Tyre MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 16 of 364

BUMPER

EXTERIOR51-4

BUMPER

M2510002000751

FRONT BUMPER CONSTRUCTION DIAGRAM

AC402884AD

Air guide panel (RH)

Air guide panel (LH)

Air guide panel

•The front b u mpe r has overh ung at the right an d

le

f t corners to suppre s s the airflow to the tyres

and

smo o then t he airf low from the bumper to th e

ve

hicle sides.•

AC601475

Front bumper assembly

AB

Overfender construction

The air g u ide p a n e ls have been inst a lled behind

th

e fr on t b u mp er to impro v e t h e co olin g ef ficie n cy

of t

he radiator .

•The front b u mpe r emp hasizes the light ima ge in

fron

t appea rance.•Overfender const r uction from the f r ont bu mper t o

the

wh eel a r ch o f fende r appea ls the sporty and

robu

st whee lin g.< RALLIAR T V e rsion - R>

Page 86 of 364

GENERAL INFORMATION

REAR SUSPENSION34-2

GENERAL INFORMATION

M2340000100825

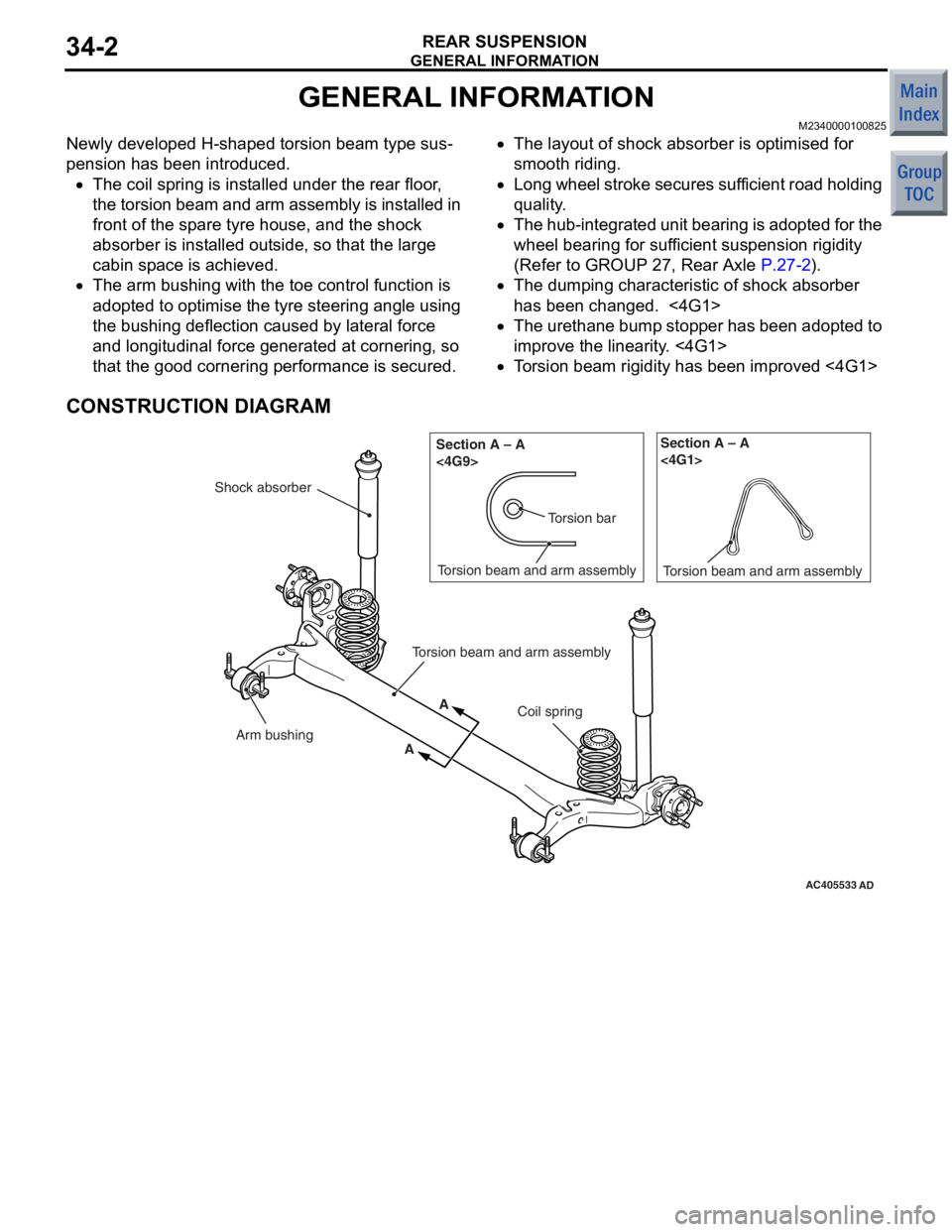

Newly developed H-shaped torsion beam type sus-

pension has been introduced.

•The coil spring is installed under the rear floor,

the torsion beam and arm assembly is installed in

front of the spare tyre house, and the shock

absorber is installed outside, so that the large

cabin space is achieved.

•The arm bushing with the toe control function is

adopted to optimise the tyre steering angle using

the bushing deflection caused by lateral force

