CV Joint MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 43 of 364

EXHAUST SYSTEM

INTAKE AND EXHAUST15-7

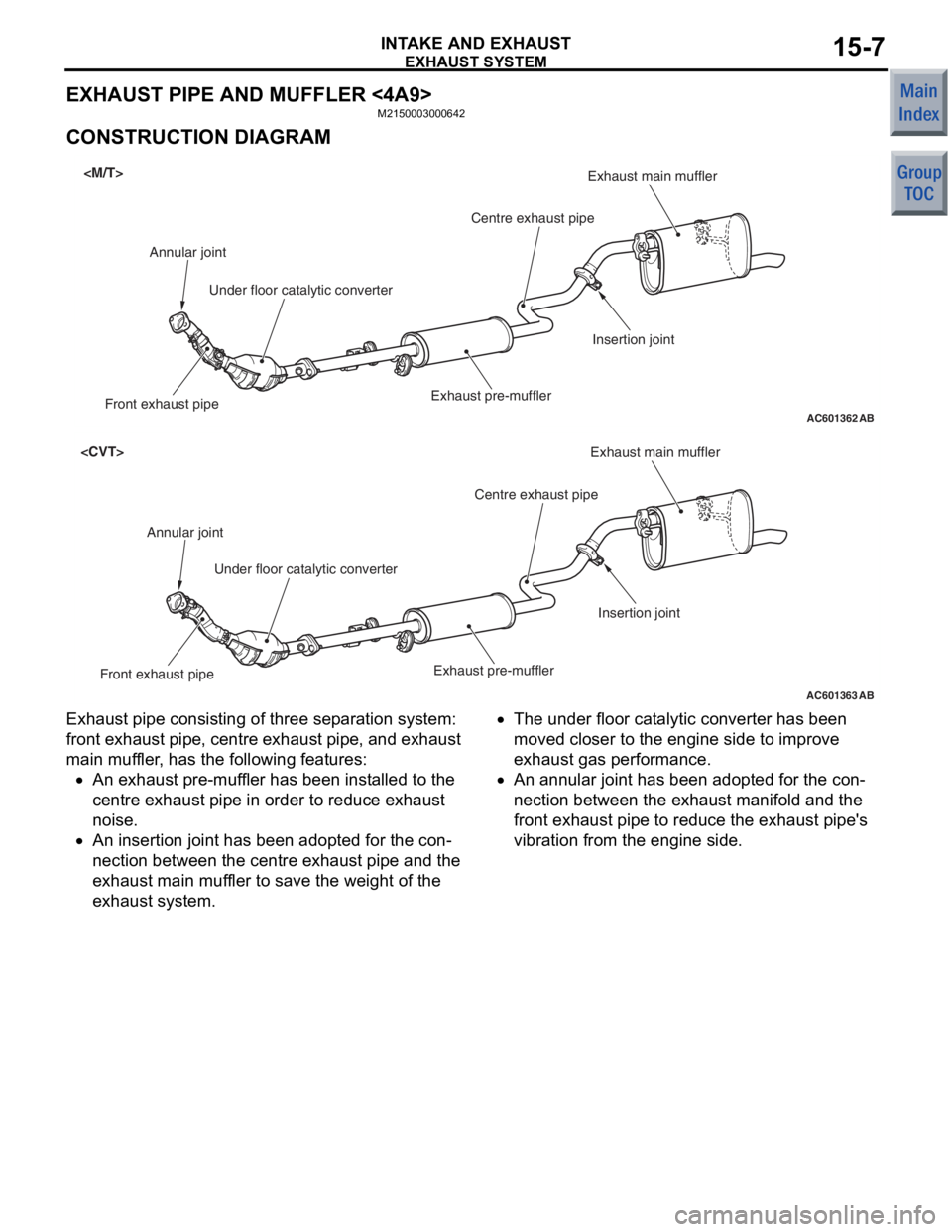

EXHAUST PIPE AND MUFFLER <4A9>

M2150003000642

CONSTRUCTION DIAGRAM

AC601362AB

Centre exhaust pipeExhaust main muffler

Front exhaust pipeAnnular joint

Under floor catalytic converter

Exhaust pre-muffler

Insertion joint

AC601363AB

Centre exhaust pipeExhaust main muffler

Front exhaust pipeAnnular joint

Under floor catalytic converter

Exhaust pre-muffler

Insertion joint

Exhaust pipe consisting of th ree sep a ratio n system:

front exhaust pipe,

centre e x hau st pip e , and exhaust

main muf

f ler , has the fo llowing fea t ures:

•An exhaust pre-muff ler ha s be en in st alled to th e

ce

ntre exhaust pipe in order t o reduce exhaust

noise.

