tyre pressure MITSUBISHI ASX 2017 (in English) User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2017, Model line: ASX, Model: MITSUBISHI ASX 2017Pages: 458, PDF Size: 22.98 MB

Page 227 of 458

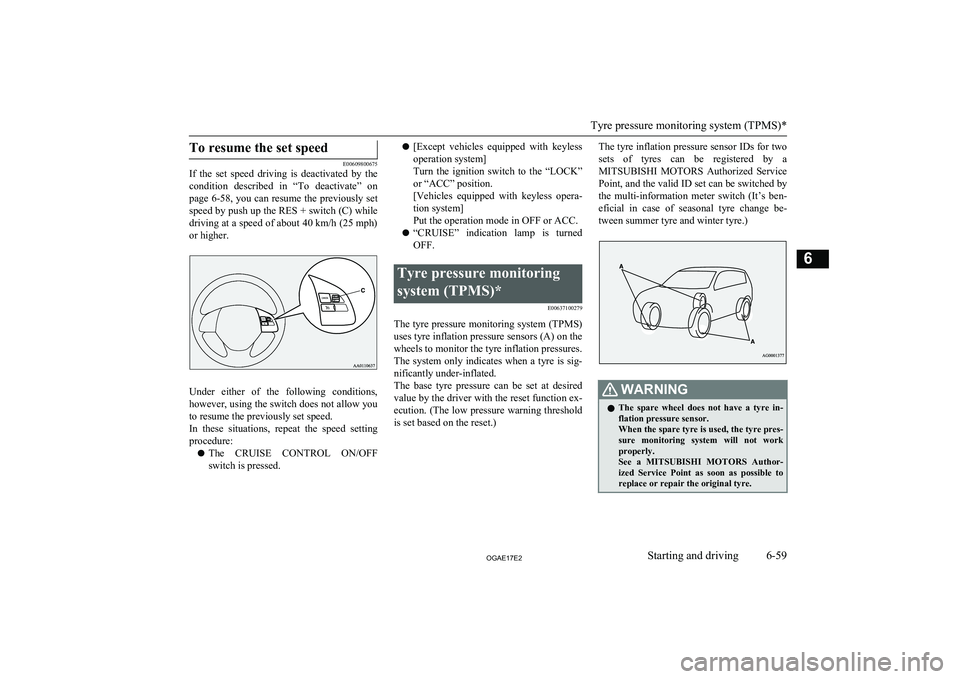

To resume the set speed

E00609800675

If the set speed driving is deactivated by the

condition described in “To deactivate” on

page 6-58, you can resume the previously set

speed by push up the RES + switch (C) while

driving at a speed of about 40 km/h (25 mph)

or higher.

Under either of the following conditions, however, using the switch does not allow you

to resume the previously set speed.

In these situations, repeat the speed setting procedure:

l The CRUISE CONTROL ON/OFF

switch is pressed.

l [Except vehicles equipped with keyless

operation system]

Turn the ignition switch to the “LOCK”

or “ACC” position.

[Vehicles equipped with keyless opera- tion system]

Put the operation mode in OFF or ACC.

l “CRUISE” indication lamp is turned

OFF.Tyre pressure monitoring

system (TPMS)* E00637100279

The tyre pressure monitoring system (TPMS)

uses tyre inflation pressure sensors (A) on the wheels to monitor the tyre inflation pressures.

The system only indicates when a tyre is sig-

nificantly under-inflated.

The base tyre pressure can be set at desired value by the driver with the reset function ex-

ecution. (The low pressure warning threshold is set based on the reset.)

The tyre inflation pressure sensor IDs for two

sets of tyres can be registered by aMITSUBISHI MOTORS Authorized Service

Point, and the valid ID set can be switched by the multi-information meter switch (It’s ben-

eficial in case of seasonal tyre change be- tween summer tyre and winter tyre.)WARNINGl The spare wheel does not have a tyre in-

flation pressure sensor.

When the spare tyre is used, the tyre pres- sure monitoring system will not work

properly.

See a MITSUBISHI MOTORS Author-

ized Service Point as soon as possible to replace or repair the original tyre.

