oil type MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 683 of 1216

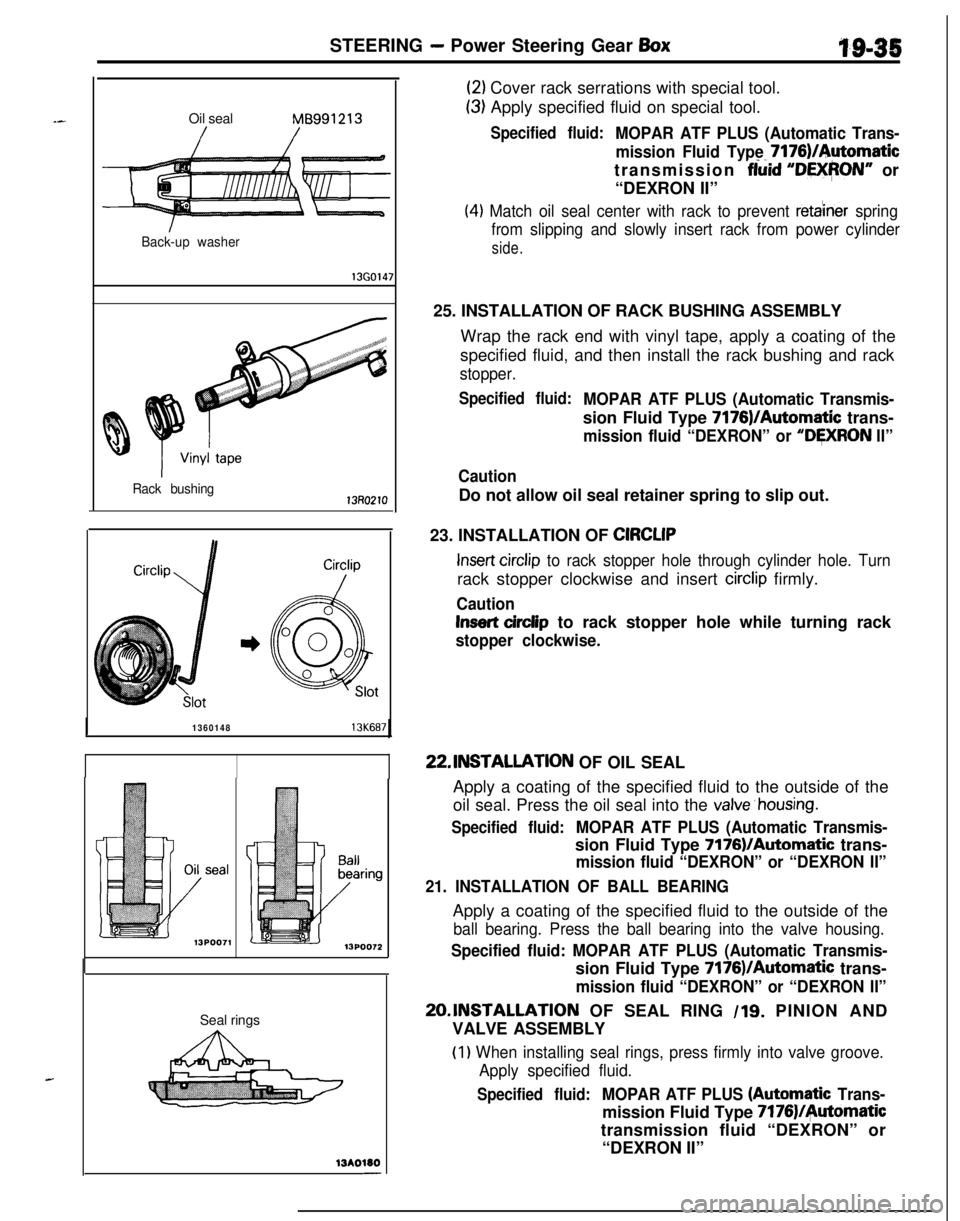

STEERING - Power Steering Gear BoxOil sealMB991213

Back-up washer

13G014;

Rack bushing

7

136014813K687Seal rings

13A0110-

(2) Cover rack serrations with special tool.

(3) Apply specified fluid on special tool.

