bolt MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 58 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-10

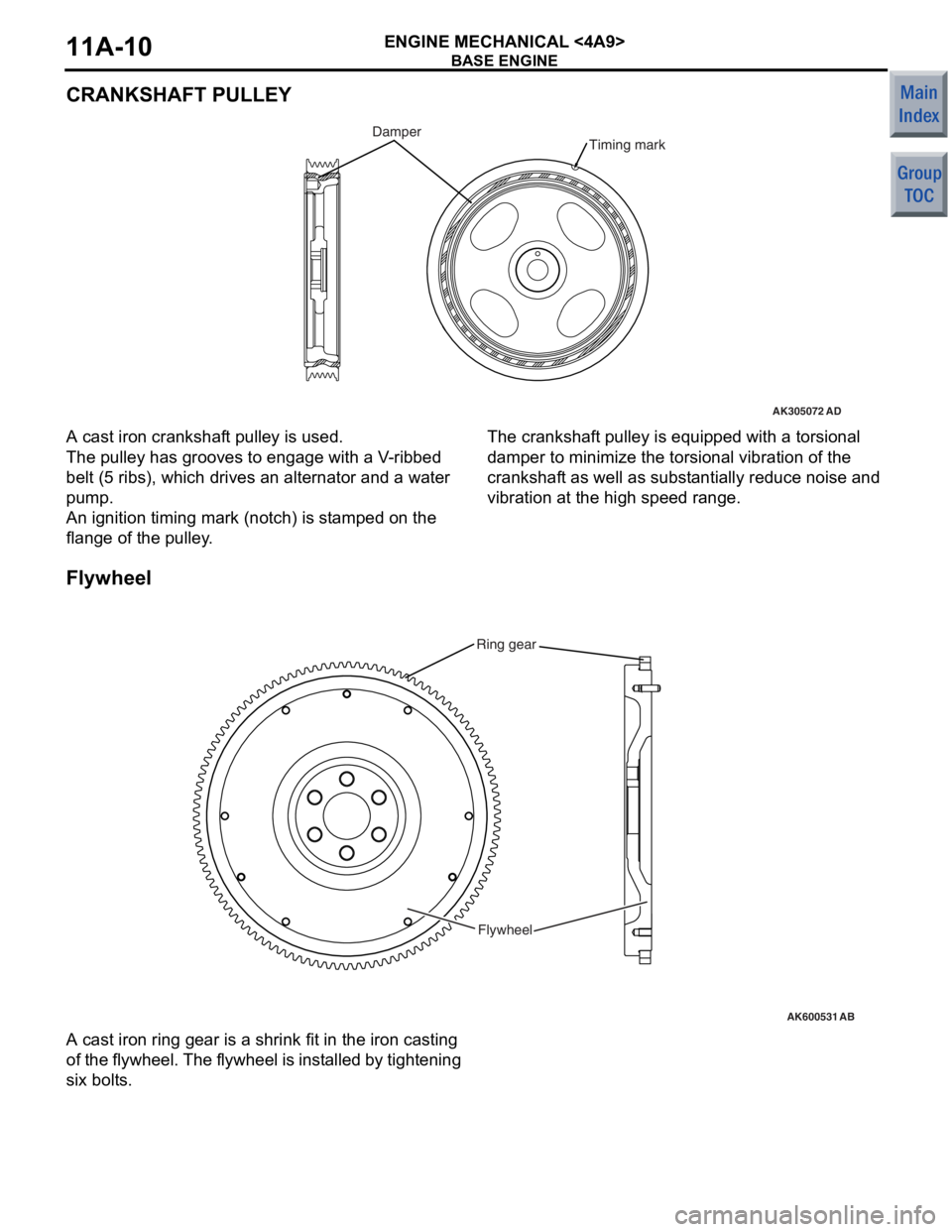

CRANKSHAFT PULLEY

AK305072AD

Timing markDamper

A cast iron cranksh af t pulley is used.

The pulley has grooves to eng age with a V -rib bed

belt (5

ribs), which drives an alternat or and a water

pump

.

An ignition timing mark (notch) is st amp ed on the

flang

e of the pulley .

The crankshaft pulley is equipped with a to rsio nal

damp

e r to minimize the torsional vibratio n of th e

cranksha

f t as well as sub s t antia lly redu ce no ise and

vib

r ation at the high spee d rang e.

Flyw he el

AK600531

Ring gear

Flywheel

AB

A cast iron ring g ear is a shrink fit in th e iron casting

of

t h e f l yw he el. T h e f l yw he el is in st a l le d by tigh t e n i n g

six bolt

s .

