drive shaft MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 57 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-9

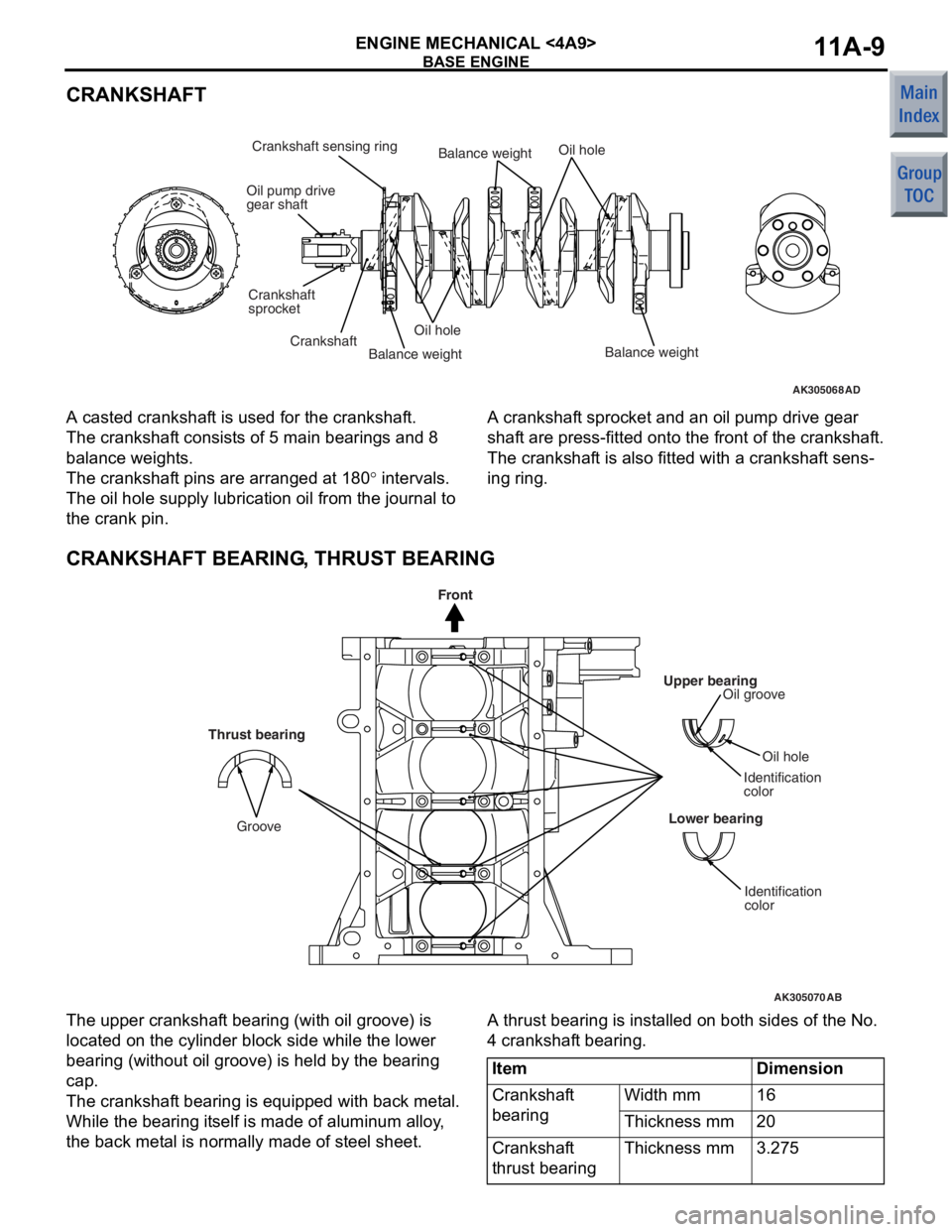

CRANKSHAFT

AK305068AD

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft sensing ring

CrankshaftOil hole

Oil hole

Balance weightBalance weightBalance weight

A casted crankshaf

t is used for t he cr ankshaf t.

The crankshaft consist s o f 5 ma in be aring s an d 8

balan

ce weight s.

The crankshaft pins a r e arrang ed at 1 8 0° inte rval s.

The oil hole supply lu brication oil from t he jo urnal to

the crank p

i n.

A cranksha f t sprocket and an oil pump drive gea r

shaf

t are press-fit t ed on to the f r ont of the crankshaf t.

The crankshaft is also fitt ed with a crankshaf t sens-

ing ring.

CRANKSHAFT BEARING, THRUST BEARING

AK305070

Upper bearingOil groove

Oil hole

Identification

color

Lower bearing

Identification

color

AB

Thrust bearing

Groove

Front

The upp er cra n kshaf t bea ring (with oil groove) is

loca

ted on the cylinder block side wh ile the lo we r

bearin

g (witho ut oil groo ve) is he ld by the b earin g

cap.

The crankshaft bea ring is e quipp ed with back me t a l.

While the b

earin g it self is ma de of a l uminum alloy ,

the back met

a l is no rmally made of steel sheet .

A thrust bearing is inst alle d on b o th sides of th e No.

4 cran

kshaf t bearing.