Specified fluid:MOPAR ATF PLUS (Automatic Trans-

mission Fluid Type 7176)/Automatic

transmission

fiiid “DEXPON” or

“DEXRON II”

(4) Match oil seal center with rack to prevent reta’iner spring

from slipping and slowly insert rack from power cylinder

side.25. INSTALLATION OF RACK BUSHING ASSEMBLY

Wrap the rack end with vinyl tape, apply a coating of the

specified fluid, and then install the rack bushing and rack

stopper.

Specified fluid:MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

mission fluid “DEXRON” or “DWRON II”

CautionDo not allow oil seal retainer spring to slip out.

23. INSTALLATION OF

CIRCLIP

Insert circlip to rack stopper hole through cylinder hole. Turnrack stopper clockwise and insert

circlip firmly.

Caution

Insert cirdip to rack stopper hole while turning rack

stopper clockwise.22.lNSTALLATlON OF OIL SEAL

Apply a coating of the specified fluid to the outside of the

oil seal. Press the oil seal into the

valve’housing.

Specified fluid:MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type

7176VAutomatic trans-

mission fluid “DEXRON” or “DEXRON II”

21. INSTALLATION OF BALL BEARINGApply a coating of the specified fluid to the outside of the

ball bearing. Press the ball bearing into the valve housing.

Specified fluid: MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

mission fluid “DEXRON” or “DEXRON II”

20,lNSTALLATlON OF SEAL RING /lg. PINION AND

VALVE ASSEMBLY

(1) When installing seal rings, press firmly into valve groove.

Apply specified fluid.

Specified fluid:MOPAR ATF PLUS (Autombtic Trans-mission Fluid Type

7176)/+tomatictransmission fluid “DEXRON” or

“DEXRON II”