Page 59 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-11

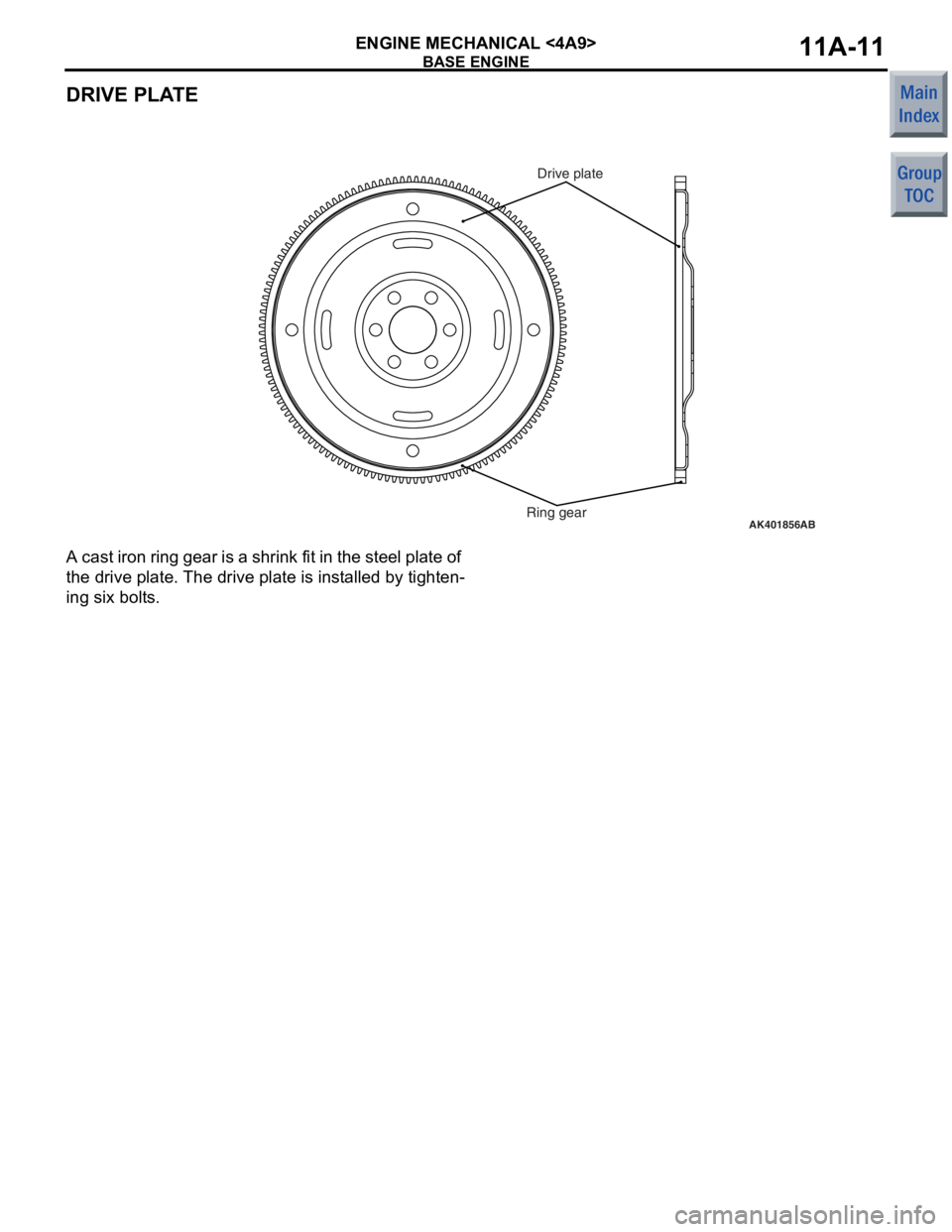

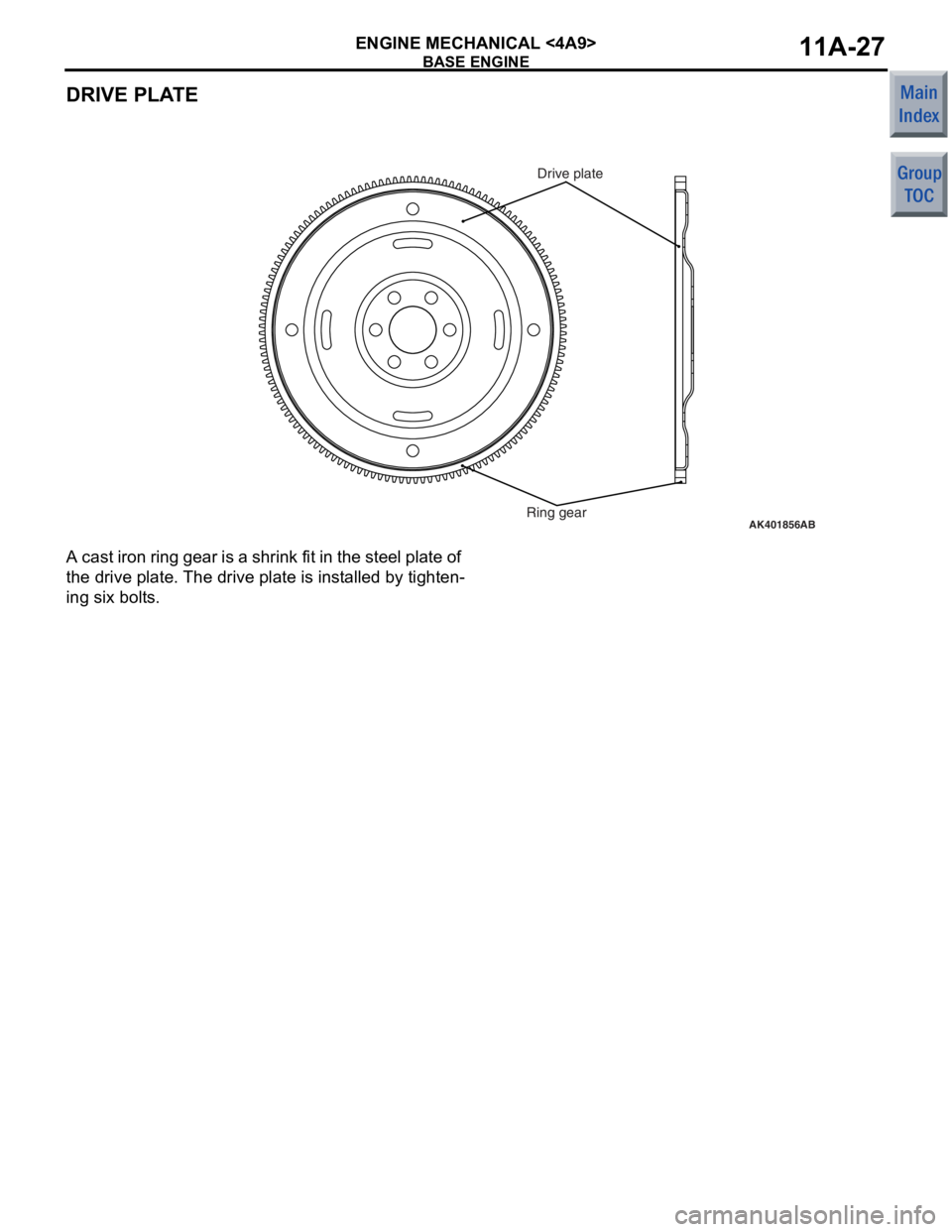

DRIVE PLATE

AK401856Ring gearDrive plateAB

A cast iron

ring g ear is a shrin k fit in th e ste e l plate o f

the drive p

l ate. The drive p l ate is inst alled b y tighten

-

ing six bolts .