and longitudinal force generated at cornering, so

that the good cornering performance is secured.

•The layout of shock absorber is optimised for

smooth riding.

•Long wheel stroke secures sufficient road holding

quality.

•The hub-integrated unit bearing is adopted for the

wheel bearing for sufficient suspension rigidity

(Refer to GROUP 27, Rear Axle

P.27-2).

•The dumping characteristic of shock absorber

has been changed. <4G1>

•The urethane bump stopper has been adopted to

improve the linearity. <4G1>

•Torsion beam rigidity has been improved <4G1>

CONSTRUCTION DIAGRAM

AC405533AD

Coil spring

Shock absorber

Torsion beam and arm assembly

Arm bushing

Torsion bar

Section A – A

<4G9>

A

A Torsion beam and arm assembly

Section A – A

<4G1>

Torsion beam and arm assembly

Page 87 of 364

GENERAL INFORMATION

REAR SUSPENSION34-3

SPECIFICATIONS

SUSPENSION SYSTEM

ItemSpecification

Suspension typeTorsion beam suspension

WHEEL ALIGNMENT

ItemSpecification

Camber−1°

Toe-inAt the centre of tyre tread mm3

Toe-angle (per wheel)0°09'

COIL SPRING

Item4A94G1

Wire diameter mm1011

Average outside diameter mm75 − 107 − 75111

Free length mm301283

Page 227 of 364

GENERAL INFORMATION

FRONT SUSPENSION33-4

SPECIFICATIONS

SUSPENSION SYSTEM

ItemSpecification

Suspension typeMacPherson strut with coil spring

WHEEL ALIGNMENT

ItemSpecification

Camber − 0 °30'

Caster 4A92°35'

4G12°40'

Kingpin inclination 13°20'

