pump MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 6 of 364

CONSTRUCTION DESCRIPTION

ANTI-SKID BRAKE SYSTEM (ABS)35B-6

CONSTRUCTION DESCRIPTION

SENSORSM2351001000427

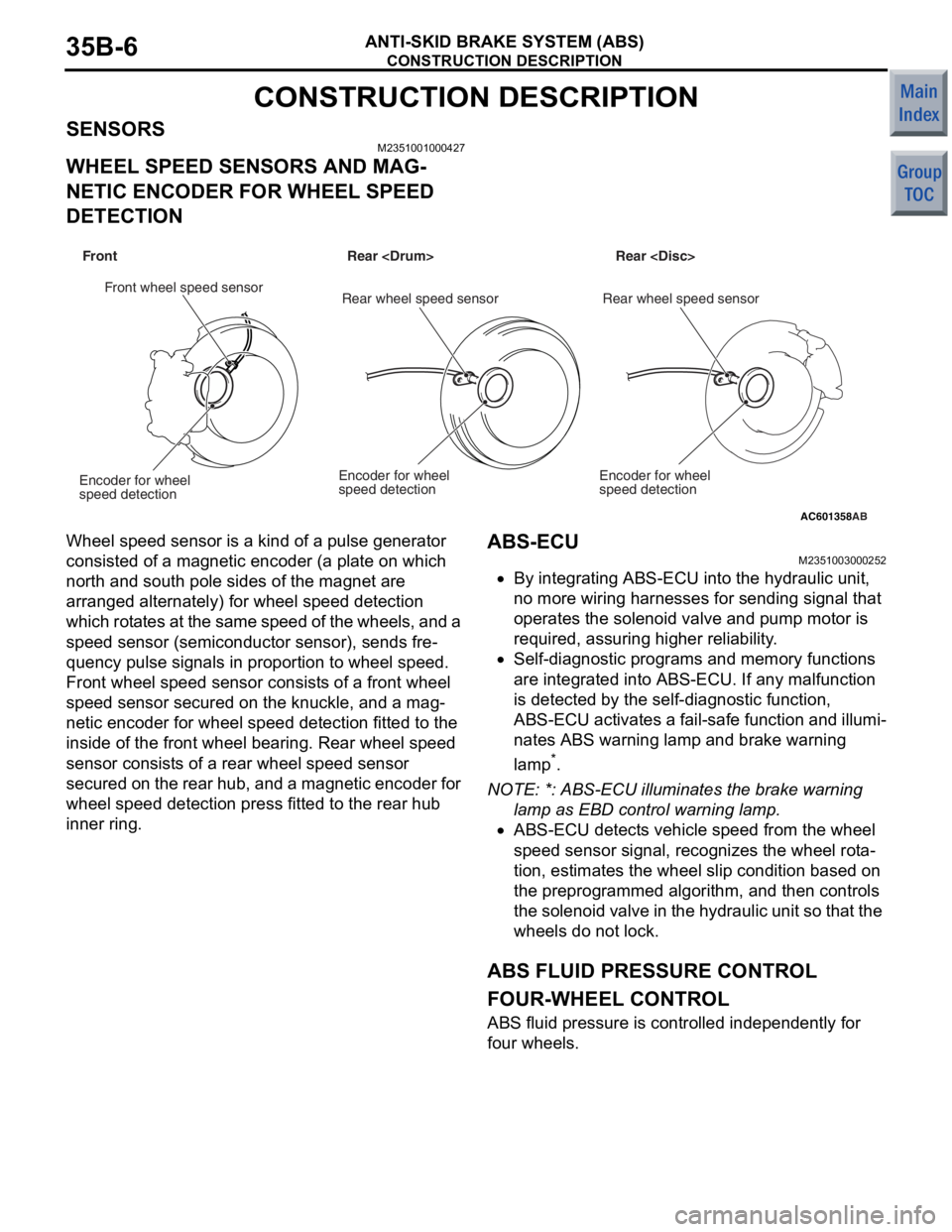

WHEEL SPEED SENSORS AND MAG-

NETIC ENCODER FOR WHEEL SPEED

DETECTION

AC601358

Rear wheel speed sensor

Front wheel speed sensor

Front Rear

Encoder for wheel

speed detection Encoder for wheel

speed detectionRear wheel speed sensor

Encoder for wheel

speed detection

AB

Wheel spee d se nsor is a kin d of a pulse gen erator

consisted of

a mag netic encoder (a pla t e on which

north an

d so uth po le sides of th e mag net are

arrange

d alte rnately) for wh eel speed detection

which rot

a tes at the same speed of the wheels, and a

spee

d sen s or (semicon duct o r se nsor), send s fre

-

quency pulse sig nals in proportion to wh eel spee d.

Front wheel sp eed sensor co nsist s of a front whe e l

spee

d sen s or secu red on the knuckle, and a mag

-

netic encoder for wheel spee d dete c tio n fitt ed to th e

inside o

f the fro n t wheel bearing. Rear wh eel speed

sensor consist

s o f a rear wh eel speed sensor

secured on

the re ar hub, and a magn etic encoder fo r

whe

e l speed detection press fit t ed to the rear hub

inner ring.

ABS-ECU

M23510030 0025 2

•By integrating ABS-ECU into the hydraulic unit ,

no

more wiring h a rnesses for sending signal that

ope

rates the solen o id valve an d pump mo tor is

requ

ired, assuring high er reliability .

•Self-diag nostic p r ograms an d memory functions

are

integrated into ABS-ECU. If any malfunction

is dete

c ted by th e se lf-diagnostic function,

ABS-ECU activates

a fail-s afe function and illumi

-

nates ABS warning lamp and brake warning

la

mp

*.

NO TE: *: ABS-E CU illuminates the brake warning

l

a

m

p as EBD c o nt ro l wa rn in g la m p .

•ABS-ECU detects vehicle speed from the wheel

speed sensor signal, reco

gnizes the whee l rot a

-

tion, estimates the wheel slip condition based on

the

preprog rammed algorithm, a nd the n co ntrols

th

e soleno id valve in the hydr aulic u n it so th at the

wheels d

o not lock.

ABS FLUID PRESSURE CONTROL

FOUR-WHEEL CONTROL

ABS fluid pressure is controlled indep enden tly for

four whee

ls.

