shift lever MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 101 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-7

Throttle position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, the engine-ECU

engine-CVT-ECU

feedback control.

Accelerator pedal position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, which determines the

accelerator position (and the intention of the driver),

the engine-ECU

effects appropriate fuel injection and throttle valve

position controls.

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU

The engine-ECU

effects injector control and other controls in

accordance with the signals received from this

sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU

engine-CVT-ECU

of the engine from these vibrations, in order to retard

the ignition timing in accordance with the strength of

the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Inhibitor switch

into the engine-CVT-ECU to determine whether the

shift lever is in the neutral position.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU

or engine-CVT-ECU

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU

in order to generate high voltage for ignition.

Name Function

Page 155 of 364

DOOR

BODY42-12

DESCRIPTION OF STRUCTURE AND

OPERATION

CENTRAL DOOR LOCKING

•When the driver's door inner lock knob is oper-

ated to the lock position with all doors closed, all

the doors (including tailgate) will lock.

•The driver’s door can be opened by pulling the

driver’s door inner handle even when the driver’s

door inner lock knob is in the lock position. This

function is called "Override function". All doors

and tailgate can be unlocked at the same time

that the driver's door is opened.

KEY-IN PREVENTION FUNCTION

If the driver’s door remained open, it cannot be

locked even though the driver’s door key cylinder or

driver’s side inside lock knob is pushed. This pre

-

vents the ignition key from being left in the passenger

compartment.

"P" POSITION SHIFT LINKED

DOOR-UNLOCK FUNCTION

When the selector lever is shifted to the "P" (parking)

position, all the doors (including tailgate) will unlock,

improving passengers' conv enience during alighting.

Using an adjustment function*, "P" position shift

linked door-unlock function can be changed to

"Active", or "Inactive". The initial setting at factory is

"Inactive".

NOTE: *: "P" position shift linked door-unlock func-

tion can be changed as a customise function. Refer

to GROUP 54B, Customise Function

P.54B-25.

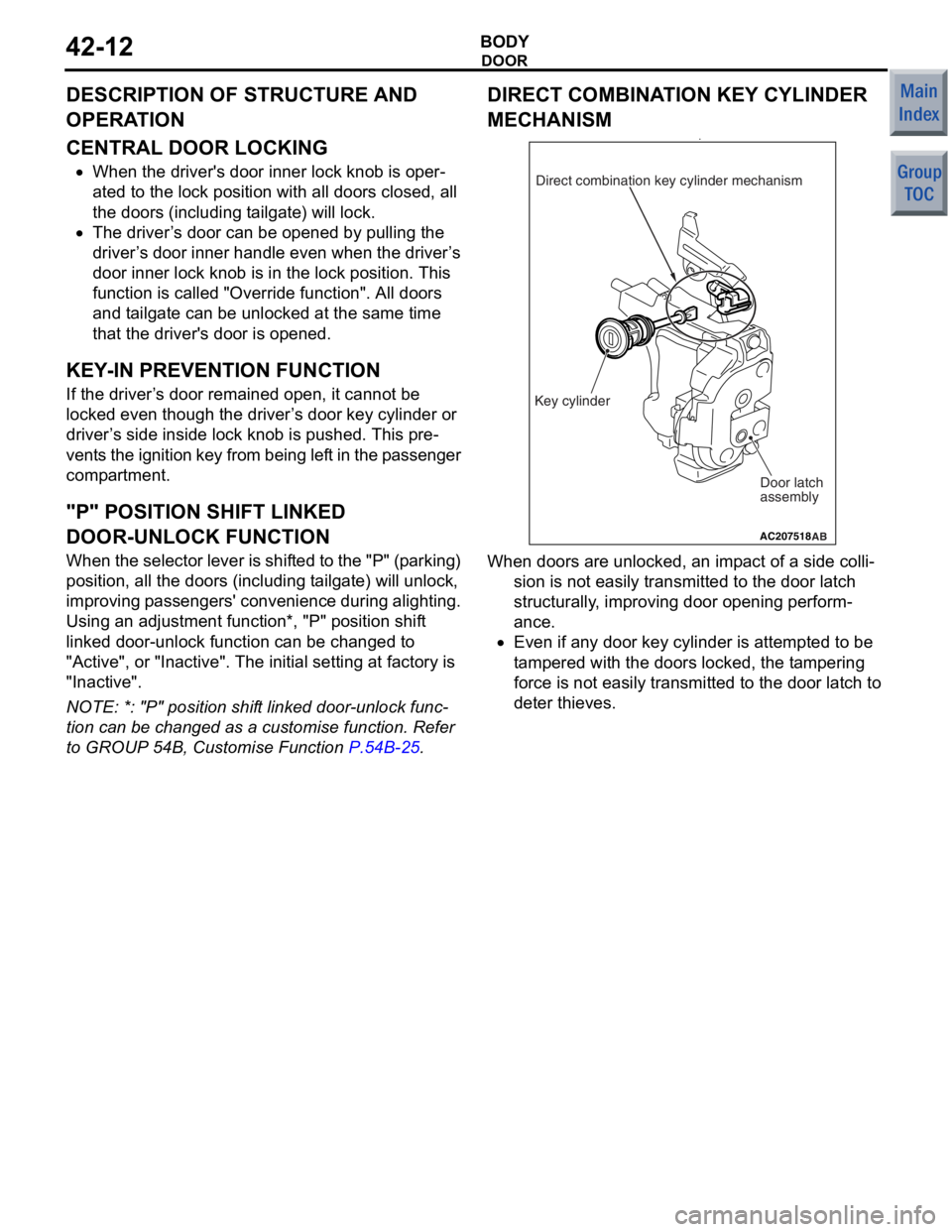

DIRECT COMBINATION KEY CYLINDER

MECHANISM

•

AC207518AB

Door latch

assembly

Key cylinder Direct combination key cylinder mechanism

When d

oors a r e unlocked, a n imp a ct of a side colli-

sion is not easily transmitted to the do or lat c h

structu

r ally , imp r oving do or open ing p e rform

-

ance.