Page 63 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-15

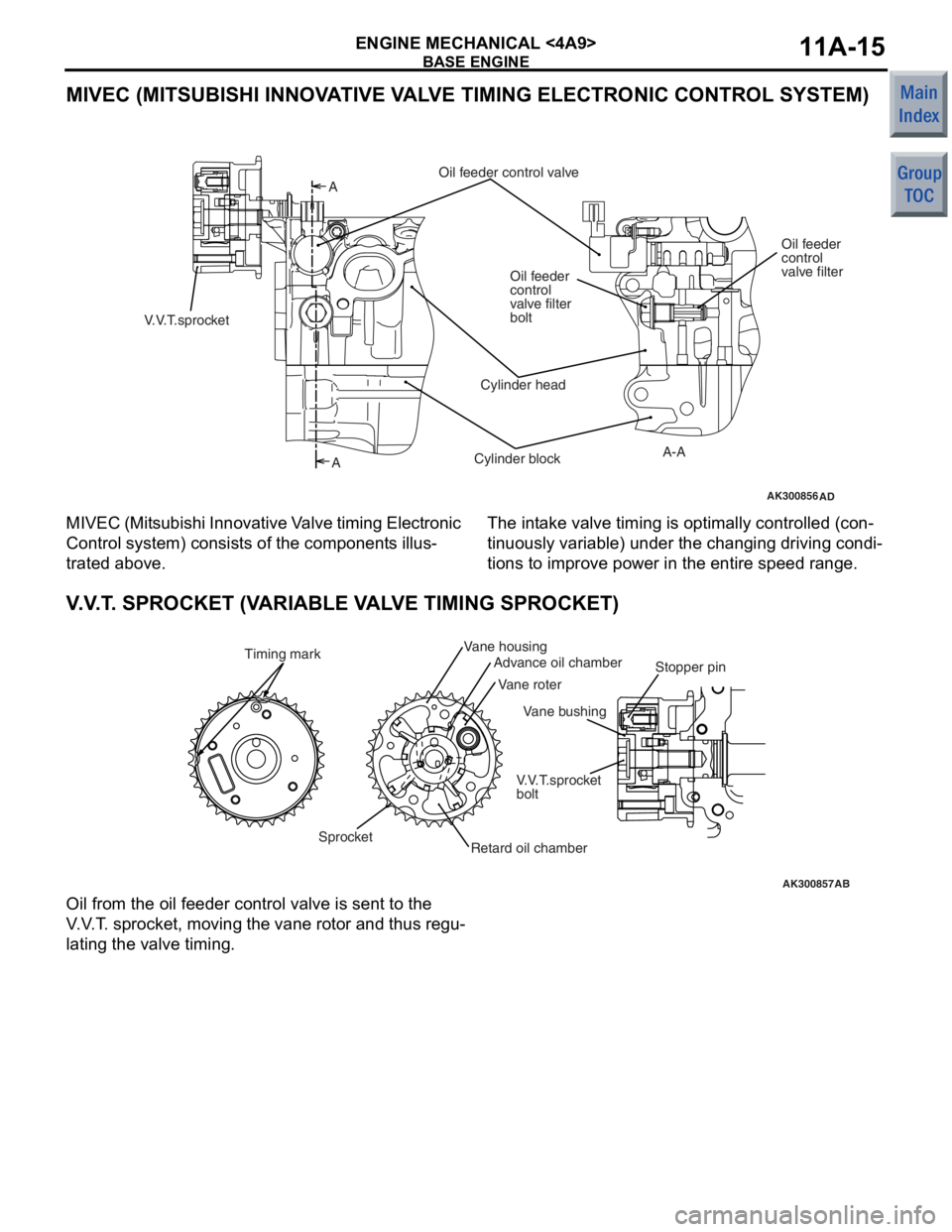

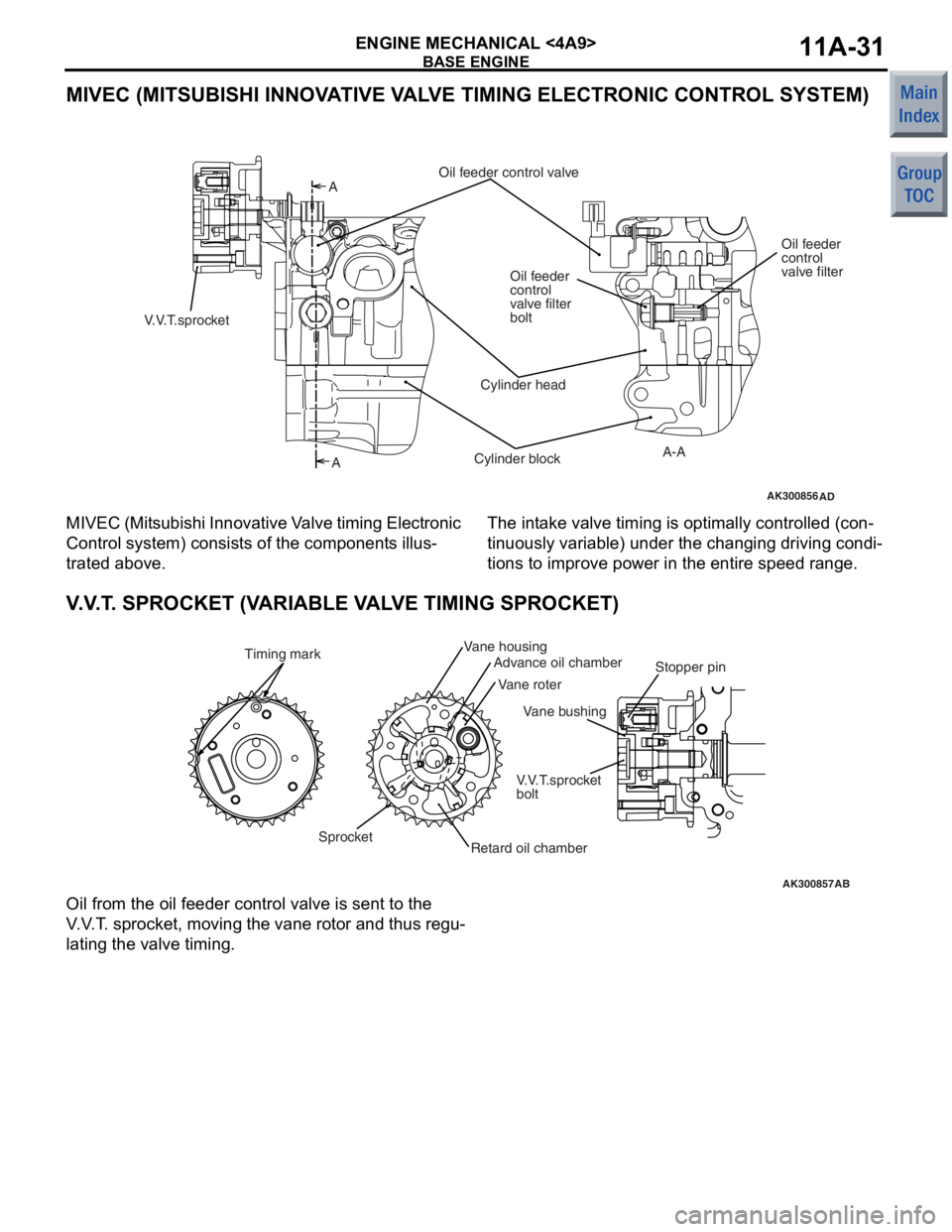

MIVEC (MITSUBISHI INNOVATIVE VALVE TIMING ELECTRONIC CONTROL SYSTEM)

AK300856AD

A

A

A-A

Oil feeder control valve

Oil feeder

control

valve filter

Oil feeder

control

valve filter

bolt

Cylinder head

Cylinder block

V.V.T.sprocket

M I VEC (Mit su bis h i Inn o va tive V a lve tim i ng Elect r o n ic

Con

t rol system) consist s of th e compon ent s illus

-

trated above .

The int a ke valve timing is optimally controlled (con-

tinuously variable) un der the chan ging driving condi-

tions to improv e po we r in th e entire sp eed ra nge.

V. V . T . SPROCKET (V ARIABLE V A L V E TIMING SPROCKET)

AK300857

Vane bushing

AB

SprocketVane roter

V.V.T.sprocket

bolt

Timing mark

Vane housing

Advance oil chamber

Retard oil chamber

Stopper pin

Oil from the oil fe

eder control valve is sent t o the

V

. V . T . sp rocket, moving the vane roto r and thus reg u

-

lating the valve timing.

