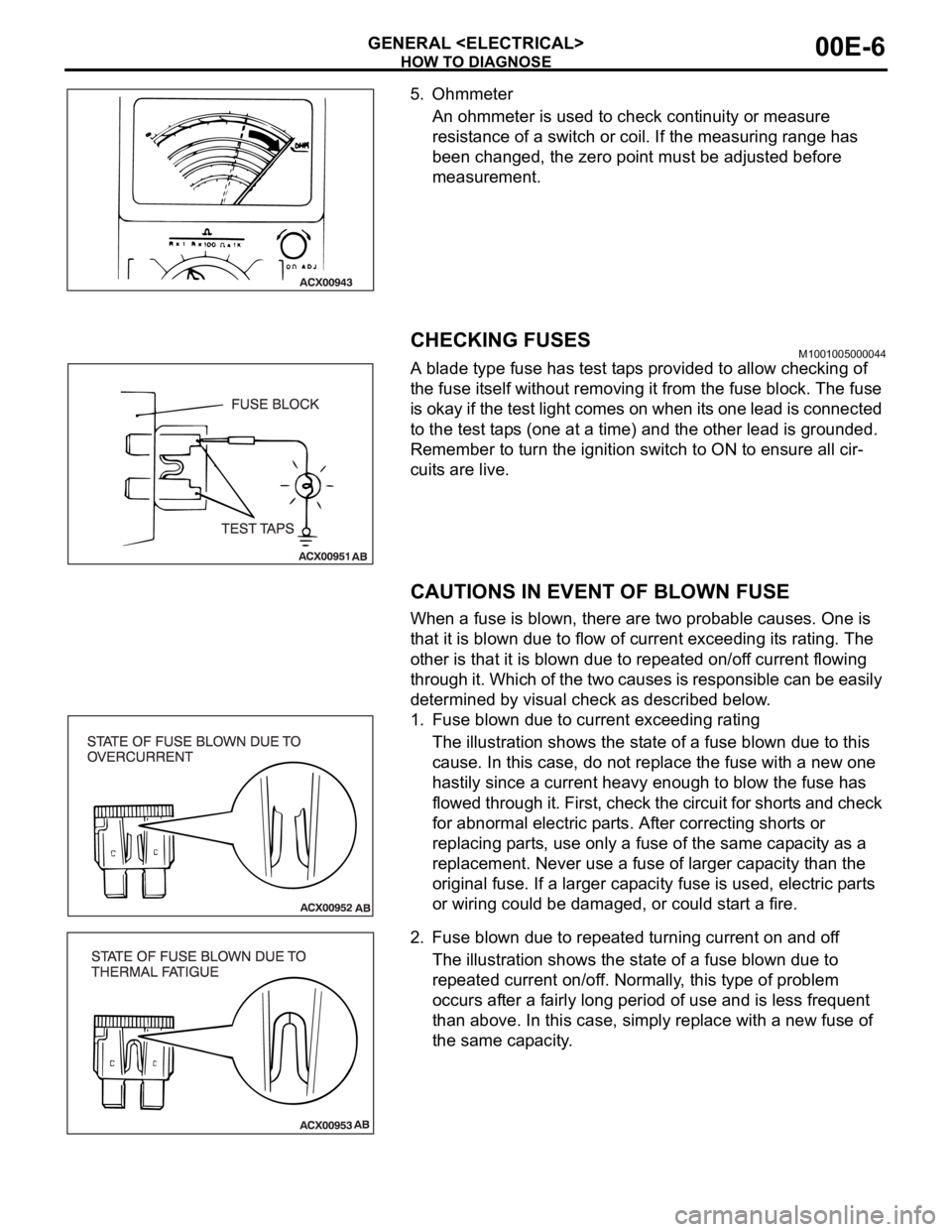

CHECKING FUSESM1001005000044

A blade type fuse has test taps provided to allow checking of

the fuse itself without removing it from the fuse block. The fuse

is okay if the test light comes on when its one lead is connected

to the test taps (one at a time) and the other lead is grounded.

Remember to turn the ignition switch to ON to ensure all cir-

cuits are live.

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes. One is

that it is blown due to flow of current exceeding its rating. The

other is that it is blown due to repeated on/off current flowing

through it. Which of the two causes is responsible can be easily

determined by visual check as described below.

1. Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse with a new one

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorts and check

for abnormal electric parts. After correcting shorts or

replacing parts, use only a fuse of the same capacity as a

replacement. Never use a fuse of larger capacity than the

original fuse. If a larger capacity fuse is used, electric parts

or wiring could be damaged, or could start a fire.

2. Fuse blown due to repeated turning current on and off

The illustration shows the state of a fuse blown due to

repeated current on/off. Normally, this type of problem

occurs after a fairly long period of use and is less frequent

than above. In this case, simply replace with a new fuse of

the same capacity.