heating MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 918 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-3

SYMPTOM CHARTM1141005600393

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Coolant Leak

DIAGNOSIS

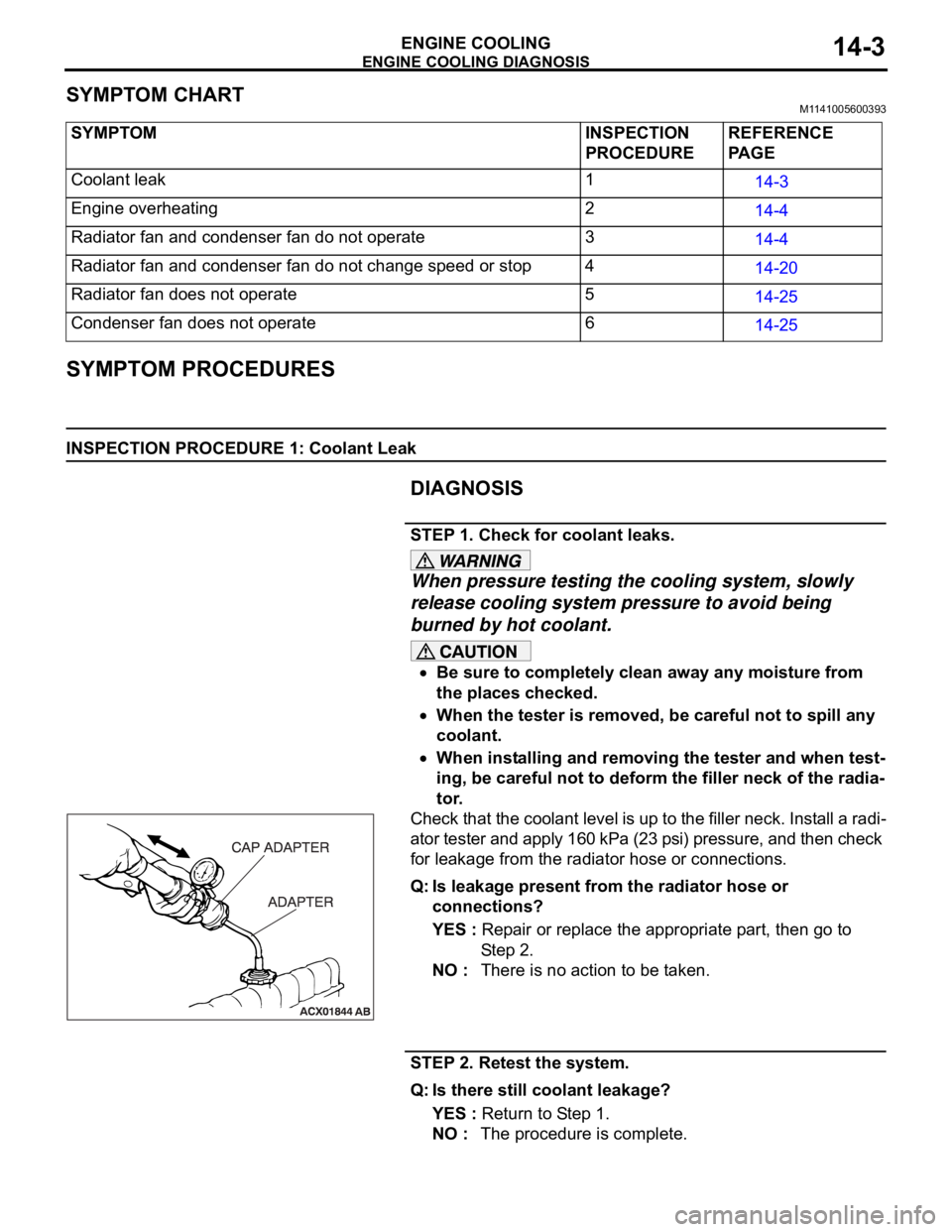

STEP 1. Check for coolant leaks.

When pressure testing the cooling system, slowly

release cooling system pressure to avoid being

burned by hot coolant.