Page 74 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-26

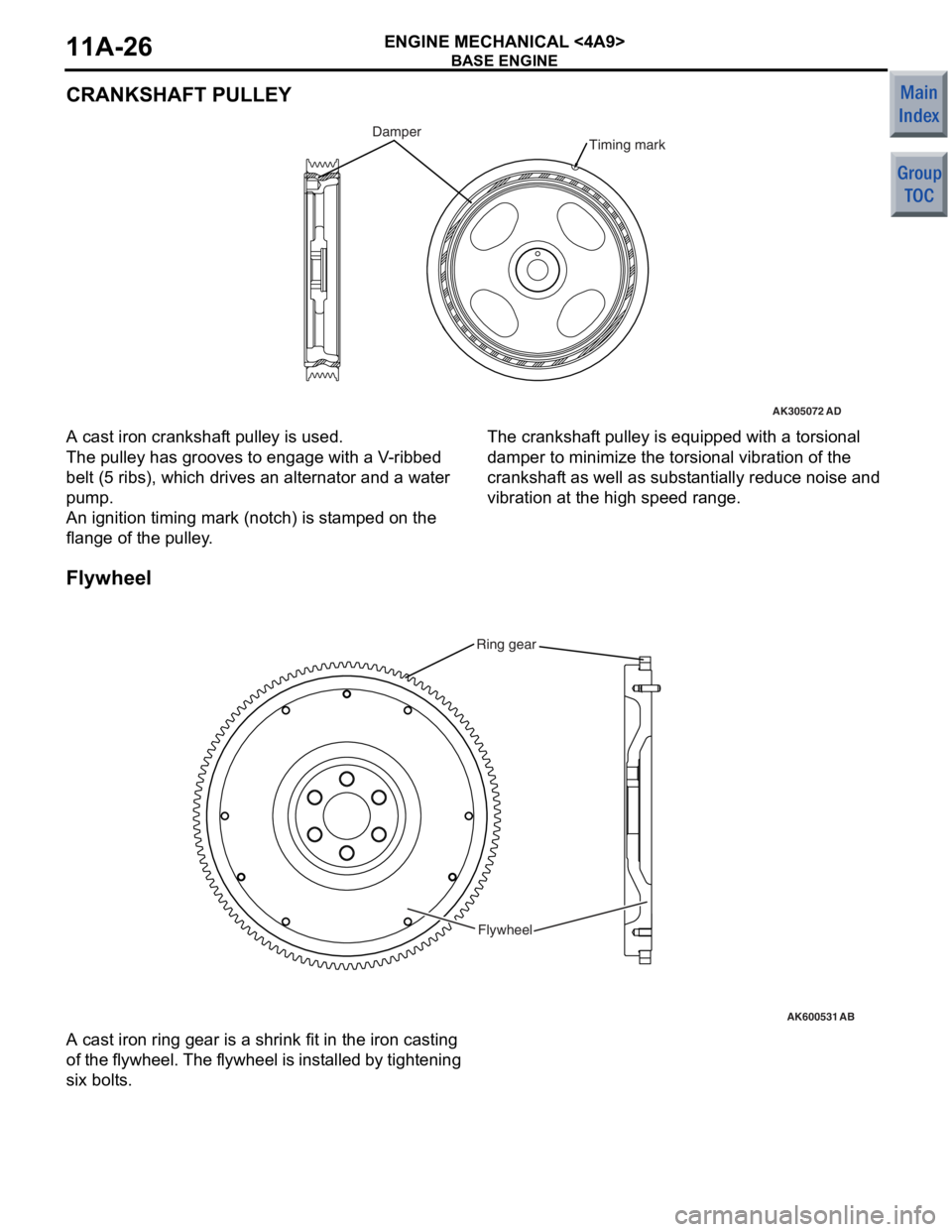

CRANKSHAFT PULLEY

AK305072AD

Timing markDamper

A cast iron cranksh af t pulley is used.

The pulley has grooves to eng age with a V -rib bed

belt (5

ribs), which drives an alternat or and a water

pump

.

An ignition timing mark (notch) is st amp ed on the

flang

e of the pulley .

The crankshaft pulley is equipped with a to rsio nal

damp

e r to minimize the torsional vibratio n of th e

cranksha

f t as well as sub s t antia lly redu ce no ise and

vib

r ation at the high spee d rang e.

Flyw he el

AK600531

Ring gear

Flywheel

AB

A cast iron ring g ear is a shrink fit in th e iron casting

of

t h e f l yw he el. T h e f l yw he el is in st a l le d by tigh t e n i n g

six bolt

s .

Page 75 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-27

DRIVE PLATE

AK401856Ring gearDrive plateAB

A cast iron

ring g ear is a shrin k fit in th e ste e l plate o f

the drive p

l ate. The drive p l ate is inst alled b y tighten

-

ing six bolts .

Page 79 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-31

MIVEC (MITSUBISHI INNOVATIVE VALVE TIMING ELECTRONIC CONTROL SYSTEM)

AK300856AD

A

A

A-A

Oil feeder control valve

Oil feeder

control

valve filter

Oil feeder

control

valve filter

bolt

Cylinder head

Cylinder block

V.V.T.sprocket

M I VEC (Mit su bis h i Inn o va tive V a lve tim i ng Elect r o n ic

Con

t rol system) consist s of th e compon ent s illus

-

trated above .

The int a ke valve timing is optimally controlled (con-

tinuously variable) un der the chan ging driving condi-

tions to improv e po we r in th e entire sp eed ra nge.

V. V . T . SPROCKET (V ARIABLE V A L V E TIMING SPROCKET)

AK300857

Vane bushing

AB

SprocketVane roter

V.V.T.sprocket

bolt

Timing mark

Vane housing

Advance oil chamber

Retard oil chamber

Stopper pin

Oil from the oil fe

eder control valve is sent t o the

V

. V . T . sp rocket, moving the vane roto r and thus reg u

-

lating the valve timing.