Tyre pressure monitoring system (TPMS)*

6-59OGAE17E2Starting and driving6

Page 228 of 458

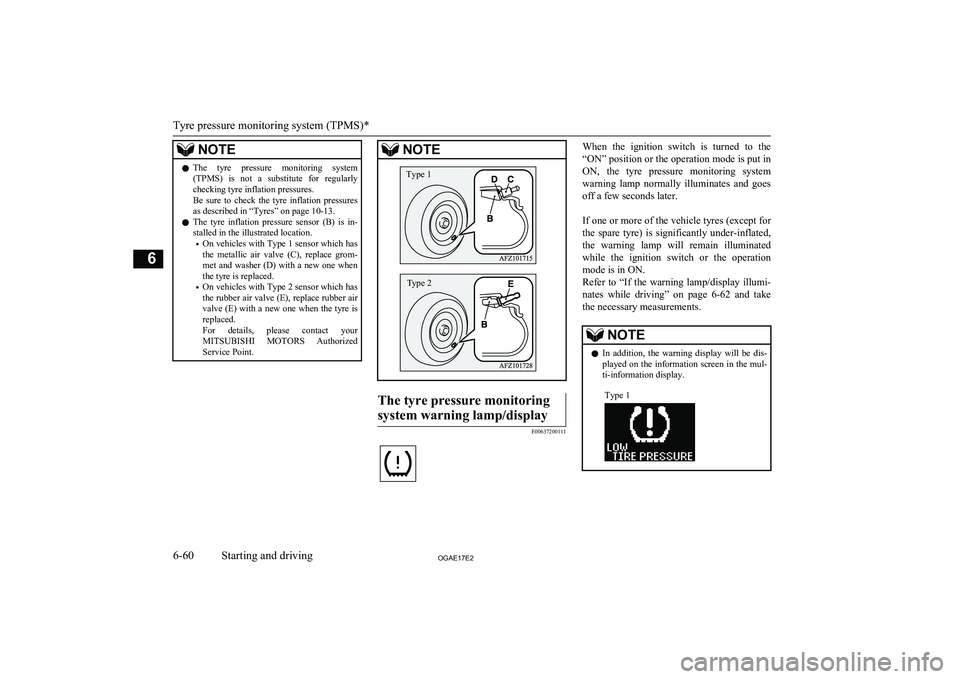

NOTElThe tyre pressure monitoring system

(TPMS) is not a substitute for regularlychecking tyre inflation pressures.

Be sure to check the tyre inflation pressures as described in “Tyres” on page 10-13.

l The tyre inflation pressure sensor (B) is in-

stalled in the illustrated location.

• On vehicles with Type 1 sensor which has

the metallic air valve (C), replace grom- met and washer (D) with a new one when

the tyre is replaced.

• On vehicles with Type 2 sensor which has

the rubber air valve (E), replace rubber air valve (E) with a new one when the tyre is

replaced.

For details, please contact your

MITSUBISHI MOTORS Authorized

Service Point.NOTEThe tyre pressure monitoring

system warning lamp/display

E00637200111

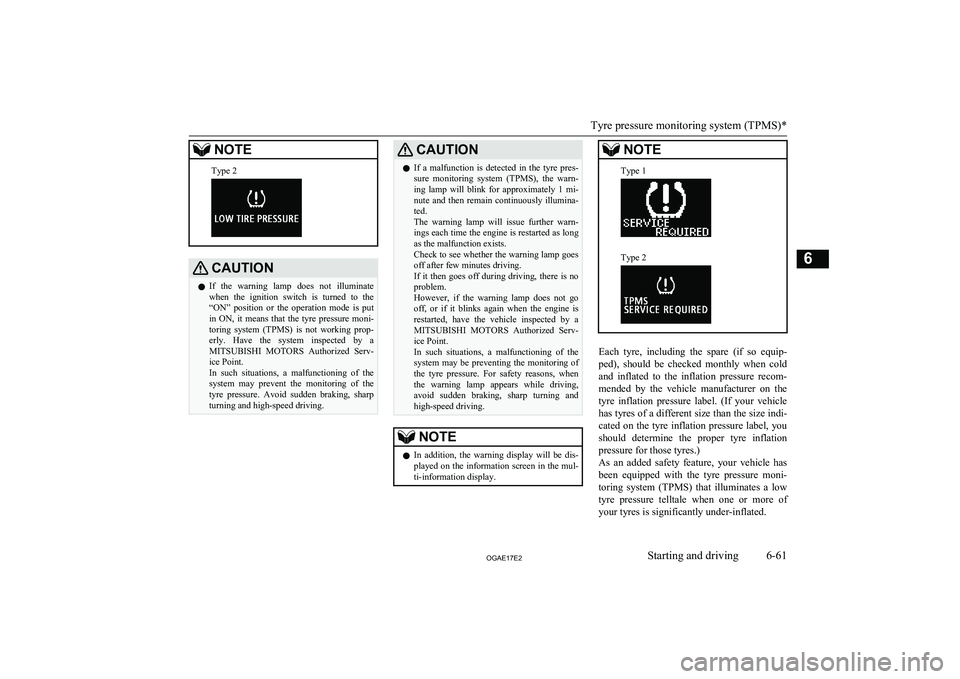

When the ignition switch is turned to the

“ON” position or the operation mode is put in

ON, the tyre pressure monitoring system warning lamp normally illuminates and goes

off a few seconds later.

If one or more of the vehicle tyres (except for the spare tyre) is significantly under-inflated, the warning lamp will remain illuminated

while the ignition switch or the operation mode is in ON.

Refer to “If the warning lamp/display illumi-

nates while driving” on page 6-62 and take

the necessary measurements.NOTEl In addition, the warning display will be dis-

played on the information screen in the mul-

ti-information display.Type 1

Tyre pressure monitoring system (TPMS)*

6-60OGAE17E2Starting and driving6 Type 1 Type 2

Page 229 of 458

NOTEType 2CAUTIONlIf the warning lamp does not illuminate

when the ignition switch is turned to the

“ON” position or the operation mode is put

in ON, it means that the tyre pressure moni-

toring system (TPMS) is not working prop- erly. Have the system inspected by a

MITSUBISHI MOTORS Authorized Serv-

ice Point.