Page 7 of 364

CONSTRUCTION DESCRIPTION

ANTI-SKID BRAKE SYSTEM (ABS)35B-7

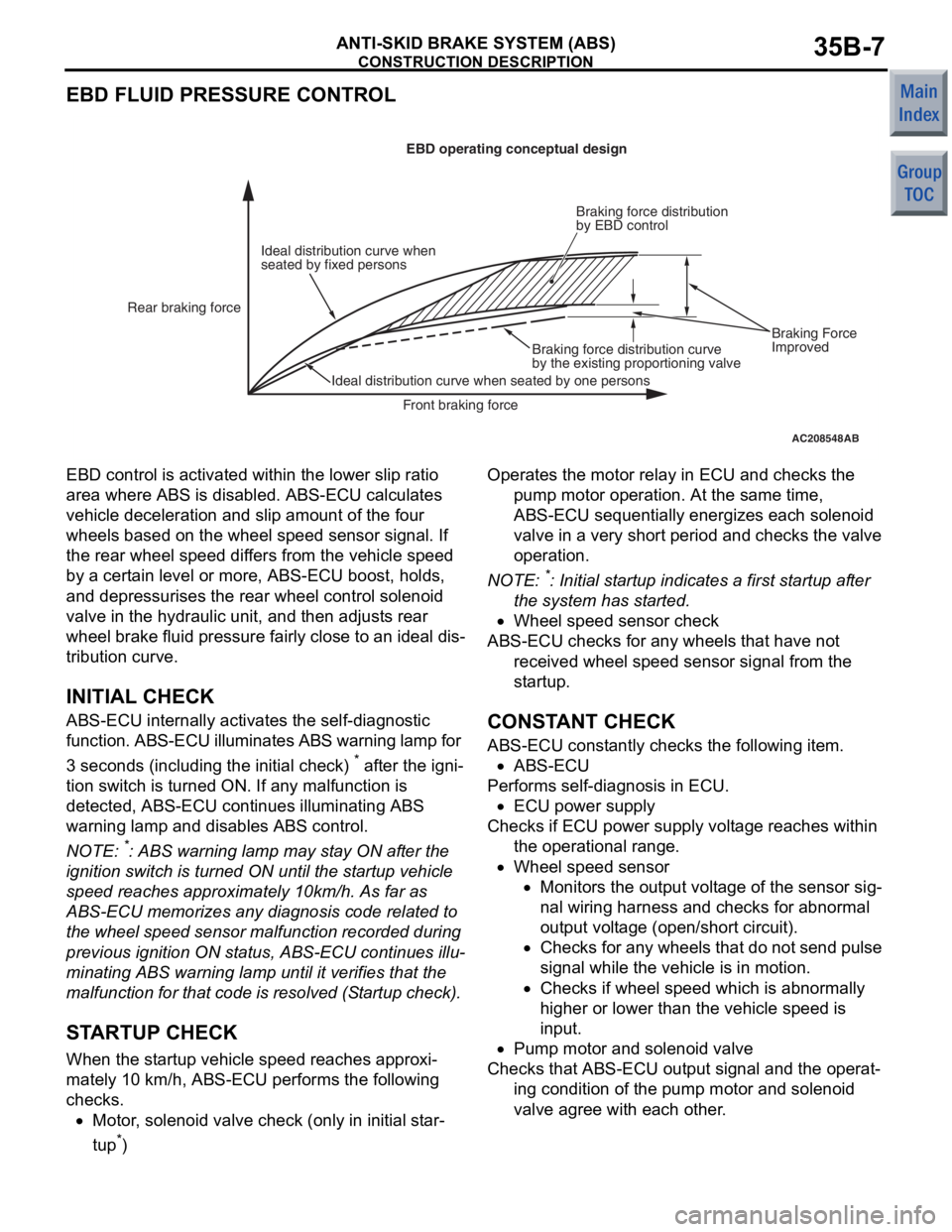

EBD FLUID PRESSURE CONTROL

AC208548AB

Ideal distribution curve when

seated by fixed personsEBD operating conceptual design

Rear braking force

Ideal distribution curve when seated by one persons Braking force distribution curve

by the existing proportioning valveBraking force distribution

by EBD control

Front braking force

Braking Force

Improved

EBD control is

activate d within the lower slip ratio

area where

ABS is disab l ed. ABS-ECU calculates

vehicle

decelera t ion a nd slip amou nt of th e four

whe

e ls based on the wheel sp eed senso r signal. If

the rear

wh eel speed dif f ers f r om th e ve hicle speed

by a

cert ain level or more, ABS-ECU boost, holds,

and de

pressurises the rea r wh eel contro l so leno id

valve in the h

y drau lic unit, and then a d just s rear

whe

e l b r ake fluid pressure fa ir ly close to an ideal dis

-

tribution curve.

INITIAL CHECK

ABS-ECU inter nally activates the self-d iagno stic

function. ABS-ECU illuminates

ABS warning l a mp for

3 seconds (in

c lu ding the in itia l check)

* after th e ign i-

tion switch is turned ON. If a n y malf unction is

detected, ABS-ECU cont

inues illuminating ABS

war

n ing lamp and disables ABS cont rol.

NOTE: *: ABS warning lamp may st ay ON af ter the

ignition

switch is turned ON un til t he st artu p ve hicle

spee

d reaches approximately 10km/h . As far as

ABS-ECU memorizes any d i agn osis code related t o

the

whee l speed sen s or malfunct i on record ed d u ring

previous ignition ON st atus, ABS-ECU continues illu

-

mina ting ABS warn ing lamp until it verif i es that th e

malfunct

i on for tha t co de is resolved (S t a rtup che ck).

STARTUP CHECK

When th e st artup veh i cle sp eed re ache s app roxi-

mately 10 km/h, ABS-ECU performs the following

checks.

•Motor, solen o id valve check (onl y i n ini t ial st ar-

tup*)

Operat es the motor relay in ECU and checks the

pump motor op eratio n. At the same time,

ABS-ECU sequentially e nergizes each solenoid

valve in a ve ry sh ort perio d and ch ecks the valve

ope ration .

NOTE: *: Initia l st artu p ind i ca tes a first st artup af ter

the

system has st arted .

•Whee l speed sensor check

ABS-ECU che cks for a n y whee ls that ha ve no t

received whee l sp eed sens or signal from the

st artu p.

CONSTANT CHECK

ABS-ECU con s t antly ch ecks th e following item.

•ABS-ECU

Performs se lf-diagnosis in ECU.

•ECU power supply

Checks if ECU po we r sup p ly volt ag e reaches within

the operat ional range .

•Whee l speed sensor

•Monitors the ou tput volt age of the sensor sig-

nal wiring ha rness an d che c ks for a bnormal

output

volt ag e (ope n/sho r t circuit).