•An insertion joint has b een a dopted for the con-

nection between the centre exha ust p i pe and the

exhaust ma

in muf f ler to save the weight of the

exhaust system.

•The under floor cat a lytic con v erter has been

moved

clo s er to the e ngine side to impro v e

exhaust gas perfo

rmance.

•An annula r joint has been adopt ed for th e co n-

nection between the exhau st manifo ld an d the

fron

t exh aust pipe to redu ce th e exhaust pipe 's

vibration from the

engine side.

Page 44 of 364

EXHAUST SYSTEM

INTAKE AND EXHAUST15-8

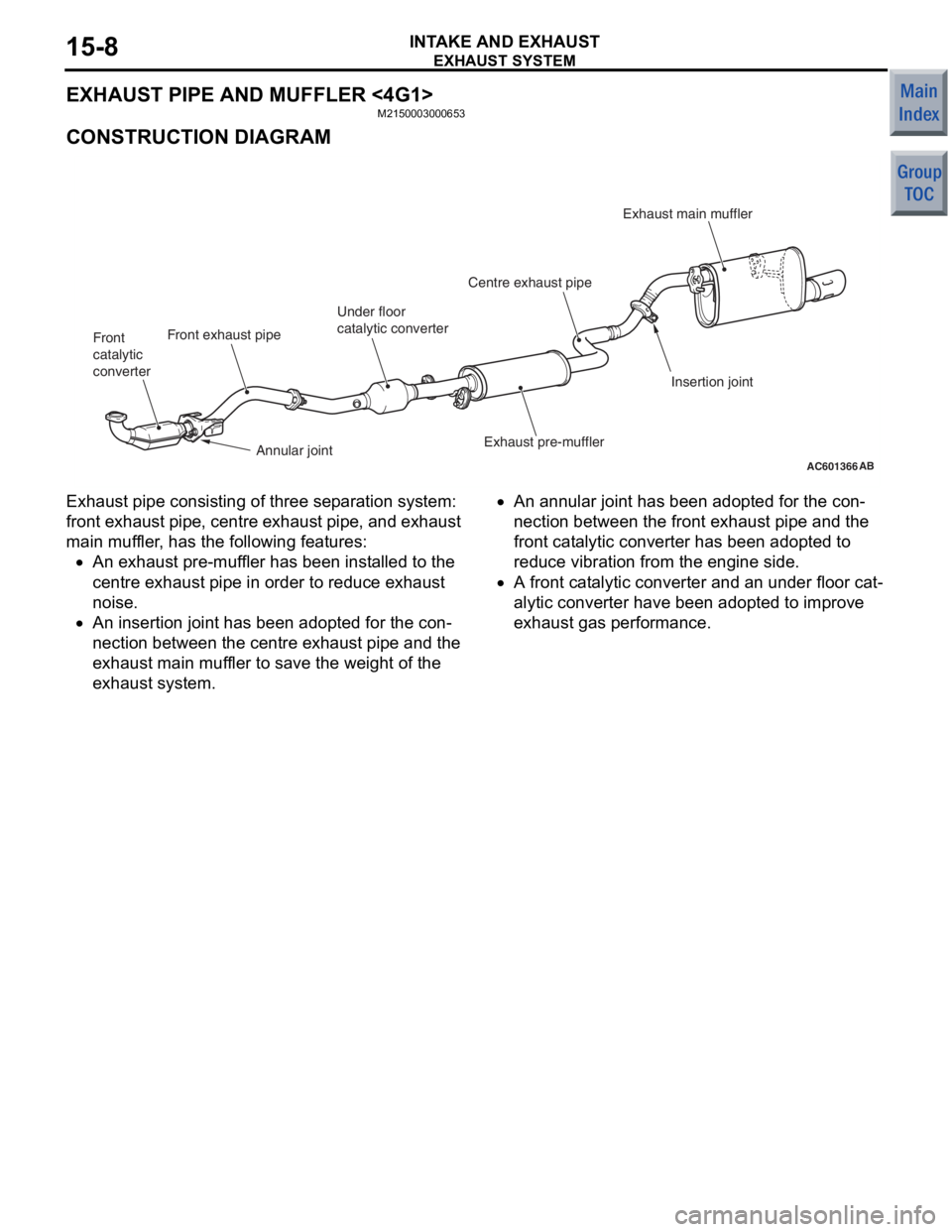

EXHAUST PIPE AND MUFFLER <4G1>

M2150003000653

CONSTRUCTION DIAGRAM

AC601366AB

Centre exhaust pipeExhaust main muffler

Front exhaust pipe

Under floor

catalytic converter

Exhaust pre-muffler

Front

catalytic

converter

Insertion joint

Annular joint

Exhaust pipe co

nsisting of th ree sep a ratio n system:

front exhaust pipe,

centre e x hau st pip e , and exhaust

main muf

f ler , has the fo llowing fea t ures:

•An exhaust pre-muff ler ha s be en in st alled to th e

ce

ntre exhaust pipe in order t o reduce exhaust

noise.

•An insertion joint has b een a dopted for the con-

nection between the centre exha ust p i pe and the

exhaust ma

in muf f ler to save the weight of the

exhaust system.

•An annula r joint has been adopt ed for th e co n-

nection between the fro n t exhaust pip e and the

fron

t cat a lytic co nvert e r has been adopt ed to

redu

ce vibra t ion from th e eng ine side .

•A front cat a lytic co nvert e r and an und er floo r cat-

alytic conver ter have bee n adop ted to imp r ove

exhaust gas perfo

rmance.

Page 148 of 364

MAIN BODY

BODY42-5

3. The dash side brace has been manufactured as an unit in order to strengthen the joint between

the front sidemember and the front pillar, increas

-

ing the rigidity of the entire body.

4. The installation position of the steering gearbox has been lowered, and the sidemember from the

front to the rear has been straightened in order to

improve rigidity of the entire body.

