remote start MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 114 of 408

ENGINEANDENGINEOVERHAUL 3-53

16. Torque the bearing cap bolts in the following

sequence: No. 3, No. 2, No. 1 and No. 4 to 85 inch

Ibs. (10 Nm).

17. Repeat the sequence increasing the torque to

14 ft. Ibs. (20 Nm).

18. Remove the auto lash adjuster retainer tools

from the rocker arms.

19. Install the camshaft sprocket and bolt.

20. Using camshaft sprocket holding tool

MB9g67 and MD998719 or equivalent, hold the

sprocket and tighten the bolt to 65 ft. Ibs. (90 Nm).

21. Install the timing belt and valve covers.

22. Using a new O-ring, install the distributor ex-

tension housing.

23. Install the intake manifold plenum stay

bracket.

24. Install the distributor assembly Be sure to

align the rotor and distributor housing matchmarks.

25. Connect the negative battery cable and check

for leaks.

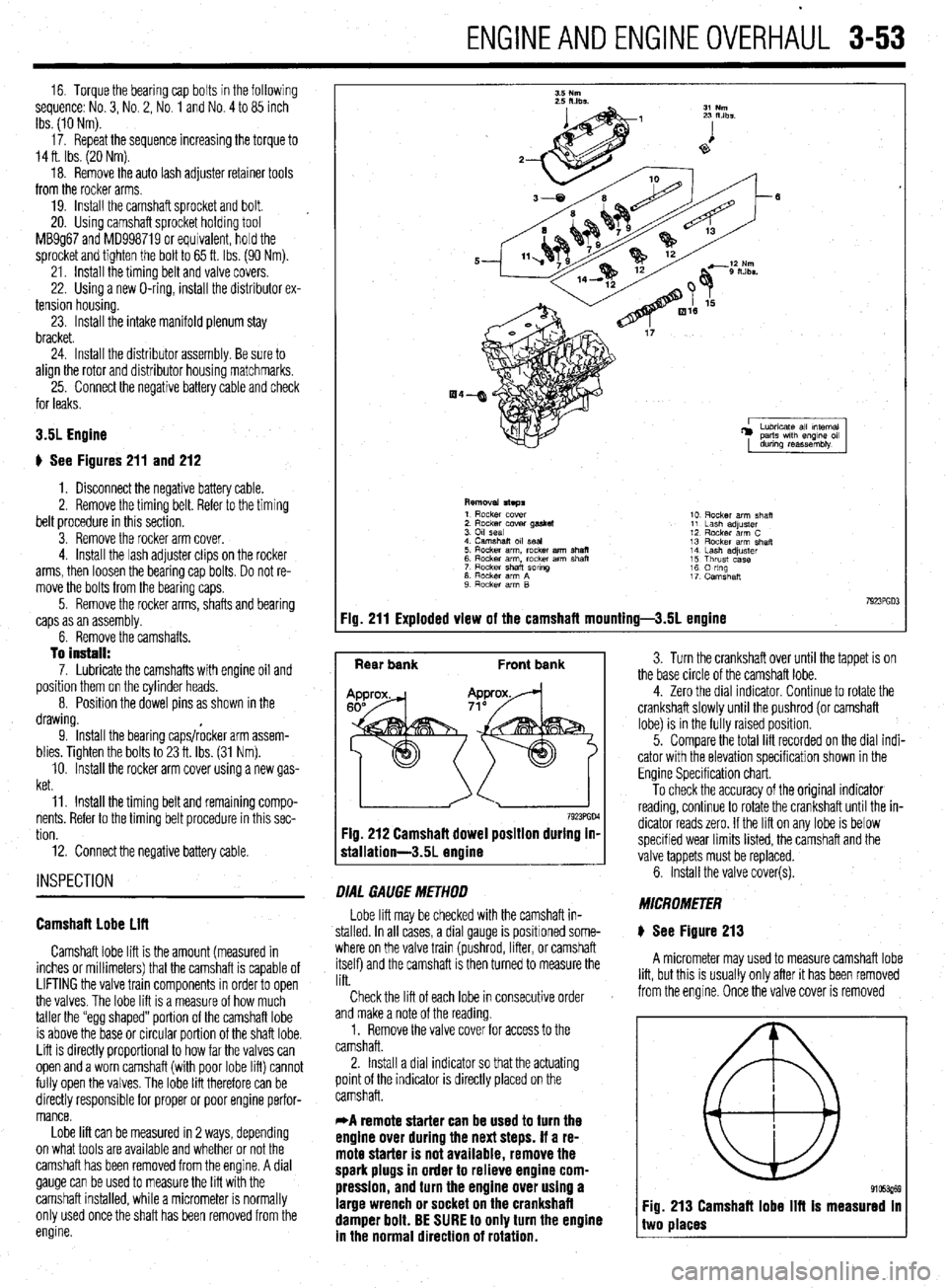

3.5L Engine

+ See Figures 211 and 212

1. Disconnect the negative battery cable.

2. Remove the timing belt. Refer to the timing

belt procedure in this section.

3. Remove the rocker arm cover.

4. Install the lash adjuster clips on the rocker

arms, then loosen the bearing cap bolts. Do not re-

move the bolts from the bearing caps.

5. Remove the rocker arms, shafts and bearing

caps as an assembly.

6. Remove the camshafts.

To install: 7. Lubricate the camshafts with engine oil and

position them on the cylinder heads.

8. Position the dowel Dins as shown in the

drawing.

9. Install the bearing caps/rocker arm assem-

blies. Tighten the bolts to 23 ft. Ibs. (31 Nm).

10. hstall the rocker arm cover using a new gas-

ket.

11. Install the timing belt and remaining compo-

nents Refer to the timing belt procedure in this sec-

tion.

12. Connect the negative battery cable.

INSPECTION

Camshaft Lobe Liff

Camshaft lobe lift is the amount (measured in