•Checks fo r any wheels tha t do n o t send pu lse

sig

nal while th e ve hicle is in motion.

•Checks if wheel spee d which is abno rmally

high

er or lo we r than the vehicle speed is

inpu

t.

•Pump mo tor and solenoid valve

Checks tha t ABS-ECU outp u t signal and t he ope rat-

ing co ndition of the pump motor an d so leno id

valve agree

with ea ch ot her .

Page 11 of 364

CONSTRUCTION DESCRIPTION

ANTI-SKID BRAKE SYSTEM (ABS)35B-11

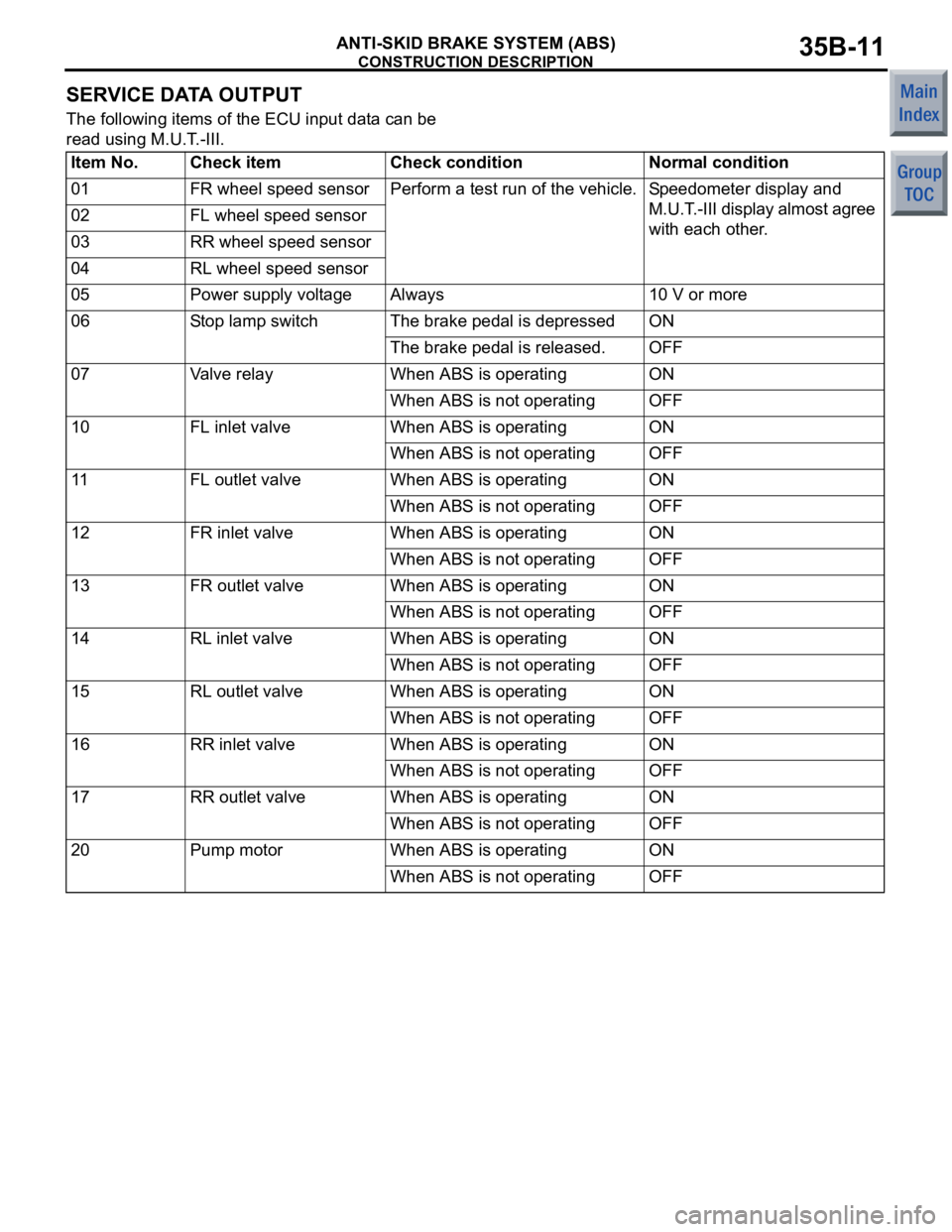

SERVICE DATA OUTPUT

The following items of the ECU input data can be

read using M.U.T.-III.

Item No.Check itemCheck conditionNormal condition

01FR wheel speed sensorPerform a test run of the vehicle.Speedometer display and

M.U.T.-III display almost agree

with each other.