ItemDimension

Crankshaft

bearingWidth mm16

Thickness mm20

Crankshaft

thrust bearingThickness mm3.275

Page 58 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-10

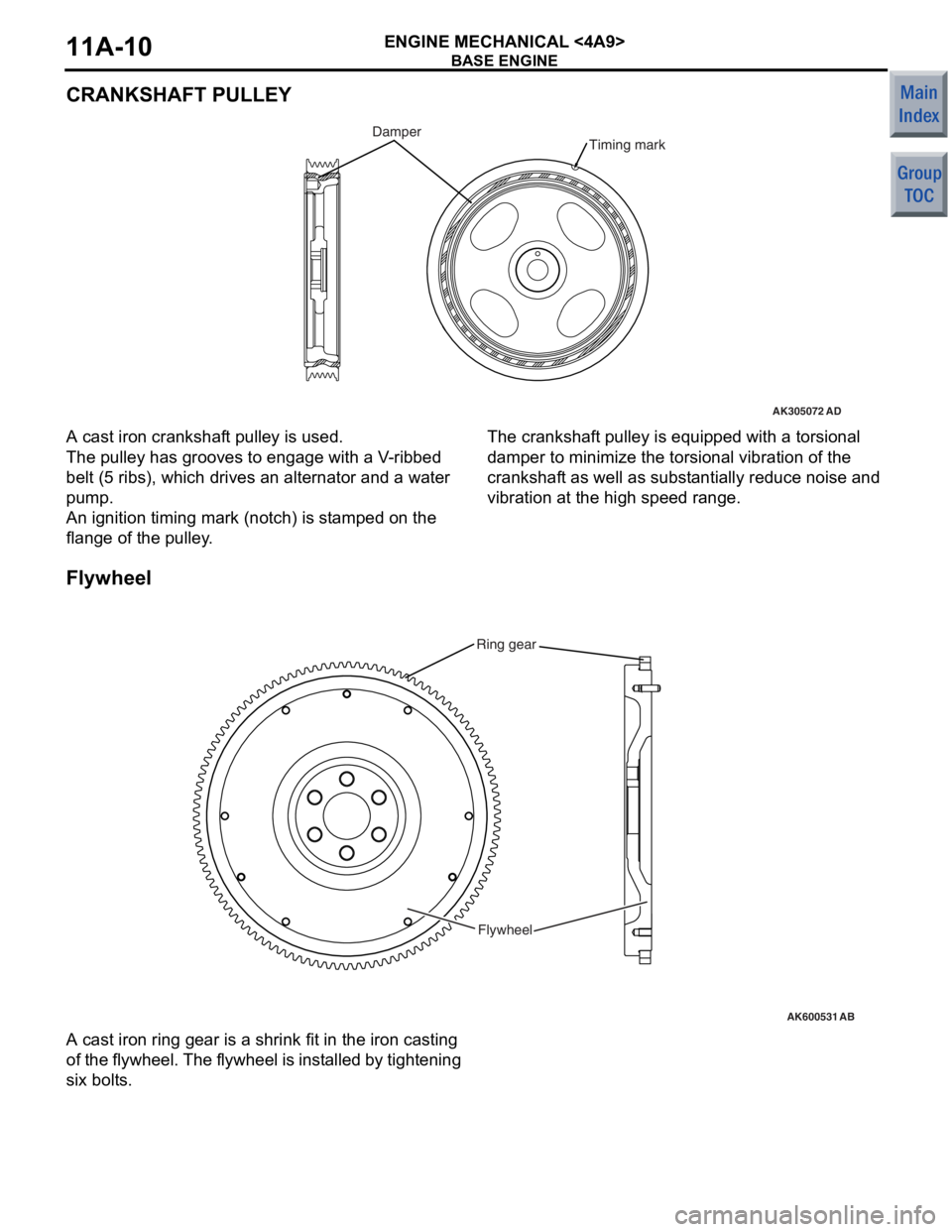

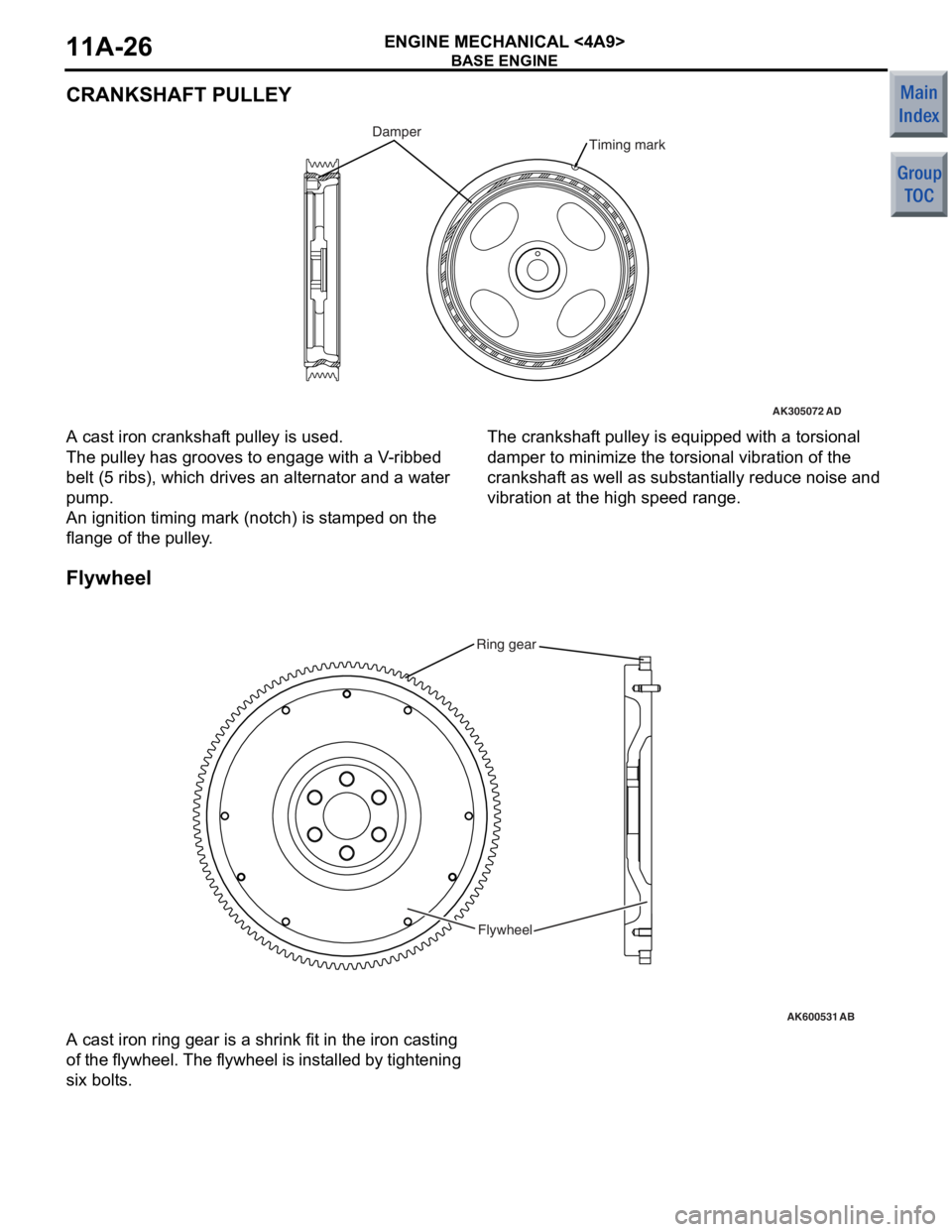

CRANKSHAFT PULLEY

AK305072AD

Timing markDamper

A cast iron cranksh af t pulley is used.

The pulley has grooves to eng age with a V -rib bed

belt (5

ribs), which drives an alternat or and a water

pump

.

An ignition timing mark (notch) is st amp ed on the

flang

e of the pulley .

The crankshaft pulley is equipped with a to rsio nal

damp

e r to minimize the torsional vibratio n of th e

cranksha

f t as well as sub s t antia lly redu ce no ise and

vib

r ation at the high spee d rang e.