Page 691 of 1216

STEERING - Power Steering Oil Pump

Terminal assembly

13K753Mark

A,B or C-43Mark

A,B or C

13G0151

/Connector13K752

Suction-ring

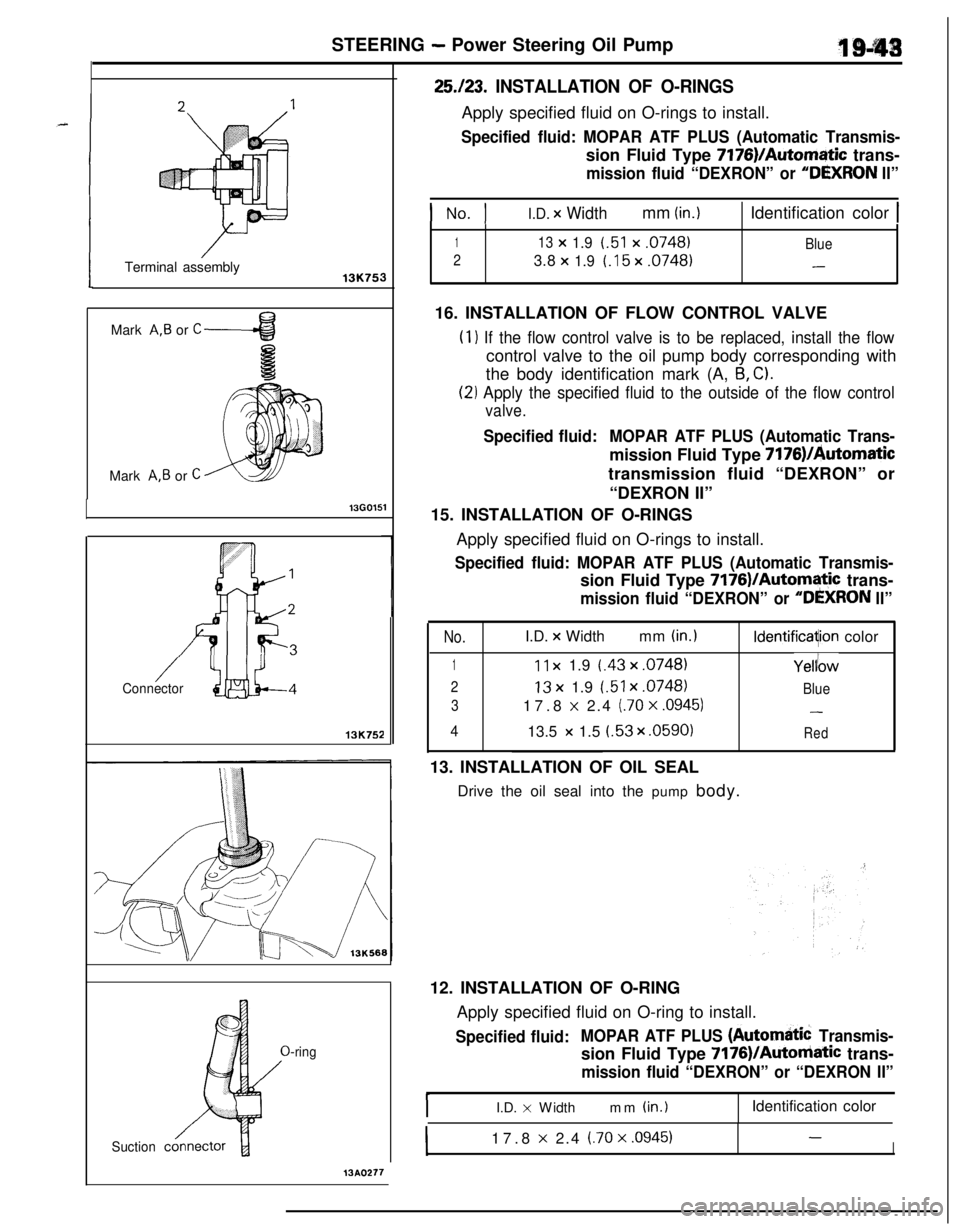

25.123. INSTALLATION OF O-RINGSApply specified fluid on O-rings to install.

Specified fluid: MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

mission fluid “DEXRON” or “DGXRON II”

I No. II.D. x Widthmm (in.)1 Identification color 1

113x1.9t.51x.0748)Blue

23.8

x1.9l.15x.0748)-16. INSTALLATION OF FLOW CONTROL VALVE

(1) If the flow control valve is to be replaced, install the flowcontrol valve to the oil pump body corresponding with

the body identification mark (A,

6, C).

(2) Apply the specified fluid to the outside of the flow control

valve.

Specified fluid:MOPAR ATF PLUS (Automatic Trans-mission Fluid Type

7176)/htomatictransmission fluid “DEXRON” or

“DEXRON II”

15. INSTALLATION OF O-RINGS

Apply specified fluid on O-rings to install.

Specified fluid: MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

mission fluid “DEXRON” or “DlkXRON II”

No.I.D. x Widthmm (in.)

1I 1 x 1.9 t.43 x .0748)

213x 1.9 l.51 x .0748)

317.8 x 2.4 j.70 X .0945)

413.5 x 1.5 t.53 x .0590)

ldentificaqion color

Yelllow

Blue

-

Red13. INSTALLATION OF OIL SEAL

Drive the oil seal into the pump body.

12. INSTALLATION OF O-RING

Apply specified fluid on O-ring to install.

Specified fluid:MOPAR ATF PLUS (Automatib Transmis-sion Fluid Type 7176)/Autoniatic trans-

mission fluid “DEXRON” or “DEXRON II”I.D.