•Even if a n y d oor ke y cylinder is a ttemp ted to b e

t

a mp ered wit h the d oors locked, t he t a mp ering

force is not

easily transmitt ed to t he doo r latch to

det

er thie ves.

Page 169 of 364

TRANSMISSION CONTROL

MANUAL TRANSMISSION22-4

TRANSMISSION CONTROL

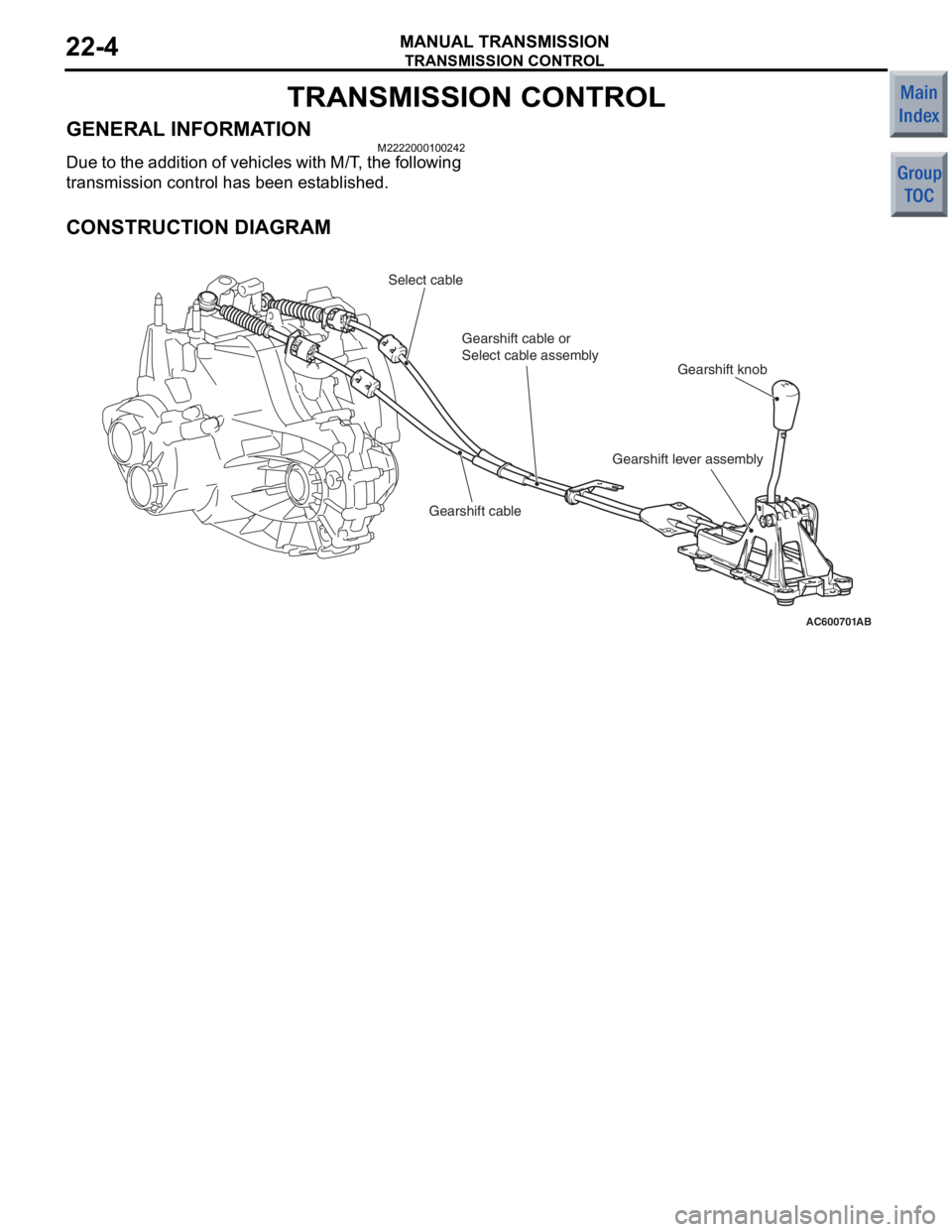

GENERAL INFORMATIONM2222000100242

Due to the addition of vehicles with M/T, the following

transmission control has been established.