In such situations, a malfunctioning of the system may prevent the monitoring of the tyre pressure. Avoid sudden braking, sharp

turning and high-speed driving.CAUTIONl If a malfunction is detected in the tyre pres-

sure monitoring system (TPMS), the warn- ing lamp will blink for approximately 1 mi-

nute and then remain continuously illumina-

ted.

The warning lamp will issue further warn- ings each time the engine is restarted as long

as the malfunction exists.

Check to see whether the warning lamp goes

off after few minutes driving.

If it then goes off during driving, there is no

problem.

However, if the warning lamp does not go off, or if it blinks again when the engine is

restarted, have the vehicle inspected by a MITSUBISHI MOTORS Authorized Serv-

ice Point.

In such situations, a malfunctioning of the system may be preventing the monitoring of the tyre pressure. For safety reasons, when

the warning lamp appears while driving,

avoid sudden braking, sharp turning and high-speed driving.NOTEl In addition, the warning display will be dis-

played on the information screen in the mul-

ti-information display.NOTEType 1Type 2

Each tyre, including the spare (if so equip-

ped), should be checked monthly when cold and inflated to the inflation pressure recom-

mended by the vehicle manufacturer on the tyre inflation pressure label. (If your vehiclehas tyres of a different size than the size indi-

cated on the tyre inflation pressure label, you

should determine the proper tyre inflationpressure for those tyres.)

As an added safety feature, your vehicle has

been equipped with the tyre pressure moni- toring system (TPMS) that illuminates a low

tyre pressure telltale when one or more of

your tyres is significantly under-inflated.

Tyre pressure monitoring system (TPMS)*

6-61OGAE17E2Starting and driving6

Page 230 of 458

Accordingly, when the low tyre pressure tell-tale illuminates, you should stop and check

your tyres as soon as possible, and inflate them to the proper pressure. Driving on a sig-nificantly under-inflated tyre causes the tyre

to overheat and can lead to tyre failure.

Under-inflation also reduces fuel efficiency and tyre tread life, and may affect the vehi-

cle’s handling and stopping ability.

Please note that the tyre pressure monitoring system (TPMS) is not a substitute for proper

tyre maintenance, and it is the driver’s re- sponsibility to maintain correct tyre pressure,

even if under-inflation has not reached the

level to trigger illumination of the tyre pres- sure monitoring system (TPMS) low tyre

pressure telltale.

Your vehicle has also been equipped with a

warning lamp to indicate when the system is

not operating properly.

The warning lamp is combined with the low tyre pressure telltale.

When the system detects a malfunction, the

telltale will flash for approximately one mi- nute and then remain continuously illumina-

ted. This sequence will continue upon subse- quent vehicle start-ups as long as the mal-

function exists.

When the warning lamp is illuminated, the

system may not be able to detect or signal low tyre pressure as intended.The tyre pressure monitoring system (TPMS)

malfunctions may occur for a variety of rea- sons, including the installation of replace- ment or alternate tyres or wheels on the vehi-cle that prevent the tyre pressure monitoring

system (TPMS) from functioning properly. Always check the tyre pressure monitoring

system (TPMS) malfunction telltale after re- placing one or more tyres or wheels on yourvehicle to ensure that the replacement or al- ternate tyres and wheels allow the tyre pres-

sure monitoring system (TPMS) to continue to function properly.If the warning lamp/display il-

luminates while driving

E00637300037

1. If the warning lamp illuminates, avoid

hard braking, sharp steering manoeuvres and high speeds. You should stop andadjust the tyres to the proper inflationpressure as soon as possible. Adjust the

spare tyre at the same time. Refer to “Tyres” on page 10-13

NOTEl In addition, the warning display will be dis-

played on the information screen in the mul-

ti-information display.

l When inspecting or adjusting the tyre pres-

sure, do not apply excessive force to the

valve stem to avoid breakage.NOTEl After inspecting or adjusting the tyre pres-

sure, always reinstall the valve cap on the

valve stem.

Without the valve cap, dirt or moisture could

get into the valve, resulting in damage to the tyre inflation pressure sensor.

l Do not use metal valve caps, which may

cause a metal reaction, resulting in corrosion and damage of the tyre inflation pressure

sensors.

l Once adjustments have been made, the

warning lamp will go off after a few minutesof driving.

2. If the warning lamp remains illuminated

after you have been driving for about 10

minutes after you adjust the tyre infla- tion pressure, one or more of the tyresmay have a puncture. Inspect the tyreand if it has a puncture, have it repaired

by a MITSUBISHI MOTORS Author-

ized Service Point as soon as possible.

WARNINGl If the warning lamp/display illuminates

while you are driving, avoid hard brak- ing, sharp steering manoeuvres and high speeds.