Flyw he el

AK600531

Ring gear

Flywheel

AB

A cast iron ring g ear is a shrink fit in th e iron casting

of

t h e f l yw he el. T h e f l yw he el is in st a l le d by tigh t e n i n g

six bolt

s .

Page 60 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-12

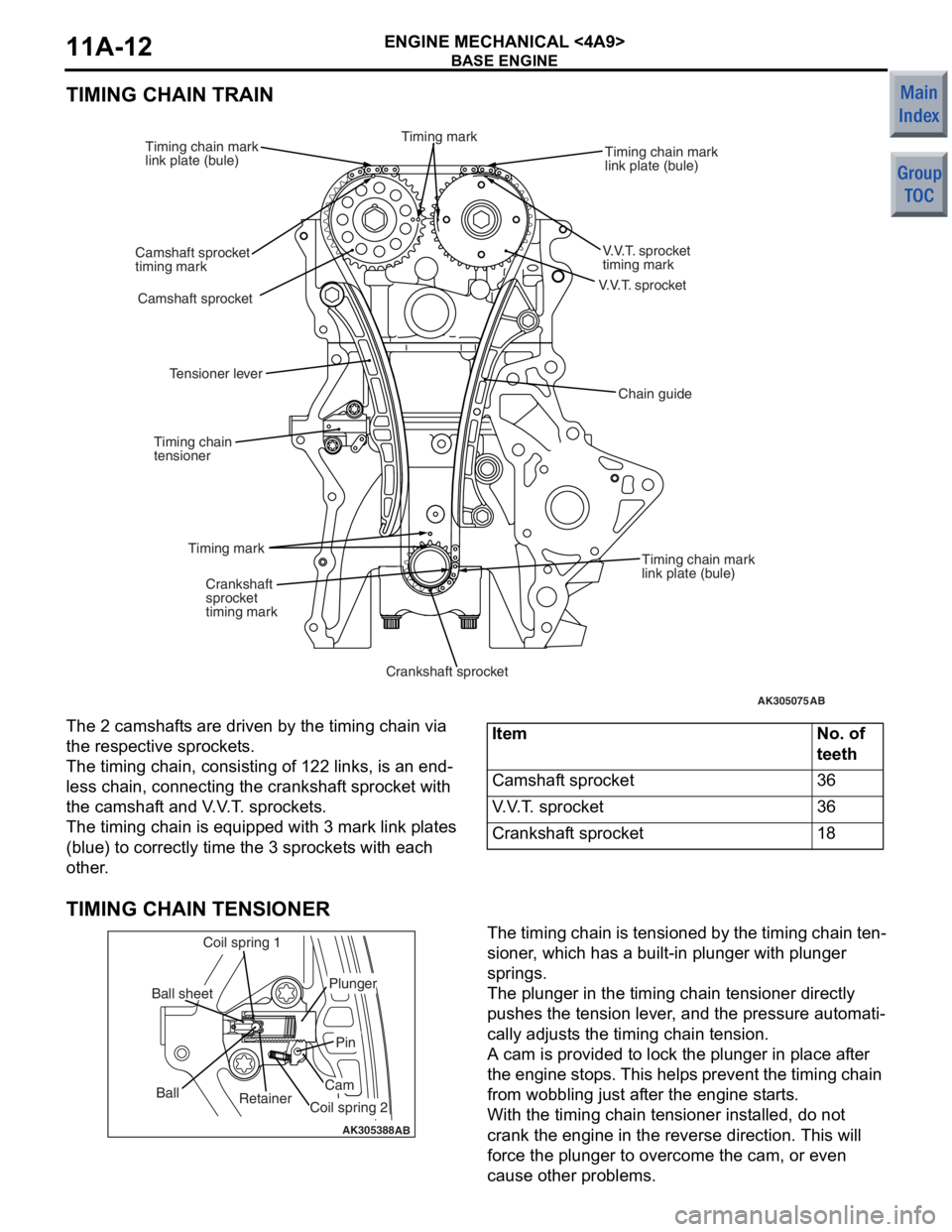

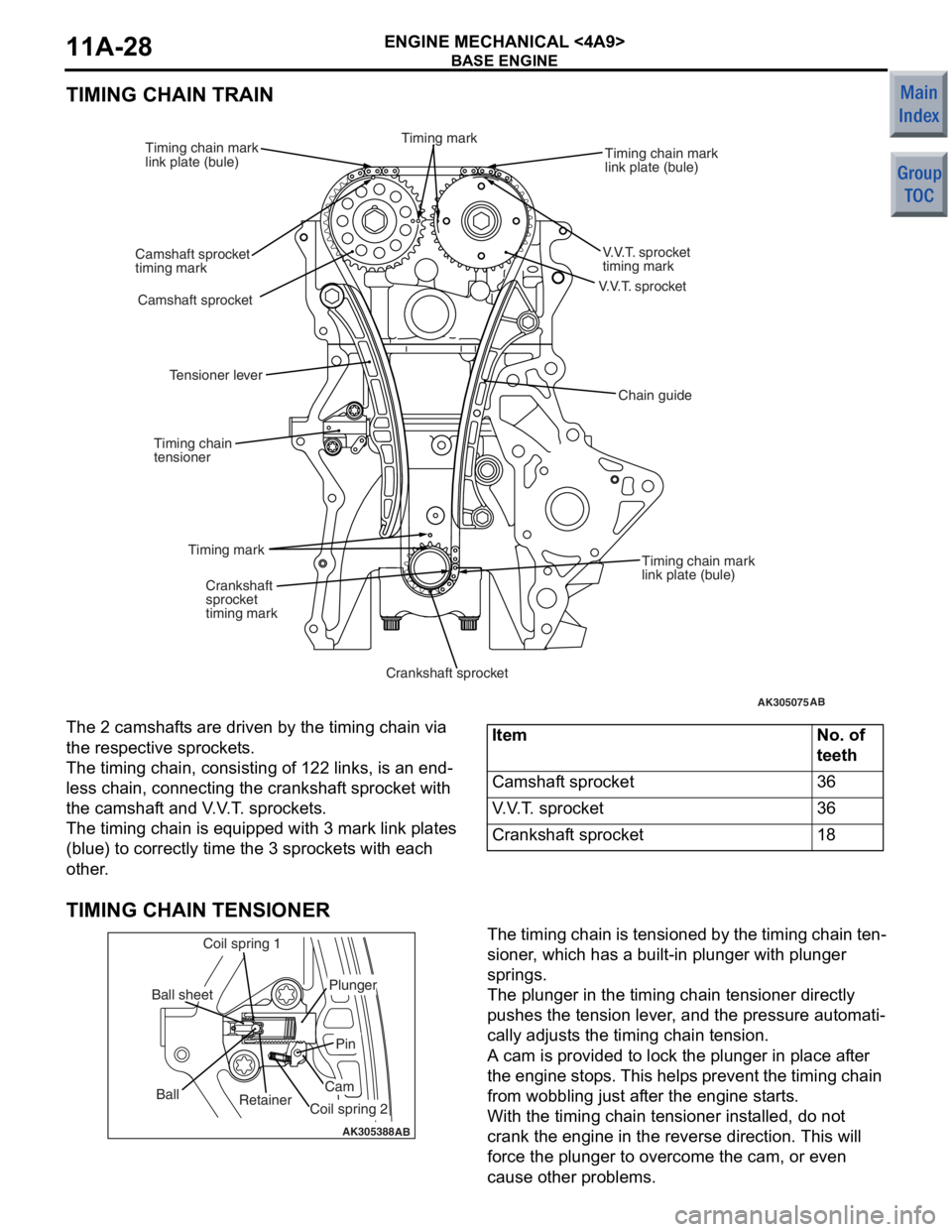

TIMING CHAIN TRAIN

AK305075

V.V.T. sprocket

AB

V.V.T. sprocket

timing mark

Timing chain mark

link plate (bule)

Camshaft sprocket

Camshaft sprocket

timing mark Timing chain mark

link plate (bule)

Timing chain mark

link plate (bule)

Crankshaft

sprocket

timing mark

Crankshaft sprocket

Timing mark

Timing chain

tensioner

Tensioner lever

Chain guide

Timing mark

The 2 camshaf

t s are driven by the t i ming chain via

the res

pec tive spro cke t s .

The timing cha i n, consist i ng o f 122 links, is an end-

less chain, conn ecting the cran ksh af t spro cke t with

the camshaf

t and V . V . T . spro cke t s .

The timing cha i n is eq uippe d with 3 mark link p l ates

(blue)

to co rrectly time t he 3 sprocket s with each

other

.

ItemNo. of

teeth

Camshaft sprocket36