inches or millimeters) that the camshaft is capable of

LIFTING the valve train components in order to open

the valves. The lobe lift is a measure of how much

taller the “egg shaped” portion of the camshaft lobe

is above the base or circular portion of the shaft lobe.

Lift is directly proportional to how far the valves can

open and a worn camshaft (with poor lobe lift) cannot

fully open the valves. The lobe lift therefore can be

directly responsible for proper or poor engine perfor-

mance.

Lobe lift can be measured in 2 ways, depending

on what tools are available and whether or not the

camshaft has been removed from the engine. A dial

gauge can be used to measure the lift with the

camshaft installed, while a micrometer is normally

only used once the shaft has been removed from the

engine.

10 Rocker arm shaft

11 Lash ad,uster

12 Rocker arm C

13 Rocker arm six,,

14 Lash adluster

15 Thrust case

16 orng

17 Camshan

:ig. 211 Exploded view of the camshaft mounting-3.51 engine 1923PGD

Rear bank Front bank

7923PGD4 Fig. 212 Camshaft dowel position during in-

stallation-3.51 engine

DIAL GAUGE METHOD

Lobe lift may be checked with the camshaft in-

stalled. In all cases, a dial gauge is positroned some-

where on the valve train (pushrod, lifter, or camshaft

itself) and the camshaft is then turned to measure the

lift.

Check the lift of each lobe in consecutive order

and make a note of the reading.

1. Remove the valve cover for access to the

camshaft.

2. Install a dial indicator so that the actuating

point of the indicator is directly placed on the

camshaft.

*A remote starter can be used to turn the

engine over during the next steps. If a re-

mote starter is not available, remove the

spark plugs in order to relieve engine com-

pression, and turn the engine over using a

large wrench or socket on the crankshaft

damper bolt. BE SURE to only turn the engine

in the normal direction of rotation.