x Widthmm (in.)Identification color

I17.8 x 2.4 (.70 x .0945)-I

13A0277

Page 692 of 1216

19-44STEERING - Power Steering Oil Pump

13AO350

13PO159

Punch mark

13c214 I

13W03ECutouts for

dowel pin

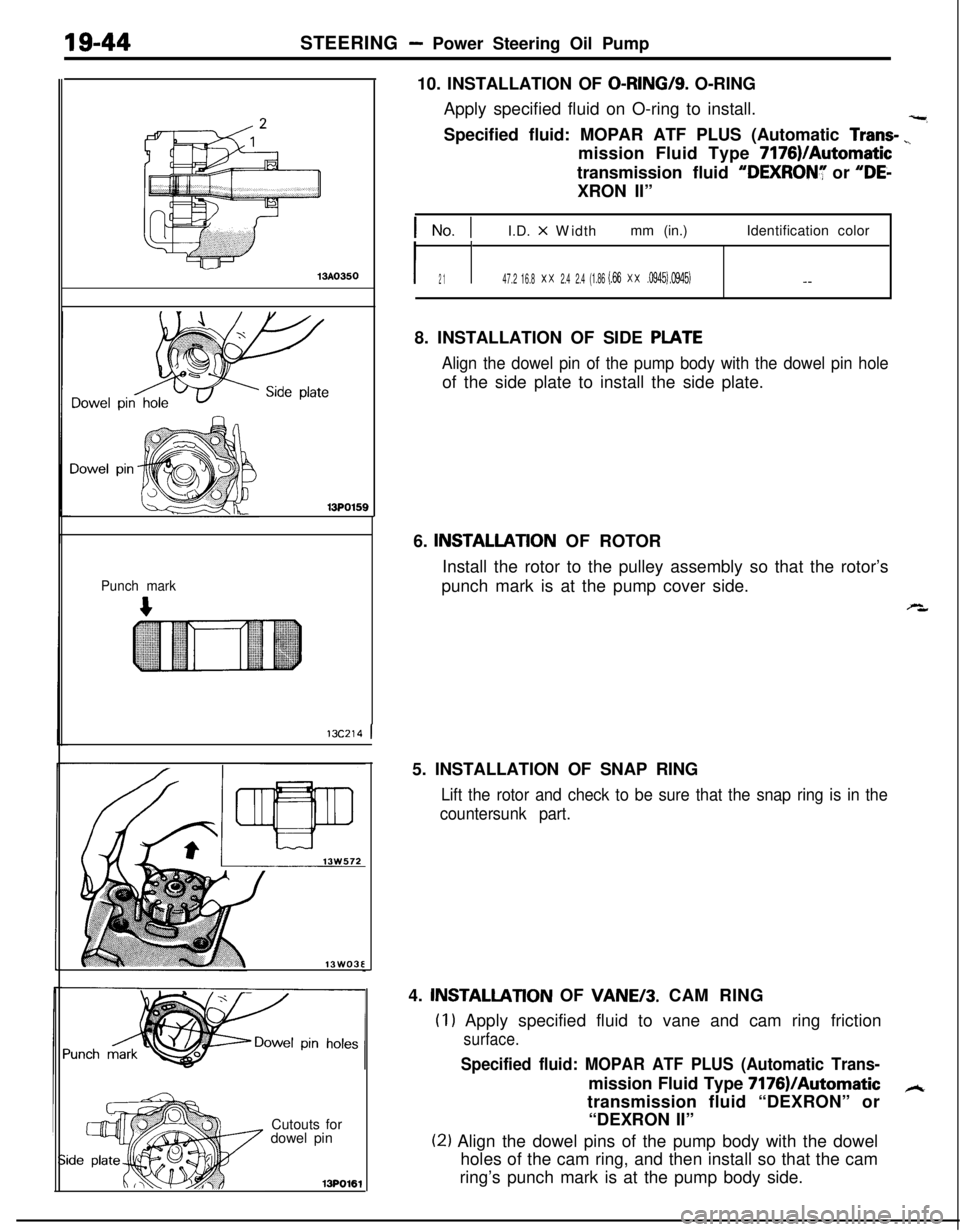

13PO16110. INSTALLATION OF

O-RING/S. O-RING

Apply specified fluid on O-ring to install.

-,Specified fluid: MOPAR ATF PLUS (Automatic

Trans- ”mission Fluid Type 7176)/Automatic

transmission fluid

“DEXRONY or “DE-XRON II”

1 No. 1I.D. x Widthmm (in.)Identification color

I2 1I47.2 16.8x x2.4 2.4(1.86 (.66x x.0945) .0945)- -8. INSTALLATION OF SIDE

PLATE

Align the dowel pin of the pump body with the dowel pin holeof the side plate to install the side plate.

6.

INSTALLATlON OF ROTOR

Install the rotor to the pulley assembly so that the rotor’s

punch mark is at the pump cover side.

s,5. INSTALLATION OF SNAP RING

Lift the rotor and check to be sure that the snap ring is in the

countersunk part.4.

INSTALLATlON OF VANE/3. CAM RING

(I1 Apply specified fluid to vane and cam ring friction

surface.