V.V.T. sprocket36

Crankshaft sprocket18

TIMING CHAIN TENSIONER

AK305388AB

Retainer

Ball

Coil spring 1

Ball sheet

Coil spring 2

Cam

Pin

Plunger

The timing chain is tensione

d by th e timing chain te n-

sioner , which ha s a b u ilt-in plunge r with plunge r

springs.

The plunger in the timing chain tension e r dire ctly

push

e s th e tension lever , and the pre s sure aut omati

-

cally ad just s the timing chain tension.

A cam is provided t o lock th e plu nger in pla c e a f te r

the eng

ine stop s. This help s prevent the timing chain

from wob

b lin g just af ter th e eng ine st a r t s .

With the timing cha i n ten s io ner in st alled, do not

crank the

engin e in the reverse directio n. This will

force

the plunger to overcome the cam, or e v en

cause oth

e r problems.

Page 73 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-25

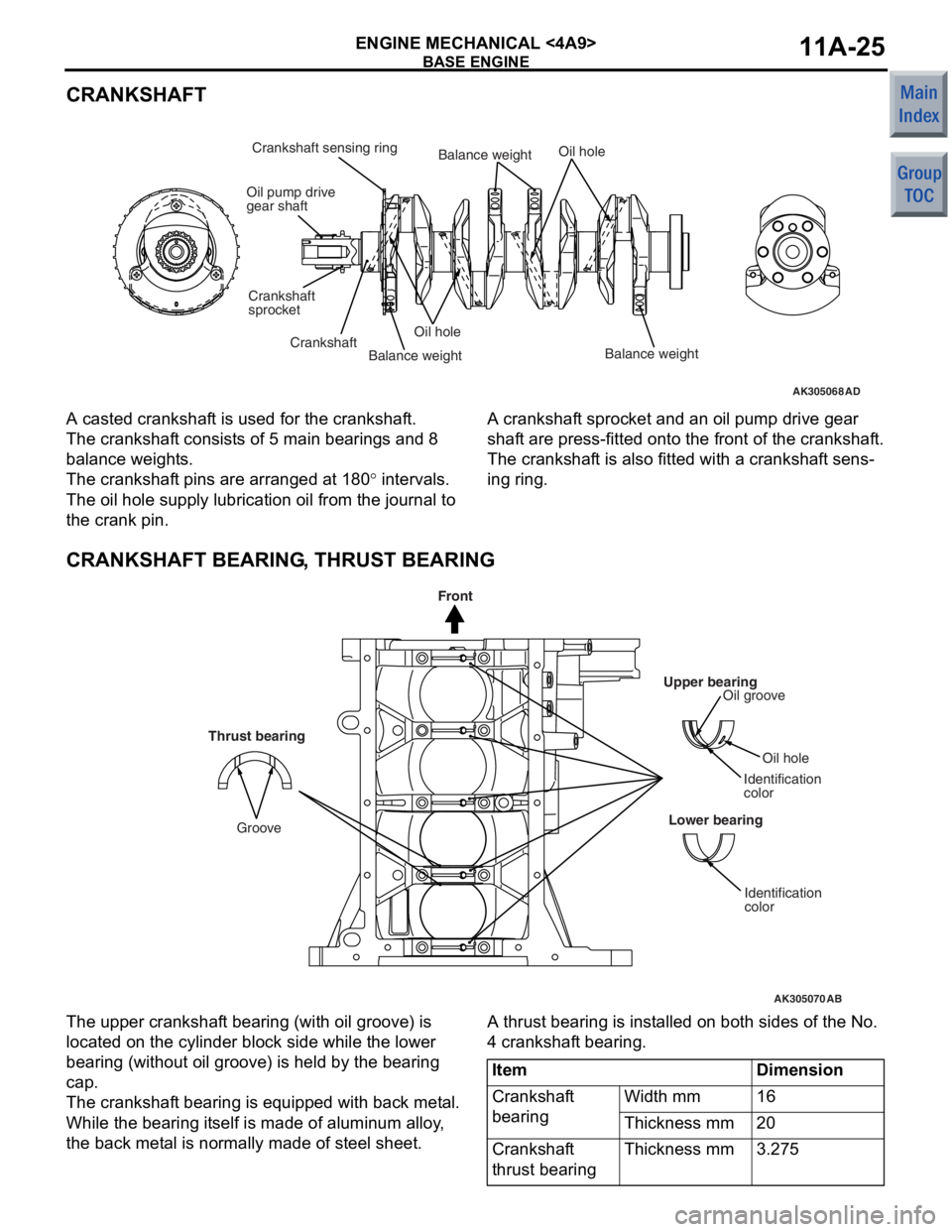

CRANKSHAFT

AK305068AD

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft sensing ring

CrankshaftOil hole

Oil hole

Balance weightBalance weightBalance weight

A casted crankshaf

t is used for t he cr ankshaf t.