CONSTRUCTION DIAGRAM

AC600701

Gearshift knob

AB

Select cable

Gearshift lever assembly

Gearshift cable or

Select cable assembly

Gearshift cable

Page 183 of 364

COMBINATION METER

CHASSIS ELECTRICAL54A-12

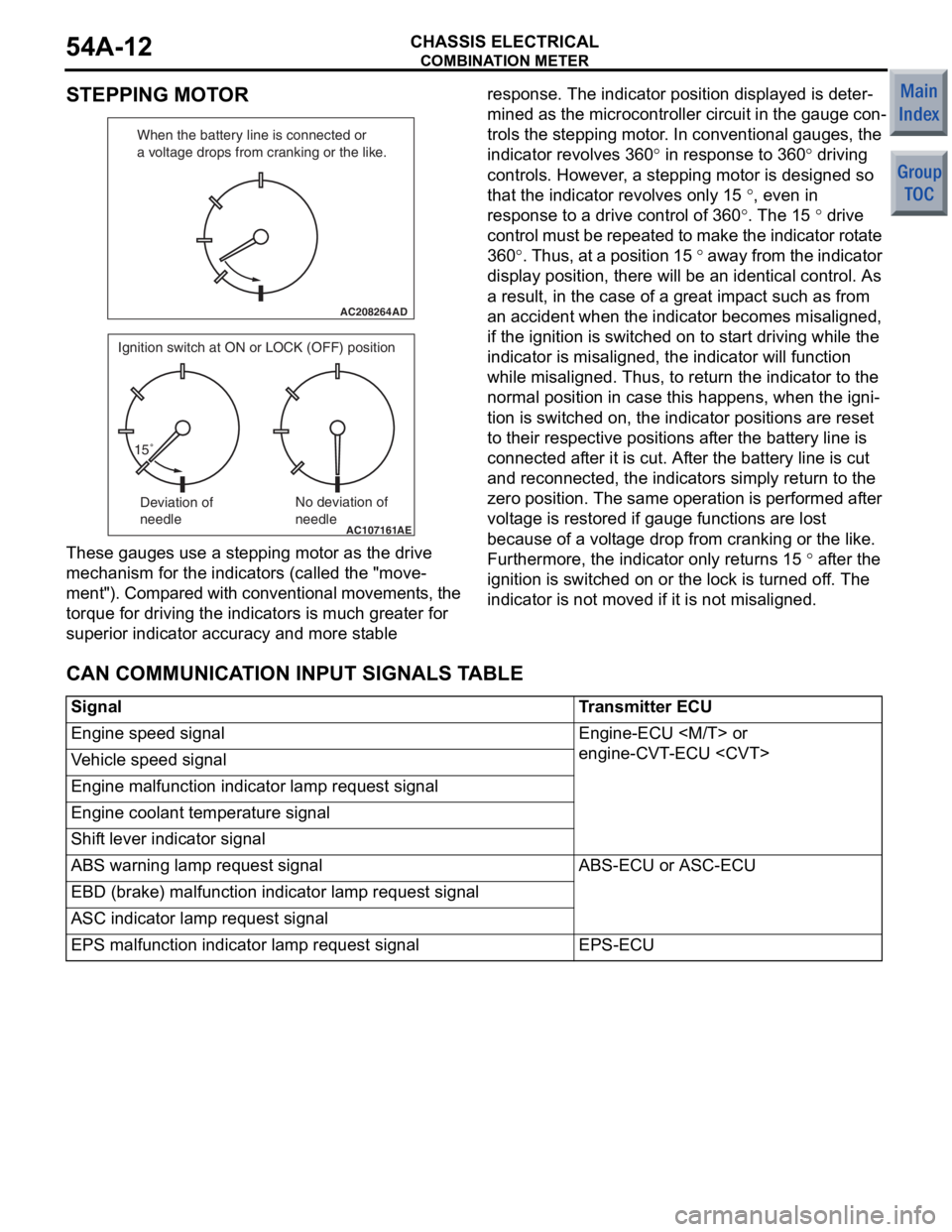

STEPPING MOTOR

AC208264

When the battery line is connected or

a voltage drops from cranking or the like.

AD

AC107161

Deviation of

needleNo deviation of

needle

15˚

AE

Ignition switch at ON or LOCK (OFF) position

These

gauge s use a stepp ing motor a s the drive

mechanism for

the indica tor s (calle d the "move

-

ment"). Compared with conventional movement s, the

torque f

o r driving the indicators is much gre a ter for

supe

rior indicator a ccu racy and more st able respo n se. The indicator po sit i on d i sp layed is dete r

-

min

ed a s t he microcon troller circuit in the gauge co n-

trols the stepping moto r . In conve n tion al gaug es, the

indicato

r revo lves 360

° in response to 3 6 0° driving

contro

ls.

Ho

we

ver

,

a ste

pping

mot

o

r is designed so

that the

ind

i

cat

o

r revolves on

ly

15

°, even in

respo

n

se

to a drive contro

l of 3

6

0

°. The 15 ° drive

c

ont

ro

l m

u

st

be

rep

eat

ed

t

o

ma

ke

th

e

ind

i

cat

o r rot a t e

36

0

°. Th us , at a po sit i o n 15 ° a w a y fr om th e in dicat o r

display positio

n, there

will be an iden tica l control. As

a resu

lt, in the

case of a

great imp a ct such as from

an accide

nt wh

en the indicator becomes misalign ed,

if the

ignition

is

switched o

n

to st art driving while t he

indicato

r is

misaligned,

the indicator will fu nction

wh

ile

misaligned.

Thus, to retu rn the indicator to the

norma

l position in

case this ha ppens, when the ig ni

-

tion is switched on , the indicator p o sitions are re set

to their respective

position s af ter th e batte ry line is

conn

ected af ter it is cut. Af ter th e batte ry line is cut

and reconne

cted , the indicators simply retu rn to th e

zero

positio n. Th e same ope ration is pe rforme d af ter

volt

ag e is resto r ed if gauge functions are lost

beca

u se o f a volt age d r op from cra n king or t he like.

Furthermore, t

he in dicator only re turns 15

° after the

ignition

is switched on

or the

lock is turne

d

of f. The

indicato

r is

not moved

if it is not misa

lig

ned.