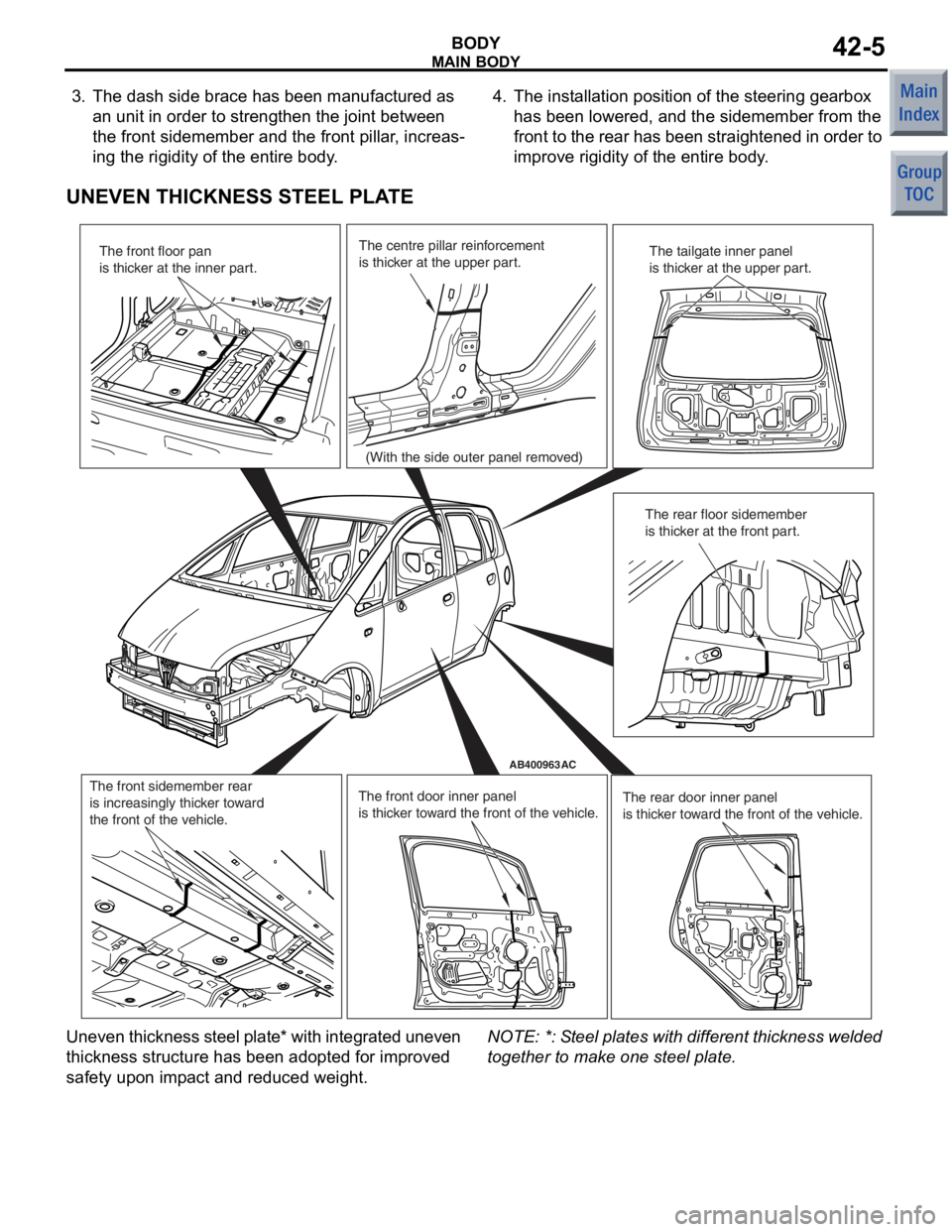

UNEVEN THICKNESS STEEL PLATE

AB400963

AB400941

AC

The rear door inner panel

is thicker toward the front of the vehicle.The front sidemember rear

is increasingly thicker toward

the front of the vehicle.The front floor pan

is thicker at the inner part.

The front door inner panel

is thicker toward the front of the vehicle.

The centre pillar reinforcement

is thicker at the upper part. (With the side outer panel removed) The tailgate inner panel

is thicker at the upper part.

The rear floor sidemember

is thicker at the front part.

Uneven thickness steel plate* wit h inte grate d uneven

thickness structure ha

s bee n ado pted fo r imp r ove d

safet

y upo n imp a ct an d redu ced weight.NOTE: *: S t ee l p l a t es with di ffer ent th ickn ess welded

togethe

r to make one steel plate .