The crankshaft consist s o f 5 ma in be aring s an d 8

balan

ce weight s.

The crankshaft pins a r e arrang ed at 1 8 0° inte rval s.

The oil hole supply lu brication oil from t he jo urnal to

the crank p

i n.

A cranksha f t sprocket and an oil pump drive gea r

shaf

t are press-fit t ed on to the f r ont of the crankshaf t.

The crankshaft is also fitt ed with a crankshaf t sens-

ing ring.

CRANKSHAFT BEARING, THRUST BEARING

AK305070

Upper bearingOil groove

Oil hole

Identification

color

Lower bearing

Identification

color

AB

Thrust bearing

Groove

Front

The upp er cra n kshaf t bea ring (with oil groove) is

loca

ted on the cylinder block side wh ile the lo we r

bearin

g (witho ut oil groo ve) is he ld by the b earin g

cap.

The crankshaft bea ring is e quipp ed with back me t a l.

While the b

earin g it self is ma de of a l uminum alloy ,

the back met

a l is no rmally made of steel sheet .

A thrust bearing is inst alle d on b o th sides of th e No.

4 cran

kshaf t bearing.

ItemDimension

Crankshaft

bearingWidth mm16

Thickness mm20

Crankshaft

thrust bearingThickness mm3.275

Page 74 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-26

CRANKSHAFT PULLEY

AK305072AD

Timing markDamper

A cast iron cranksh af t pulley is used.

The pulley has grooves to eng age with a V -rib bed

belt (5

ribs), which drives an alternat or and a water

pump

.

An ignition timing mark (notch) is st amp ed on the

flang

e of the pulley .

The crankshaft pulley is equipped with a to rsio nal

damp

e r to minimize the torsional vibratio n of th e

cranksha

f t as well as sub s t antia lly redu ce no ise and

vib

r ation at the high spee d rang e.

Flyw he el

AK600531

Ring gear

Flywheel

AB

A cast iron ring g ear is a shrink fit in th e iron casting

of

t h e f l yw he el. T h e f l yw he el is in st a l le d by tigh t e n i n g

six bolt

s .

Page 76 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-28

TIMING CHAIN TRAIN

AK305075

V.V.T. sprocket

AB

V.V.T. sprocket

timing mark

Timing chain mark

link plate (bule)

Camshaft sprocket

Camshaft sprocket

timing mark Timing chain mark

link plate (bule)

Timing chain mark

link plate (bule)

Crankshaft

sprocket

timing mark

Crankshaft sprocket

Timing mark

Timing chain

tensioner

Tensioner lever

Chain guide

Timing mark

The 2 camshaf

t s are driven by the t i ming chain via

the res

pec tive spro cke t s .

The timing cha i n, consist i ng o f 122 links, is an end-

less chain, conn ecting the cran ksh af t spro cke t with

the camshaf

t and V . V . T . spro cke t s .

The timing cha i n is eq uippe d with 3 mark link p l ates

(blue)

to co rrectly time t he 3 sprocket s with each

other

.

ItemNo. of

teeth

Camshaft sprocket36

V.V.T. sprocket36

Crankshaft sprocket18

TIMING CHAIN TENSIONER

AK305388AB

Retainer

Ball

Coil spring 1

Ball sheet

Coil spring 2

Cam

Pin

Plunger

The timing chain is tensione

d by th e timing chain te n-

sioner , which ha s a b u ilt-in plunge r with plunge r

springs.

The plunger in the timing chain tension e r dire ctly

push

e s th e tension lever , and the pre s sure aut omati

-

cally ad just s the timing chain tension.

A cam is provided t o lock th e plu nger in pla c e a f te r

the eng

ine stop s. This help s prevent the timing chain

from wob

b lin g just af ter th e eng ine st a r t s .

With the timing cha i n ten s io ner in st alled, do not

crank the

engin e in the reverse directio n. This will

force

the plunger to overcome the cam, or e v en

cause oth

e r problems.