CAN COMMUNICA TION INPUT SIGNALS T ABLE

SignalTransmitter ECU

Engine speed signalEngine-ECU

engine-CVT-ECU

Vehicle speed signal

Engine malfunction indicator lamp request signal

Engine coolant temperature signal

Shift lever indicator signal

ABS warning lamp request signalABS-ECU or ASC-ECU

EBD (brake) malfunction indicator lamp request signal

ASC indicator lamp request signal

EPS malfunction indicator lamp request signalEPS-ECU

Page 195 of 364

TECHNICAL FEATURES

GENERAL00-10

TRANSMISSION

M2000021000594

MANUAL TRANSMISSION

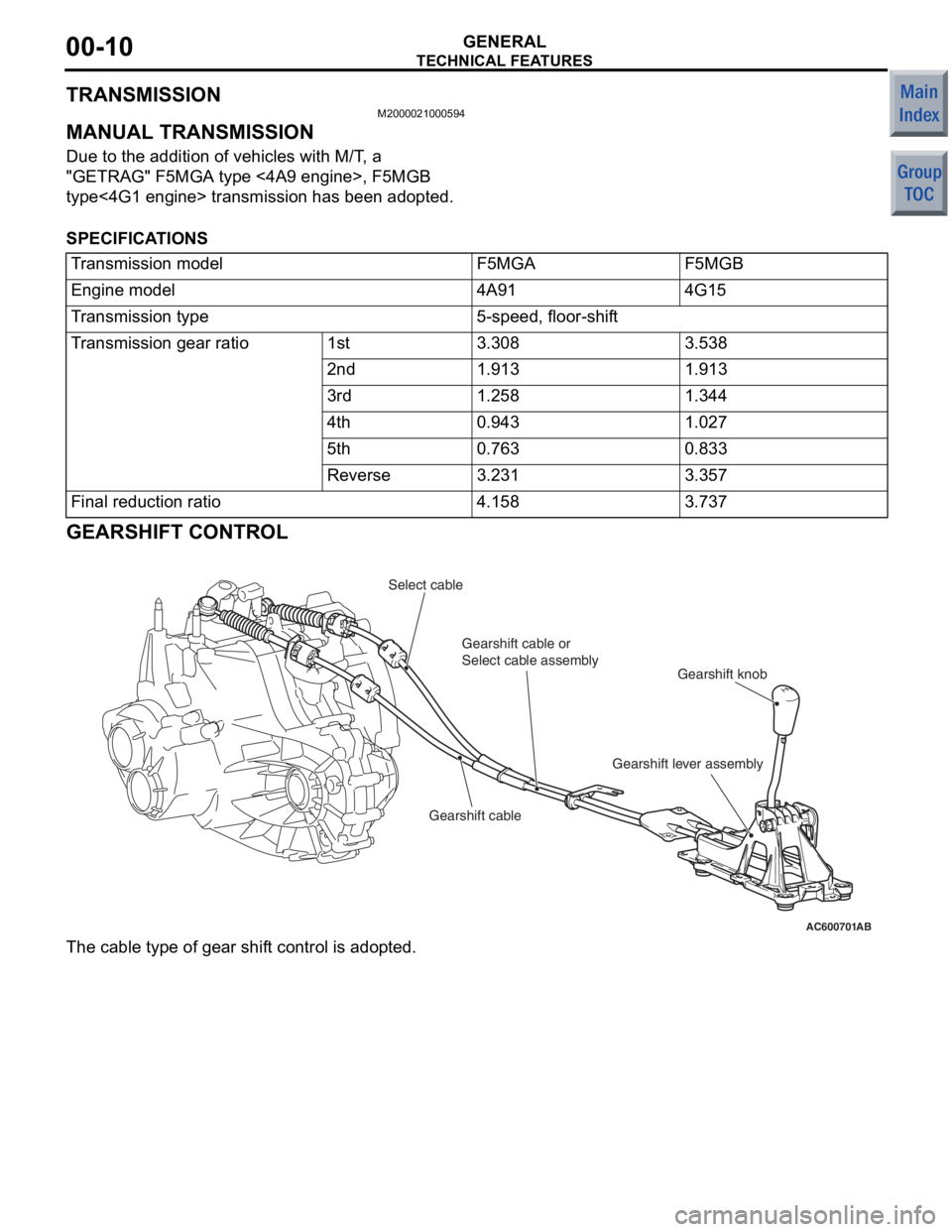

Due to the addition of vehicles with M/T, a

"GETRAG" F5MGA type <4A9 engine>, F5MGB

type<4G1 engine> transmission has been adopted.

SPECIFICATIONS

Transmission modelF5MGAF5MGB

Engine model4A914G15

Transmission type5-speed, floor-shift

Transmission gear ratio1st3.3083.538

2nd1.9131.913

3rd1.2581.344

4th0.9431.027

5th0.7630.833

Reverse3.2313.357

Final reduction ratio4.1583.737

GEARSHIFT CONTROL

AC600701

Gearshift knob

AB

Select cable

Gearshift lever assembly

Gearshift cable or

Select cable assembly

Gearshift cable

The cable type of gea r shift contro l is adop ted.