Toe-inAt the centre of tyre tread mm0

Toe-angle (per wheel)0°

COIL SPRING

<4A9>

ItemSpecification

Wire diameter mm12

Average outside diameter mm133 − 149 − 154

Free length mmCVT331

5MT301

<4G1>

ItemSpecification

Wire diameter mm13

Average outside diameter mm133 − 150 − 154

Free length mm300

Page 228 of 364

GROUP 31

WHEEL AND TYRE

CONTENTS

GENERAL INFORMATION . . . . . . . .31-2

Page 229 of 364

GENERAL INFORMATION

WHEEL AND TYRE31-2

GENERAL INFORMATION

M2310000100800

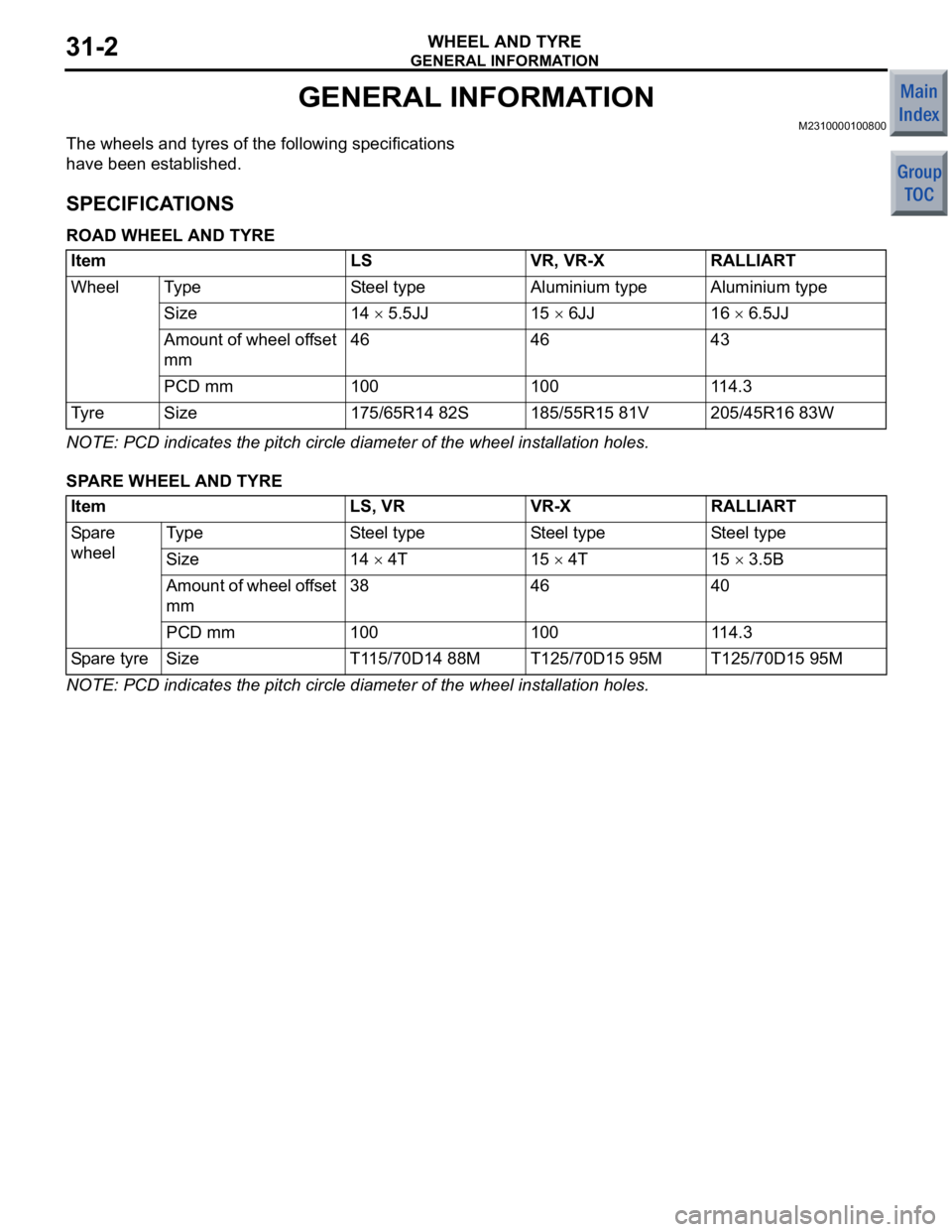

The wheels and tyres of the following specifications

have been established.

SPECIFICATIONS

ROAD WHEEL AND TYRE

ItemLSVR, VR-XRALLIART

WheelTy p eSteel typeAluminium typeAluminium type

Size14 × 5.5JJ15 × 6JJ16 × 6.5JJ

Amount of wheel offset

mm464643

PCD mm100100114.3

Ty r eSize175/65R14 82S185/55R15 81V205/45R16 83W

NOTE: PCD indicates the pitch circle diameter of the wheel installation holes.

SPARE WHEEL AND TYRE

ItemLS, VRVR-XRALLIART

Spare

wheelTy p eSteel typeSteel typeSteel type

Size14 × 4T15 × 4T15 × 3.5B

Amount of wheel offset

mm384640

PCD mm10010011 4 . 3

Spare tyreSizeT115/70D14 88MT125/70D15 95MT125/70D15 95M

NOTE: PCD indicates the pitch circle diameter of the wheel installation holes.