Page 101 of 364

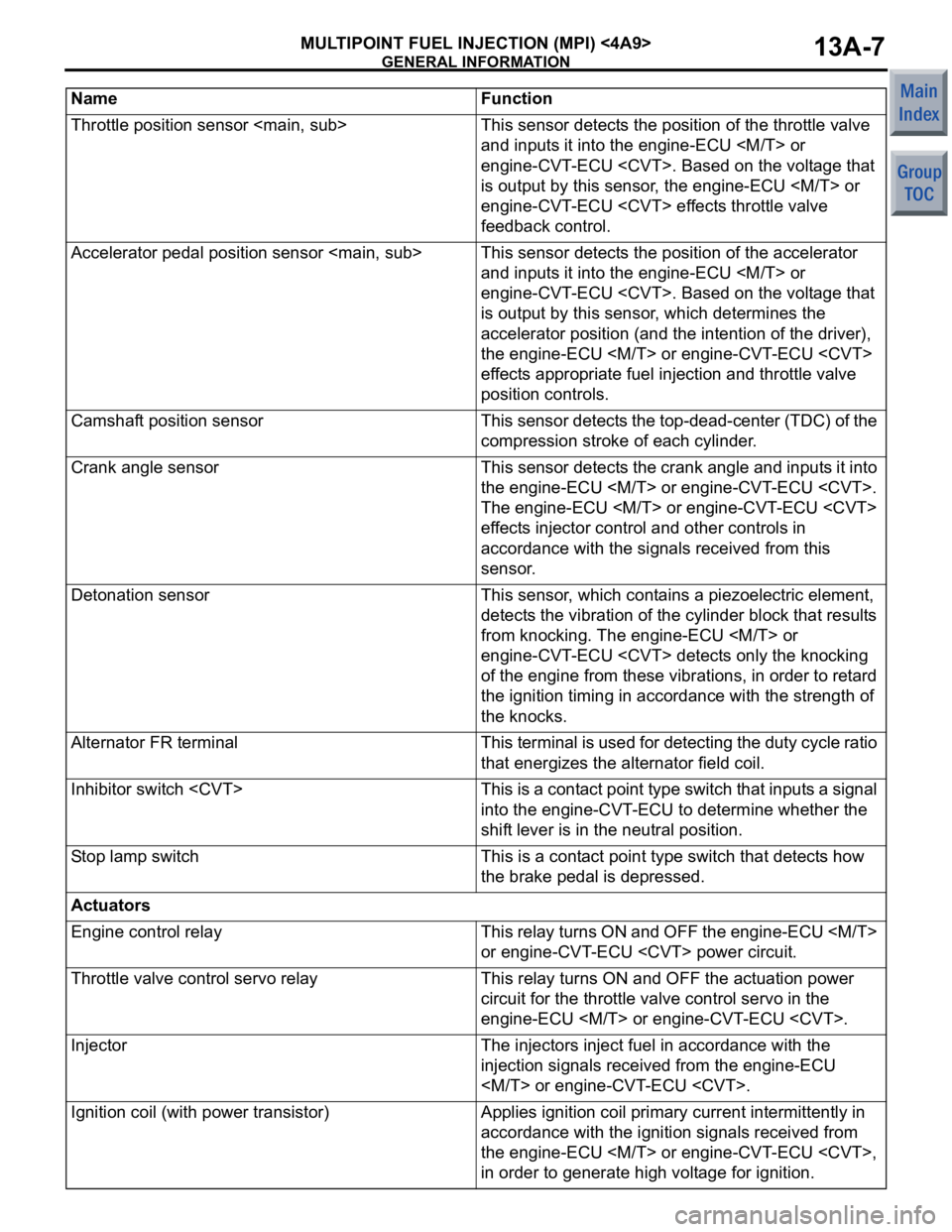

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-7

Throttle position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, the engine-ECU

engine-CVT-ECU

feedback control.

Accelerator pedal position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, which determines the

accelerator position (and the intention of the driver),

the engine-ECU

effects appropriate fuel injection and throttle valve

position controls.

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU

The engine-ECU

effects injector control and other controls in

accordance with the signals received from this

sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU

engine-CVT-ECU

of the engine from these vibrations, in order to retard

the ignition timing in accordance with the strength of

the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Inhibitor switch

into the engine-CVT-ECU to determine whether the

shift lever is in the neutral position.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU

or engine-CVT-ECU

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU

in order to generate high voltage for ignition.

Name Function

Page 119 of 364

GENERAL INFORMATION

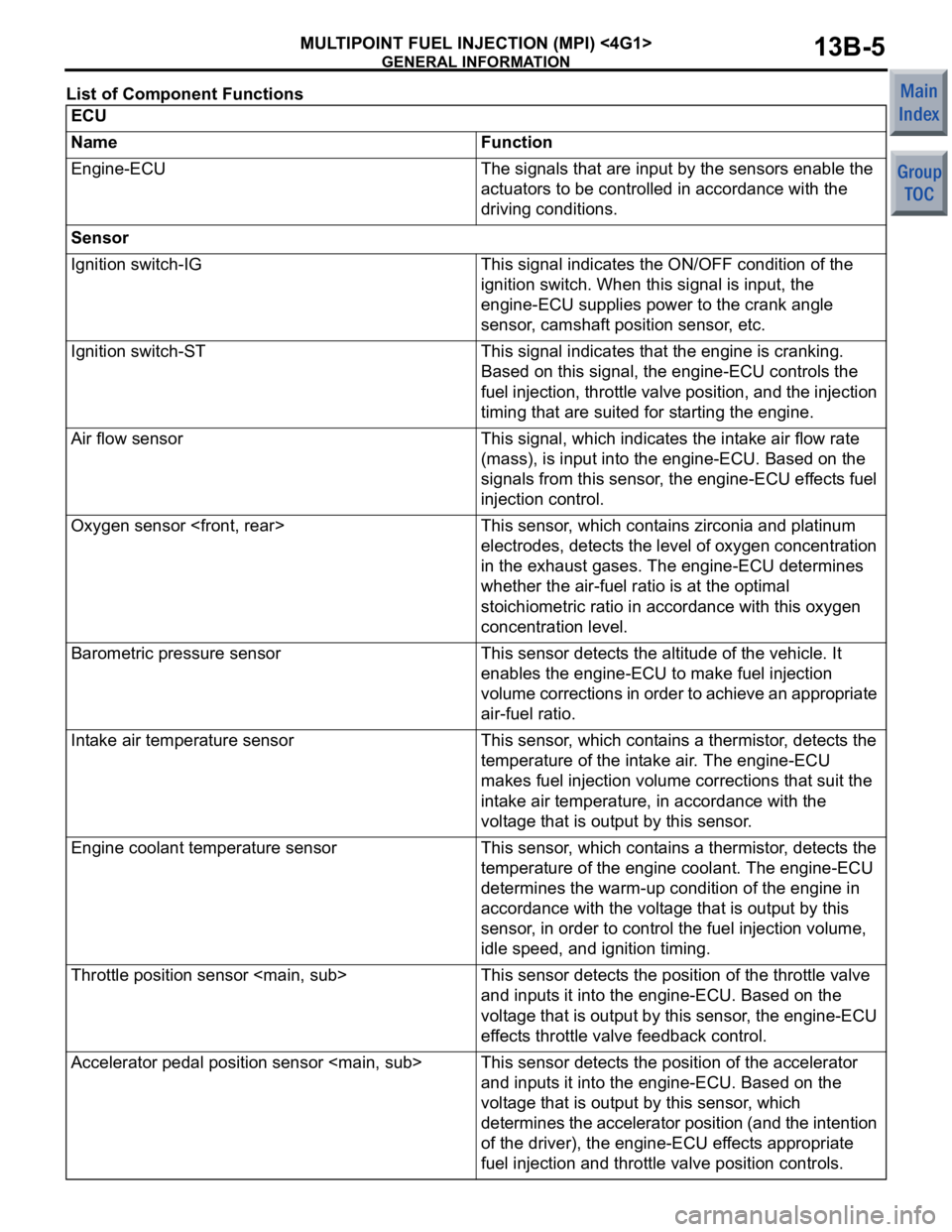

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-5

List of Component Functions

ECU

NameFunction

Engine-ECUThe signals that are input by the sensors enable the

actuators to be controlled in accordance with the

driving conditions.

Sensor

Ignition switch-IGThis signal indicates the ON/OFF condition of the

ignition switch. When this signal is input, the

engine-ECU supplies power to the crank angle

sensor, camshaft position sensor, etc.

Ignition switch-STThis signal indicates that the engine is cranking.

Based on this signal, the engine-ECU controls the

fuel injection, throttle valve position, and the injection

timing that are suited for starting the engine.

Air flow sensor This signal, which indicates the intake air flow rate

(mass), is input into the engine-ECU. Based on the

signals from this sensor, the engine-ECU effects fuel

injection control.