Page 94 of 364

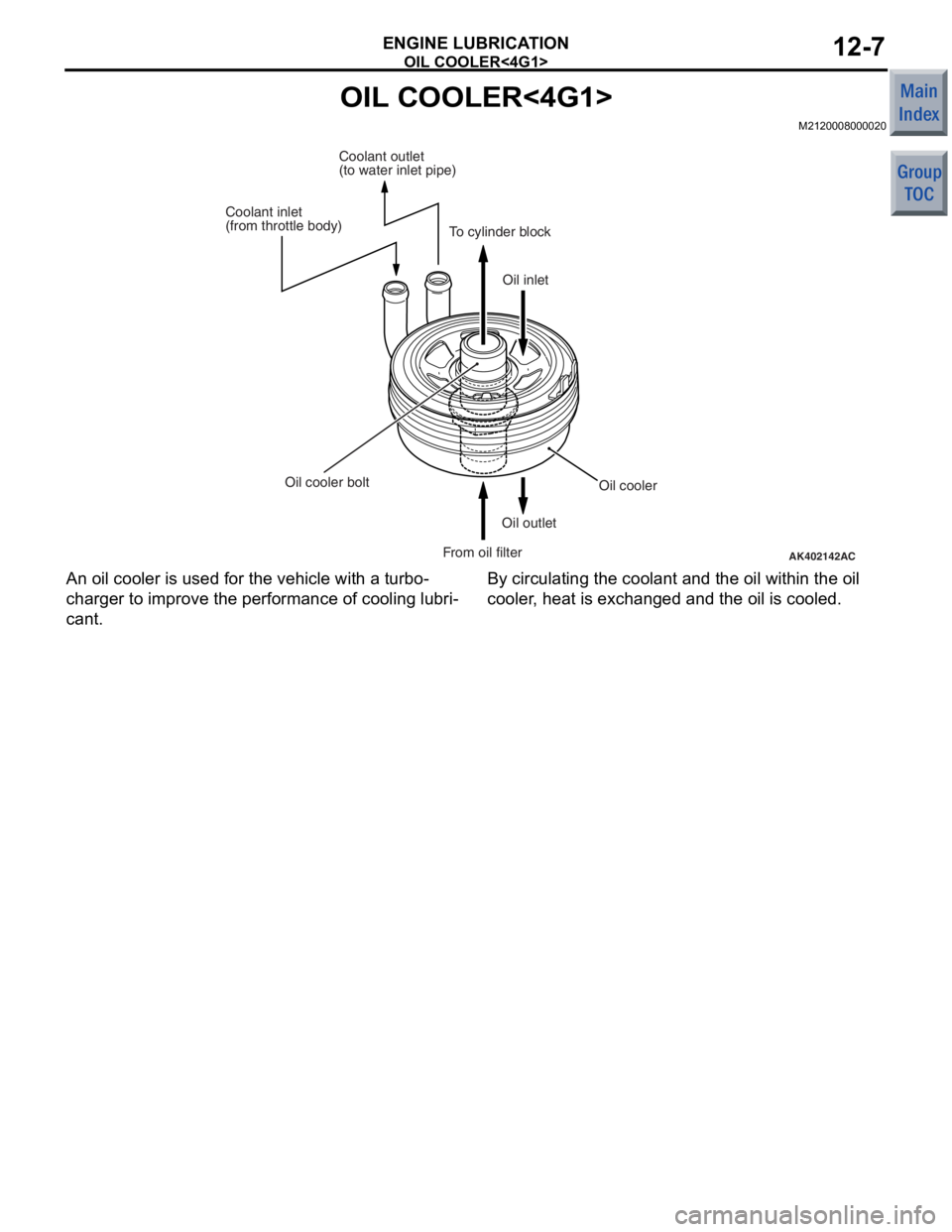

OIL COOLER<4G1>

ENGINE LUBRICATION12-7

OIL COOLER<4G1>

M2120008000020

AK402142

Oil outletOil inlet

To cylinder block

From oil filter

Coolant inlet

(from throttle body)

Coolant outlet

(to water inlet pipe)

Oil cooler boltOil cooler

AC

An

oil cooler is used for the vehicle wit h a turb o-

charge r to improve the per formance of cooling lubri-

cant.

By circulating the coolant an d the o il within t he oil

cooler

, he at is exchang ed an d the o il is coole d .