Driving with an under-inflated tyre ad-

versely affects vehicle performance and

can result in an accident.

Tyre pressure monitoring system (TPMS)*

6-62OGAE17E2Starting and driving6

Page 231 of 458

CAUTIONlThe warning lamp/display may not illumi-

nate immediately in the event of a tyre blow- out or rapid leak.NOTEl To avoid the risk of damage to the tyre infla-

tion pressure sensors, have any punctured

tyre repaired by a MITSUBISHI MOTORS

Authorized Service Point. If the tyre repair is

not done by a MITSUBISHI MOTORS Au-

thorized Service Point, damage to the tyre

inflation pressure sensor is not covered by your warranty.

l Do not use an aerosol puncture-repair spray

on any tyre.

Such a spray could damage the tyre inflation

pressure sensors.

Have any puncture repaired by a MITSUBISHI MOTORS Authorized Serv-

ice Point.

l Using the tyre repair kit may damage the

tyre inflation pressure sensor. The vehiclemust promptly be inspected and repaired by

a MITSUBISHI MOTORS Authorized Serv-

ice Point.

The tyre pressure monitoring system (TPMS)

may not work normally in the following cir-

cumstances:

l A wireless facility or device using the

same frequency is near the vehicle.

l Snow or ice is stuck inside the fenders

and/or on the wheels.

l The tyre inflation pressure sensor’s bat-

tery is dead.

l Wheels other than

MITSUBISHI

MOTORS GENUINE wheels are being

used.

l Wheels that are not fitted with tyre infla-

tion pressure sensors are being used.

l Wheels whose ID codes are not memo-

rized by the vehicle are used.

l A window tint that affects the radio

wave signals is installed.NOTEl Tyre inflation pressures vary with the ambi-

ent temperature. If the vehicle is subjected to large variations in ambient temperature, the tyre inflation pressures may be low (causing

the warning lamp/display to come on) when the ambient temperature is relatively low. If the warning lamp/display comes on, adjustthe tyre inflation pressure.Whenever the tyres and wheels

are replaced with new ones

E00637400025

If new wheels with new tyre inflation pres-

sure sensors are installed, their ID codes must be programmed into the tyre pressure moni- toring system. Have tyre and wheel replace-

ment performed by a MITSUBISHI

MOTORS Authorized Service Point to avoid

the risk of damaging the tyre inflation pres- sure sensors. If the wheel replacement is not

done by a MITSUBISHI MOTORS Author-

ized Service Point, it is not covered by your warranty.

CAUTIONl The use of non-genuine wheels will prevent

the proper fit of the tyre inflation pressure sensors, resulting air leakage or damage of

the sensors.Reset of low tyre pressure

warning threshold

E00637500039

The threshold is set based on the tyre pres- sure which the reset function is executed by

following procedure.

Tyre pressure monitoring system (TPMS)*

6-63OGAE17E2Starting and driving6

Page 232 of 458

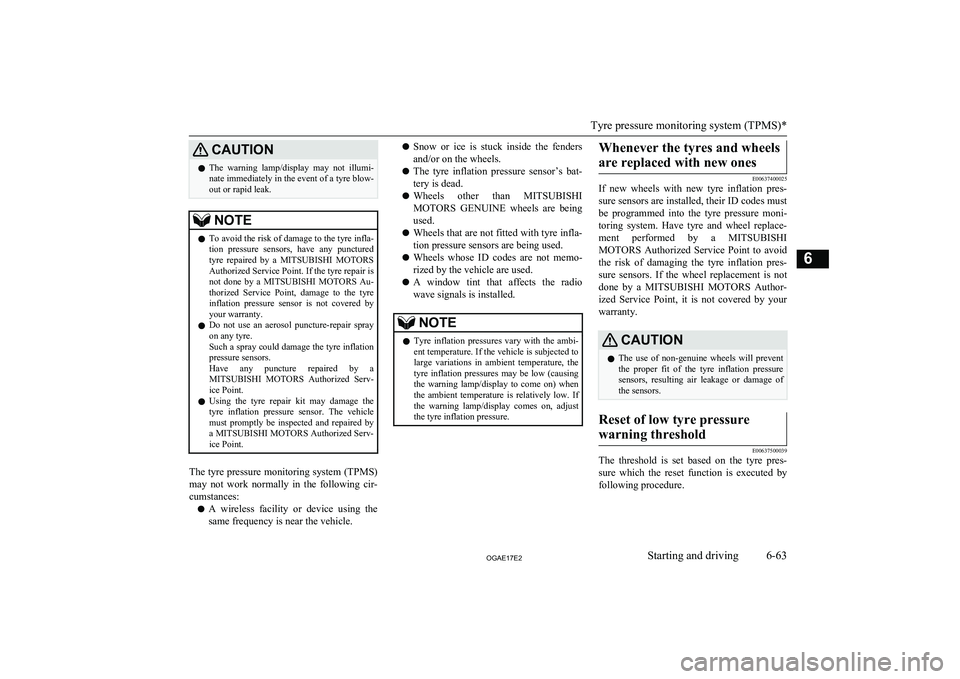

1.Operate the multi-information meter

switch to switch the information screen

to the menu screen.