Page 209 of 364

TECHNICAL FEATURES

GENERAL00-24

PASSIVE SAFETY

M2000032000628

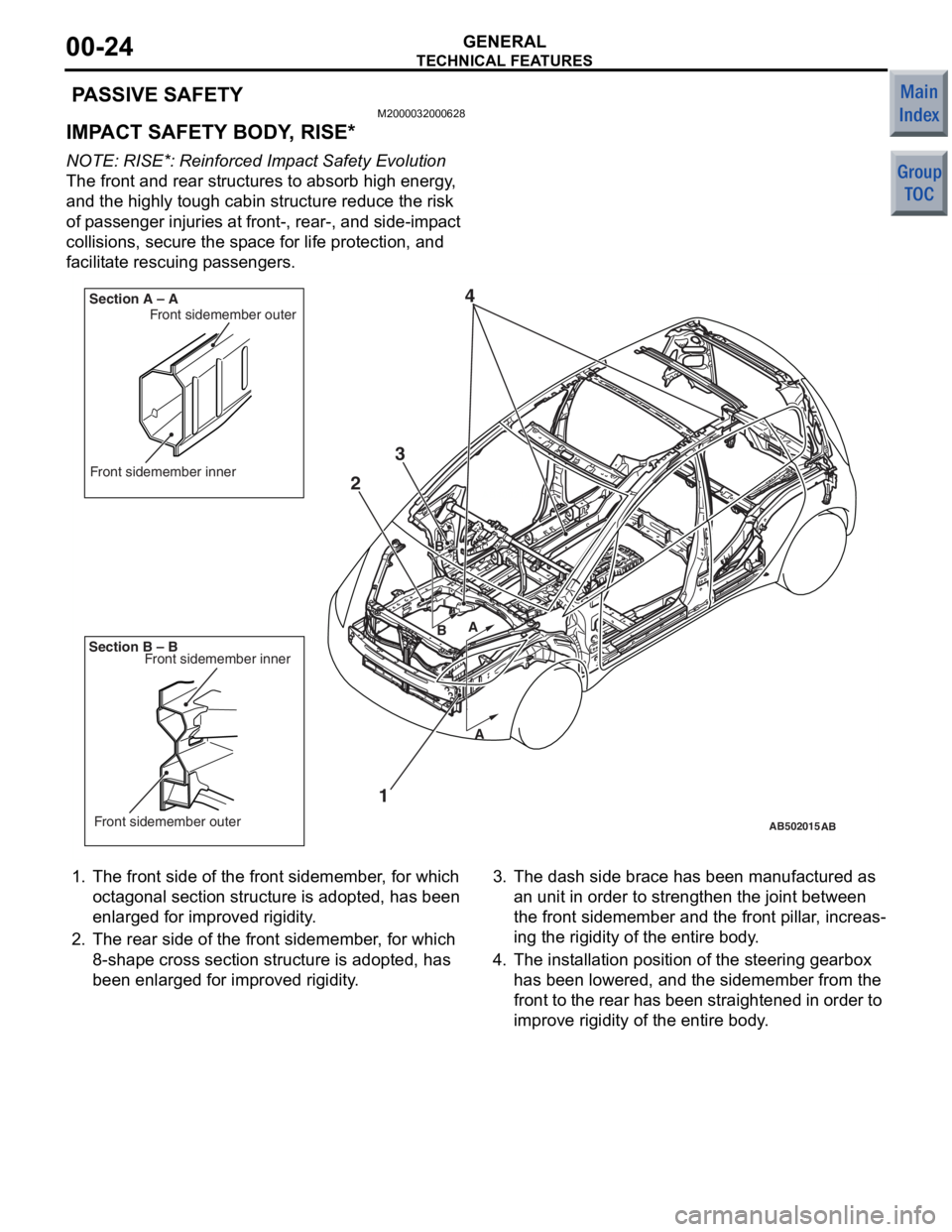

IMPACT SAFETY BODY, RISE*

NOTE: RISE*: Reinforced Impact Safety Evolution

The front and rear structures to absorb high energy,

and the highly tough cabin structure reduce the risk

of passenger injuries at front-, rear-, and side-impact

collisions, secure the space for life protection, and

facilitate rescuing passengers.

AB201266

AB201267AB502015

AB400214

AB

1

2

4

Front sidemember inner

Front sidemember outer

B AA

B

Section B – B Section A – A

Front sidemember inner

Front sidemember outer

3

1.

The front side of the front sidemember , for which

oct agonal section structure is a dopted, has been

enlarged for improved rigidity .

2.The rear side o f the fro nt sidememb er, for which

8-shape cross section structu re is adop ted, has

bee n enlarged f or improved rig idit y.

3. The dash side brace ha s been manufactured a s

an unit in ord er to strength en the joint betwee n

the front side member and the front pillar , increas

-

in g the rigid ity of the e ntire body .

4.The inst allation po sition o f the steering gea rbox

has bee n lowere d, and the sidememb er from the

fron t to the re ar has been straigh tened in orde r to

improve rig idit y of t he ent ire body.