3. Turn the crankshaft over until the tappet is on

the base circle of the camshaft lobe.

4. Zero the dial indicator. Continue to rotate the

crankshaft slowly until the pushrod (or camshaft

lobe) is in the fully raised position.

5. Compare the total lift recorded on the dial indi-

cator with the elevation specification shown in the

Engine Specification chart.

To check the accuracy of the original indicator

reading, continue to rotate the crankshaft until the in-

dicator reads zero. If the lift on any lobe is below

specified wear limits listed, the camshaft and the

valve tappets must be replaced.

6. Install the valve cover(s).

MICROMETER

) See Figure 213

A micrometer may used to measure camshaft lobe

lift, but this is usually only after it has been removed

from the engine. Once the valve cover is removed

I

@

Fig. 213 Camshaff lobe IIR Is measured In

Page 118 of 408

ENGINEANDENGINEOVERHAUL 3-57

Anything that generates heat and/or friction WIII

eventually burn or wear out (for example, a light bulb

generates heat, therefore its life span is limited). With

this in mind, a running engine generates tremendous

amounts of both; friction is encountered by the mov-

ing and rotating parts inside the engine and heat is

created by friction and combustion of the fuel How-

ever, the engine has systems designed to help reduce

the effects of heat and friction and provide added

longevrty. The oiling system reduces the amount of

friction encountered by the moving parts inside the

engine, while the cooling system reduces heat cre-

ated by friction and combustion If either system is

not maintained, a break-down will be inevitable.

Therefore, you can see how regular maintenance can

affect the service life of your vehicle, If you do not

drain, flush and refill your cooling system at the

proper intervals, deposits WIII begin to accumulate in

the radiator, thereby reducing the amount of heat it

can extract from the coolant The same applies to

your oil and filter; If it is not changed often enough it

becomes laden with contaminates and is unable to

properly lubricate the engine. This increases friction

and wear.

There are a number of methods for evaluating the

condition of your engine. A compression test can re-

veal the condition of your pistons, piston rings,

cylinder bores, head gasket(s), valves and valve

seats. An oil pressure test can warn you of possible

engine bearing, or oil pump failures. Excessrve oil

consumption, evidence of oil in the engine air intake

area and/or bluish smoke from the tailpipe may indi-

cate worn piston rings, worn valve guides and/or

valve seals. As a general rule, an engine that uses no

more than one quart of oil every 1000 miles is in

good condition. Engines that use one quart of oil or

more in less than 1000 miles should first be checked

for oil leaks. If any oil leaks are present, have them

fixed before determining how much oil is consumed

by the engine, especrally if blue smoke is not visible

at the tailpipe

COMPRESSION TEST

# See Figure 226

tccs3801 Fig. 226 A screw-in type compression gauge

is more accurate and easier to use without

an assistant

A noticeable lack of engine power, excessive oil

consumption and/or poor fuel mileage measured

over an extended period are all indicators of internal

engine wear. Worn piston rings, scored or worn

cylinder bores, blown head gaskets, sticking or burnt

valves, and worn valve seats are all possible culprits.

A check of each cylinders compression WIII help lo-

cate the problem.

*A screw-in type compression gauge is

more accurate than the type you simply hold

against the spark plug hole. Although it takes

slightly longer to use, it’s worth the effort to

obtain a more accurate reading.

1 Make sure that the proper amount and vis-

cosity of engine oil is in the crankcase, then ensure

the battery is fully charged.

2. Warm-up the engine to normal operating

temperature, then shut the engine

OFF. 3. Disable the ignition system.

4. Label and disconnect all of the spark plug

wires from the plugs,

5. Thoroughly clean the cylinder head area

around the spark plug ports, then remove the spark

plugs.

6. Set the throttle plate to the fully open (wide-

open throttle) position You can block the accelerator

linkage open for this, or you can have an assistant

fully depress the accelerator pedal.

7. Install a screw-in type compression gauge

into the No. 1 spark plug hole until the fitting is snug.