Be sure to completely clean away any moisture from

the places checked.

When the tester is removed, be careful not to spill any

coolant.

When installing and removing the tester and when test-

ing, be careful not to deform the filler neck of the radia-

tor.

Check that the coolant level is up to the filler neck. Install a radi-

ator tester and apply 160 kPa (23 psi) pressure, and then check

for leakage from the radiator hose or connections.

Q: Is leakage present from the radiator hose or

connections?

YES : Repair or replace the appropriate part, then go to

St e p 2 .

NO : There is no action to be taken.

STEP 2. Retest the system.

Q: Is there still coolant leakage?

YES : Return to Step 1.

NO : The procedure is complete. SYMPTOM INSPECTION

PROCEDUREREFERENCE

PA G E

Coolant leak 1

14-3

Engine overheating 2

14-4

Radiator fan and condenser fan do not operate 3

14-4

Radiator fan and condenser fan do not change speed or stop 4

14-20

Radiator fan does not operate 5

14-25

Condenser fan does not operate 6

14-25

Page 919 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-4

INSPECTION PROCEDURE 2: Engine Overheating

DIAGNOSIS

STEP 1. Remove the radiator cap and check for coolant

contamination.

Q: Is the coolant contaminated with rust and oil?

YES : Replace it. Refer to P.14-27.

NO : There is no action to be taken. Go to Step 2.