Page 221 of 364

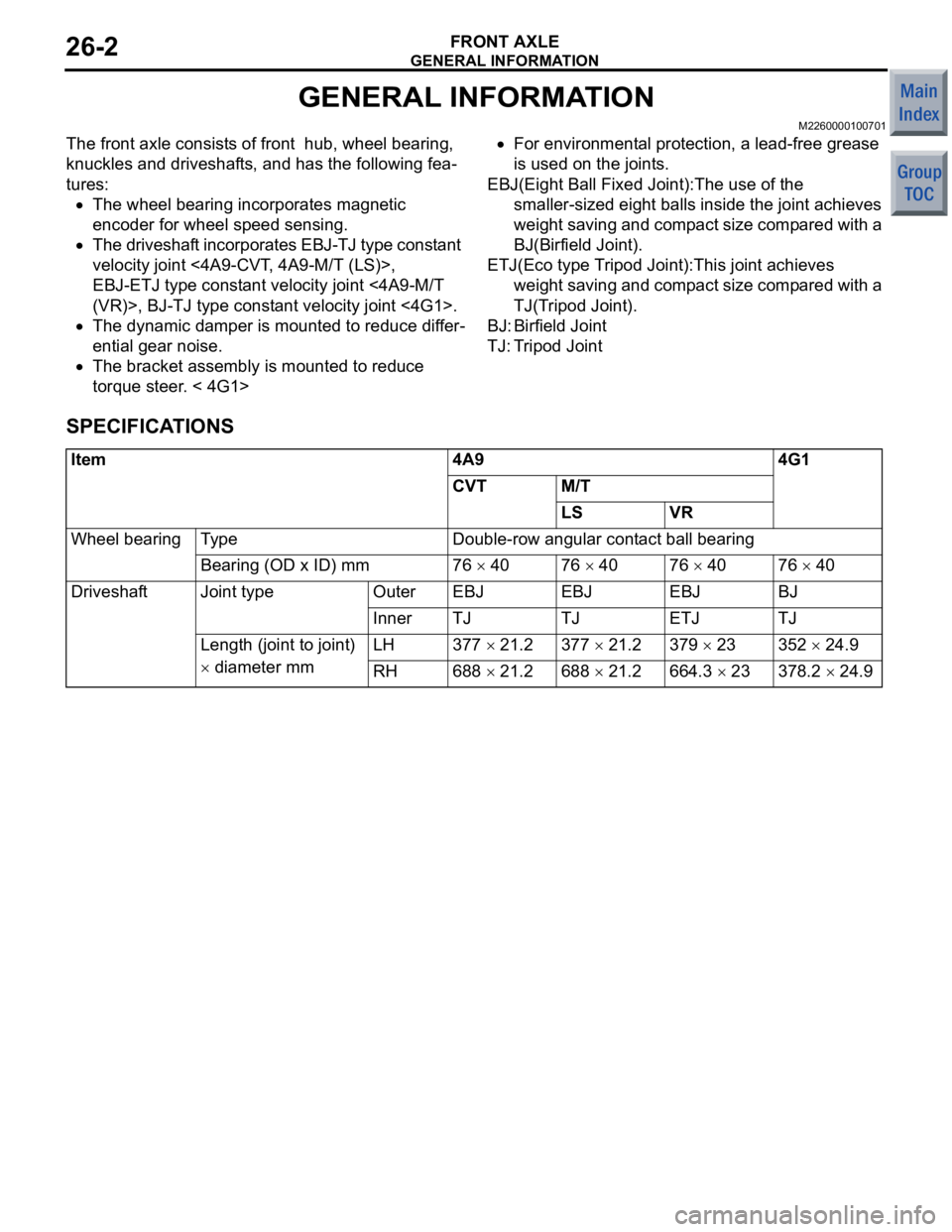

GENERAL INFORMATION

FRONT AXLE26-2

GENERAL INFORMATION

M2260000100701

The front axle consists of front hub, wheel bearing,

knuckles and driveshafts, and has the following fea

-

tures:

•The wheel bearing incorporates magnetic

encoder for wheel speed sensing.

•The driveshaft incorporates EBJ-TJ type constant

velocity joint <4A9-CVT, 4A9-M/T (LS)>,

EBJ-ETJ type constant velocity joint <4A9-M/T

(VR)>, BJ-TJ type constant velocity joint <4G1>.

•The dynamic damper is mounted to reduce differ-

ential gear noise.

•The bracket assembly is mounted to reduce

torque steer. < 4G1>

•For environmental protection, a lead-free grease

is used on the joints.

EBJ(Eight Ball Fixed Joint):The use of the

smaller-sized eight balls inside the joint achieves

weight saving and compact size compared with a

BJ(Birfield Joint).

ETJ(Eco type Tripod Joint):This joint achieves

weight saving and compact size compared with a

TJ(Tripod Joint).

BJ:Birfield Joint

TJ:Tripod Joint

SPECIFICATIONS

Item4A94G1

CVTM/T

LSVR

Wheel bearingTy p eDouble-row angular contact ball bearing

Bearing (OD x ID) mm76 × 4076 × 4076 × 4076 × 40

DriveshaftJoint typeOuterEBJEBJEBJBJ

InnerTJTJETJTJ

Length (joint to joint)