Be careful not to crossthread the spark plug

hole.

8. According to the tool manufacturers instruc-

tions, connect a remote starting switch to the starting

circuit.

9. With the ignition switch in the

OFF position,

use the remote starting switch to crank the engine

through at least five compression strokes (approxi-

mately 5 seconds of cranking) and record the highest

reading on the gauge

10. Repeat the test on each cylinder, cranking the

engine approximately the same number of compres-

sion strokes and/or time as the first.

11. Compare the hrghest readings from each

cylinder to that of the others. The indicated compres-

sion pressures are considered within specifications if

the lowest reading cylinder is within 75 percent of the

pressure recorded for the highest reading cylinder

For example, if your highest reading cylinder pres-

sure was 150 psi (1034 kPa), then 75 percent of that

would be 113 psi (779 kPa). So the lowest reading

cylinder should be no less than 113 psi (779 kPa).

12. If a cylinder exhibits an unusually low com-

pression reading, pour a tablespoon of clean engine

oil into the cylinder through the spark plug hole and

repeat the compression test. If the compression rises

after adding oil, it means that the cylinder’s piston

rings and/or cylinder bore are damaged or worn, If

the pressure remains low, the valves may not be seat-

ing properly (a valve job is needed), or the head gas-

ket may be blown near that cylinder. If compression in any two adjacent cylinders is low, and if the addi-

tion of oil doesn’t help raise compression, there is

leakage past the head gasket. Oil and coolant in the

combustion chamber, combined with blue or con-

stant white smoke from the tailpipe, are symptoms of

this problem. However, don’t be alarmed by the nor-

mal white smoke emitted from the tailpipe during en-

gine warm-up or from cold weather driving. There

may be evidence of water droplets on the engine dip-

stick and/or oil droplets in the cooling system if a

head gasket is blown.

OIL PRESSURETEST

Check for proper oil pressure at the sending unit

passage with an externally mounted mechanical oil

pressure gauge (as opposed to relying on a factory

Installed dash-mounted gauge). A tachometer may

also be needed, as some specifications may require

running the engine at a specific rpm.

1. With the engine cold, locate and remove the oil

pressure sending unit.

2. Followrng the manufacturers instructions,

connect a mechanical oil pressure gauge and, if nec-

essary, a tachometer to the engine.

3 Start the engine and allow it to idle.

4 Check the oil pressure reading when cold and

record the number. You may need to run the engine

at a specified rpm, so check the specifications,

5. Run the engine until normal operating temper-

ature is reached (upper radiator hose will feel warm)

6. Check the oil pressure reading again with the

engine hot and record the number. Turn the engine

OFF. 7. Compare your hot oil pressure reading to that

given in the chart If the reading is low, check the

cold pressure reading against the chart. If the cold

pressure IS well above the specification, and the hot

reading was lower than the specification, you may

have the wrong viscosity oil in the engine. Change

the oil, making sure to use the proper grade and

quantity, then repeat the test.

Low oil pressure readings could be attributed to

internal component wear, pump related problems, a

low oil level, or oil viscosity that is too low. High oil

pressure readings could be caused by an overfilled

crankcase, too htgh of an oil viscosity or a faulty

pressure relief valve.

Now that you have determined that your engine is

worn out, you must make some decisions. The ques-

tion of whether or not an engine IS worth rebuilding

is largely a subjective matter and one of personal

worth. Is the engine a popular one, or IS it an obso-

lete model? Are parts available? Will it get acceptable

gas mileage once It is rebuilt? Is the car its being put

into worth keeping? Would it be less expensive to

buy a new engine, have your engine rebuilt by a pro,

rebuild it yourself or buy a used engine from a sal-

vage yard? Or would It be simpler and less expensive

to buy another car? If you have considered all these

matters and more, and have still decided to rebuild

the engine, then it is time to decide how you will re-

build it.