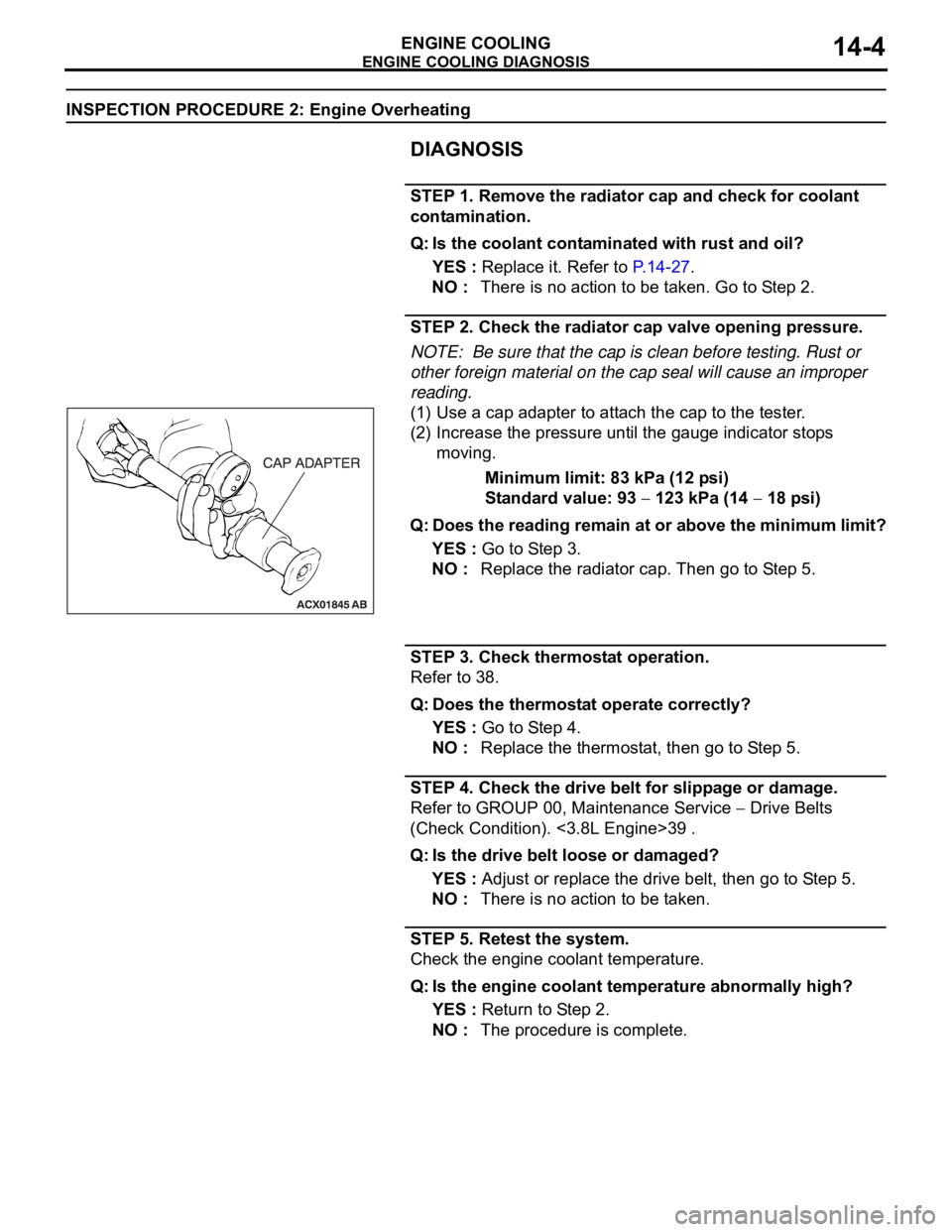

STEP 2. Check the radiator cap valve opening pressure.

NOTE: Be sure that the cap is clean before testing. Rust or

other foreign material on the cap seal will cause an improper

reading.

(1) Use a cap adapter to attach the cap to the tester.

(2) Increase the pressure until the gauge indicator stops

moving.

Minimum limit: 83 kPa (12 psi)

Standard value: 93

123 kPa (14 18 psi)

Q: Does the reading remain at or above the minimum limit?

YES : Go to Step 3.

NO : Replace the radiator cap. Then go to Step 5.

STEP 3. Check thermostat operation.

Refer to 38.

Q: Does the thermostat operate correctly?

YES : Go to Step 4.

NO : Replace the thermostat, then go to Step 5.

STEP 4. Check the drive belt for slippage or damage.

Refer to GROUP 00, Maintenance Service

Drive Belts

(Check Condition). <3.8L Engine>39 .

Q: Is the drive belt loose or damaged?

YES : Adjust or replace the drive belt, then go to Step 5.

NO : There is no action to be taken.

STEP 5. Retest the system.

Check the engine coolant temperature.

Q: Is the engine coolant temperature abnormally high?

YES : Return to Step 2.

NO : The procedure is complete.