Specified fluid: MOPAR ATF PLUS (Automatic Trans-mission Fluid Type 7176)IAutomatic

Atransmission fluid “DEXRON” or

“DEXRON II”

(21 Align the dowel pins of the pump body with the dowel

holes of the cam ring, and then install so that the cam

ring’s punch mark is at the pump body side.

Page 693 of 1216

STEERING - Power Steering Oil Pump

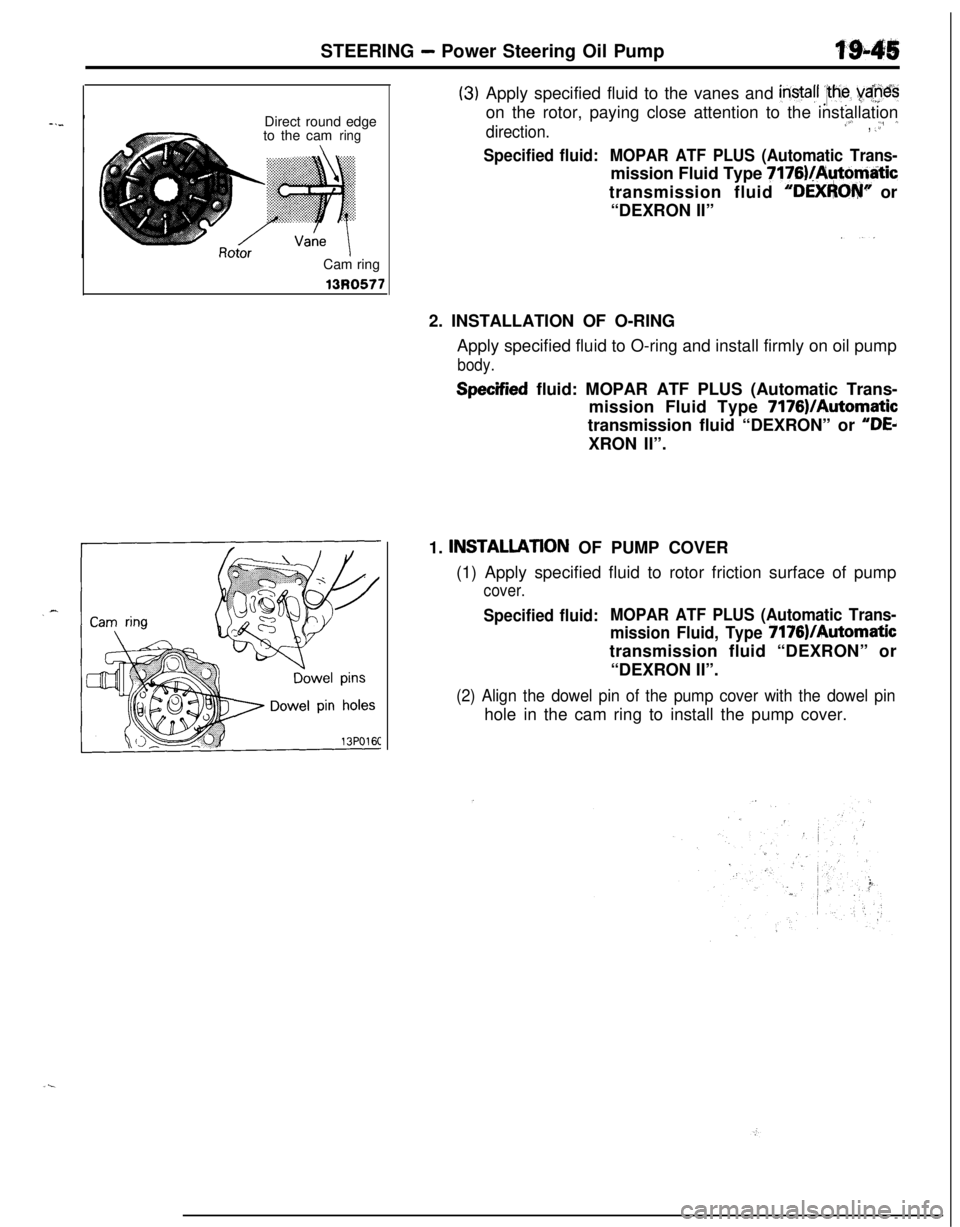

Direct round edge

to the cam

ringCam ring13R0577

(3)Apply specified fluid to the vanes and instafl :lhe yaneson the rotor, paying close attention to the installation

direction.,L.,., ‘,, :.I

Specified fluid:MOPAR ATF PLUS (Automatic Trans-mission Fluid Type

7176)/Auto@tictransmission fluid

“DEXFhOW’ or

“DEXRON II”

2. INSTALLATION OF O-RING

Apply specified fluid to O-ring and install firmly on oil pump

body.