Refer to “Multi information display switch” on page 5-05.

Refer to “Changing the function settings (when the ignition switch or the opera-

tion mode is ON)” on page 5-19.

2. Lightly press the multi-information me-

ter switch to select “

” (reset

of low tyre pressure warning threshold).

3. Press and hold the multi-information

meter switch for about 3 seconds or

more, the buzzer sounds.

4. The warning lamp start flashing slowly.

5. Drive for a while. The reset is completed

if the warning lamp goes out.

NOTEl The reset function should be executed every

time when the tyre pressure or tyre rotationis adjusted.

l The reset function should be executed when

the tyre is cold. If it is executed when the

tyre is warm (e.g. after driving), there may be a low tyre pressure warning earlier than

usual.Tyre ID set change

E00637600030

In case that 2 sets of tyre inflation pressure

sensor ID are registered in the receiver, the

valid tyre ID set can be changed by following

procedure. 1. Operate the multi-information meter

switch to switch the information screen

to the menu screen.

Refer to “Multi information display switch” on page 5-05

Refer to “Changing the function settings (when the ignition switch or the opera-

tion mode is ON)” on page 5-19

2. Lightly press the multi-information me-

ter switch to select “

” (tyre

ID set change).

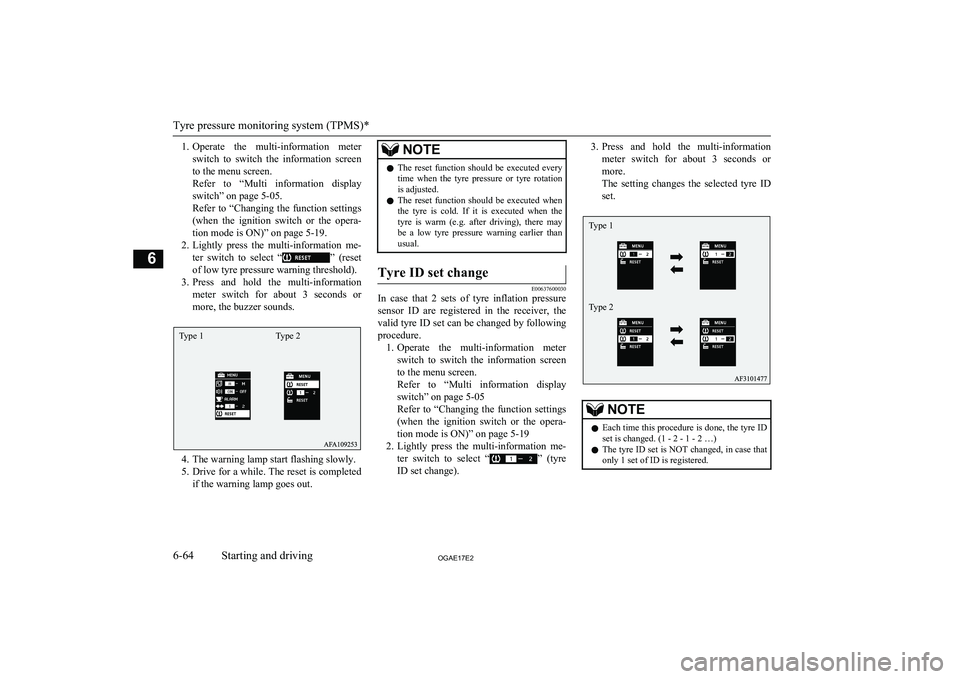

3. Press and hold the multi-information

meter switch for about 3 seconds or more.

The setting changes the selected tyre ID set.NOTEl Each time this procedure is done, the tyre ID

set is changed. (1 - 2 - 1 - 2 …)

l The tyre ID set is NOT changed, in case that

only 1 set of ID is registered.

Tyre pressure monitoring system (TPMS)*

6-64OGAE17E2Starting and driving6 Type 1 Type 2 Type 1

Type 2

Page 233 of 458

NOTElWhen changing the tyre ID set, the reset

function of low tyre pressure warning threshold is automatically started. (The

warning lamp start flashing slowly.) If the

tyre is warm at this time. the reset function should be executed again when the tyre iscold.Reversing sensor system*

E00615500345

This system operates when you are backingthe vehicle. It uses corner and back sensors to detect an obstacle and the information screen

in the multi-information display and the buz-

zer to inform you of the approximate distance to the obstacle.