02FL wheel speed sensor

03RR wheel speed sensor

04RL wheel speed sensor

05Power supply voltageAlways10 V or more

06Stop lamp switchThe brake pedal is depressedON

The brake pedal is released.OFF

07Va l v e r e l a yWhen ABS is operatingON

When ABS is not operatingOFF

10FL inlet valve When ABS is operatingON

When ABS is not operatingOFF

11FL outlet valve When ABS is operatingON

When ABS is not operatingOFF

12FR inlet valve When ABS is operatingON

When ABS is not operatingOFF

13FR outlet valve When ABS is operatingON

When ABS is not operatingOFF

14RL inlet valve When ABS is operatingON

When ABS is not operatingOFF

15RL outlet valve When ABS is operatingON

When ABS is not operatingOFF

16RR inlet valve When ABS is operatingON

When ABS is not operatingOFF

17RR outlet valve When ABS is operatingON

When ABS is not operatingOFF

20Pump motorWhen ABS is operatingON

When ABS is not operatingOFF

Page 12 of 364

CONSTRUCTION DESCRIPTION

ANTI-SKID BRAKE SYSTEM (ABS)35B-12

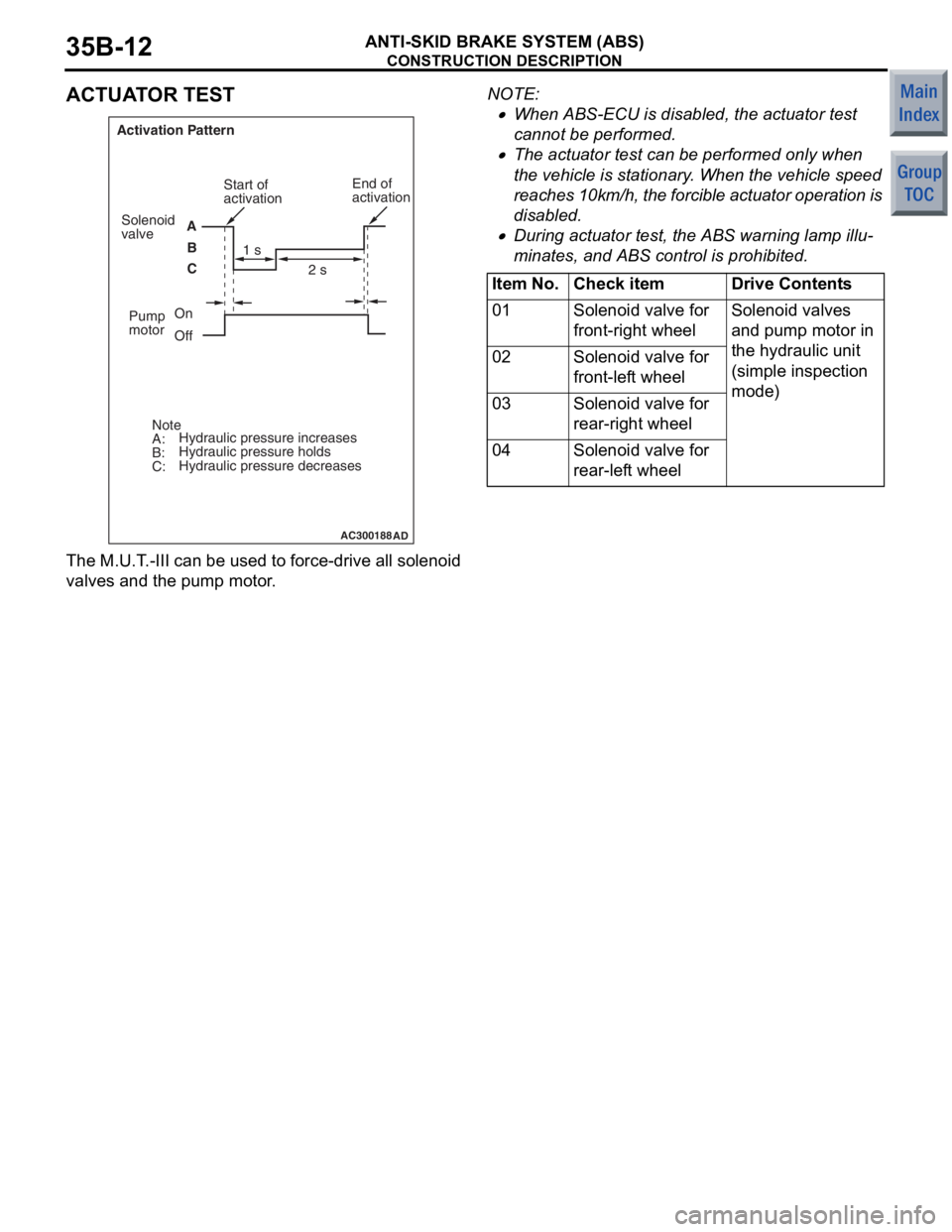

ACTUATOR TEST

AC300188AD

Activation PatternAB

C Start of

activation

1 s 2 s

On

Off

Note

A:

B:

C: Hydraulic pressure increases

Hydraulic pressure holds

Hydraulic pressure decreases End of

activation

Solenoid

valve

Pump

motor

The M.U.T . -III can be u s ed to force-drive a ll sole noid

valves and th

e pump mo tor .

NOTE: .

•Whe n ABS-ECU is disabled, the actu ator te st

cannot b

e perfo rmed.

•The actu ator test can be p e rformed on ly whe n

the

veh i cle is st a t iona ry . Whe n the ve hicle speed

rea

c h e s 10km/h, the f o rcible a c t uator operation is

disabled.

•During actuator test, the ABS warning lamp illu-

minates , an d ABS contro l is proh ibit ed.

Item No.Check itemDrive Contents

01Solenoid valve for

front-right wheelSolenoid valves

and pump motor in

the hydraulic unit

(simple inspection

mode)