Page 198 of 364

TECHNICAL FEATURES

GENERAL00-13

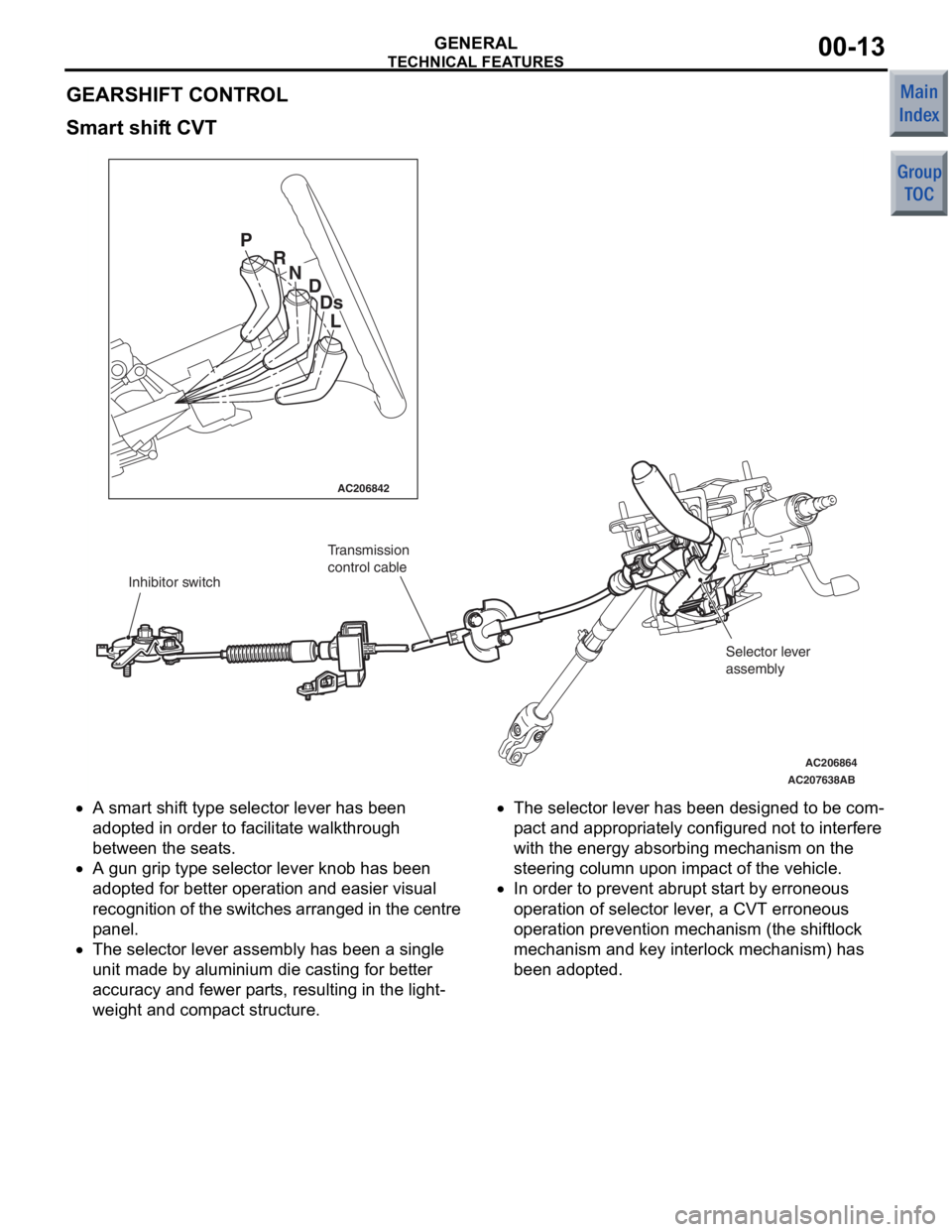

GEARSHIFT CONTROL

Smart shift CVT

AC206842

AC206864

AC207638

AB

P R

ND

Ds

L

Inhibitor switch Transmission

control cable

Selector lever

assembly

•A smart shift type selector lever h as b een

ado pted in orde r to facilitate walkthrou gh

bet wee n the seats.

•A gun grip type selector lever kno b has been

ado pted fo r better operat ion and easier visual

re cog nitio n of th e swit ches ar ra ng ed in th e ce ntre

p anel.

•The selecto r lever assembly has been a single

unit ma de by alu minium die casting f or bette r

accura cy and fewer pa rts, resu lting in the light

-

weig ht and compact struct ure.

•The selecto r lever has been designed to be com-

pa ct a nd appro priate ly configured no t to interf ere

with the en ergy absor bing mechanism on the

steerin g column upon impact of th e vehicle.

•In order to prevent abru pt st art b y erro neous

ope ration of selector lever , a CVT errone ous

ope ration preventio n mechanism (the shiftlock

m echa nis m and key interloc k mech anis m) h as

bee n adop ted.