Specified fluid: MOPAR ATF PLUS (Automatic Trans-

mission Fluid Type 7176)/Automatic

transmission fluid “DEXRON” or

“DEdXRON II”.

1.

INSTALLATlON OF PUMP COVER

(1) Apply specified fluid to rotor friction surface of pump

cover.

Specified fluid:MOPAR ATF PLUS (Automatic Trans-

mission Fluid, Type

7176)/Automatictransmission fluid “DEXRON” or

“DEXRON II”.

(2) Align the dowel pin of the pump cover with the dowel pinhole in the cam ring to install the pump cover.

Page 699 of 1216

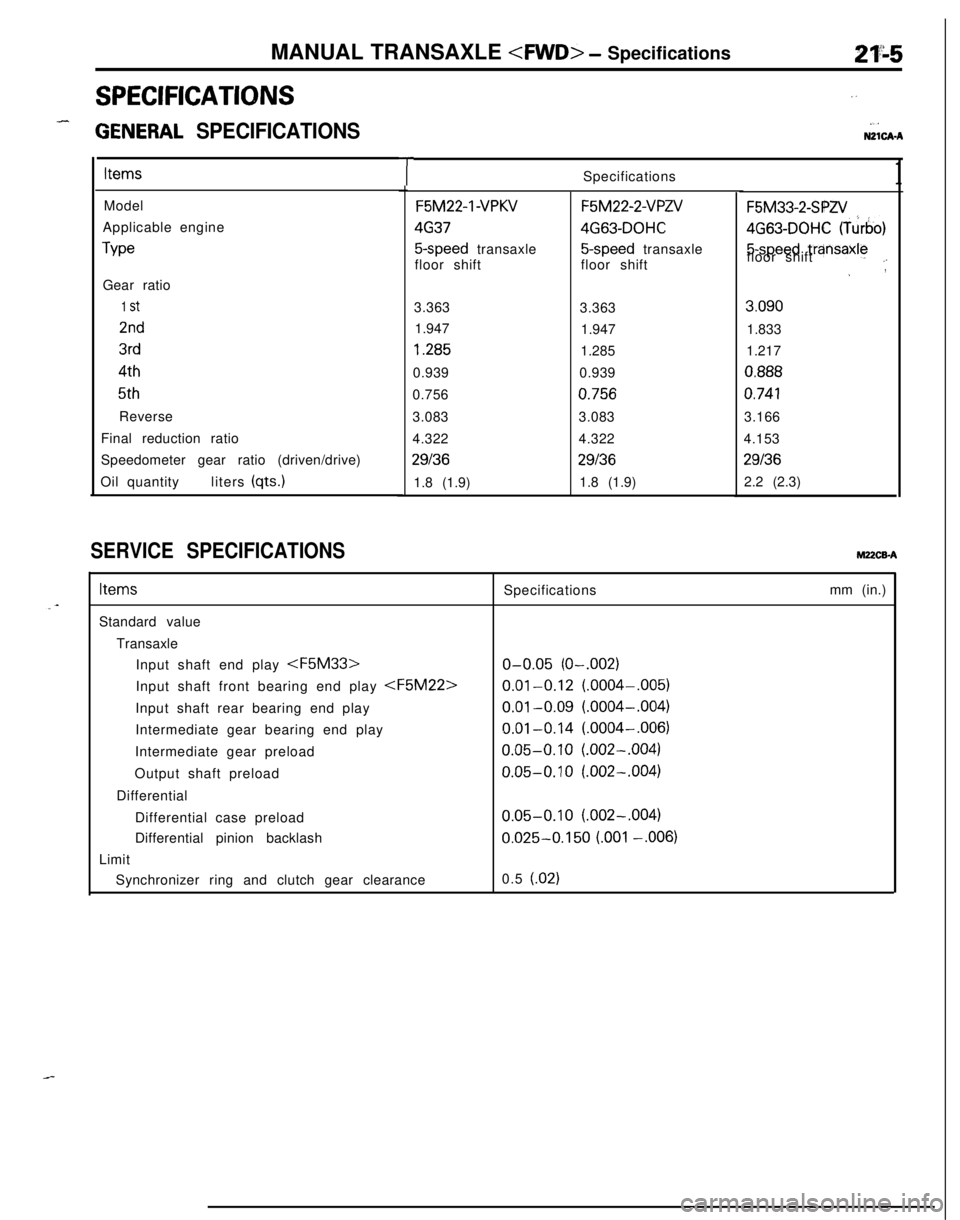

MANUAL TRANSAXLE

SPECIFICATIQNS

3ENERAL SPECIFICATIONS

ItemsModel

Applicable engine

TypeGear ratio

1 st2nd3rd

4th5th

Reverse

Final reduction ratio

Speedometer gear ratio (driven/drive)

Oil quantityliters (qts.)

SERVICE SPECIFICATIONShl22CBA

”

.,NZlCA-ASpecifications

1TF5M22-1

-VFWF5M22-2-VPZV

46374G63-DOHC

5-speed transaxle5-speed transaxle

floor shiftfloor shift

3.363

3.363

1.947

1.9471.285

1.285

0.9390.939

0.756

0.7563.0833.083

4.3224.322

29136291361.8 (1.9)1.8 (1.9)

F5M33-2-SPA!4G63-DOHC (Turbo)5-speed

trzinsaxlefloor shift.-~,3.090

1.833

1.217

0.888

0.7413.166

4.153

291362.2 (2.3)

ItemsStandard value

Transaxle

Input shaft end play

Intermediate gear bearing end play

Intermediate gear preload

Output shaft preload

Differential

Differential case preload

Differential pinion backlash

LimitSpecifications

o-0.05 (O-.002)

0.01-0.12 (.0004-.005)

0.01-0.09 (.0004-.004)

0.01-0.14 (.0004-,006)

0.05-0.10 (.002-.004)

0.05-0.10 (.002-.004)

0.05-0.10 (.002-.004)

0.025-0.150 LOO1 -.006)mm (in.)

Synchronizer ring and clutch gear clearance0.5 (.02)