02Solenoid valve for

front-left wheel

03Solenoid valve for

rear-right wheel

04Solenoid valve for

rear-left wheel

Page 57 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-9

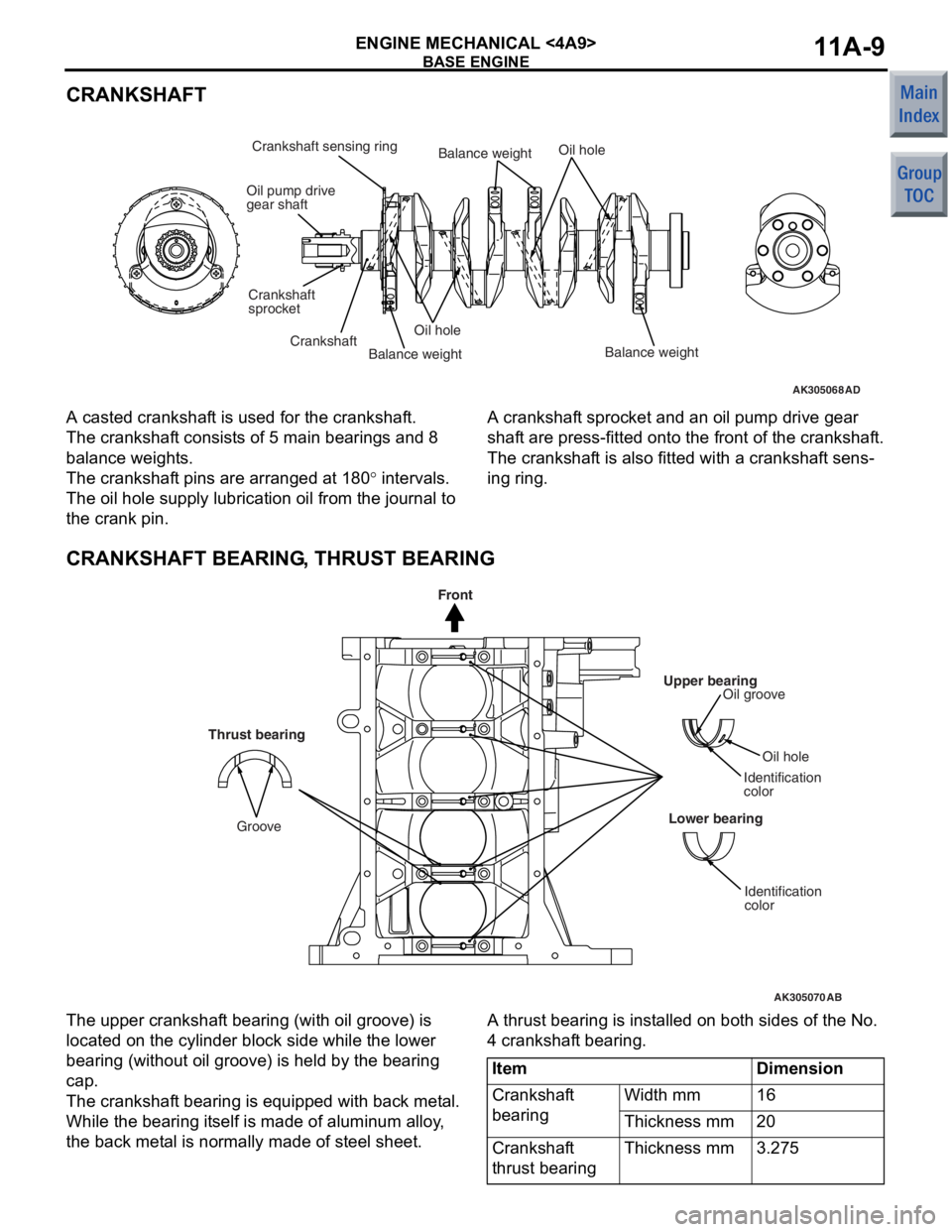

CRANKSHAFT

AK305068AD

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft sensing ring

CrankshaftOil hole

Oil hole

Balance weightBalance weightBalance weight

A casted crankshaf

t is used for t he cr ankshaf t.

The crankshaft consist s o f 5 ma in be aring s an d 8

balan

ce weight s.

The crankshaft pins a r e arrang ed at 1 8 0° inte rval s.

The oil hole supply lu brication oil from t he jo urnal to

the crank p

i n.

A cranksha f t sprocket and an oil pump drive gea r

shaf

t are press-fit t ed on to the f r ont of the crankshaf t.

The crankshaft is also fitt ed with a crankshaf t sens-

ing ring.

CRANKSHAFT BEARING, THRUST BEARING

AK305070

Upper bearingOil groove

Oil hole

Identification

color

Lower bearing

Identification

color

AB

Thrust bearing

Groove

Front

The upp er cra n kshaf t bea ring (with oil groove) is

loca

ted on the cylinder block side wh ile the lo we r

bearin

g (witho ut oil groo ve) is he ld by the b earin g

cap.

The crankshaft bea ring is e quipp ed with back me t a l.

While the b

earin g it self is ma de of a l uminum alloy ,

the back met

a l is no rmally made of steel sheet .

A thrust bearing is inst alle d on b o th sides of th e No.

4 cran

kshaf t bearing.

ItemDimension

Crankshaft

bearingWidth mm16

Thickness mm20

Crankshaft

thrust bearingThickness mm3.275

Page 58 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-10

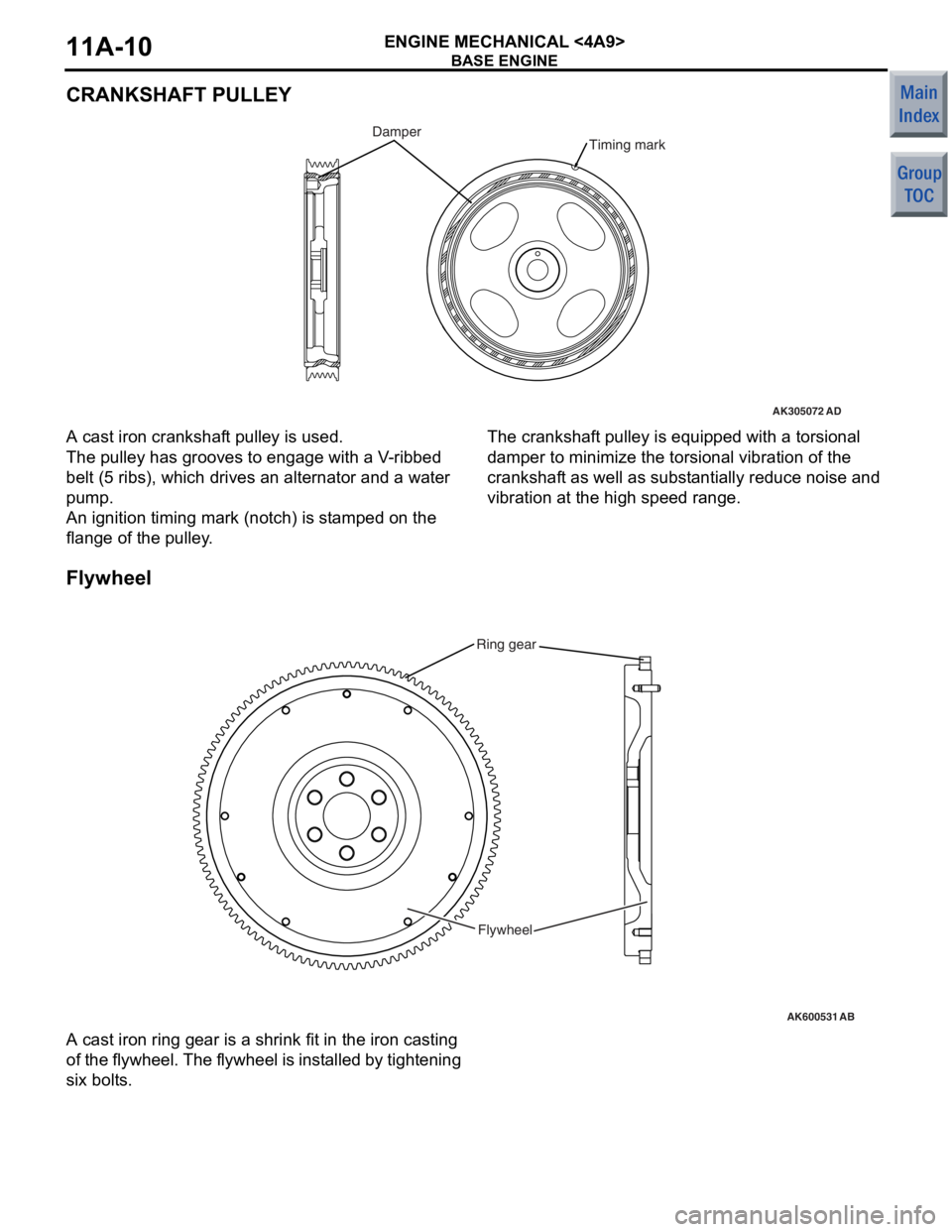

CRANKSHAFT PULLEY

AK305072AD

Timing markDamper

A cast iron cranksh af t pulley is used.