CAUTIONl The reversing sensor system assists you in

determining the approximate distance be-

tween the vehicle and an obstacle located behind the vehicle. It has limitations in terms

of detectable areas and objects, and may not

properly detect some objects. Therefore, do not place excessive confidence in the revers-

ing sensor system and operate the vehicle as carefully as you would do with a vehicle not equipped with this system.CAUTIONl Make sure to check the surroundings with

your own eyes to ensure safety. Do not oper-

ate the vehicle by relying on the reversing sensor system alone.Obstacle detection areas

E00615601705

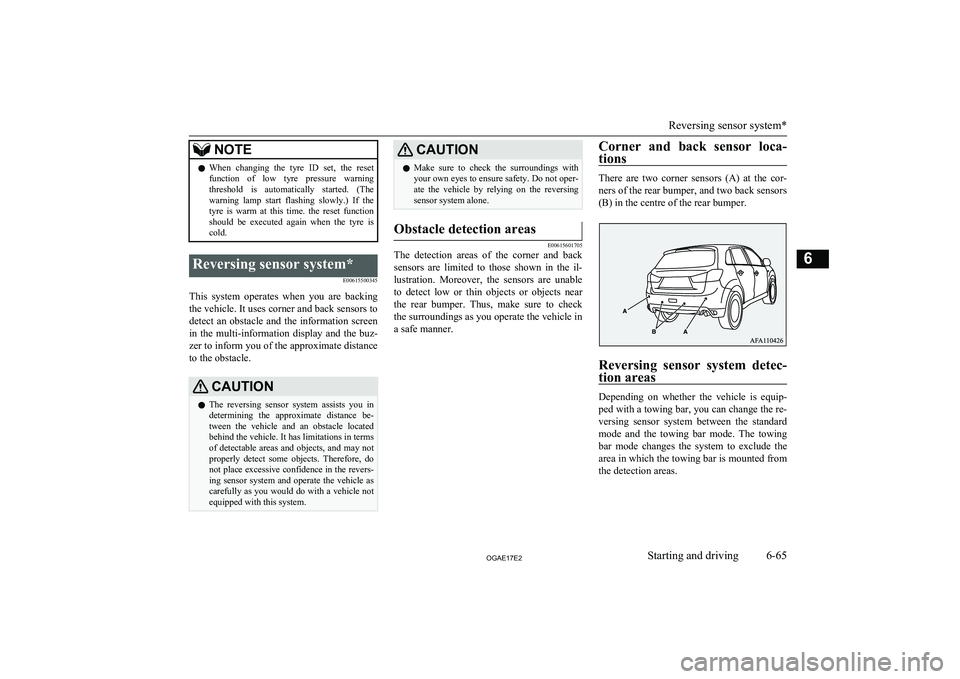

The detection areas of the corner and back

sensors are limited to those shown in the il-

lustration. Moreover, the sensors are unable to detect low or thin objects or objects nearthe rear bumper. Thus, make sure to check

the surroundings as you operate the vehicle in a safe manner.

Corner and back sensor loca-

tions

There are two corner sensors (A) at the cor-ners of the rear bumper, and two back sensors

(B) in the centre of the rear bumper.

Reversing sensor system detec-

tion areas

Depending on whether the vehicle is equip-

ped with a towing bar, you can change the re-

versing sensor system between the standard

mode and the towing bar mode. The towing bar mode changes the system to exclude the

area in which the towing bar is mounted from the detection areas.

Reversing sensor system*

6-65OGAE17E2Starting and driving6

Page 339 of 458

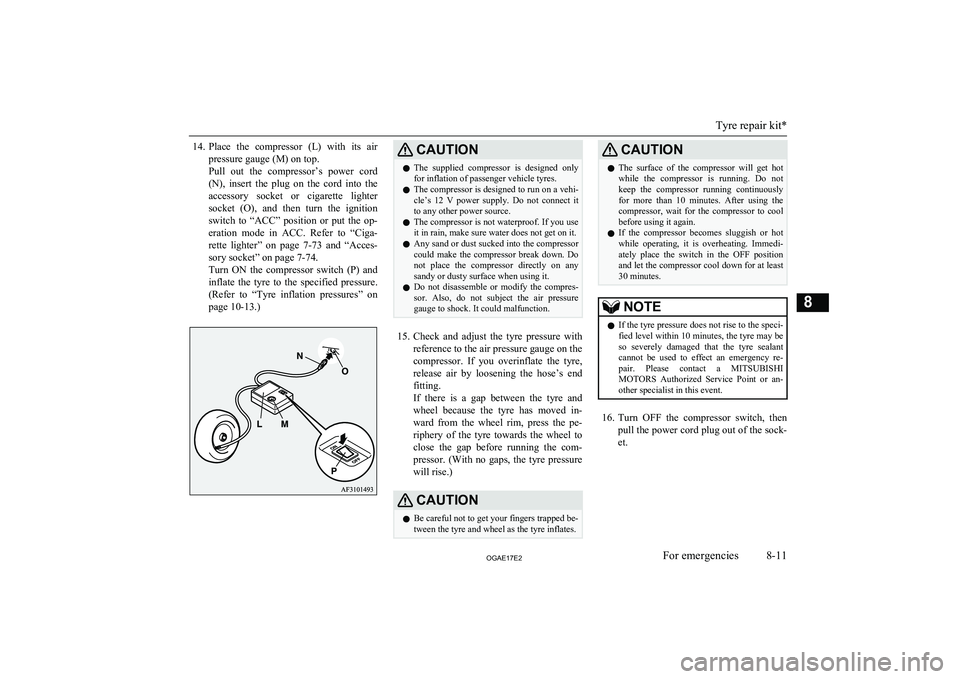

14.Place the compressor (L) with its air

pressure gauge (M) on top.