Page 236 of 364

GENERAL INFORMATION

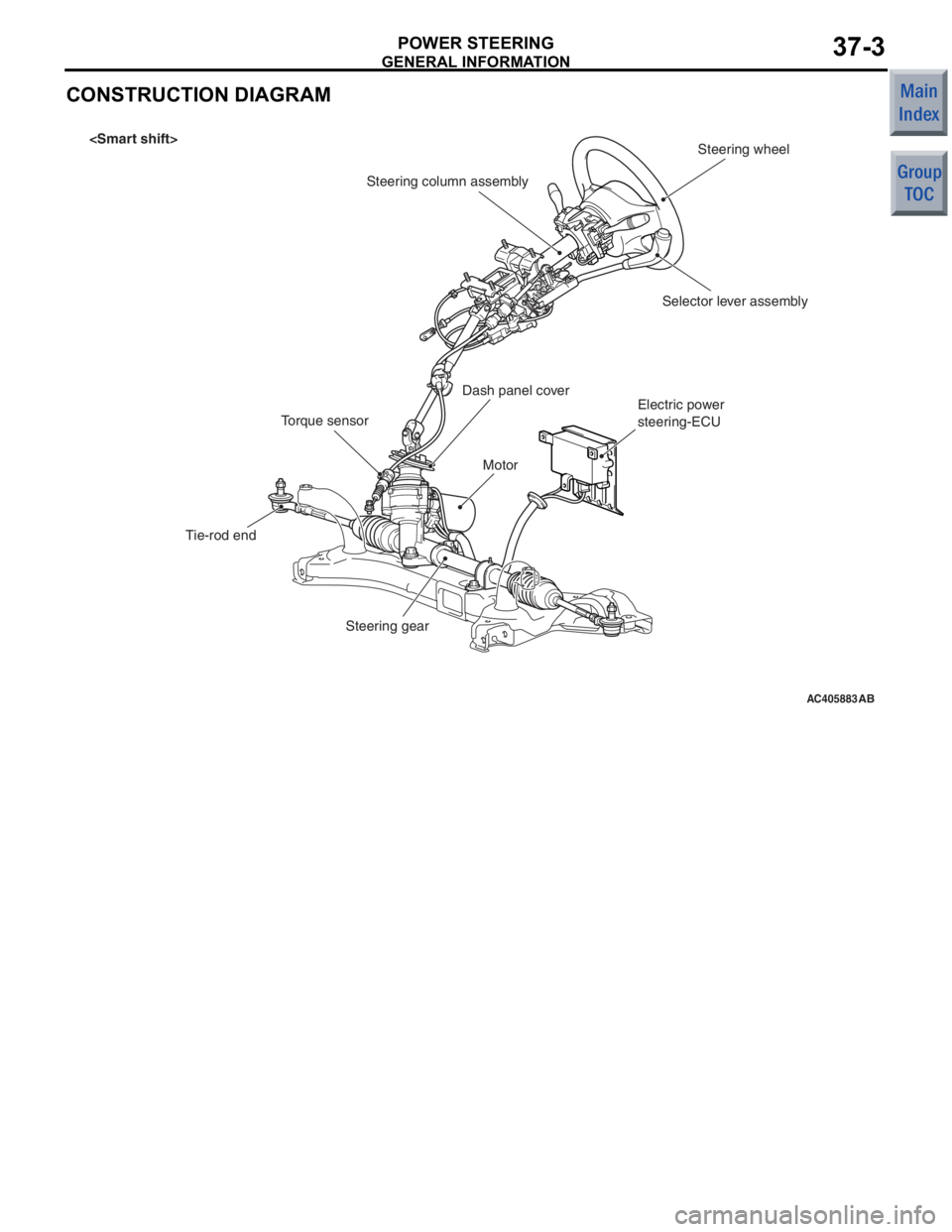

POWER STEERING37-3

CONSTRUCTION DIAGRAM

AC405883AB

Steering wheel

Steering column assembly

Selector lever assembly

Electric power

steering-ECU

Motor

Torque sensor

Tie-rod end Steering gearDash panel cover

Page 274 of 364

DIAGNOSTIC FUNCTION

SMART WIRING SYSTEM (SWS)54B-8

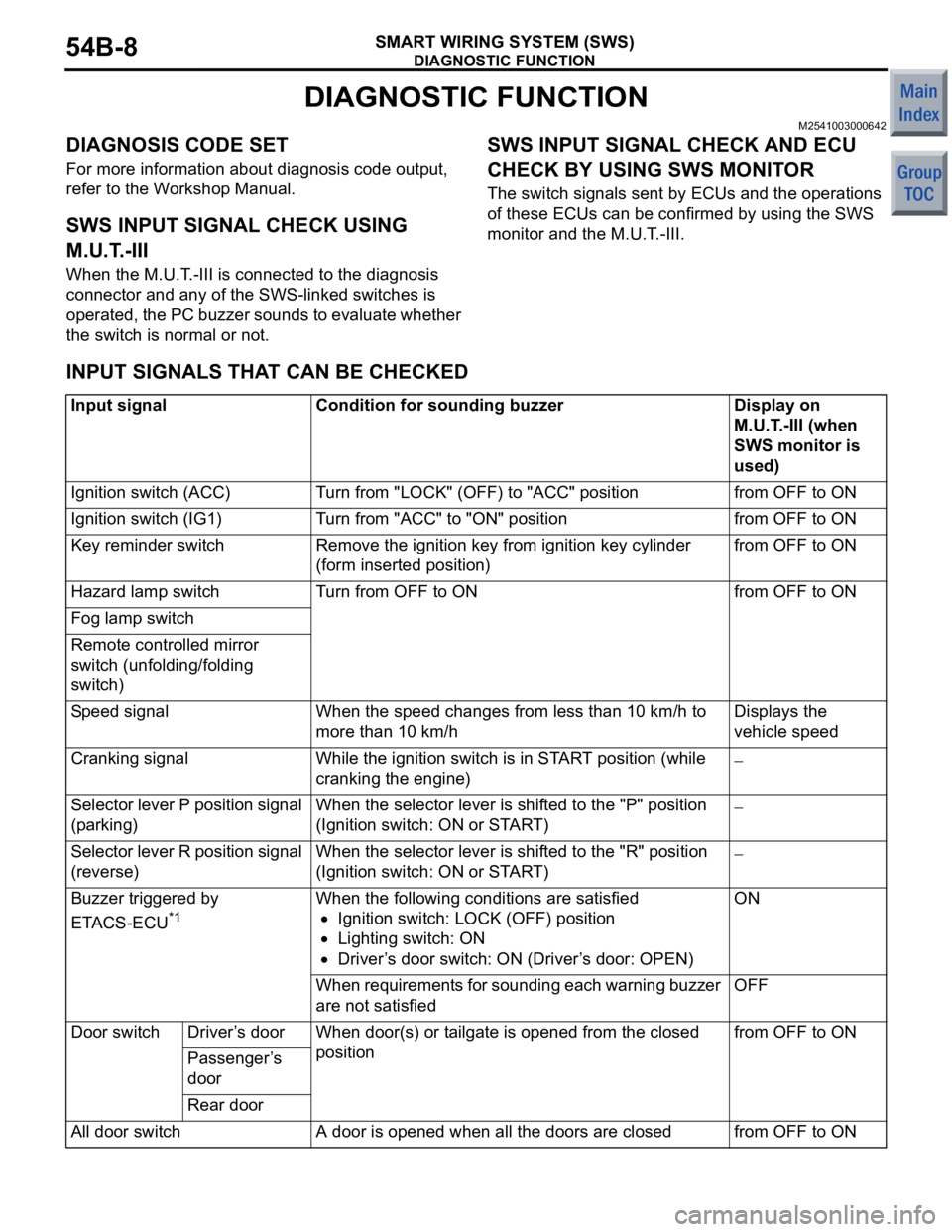

DIAGNOSTIC FUNCTION

M2541003000642

DIAGNOSIS CODE SET

For more information about diagnosis code output,

refer to the Workshop Manual.

SWS INPUT SIGNAL CHECK USING

M.U.T.-III

When the M.U.T.-III is connected to the diagnosis

connector and any of the SWS-linked switches is

operated, the PC buzzer sounds to evaluate whether

the switch is normal or not.

SWS INPUT SIGNAL CHECK AND ECU

CHECK BY USING SWS MONITOR

The switch signals sent by ECUs and the operations

of these ECUs can be confirmed by using the SWS

monitor and the M.U.T.-III.