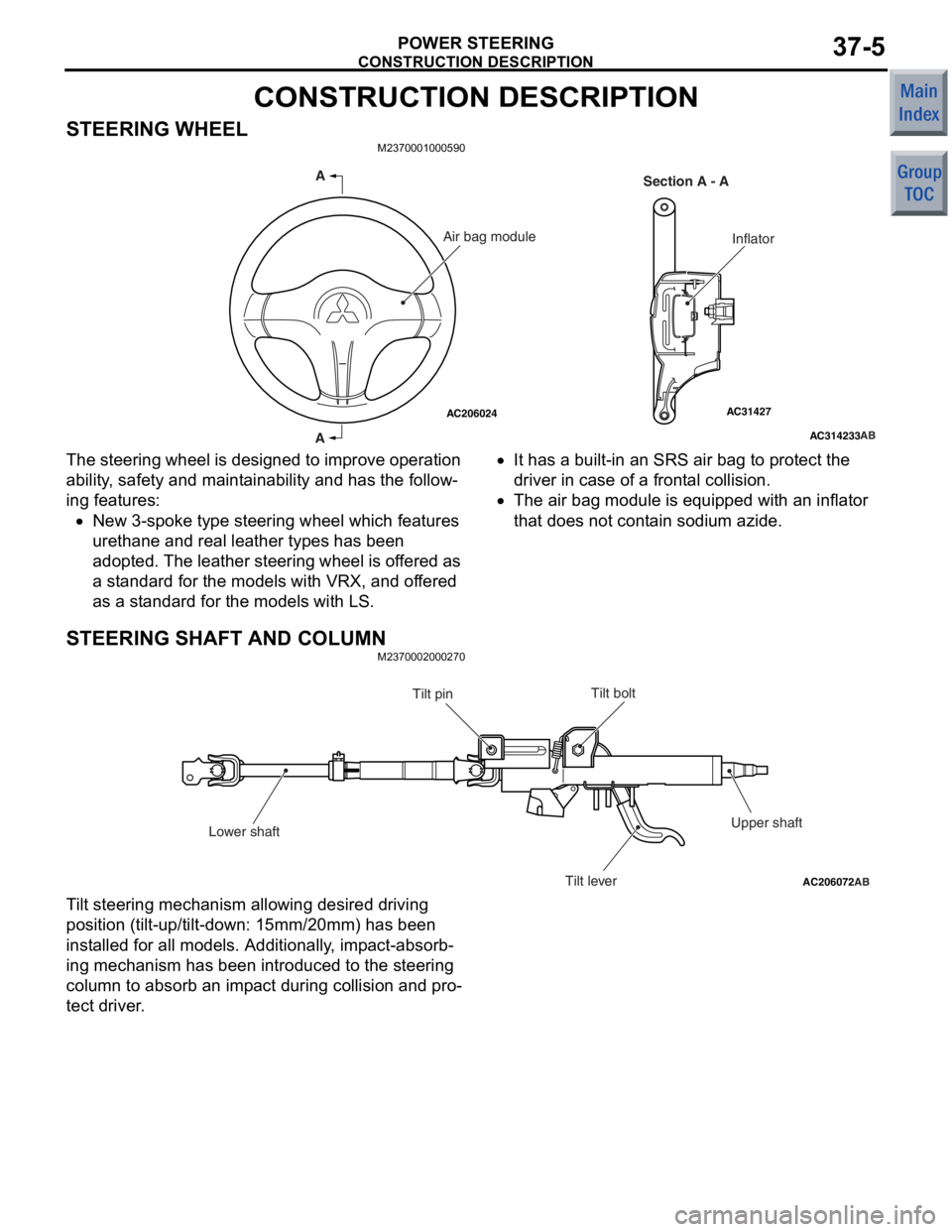

Page 238 of 364

CONSTRUCTION DESCRIPTION

POWER STEERING37-5

CONSTRUCTION DESCRIPTION

STEERING WHEELM2370001000590

AC314233

AC31427AC206024AB

A

A Section A - A

InflatorAir bag module

The steering wh

eel is de sig ned to impro v e operat ion

ability

, safety and main t a inabilit y and has the follow

-

ing features:

•New 3-spoke type stee ring whe e l which fe atures

uret

hane a nd real lea t her types has been

ado

pted. The leather stee ring wh eel is o f fere d as

a st

a ndard f o r the models with VRX, and of fered

as a st

an dard for the models with LS.

•It ha s a built-in a n SRS a i r ba g to pro t ect t he

driv

er in c a s e of a front a l c o ll is i o n.

•The air b ag mo dule is equip ped wit h an inflat or

tha

t does not cont ain sod i um azide.

STEERING SHAFT AND COLUMN

M23700020 0027 0

AC206072AB

Tilt bolt

Tilt pin

Lower shaft Tilt leverUpper shaft