× diameter mm

LH377 × 21.2377 × 21.2379 × 23352 × 24.9

RH688 × 21.2688 × 21.2664.3 × 23378.2 × 24.9

Page 226 of 364

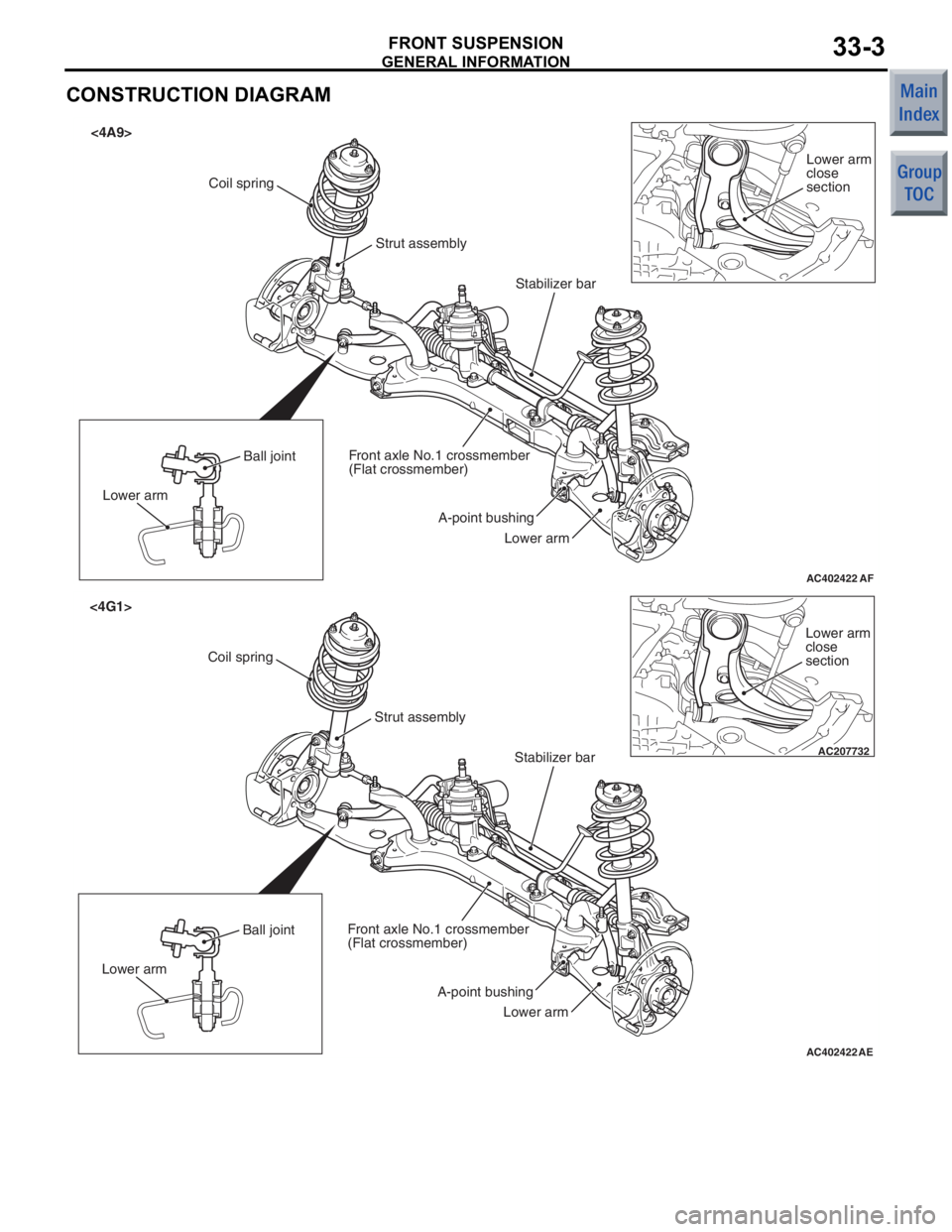

GENERAL INFORMATION

FRONT SUSPENSION33-3

CONSTRUCTION DIAGRAM

AC402422AF

<4A9>

A-point bushing

Stabilizer bar

Coil spring

Strut assembly

Lower arm

Front axle No.1 crossmember

(Flat crossmember)

Lower arm Ball joint

Lower arm

close

section

AC402422AE

<4G1>

A-point bushing

Stabilizer bar

Coil spring

Strut assembly

Lower arm

Front axle No.1 crossmember

(Flat crossmember)

Lower arm Ball jointAC207732

Lower arm

close

section