Page 985 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-8

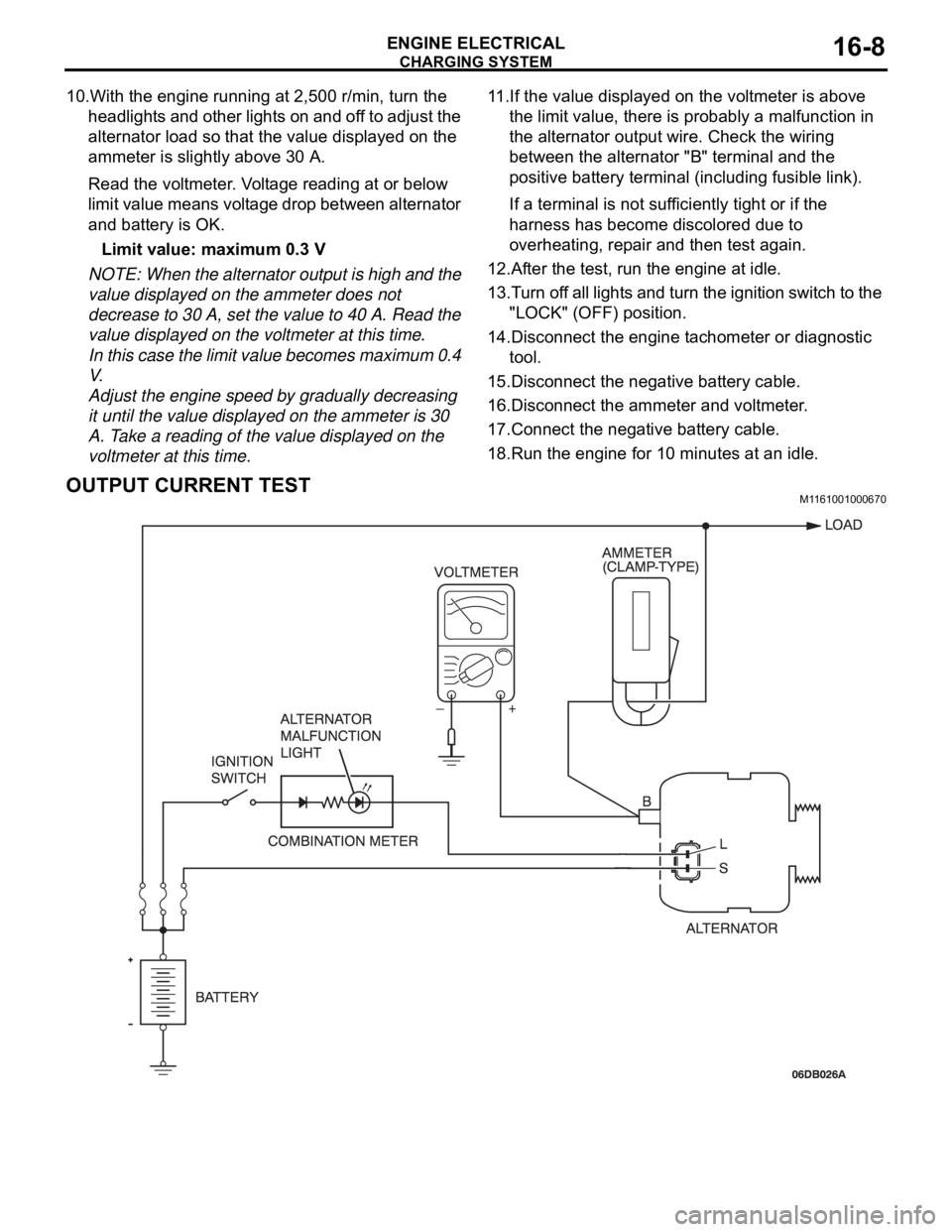

10.With the engine running at 2,500 r/min, turn the

headlights and other lights on and off to adjust the

alternator load so that the value displayed on the

ammeter is slightly above 30 A.

Read the voltmeter. Voltage reading at or below

limit value means voltage drop between alternator

and battery is OK.

Limit value: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease to 30 A, set the value to 40 A. Read the

value displayed on the voltmeter at this time.

In this case the limit value becomes maximum 0.4

V.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire. Check the wiring

between the alternator "B" terminal and the

positive battery terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lights and turn the ignition switch to the

"LOCK" (OFF) position.

14.Disconnect the engine tachometer or diagnostic

tool.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

18.Run the engine for 10 minutes at an idle.

OUTPUT CURRENT TESTM1161001000670

Page 1185 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-20

.