The pulley has grooves to eng age with a V -rib bed

belt (5

ribs), which drives an alternat or and a water

pump

.

An ignition timing mark (notch) is st amp ed on the

flang

e of the pulley .

The crankshaft pulley is equipped with a to rsio nal

damp

e r to minimize the torsional vibratio n of th e

cranksha

f t as well as sub s t antia lly redu ce no ise and

vib

r ation at the high spee d rang e.

Flyw he el

AK600531

Ring gear

Flywheel

AB

A cast iron ring g ear is a shrink fit in th e iron casting

of

t h e f l yw he el. T h e f l yw he el is in st a l le d by tigh t e n i n g

six bolt

s .

Page 64 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-16

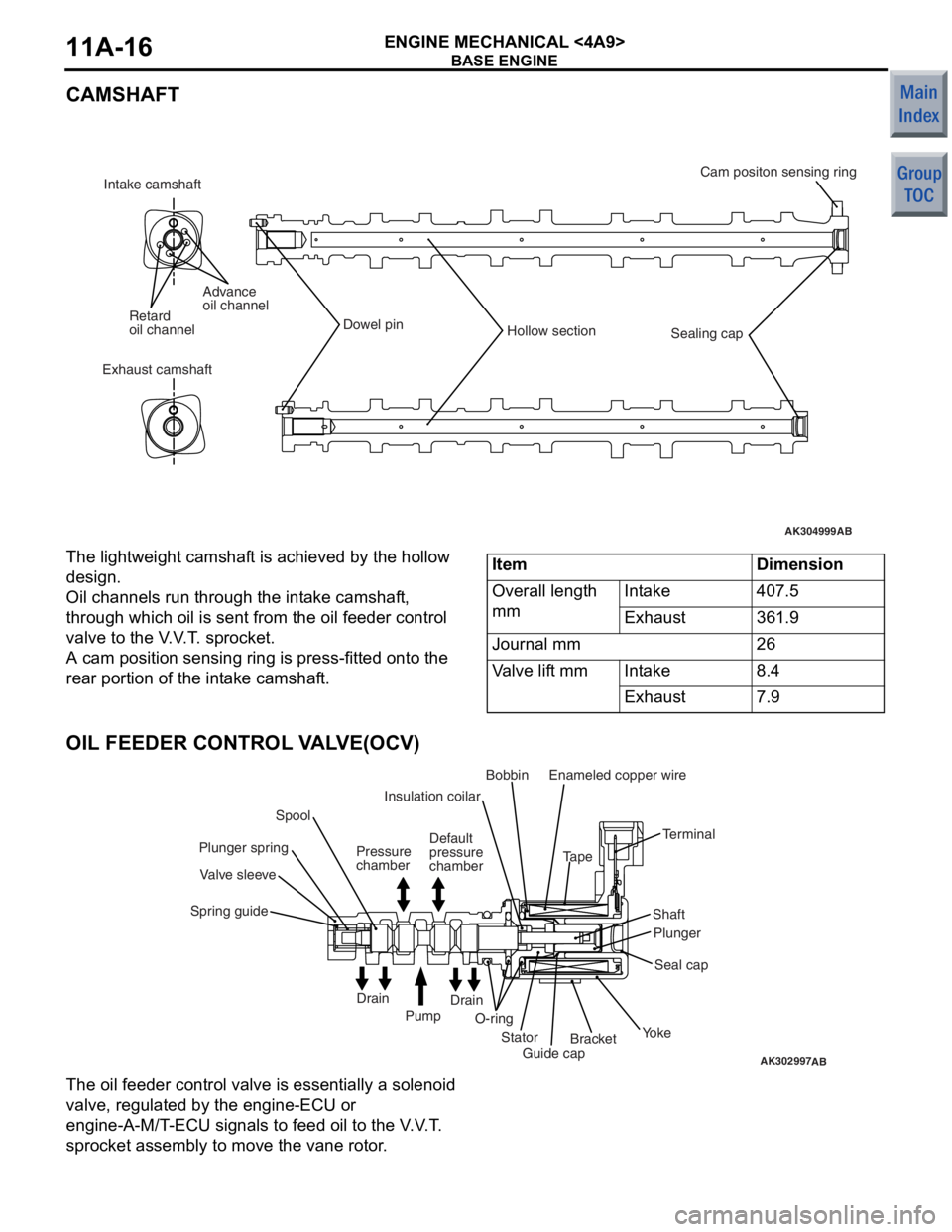

CAMSHAFT

AK304999

Intake camshaft

Exhaust camshaft

AB

Hollow section

Advance

oil channel

Retard

oil channel

Cam positon sensing ring

Dowel pinSealing cap

The lightweight camshaf t is ach i eved by the h o llo w

design.

Oil channels run through the int a ke camshaf t,

through

wh ich oil is sent from t he oil fee der co ntrol

valve to

the V . V . T . sprocket.

A cam position sen s in g ring is press-fitt ed onto the

rear port

i on o f the int a ke camshaf t.

ItemDimension

Overall length

mmIntake407.5

Exhaust361.9

Journal mm26

Valve lift mmIntake8.4

Exhaust7.9

OIL FEEDER CONT ROL V A L V E(OCV)

AK302997AB

Spring guideValve sleeve

Plunger spring Spool

O-ring

Insulation coilar

StatorGuide cap Bracket

Yo k eSeal cap

Plunger

Shaft Terminal

Bobbin

Tape

Enameled copper wire

Drain

Drain

Pump

Pressure

chamber

Default

pressure

chamber

The oil fee

der co ntrol valve is essen t ially a solenoid

valve, re

gulat ed by the en gine -ECU or

engin

e -A-M/T -ECU signals to feed o il to the V . V . T .

sprocket

assemb ly t o move the van e rotor .