INPUT SIGNALS THAT CAN BE CHECKED

Input signalCondition for sounding buzzerDisplay on

M.U.T.-III (when

SWS monitor is

used)

Ignition switch (ACC)Turn from "LOCK" (OFF) to "ACC" positionfrom OFF to ON

Ignition switch (IG1)Turn from "ACC" to "ON" positionfrom OFF to ON

Key reminder switchRemove the ignition key from ignition key cylinder

(form inserted position)from OFF to ON

Hazard lamp switchTurn from OFF to ONfrom OFF to ON

Fog lamp switch

Remote controlled mirror

switch (unfolding/folding

switch)

Speed signal When the speed changes from less than 10 km/h to

more than 10 km/hDisplays the

vehicle speed

Cranking signalWhile the ignition switch is in START position (while

cranking the engine)−

Selector lever P position signal

(parking)When the selector lever is shifted to the "P" position

(Ignition switch: ON or START)−

Selector lever R position signal

(reverse)When the selector lever is shifted to the "R" position

(Ignition switch: ON or START)−

Buzzer triggered by

ETACS-ECU

*1

When the following conditions are satisfied

•Ignition switch: LOCK (OFF) position

•Lighting switch: ON

•Driver’s door switch: ON (Driver’s door: OPEN)

ON

When requirements for sounding each warning buzzer

are not satisfiedOFF

Door switchDriver’s doorWhen door(s) or tailgate is opened from the closed

positionfrom OFF to ON

Passenger’s

door

Rear door

All door switchA door is opened when all the doors are closedfrom OFF to ON

Page 291 of 364

CUSTOMISE FUNCTION

SMART WIRING SYSTEM (SWS)54B-25

CUSTOMISE FUNCTION

M2541006000243

Using M.U.T.-III adjusts the following function. The

programmed information is held even when the bat

-

tery is disconnected.

•Vehicle speed-dependent wiper function

With the windshield wiper switch in the intermittent

position, the intermittent duration changes

depending on the intermittent adjusting knob

position and the vehicle speed.

•The selector "P" position-linked central door

unlocking function

When the selector lever is shifted to the "P" position,

all the doors unlock.

•Turn-signal lamp operation sound function

Synchronized with the hazard lamp and the turn sig-

nal lamp, the buzzer sounds.

•Dimmer interior lamp control duration

When the door is closed with the ignition switch

LOCK (OFF), the interior lamp is turned OFF

automatically in the specified time.

•Timer lock time after executing the keyless entry

unlock

If any door including a tailgate is not opened after

being unlocked with the keyless transmitter,

doors are locked automatically within the speci

-

fied time.

•Door-ajar warning function

Driving with any door, including a tailgate, not prop-

erly closed sounds the buzzer to let the driver

know the door-ajar state.

•Rear wiper intermittent duration

When the rear wiper switch is turned ON, the rear

wiper operates in the intermittent action. When

the rear wiper switch is turned from OFF to ON

two cycles, the rear wiper makes continuous

operation regardless of the intermittent operation

duration setting.

•Wiper linked with washer function

When this function is active, the windshield wiper

operates if the washer switch is turned ON.

•Hazard answer back function of the keyless entry

system

When lock/unlock is operated with the keyless entry

transmitter, the horn sounds so that the driver can

recognize the lock/unlock status of the vehicle

even if the driver is away from it.

•Initialising all functions (Returning to the initial

condition)

All adjusting functions are returned to the settings at

the time of factory shipment.

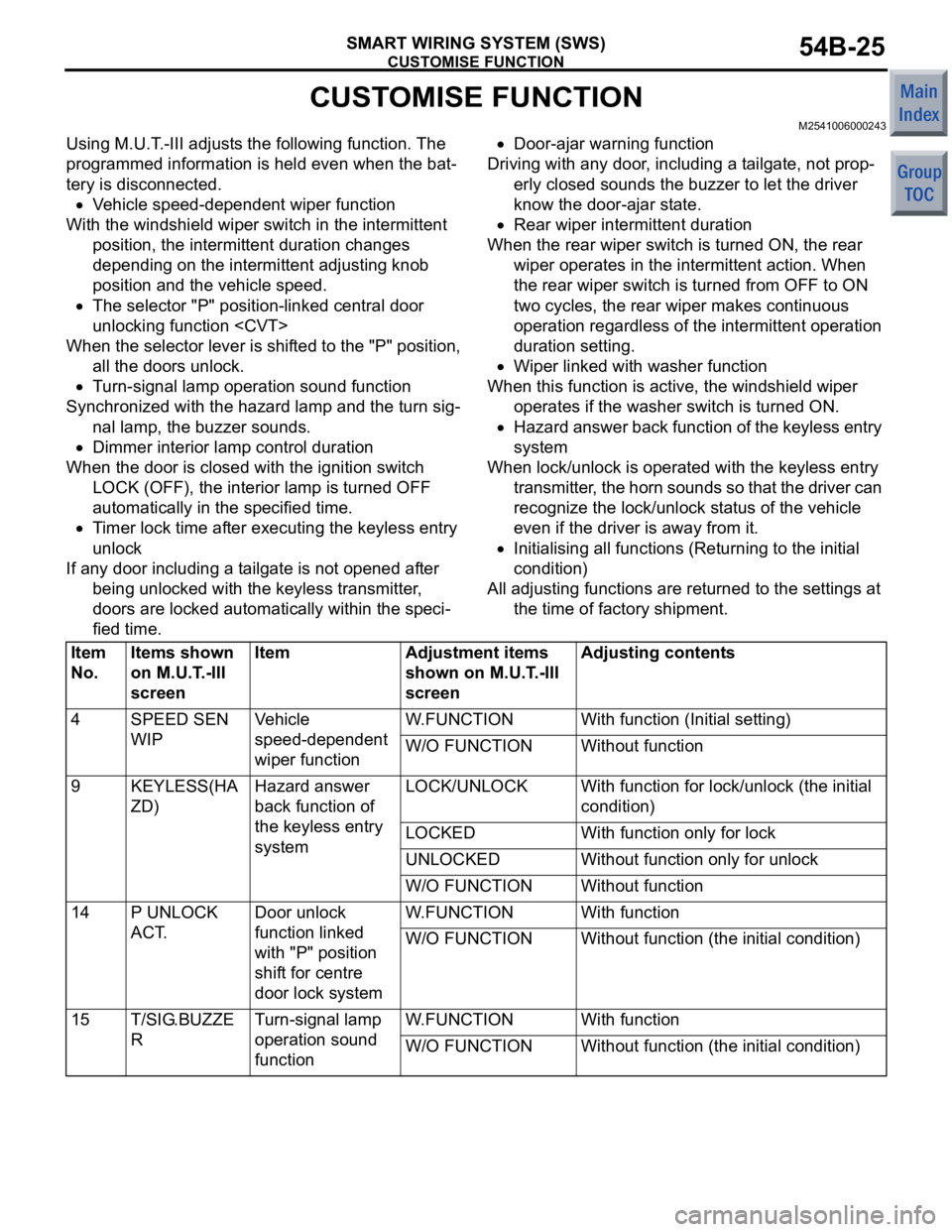

Item

No.Items shown

on M.U.T.-III

screenItemAdjustment items

shown on M.U.T.-III

screenAdjusting contents

4SPEED SEN

WIPVehicle

speed-dependent

wiper functionW.FUNCTIONWith function (Initial setting)