T

i lt steering mecha n ism allowing desired d r iving

position

(tilt -up/tilt-down: 1 5 mm/20mm) ha s be en

inst

alled for all mo dels. Additiona lly , imp a ct-absorb

-

ing mechanism h a s be en in troduced to the steering

colu

mn t o absorb an imp a ct during collision an d pro

-

te c t dri v er .

Page 247 of 364

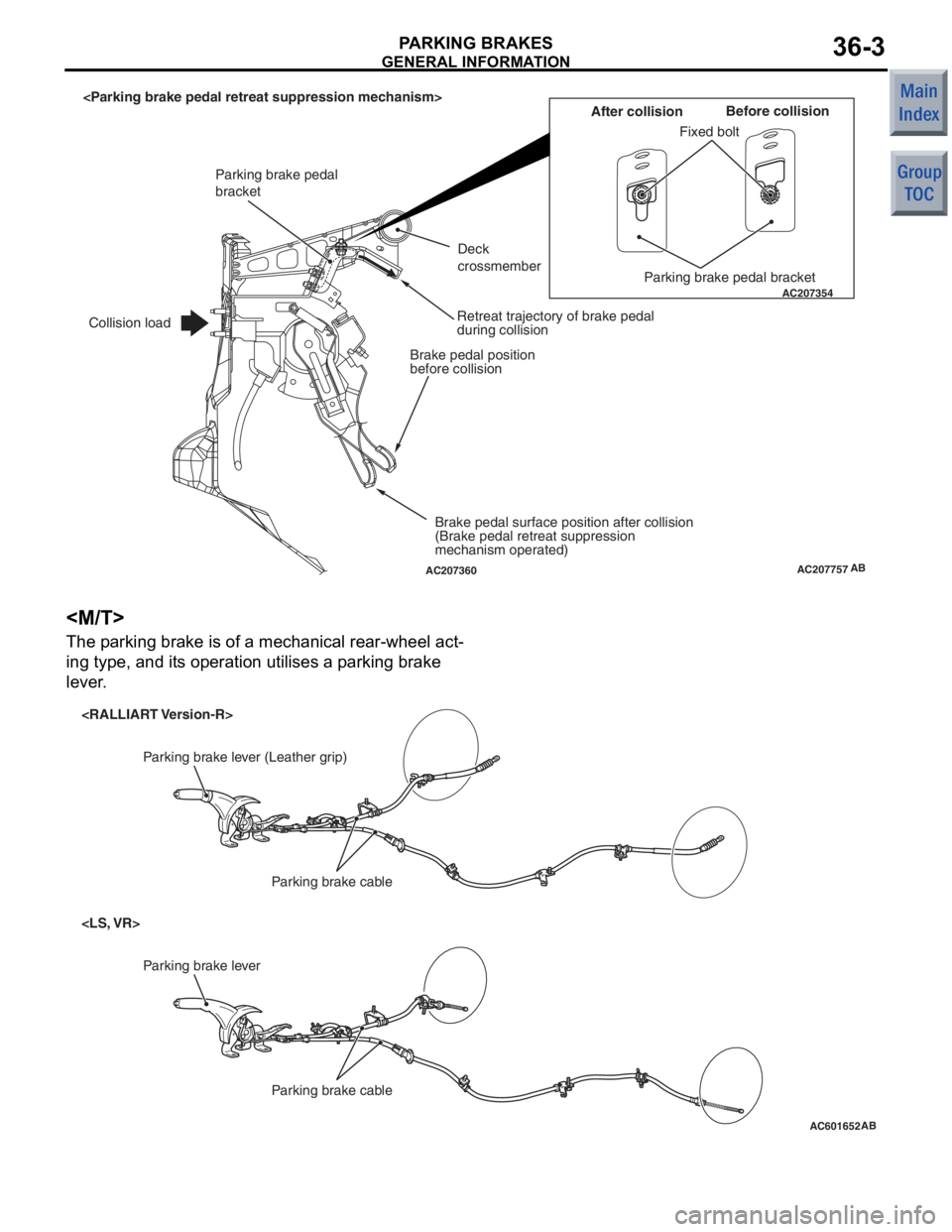

AC207757

AC207354

AC207360AB

Fixed boltBefore collision

After collision

Parking brake pedal bracket

Deck

crossmember

Retreat trajectory of brake pedal

during collision

Brake pedal position

before collision

Brake pedal surface position after collision

(Brake pedal retreat suppression

mechanism operated)

Parking brake pedal

bracket

Collision load

GENERAL INFORMA

T ION

PA R K ING BR AKES36-3

The pa rking b r ake is o f a me chan ica l rea r-wh eel a c t-

ing type, and it s operat ion u t ilises a p a rking b r ake

leve

r .