Page 65 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-17

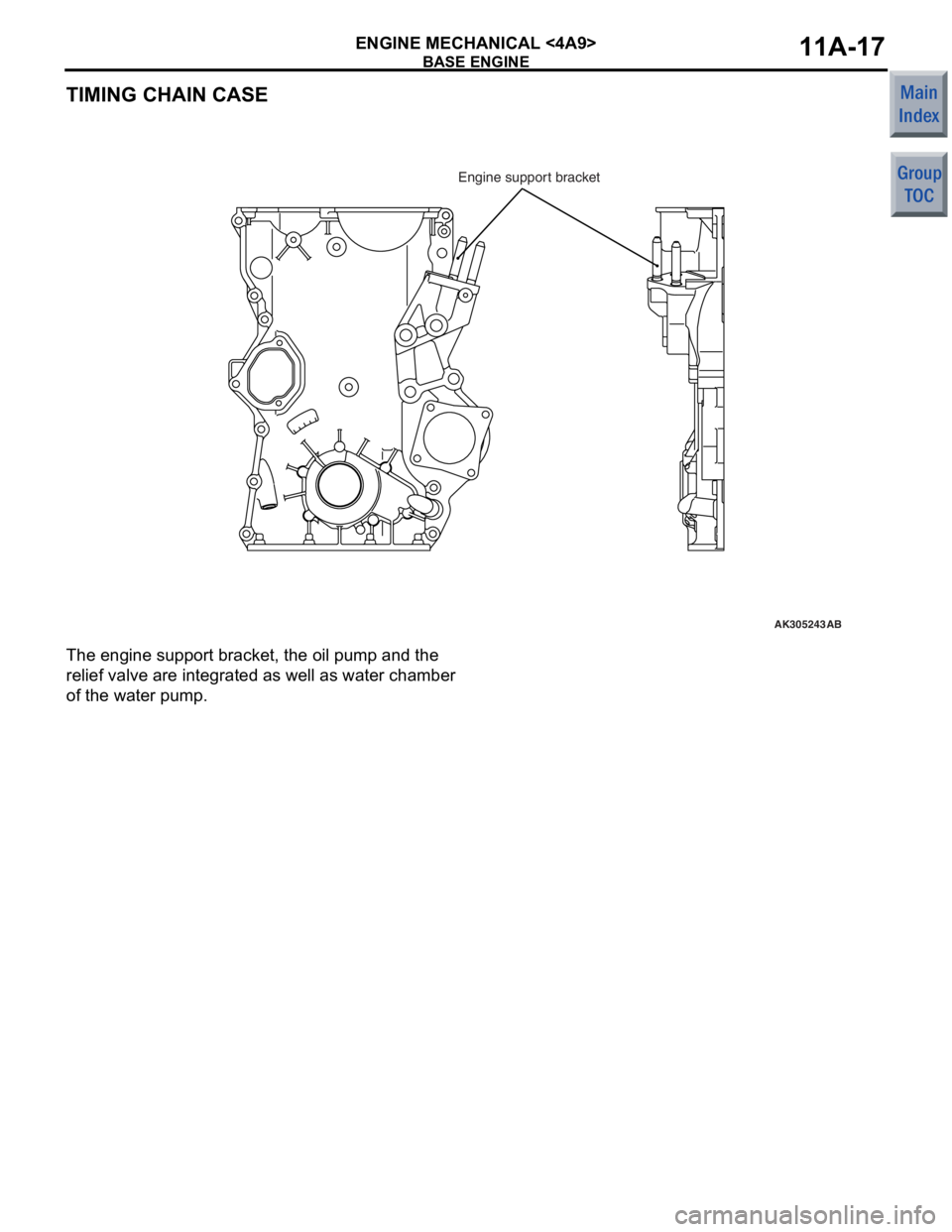

TIMING CHAIN CASE

AK305243

Engine support bracket

AB

The engine supp ort bracket, the oil pu mp a nd the

relie

f valve are in tegrate d as we ll as water chamber

of the wat

e r pump.

Page 73 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-25

CRANKSHAFT

AK305068AD

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft sensing ring

CrankshaftOil hole

Oil hole

Balance weightBalance weightBalance weight

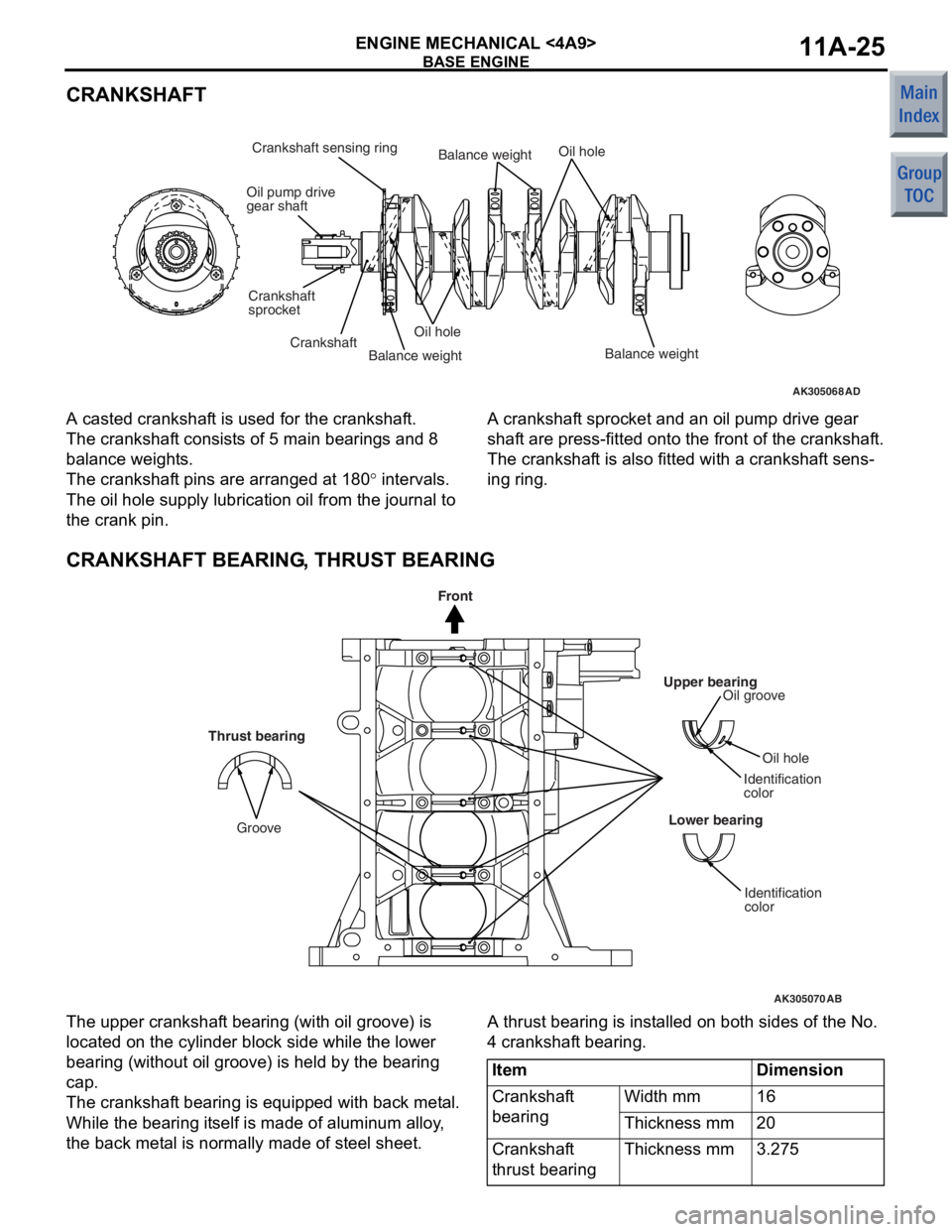

A casted crankshaf

t is used for t he cr ankshaf t.