Oxygen sensor

electrodes, detects the level of oxygen concentration

in the exhaust gases. The engine-ECU determines

whether the air-fuel ratio is at the optimal

stoichiometric ratio in accordance with this oxygen

concentration level.

Barometric pressure sensorThis sensor detects the altitude of the vehicle. It

enables the engine-ECU to make fuel injection

volume corrections in order to achieve an appropriate

air-fuel ratio.

Intake air temperature sensorThis sensor, which contains a thermistor, detects the

temperature of the intake air. The engine-ECU

makes fuel injection volume corrections that suit the

intake air temperature, in accordance with the

voltage that is output by this sensor.

Engine coolant temperature sensorThis sensor, which contains a thermistor, detects the

temperature of the engine coolant. The engine-ECU

determines the warm-up condition of the engine in

accordance with the voltage that is output by this

sensor, in order to control the fuel injection volume,

idle speed, and ignition timing.

Throttle position sensor

and inputs it into the engine-ECU. Based on the

voltage that is output by this sensor, the engine-ECU

effects throttle valve feedback control.

Accelerator pedal position sensor

and inputs it into the engine-ECU. Based on the

voltage that is output by this sensor, which

determines the accelerator position (and the intention

of the driver), the engine-ECU effects appropriate

fuel injection and throttle valve position controls.

Page 211 of 364

TECHNICAL FEATURES

GENERAL00-26

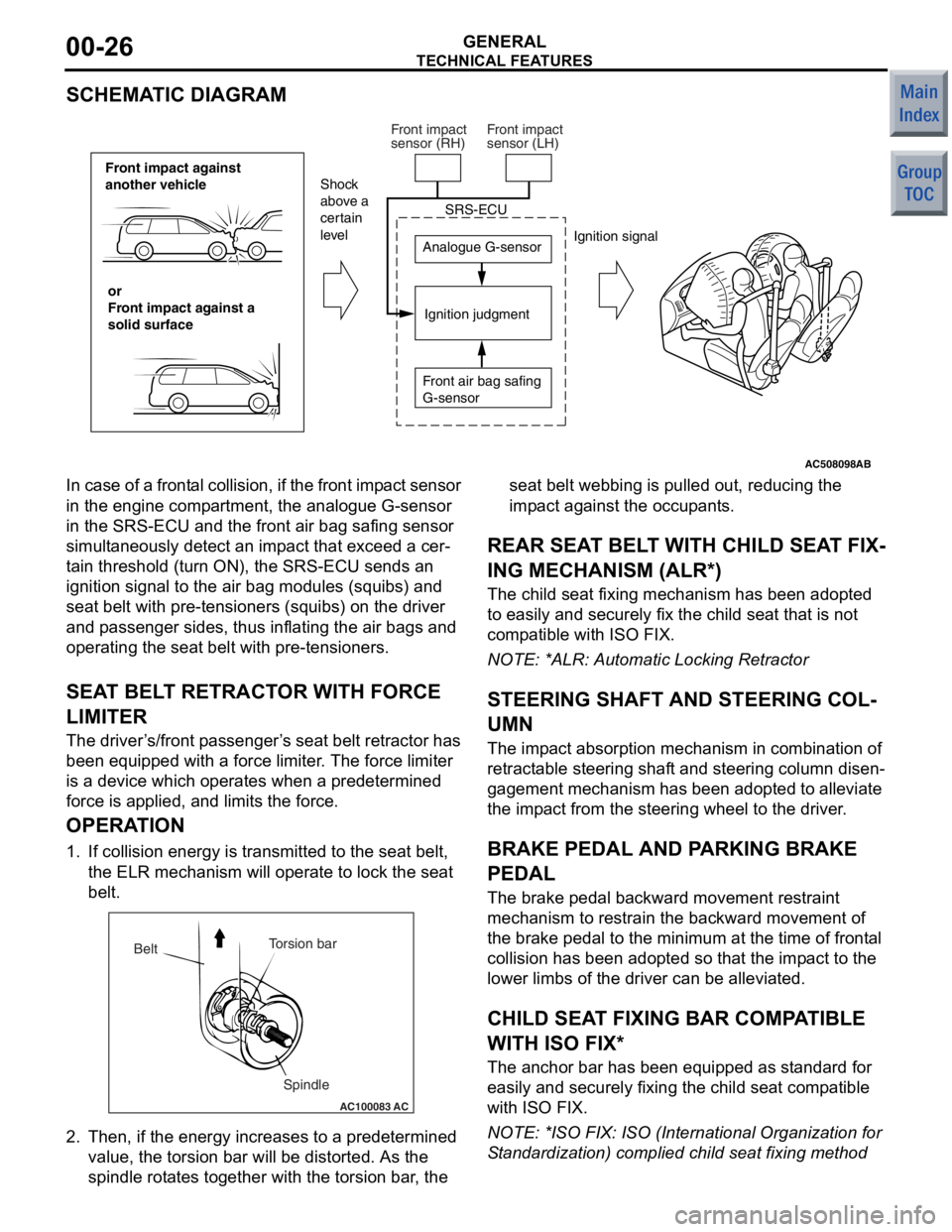

SCHEMATIC DIAGRAM

AC508098

Front impact against

another vehicleor

Front impact against a

solid surface Analogue G-sensor

Ignition judgment

Shock

above a

certain

level

Ignition signal

SRS-ECU

Front air bag safing

G-sensor

Front impact

sensor (RH)

Front impact

sensor (LH)

AB

In case of a

frontal collision, if the front imp act sensor

in the engine comp artment, the analogue G-sensor

in the SRS-ECU and t he front air bag safing sensor

simult aneously de tect an imp act th at excee d a cer

-

ta in threshold (turn ON), the SRS-ECU sen ds an

ignition signal to the air bag modules (squ ibs) and

seat belt with pre-te nsioners (squibs) on the driver

and p asseng er sides, thus inflating the air bag s and

operating the seat belt with pre -tensioner s.

SEAT BEL T RETRACT OR WITH FORCE

LIMITE R

The driver ’s /front p asseng er’s seat belt retractor has

been e quipped with a force limit er. The force limiter

is a device which operat es when a predetermined

force is applied, an d limits the for ce.

OPERA TION

1. If collision energy is transmit ted to the seat belt,

th e ELR mechanism will oper ate to lock the seat

be lt.

AC100083

Torsion bar

Spindle

Belt

AC

2.

Then, if the en ergy increase s to a prede termined

value , the to rsion bar will b e distorted . As th e

spind le rot ate s tog ether with the t orsion bar , the seat b

elt webb ing is p ulle d out, reducing th e

imp act against t he occupants.