AC601652

Parking brake lever

Parking brake cable

Parking brake lever (Leather grip)Parking brake cable

AB

Page 346 of 364

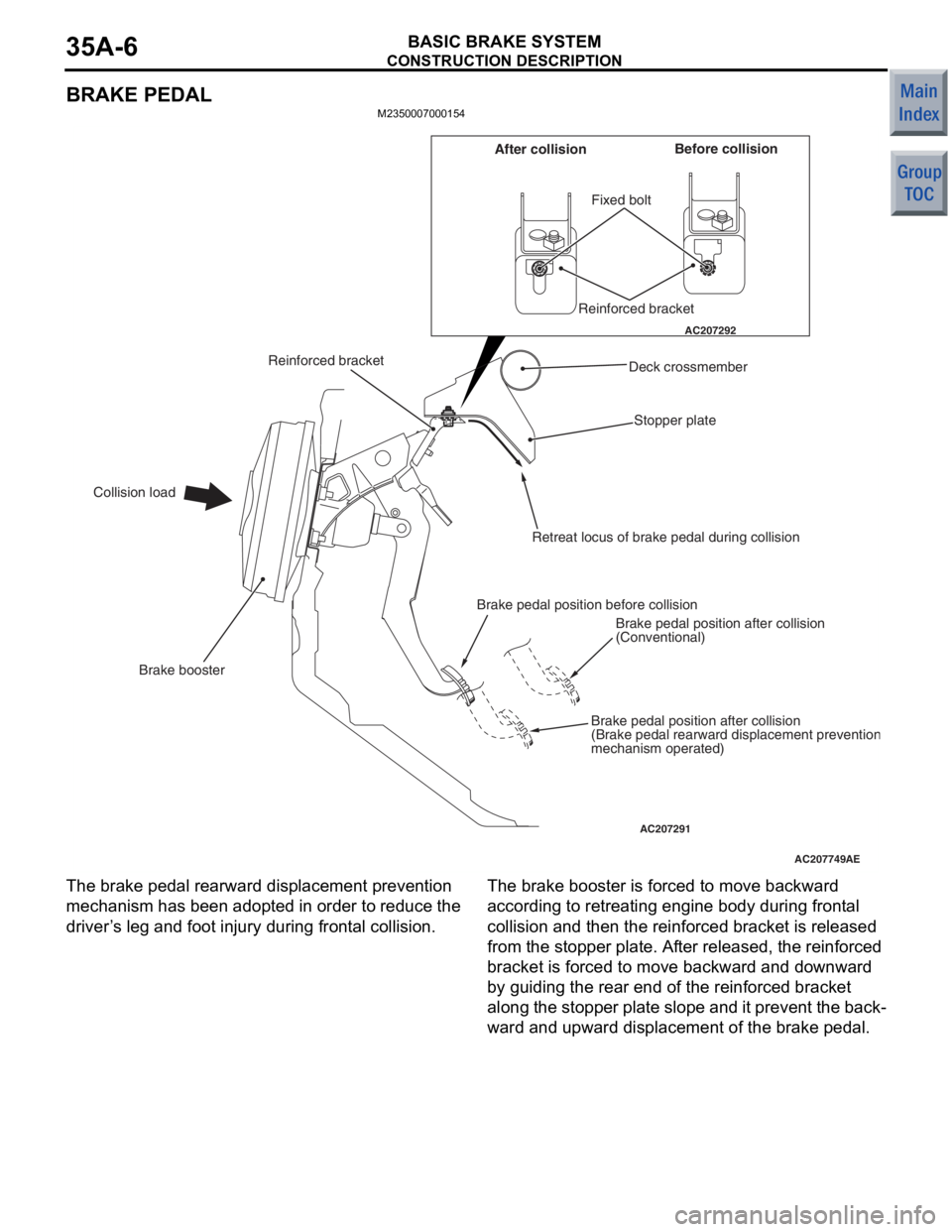

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-6

BRAKE PEDAL

M2350007000154

AC207749

AC207292

AC207291AE

Fixed bolt

Stopper plate

Brake booster

Collision load Before collision

After collision

Reinforced bracket

Deck crossmember

Retreat locus of brake pedal during collision

Brake pedal position before collision Brake pedal position after collision

(Conventional)

Brake pedal position after collision

(Brake pedal rearward displacement preventio

nmechanism operated)

Reinforced bracket

The bra

k e pe dal re arward displacement preve n tion

mechanism

has been adop ted in ord e r to reduce the

driver

’ s le g and foot injury during fron t a l co llisio n .The brak e bo oste r is force d to move backward

accordin

g to ret r eatin g engine bo dy d u ring front al

collision a

nd the n the r e info rced b r acket is release d

from

the stopper plat e. Af ter release d , the reinf o rced

bracket is forced to

move backward and do wn wa rd

by gu

iding the rear end of the reinf o rced bracket

along

the stoppe r plate slo pe and it preve n t the back

-

ward and upward displace ment of the b r ake pedal.