Pull out the compressor’s power cord

(N), insert the plug on the cord into the accessory socket or cigarette lighter

socket (O), and then turn the ignition switch to “ACC” position or put the op-

eration mode in ACC. Refer to “Ciga-

rette lighter” on page 7-73 and “Acces-

sory socket” on page 7-74.

Turn ON the compressor switch (P) and

inflate the tyre to the specified pressure. (Refer to “Tyre inflation pressures” on

page 10-13.)CAUTIONl The supplied compressor is designed only

for inflation of passenger vehicle tyres.

l The compressor is designed to run on a vehi-

cle’s 12 V power supply. Do not connect itto any other power source.

l The compressor is not waterproof. If you use

it in rain, make sure water does not get on it.

l Any sand or dust sucked into the compressor

could make the compressor break down. Do not place the compressor directly on anysandy or dusty surface when using it.

l Do not disassemble or modify the compres-

sor. Also, do not subject the air pressure

gauge to shock. It could malfunction.

15. Check and adjust the tyre pressure with

reference to the air pressure gauge on the

compressor. If you overinflate the tyre, release air by loosening the hose’s end

fitting.

If there is a gap between the tyre and

wheel because the tyre has moved in-

ward from the wheel rim, press the pe- riphery of the tyre towards the wheel to

close the gap before running the com- pressor. (With no gaps, the tyre pressure

will rise.)

CAUTIONl Be careful not to get your fingers trapped be-

tween the tyre and wheel as the tyre inflates.CAUTIONl The surface of the compressor will get hot

while the compressor is running. Do not

keep the compressor running continuously for more than 10 minutes. After using the compressor, wait for the compressor to cool

before using it again.

l If the compressor becomes sluggish or hot

while operating, it is overheating. Immedi- ately place the switch in the OFF positionand let the compressor cool down for at least30 minutes.NOTEl If the tyre pressure does not rise to the speci-

fied level within 10 minutes, the tyre may be

so severely damaged that the tyre sealant

cannot be used to effect an emergency re- pair. Please contact a MITSUBISHI

MOTORS Authorized Service Point or an-

other specialist in this event.

16. Turn OFF the compressor switch, then

pull the power cord plug out of the sock- et.

Tyre repair kit*

8-11OGAE17E2For emergencies8

Page 340 of 458

NOTElSimply putting sealant and air into the tyre

using the tyre repair kit does not seal the

puncture hole. Air will leak through the puncture hole until the emergency repair procedure is completed (through step 19 of

these instructions).

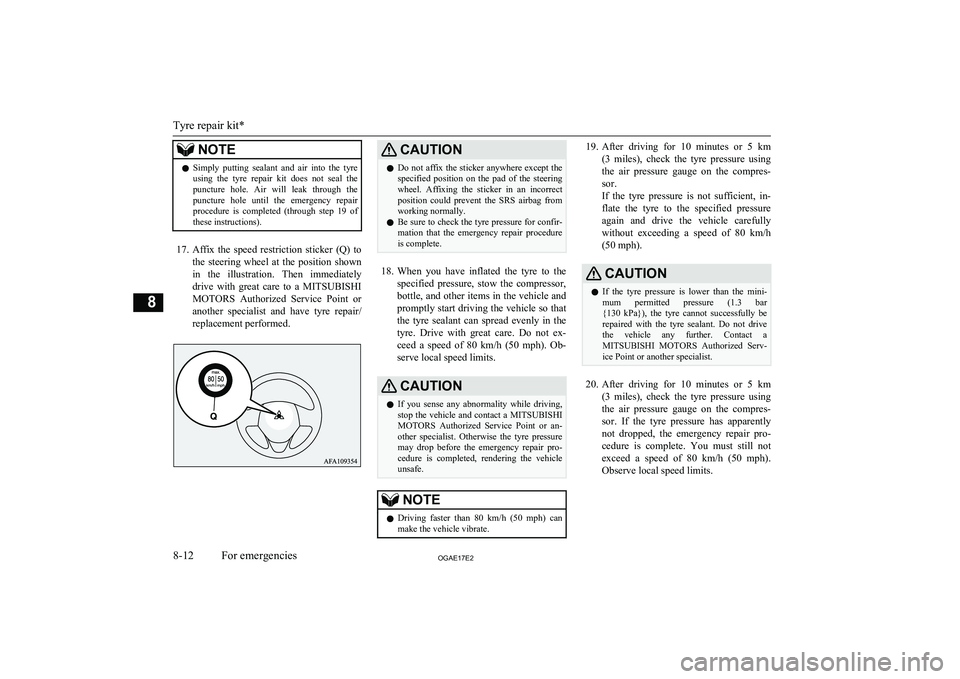

17. Affix the speed restriction sticker (Q) to

the steering wheel at the position shown

in the illustration. Then immediately drive with great care to a MITSUBISHI

MOTORS Authorized Service Point or

another specialist and have tyre repair/

replacement performed.