REAR SEA T BELT WITH CHILD SEA T FIX-

ING MECHANISM (ALR*)

The child seat fixing mechanism h as b een ad opted

to easily and securely fix the child seat that is not

comp atible with ISO FIX.

NO TE: *ALR: Automatic Lockin g Retractor

STEERING SHAFT AND STEERING COL-

UMN

The impact ab sorption mech anism in combin ation of

retract able steerin g shaft and steering co lumn disen

-

gagement mecha nism has been ad opted t o alle viate

the imp act from th e steering wheel to the d rive r.

BRAKE PEDAL AND PA RKING BRAKE

PEDAL

The bra ke pe dal b ackward mo vement restraint

mechanism to restrain the backward movement of

the brake p edal to the minimum at the time o f f ront al

collision h as b een ad opted so that the impact to th e

lower limb s of the driver can be alleviated.

CHILD SEAT FIXING BAR COMP ATIBLE

WITH ISO FIX*

The an chor bar has been equipped a s st andard fo r

easily and secu rely fixing the child seat comp atible

with ISO FIX.

NO TE: *ISO F IX: ISO (In ternational Orga nization for

S tand ardizatio n) complied child se at fixing method

Page 221 of 364

GENERAL INFORMATION

FRONT AXLE26-2

GENERAL INFORMATION

M2260000100701

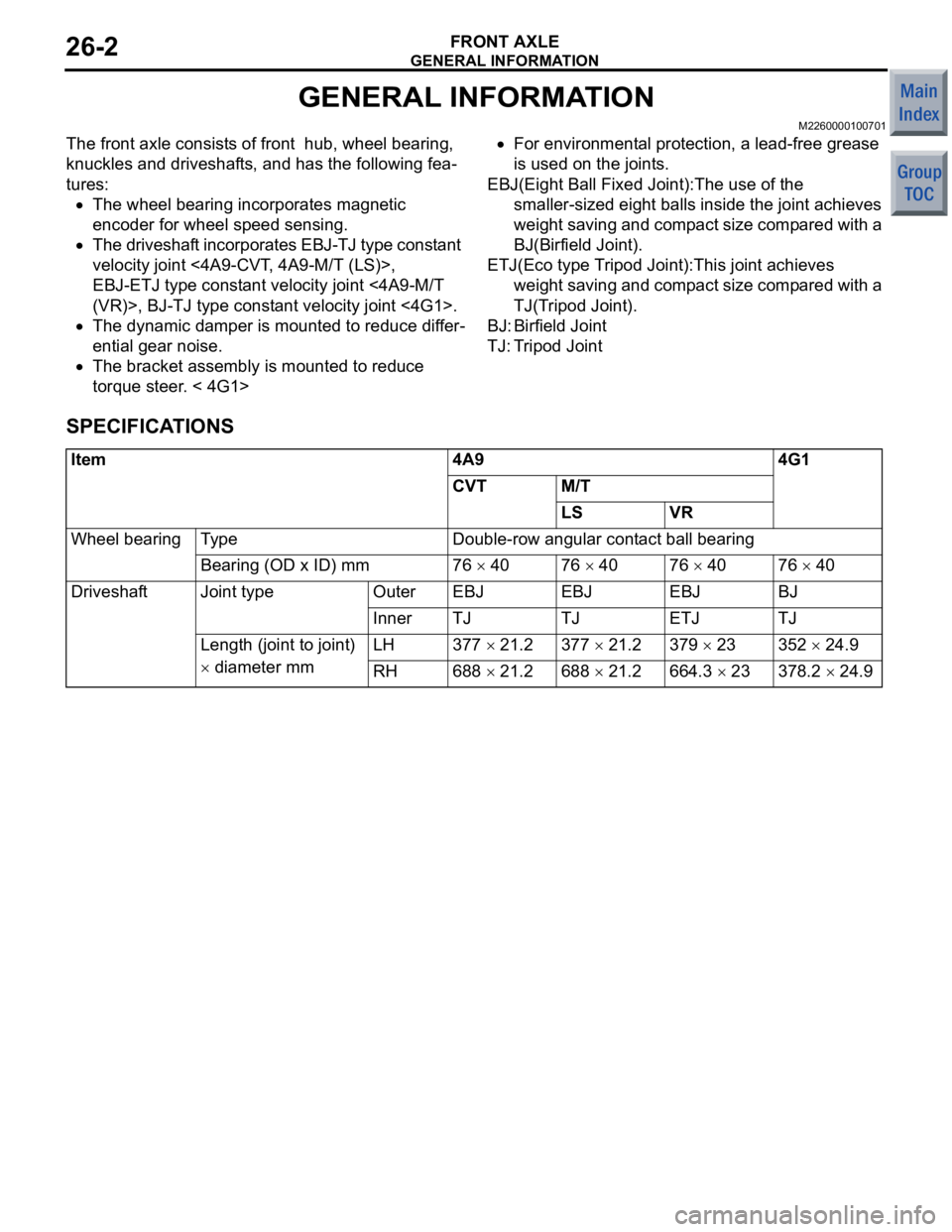

The front axle consists of front hub, wheel bearing,

knuckles and driveshafts, and has the following fea

-

tures:

•The wheel bearing incorporates magnetic

encoder for wheel speed sensing.

•The driveshaft incorporates EBJ-TJ type constant

velocity joint <4A9-CVT, 4A9-M/T (LS)>,

EBJ-ETJ type constant velocity joint <4A9-M/T

(VR)>, BJ-TJ type constant velocity joint <4G1>.

•The dynamic damper is mounted to reduce differ-

ential gear noise.

•The bracket assembly is mounted to reduce

torque steer. < 4G1>

•For environmental protection, a lead-free grease

is used on the joints.

EBJ(Eight Ball Fixed Joint):The use of the

smaller-sized eight balls inside the joint achieves

weight saving and compact size compared with a

BJ(Birfield Joint).

ETJ(Eco type Tripod Joint):This joint achieves

weight saving and compact size compared with a

TJ(Tripod Joint).

BJ:Birfield Joint

TJ:Tripod Joint

SPECIFICATIONS

Item4A94G1

CVTM/T

LSVR

Wheel bearingTy p eDouble-row angular contact ball bearing

Bearing (OD x ID) mm76 × 4076 × 4076 × 4076 × 40

DriveshaftJoint typeOuterEBJEBJEBJBJ

InnerTJTJETJTJ

Length (joint to joint)

× diameter mm

LH377 × 21.2377 × 21.2379 × 23352 × 24.9

RH688 × 21.2688 × 21.2664.3 × 23378.2 × 24.9