W/O FUNCTIONWithout function

9KEYLESS(HA

ZD)Hazard answer

back function of

the keyless entry

systemLOCK/UNLOCKWith function for lock/unlock (the initial

condition)

LOCKEDWith function only for lock

UNLOCKEDWithout function only for unlock

W/O FUNCTIONWithout function

14P UNLOCK

ACT.Door unlock

function linked

with "P" position

shift for centre

door lock systemW.FUNCTIONWith function

W/O FUNCTIONWithout function (the initial condition)

15T/SIG.BUZZE

RTurn-signal lamp

operation sound

functionW.FUNCTIONWith function

W/O FUNCTIONWithout function (the initial condition)

Page 354 of 364

TRANSMISSION CONTROL

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)23-6

TRANSMISSION CONTROL

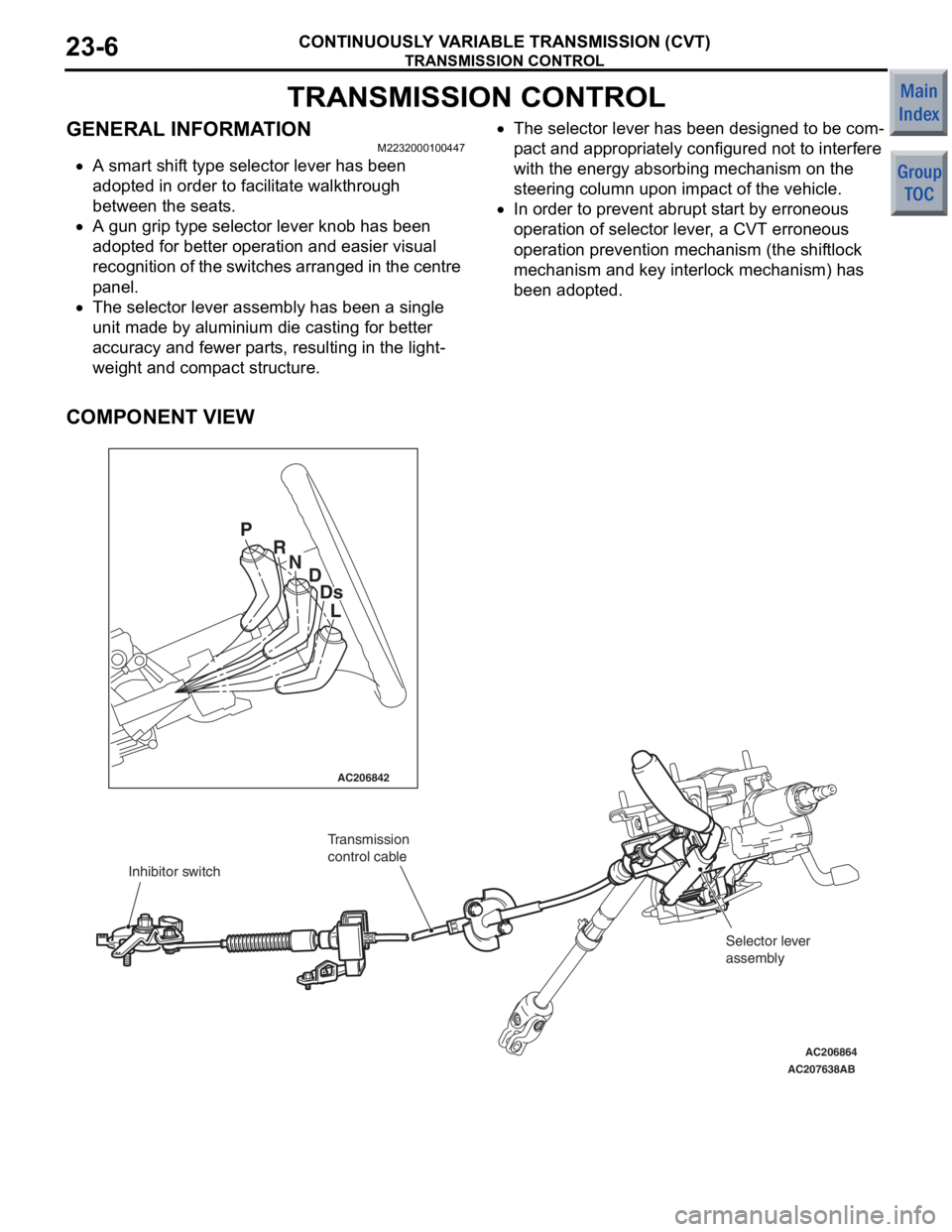

GENERAL INFORMATIONM2232000100447

•A smart shift type selector lever has been

adopted in order to facilitate walkthrough

between the seats.

•A gun grip type selector lever knob has been

adopted for better operation and easier visual

recognition of the switches arranged in the centre

panel.

•The selector lever assembly has been a single

unit made by aluminium die casting for better

accuracy and fewer parts, resulting in the light

-

weight and compact structure.

•The selector lever has been designed to be com-

pact and appropriately configured not to interfere

with the energy absorbing mechanism on the

steering column upon impact of the vehicle.

•In order to prevent abrupt start by erroneous

operation of selector lever, a CVT erroneous

operation prevention mechanism (the shiftlock

mechanism and key interlock mechanism) has

been adopted.

COMPONENT VIEW

AC206842

AC206864

AC207638

AB

P R

ND

Ds

L

Inhibitor switch Transmission

control cable

Selector lever

assembly