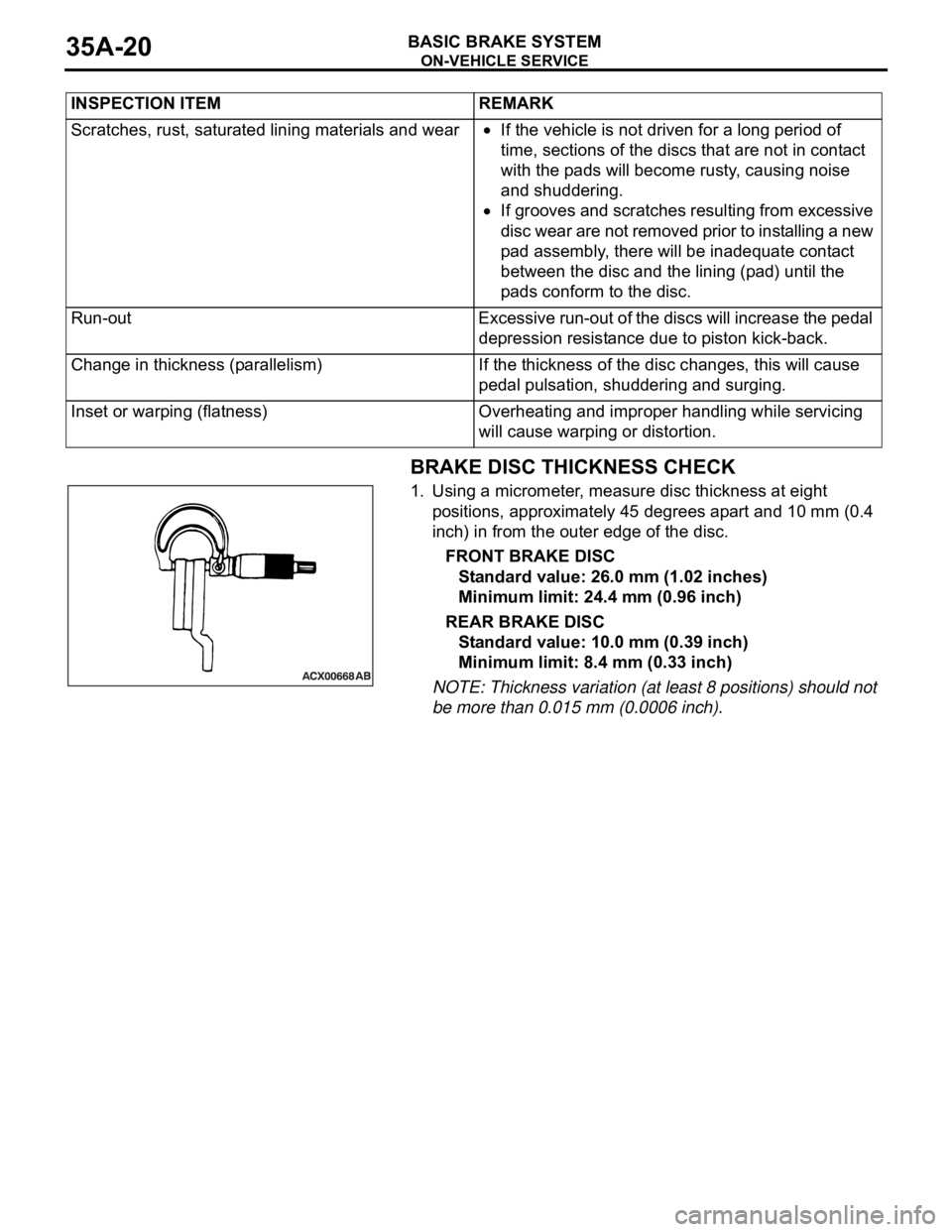

BRAKE DISC THICKNESS CHECK

1. Using a micrometer, measure disc thickness at eight

positions, approximately 45 degrees apart and 10 mm (0.4

inch) in from the outer edge of the disc.

FRONT BRAKE DISC

Standard value: 26.0 mm (1.02 inches)

Minimum limit: 24.4 mm (0.96 inch)

REAR BRAKE DISC

Standard value: 10.0 mm (0.39 inch)

Minimum limit: 8.4 mm (0.33 inch)

NOTE: Thickness variation (at least 8 positions) should not

be more than 0.015 mm (0.0006 inch). INSPECTION ITEM REMARK

Scratches, rust, saturated lining materials and wear

If the vehicle is not driven for a long period of

time, sections of the discs that are not in contact

with the pads will become rusty, causing noise

and shuddering.

If grooves and scratches resulting from excessive

disc wear are not removed prior to installing a new

pad assembly, there will be inadequate contact

between the disc and the lining (pad) until the

pads conform to the disc.

Run-out Excessive run-out of the discs will increase the pedal

depression resistance due to piston kick-back.

Change in thickness (parallelism) If the thickness of the disc changes, this will cause

pedal pulsation, shuddering and surging.

Inset or warping (flatness) Overheating and improper handling while servicing

will cause warping or distortion.