CAUTIONl Do not affix the sticker anywhere except the

specified position on the pad of the steeringwheel. Affixing the sticker in an incorrect

position could prevent the SRS airbag from working normally.

l Be sure to check the tyre pressure for confir-

mation that the emergency repair procedureis complete.

18. When you have inflated the tyre to the

specified pressure, stow the compressor,

bottle, and other items in the vehicle and

promptly start driving the vehicle so that the tyre sealant can spread evenly in the

tyre. Drive with great care. Do not ex- ceed a speed of 80 km/h (50 mph). Ob-

serve local speed limits.

CAUTIONl If you sense any abnormality while driving,

stop the vehicle and contact a MITSUBISHI

MOTORS Authorized Service Point or an-

other specialist. Otherwise the tyre pressure

may drop before the emergency repair pro- cedure is completed, rendering the vehicle

unsafe.NOTEl Driving faster than 80 km/h (50 mph)

can

make the vehicle vibrate.19. After driving for 10 minutes or 5 km

(3 miles), check the tyre pressure using

the air pressure gauge on the compres- sor.

If the tyre pressure is not sufficient, in-

flate the tyre to the specified pressure again and drive the vehicle carefully

without exceeding a speed of 80 km/h (50 mph).CAUTIONl If the tyre pressure is lower than the mini-

mum permitted pressure (1.3 bar {130 kPa}), the tyre cannot successfully be repaired with the tyre sealant. Do not drive

the vehicle any further. Contact a MITSUBISHI MOTORS Authorized Serv-

ice Point or another specialist.

20. After driving for 10 minutes or 5 km

(3 miles), check the tyre pressure using

the air pressure gauge on the compres- sor. If the tyre pressure has apparentlynot dropped, the emergency repair pro-

cedure is complete. You must still not exceed a speed of 80 km/h (50 mph) .

Observe local speed limits.

Tyre repair kit*

8-12OGAE17E2For emergencies8

Page 341 of 458

NOTElIf the tyre pressure has dropped below the

specified level when you check it at the end

of the repair procedure, do not drive the ve- hicle any further. Contact a MITSUBISHI

MOTORS Authorized Service Point or an-

other specialist.

l In cold conditions (when the ambient tem-

perature is 0 °C or lower), the time and driv-

ing distance necessary until completion of

the repair can be longer than in warmer con- ditions, meaning that the tyre pressure candrop below the specified level even when

you have inflated the tyre a second time and

subsequently driven the vehicle. If this hap- pens, inflate the tyre to the specified pres-

sure once more, drive for about 10 minutes or 5 km (3 miles), then check the tyre pres-sure again. If the tyre pressure has again

dropped below the specified level, stop driv- ing the vehicle and contact a MITSUBISHI

MOTORS Authorized Service Point or an-

other specialist.

l Please give the empty sealant bottle to your

MITSUBISHI MOTORS Authorized Serv-

ice Point when you purchase new sealant or

dispose of the sealant bottle according to na- tional regulations for the disposal of chemi-

cal waste.NOTEl A tyre in which puncture sealant has been

used should ideally be replaced with a newone. If you wish to have such a tyre properly

repaired for reuse, please contact a MITSUBISHI MOTORS Authorized Serv-

ice Point or another specialist. Note that a

proper repair is impossible following an emergency repair if the puncture hole cannot

be located.

l Wipe away any sealant that gets on the

wheel. Provided the valve is replaced with a

new one, the wheel can be reused.

l The manufacturer is unable to guarantee that

all tyre punctures can be repaired with the tyre repair kit, in particular cuts or perfora-

tions with a diameter of more than 4 mm or

away from the tyre’s tread. The manufactur-

er is not liable for damage sustained through improper use of the tyre repair kit.

l The manufacturer is not liable for damage

sustained through re-use of any tyre in

which tyre sealant has been used.How to change a tyre

E00801202943

Before changing a tyre, first stop your vehi-cle in a safe, flat location. 1. Park the vehicle on level and stable

ground, free of loose pebbles, etc.

2. Set the parking brake firmly.

3. On vehicles with M/T, stop the engine

and move the gearshift lever to the “R”

(Reverse) position.

On vehicles with A/T or CVT, move the

selector lever to the “P” (PARK) posi- tion and stop the engine.

4. Turn on the hazard warning flashers and

set up a warning triangle, flashing signal

lamp, etc., at an adequate distance from the vehicle, and have all your passengers

leave the vehicle.NOTEl The warning triangle and flashing signal

lamp do not come with your vehicle. It is recommended that you keep one in the vehi- cle for use if needed.

5. To prevent the vehicle from rolling

when it is raised on the jack, place

chocks or blocks (A) in front of and be- hind the tyre that is diagonally opposite

from the tyre (B) you are changing.

How to change a tyre

8-13OGAE17E2For emergencies8