The crankshaft consist s o f 5 ma in be aring s an d 8

balan

ce weight s.

The crankshaft pins a r e arrang ed at 1 8 0° inte rval s.

The oil hole supply lu brication oil from t he jo urnal to

the crank p

i n.

A cranksha f t sprocket and an oil pump drive gea r

shaf

t are press-fit t ed on to the f r ont of the crankshaf t.

The crankshaft is also fitt ed with a crankshaf t sens-

ing ring.

CRANKSHAFT BEARING, THRUST BEARING

AK305070

Upper bearingOil groove

Oil hole

Identification

color

Lower bearing

Identification

color

AB

Thrust bearing

Groove

Front

The upp er cra n kshaf t bea ring (with oil groove) is

loca

ted on the cylinder block side wh ile the lo we r

bearin

g (witho ut oil groo ve) is he ld by the b earin g

cap.

The crankshaft bea ring is e quipp ed with back me t a l.

While the b

earin g it self is ma de of a l uminum alloy ,

the back met

a l is no rmally made of steel sheet .

A thrust bearing is inst alle d on b o th sides of th e No.

4 cran

kshaf t bearing.

ItemDimension

Crankshaft

bearingWidth mm16

Thickness mm20

Crankshaft

thrust bearingThickness mm3.275

Page 74 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-26

CRANKSHAFT PULLEY

AK305072AD

Timing markDamper

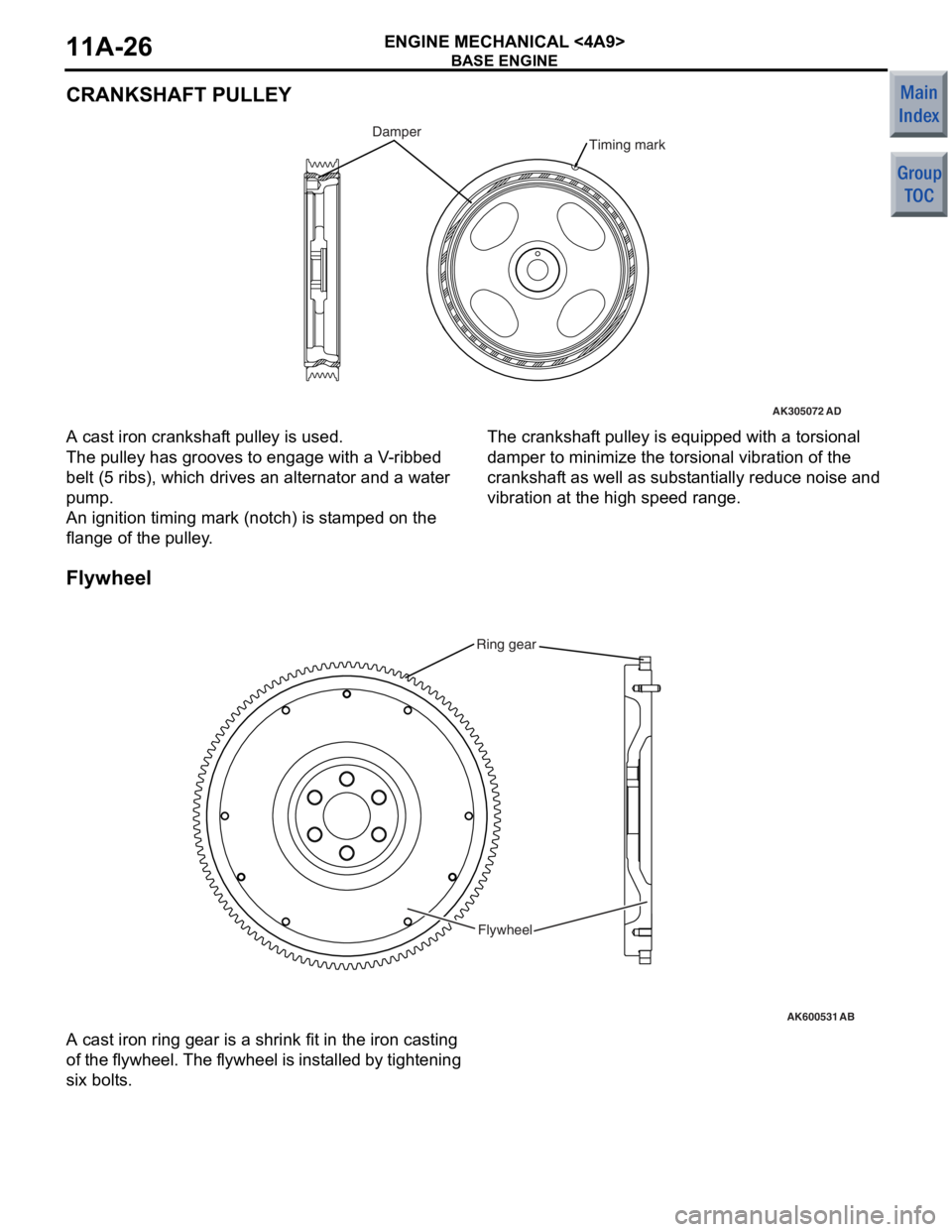

A cast iron cranksh af t pulley is used.

The pulley has grooves to eng age with a V -rib bed

belt (5

ribs), which drives an alternat or and a water

pump

.

An ignition timing mark (notch) is st amp ed on the

flang

e of the pulley .

The crankshaft pulley is equipped with a to rsio nal

damp

e r to minimize the torsional vibratio n of th e

cranksha

f t as well as sub s t antia lly redu ce no ise and

vib

r ation at the high spee d rang e.

Flyw he el

AK600531

Ring gear

Flywheel

AB

A cast iron ring g ear is a shrink fit in th e iron casting

of

t h e f l yw he el. T h e f l yw he el is in st a l le d by tigh t e n i n g

six bolt

s .