Page 763 of 1216

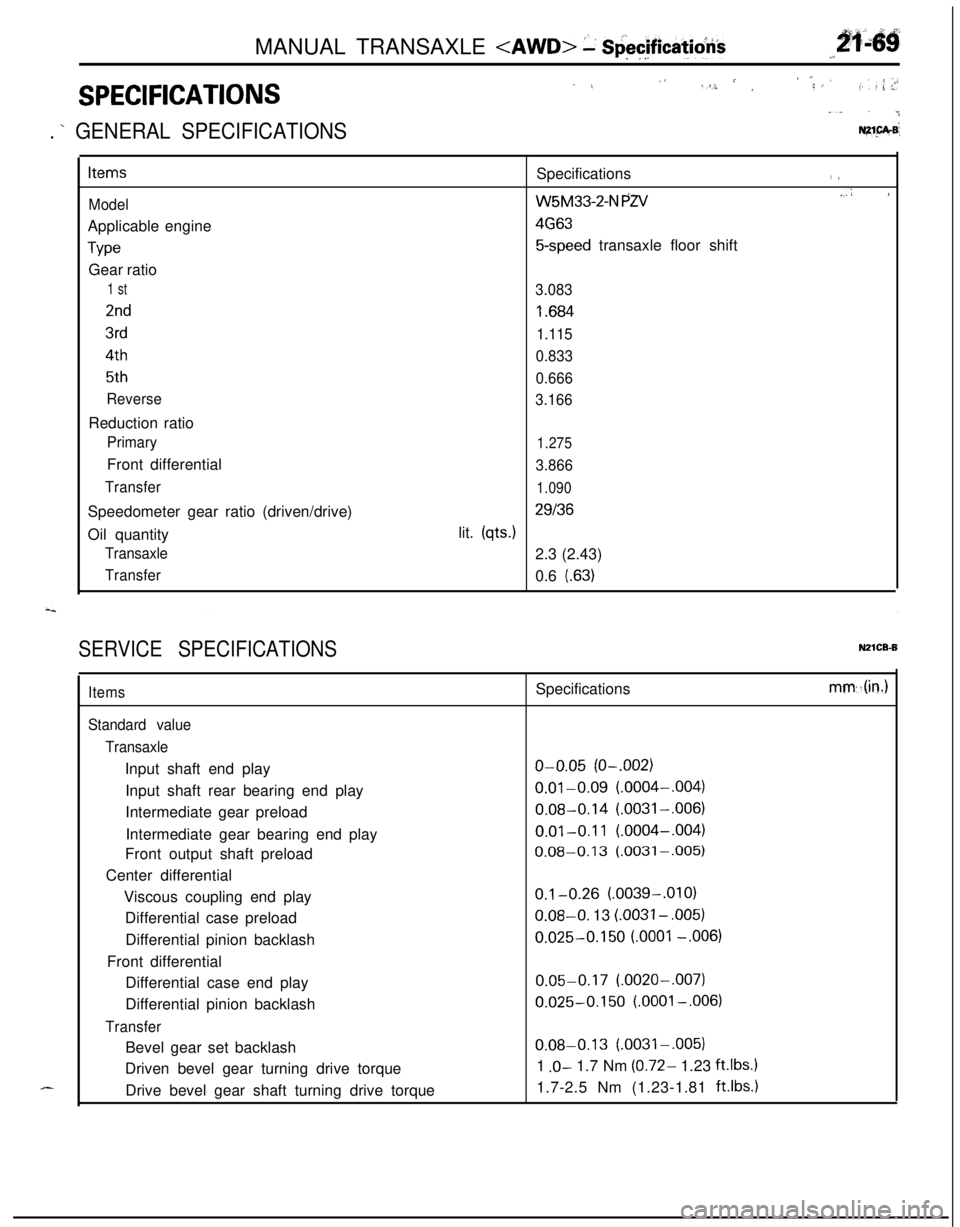

MANUAL TRANSAXLE

2f.46g

\ ,...,

,,, .,

SPECIFICATIONS

1 L,‘S. / ,‘; ,< ’,f. : ,: ; .>r

“. . ..&

. ’ GENERAL SPECIFICATIONSNZ1.pA.B’

Items

ModelApplicable engine

TypeGear ratio

1 st

2nd

3rd

4th

5th

ReverseReduction ratio

PrimaryFront differential

TransferSpeedometer gear ratio (driven/drive)

Oil quantity

Transaxle

TransferSpecifications

(I

W5M33-2-N PZV.,A I

4G63

5-speed transaxle floor shift

3.083

I .684

1.115

0.833

0.666

3.166

1.275

3.866

1.090

29136lit.

(qts.)2.3 (2.43)

0.6

l.63)

SERVICE SPECIFICATIONSN21CB-B

d-...

Items

Standard value

TransaxleInput shaft end play

Input shaft rear bearing end play

Intermediate gear preload

Intermediate gear bearing end play

Front output shaft preload

Center differential

Viscous coupling end play

Differential case preload

Differential pinion backlash

Front differential

Differential case end play

Differential pinion backlash

TransferBevel gear set backlash

Driven bevel gear turning drive torque

Drive bevel gear shaft turning drive torqueSpecifications

o-0.05 (O-.002)

0.01-0.09 (.0004-,004)

0.08-0.14 (.0031-,006)

0.01-0.11 (.0004-,004)

0.08-0.13 (.0031-,005)

0.1-0.26 (.0039-.OlO)0.08-O. 13

LOO31 - ,005)

0.025-0.150 LOO01 -.006)

0.05-0.17 (.0020-,007)

0.025-0.150 (.OOOl-,006)

0.08-0.13 (.0031-.005)

1

.O- 1.7 Nm (0.72- 1.23 ft.lbs.11.7-2.5 Nm (1.23-1.81

ft.lbs.1

mm,.(in.)

Page 774 of 1216

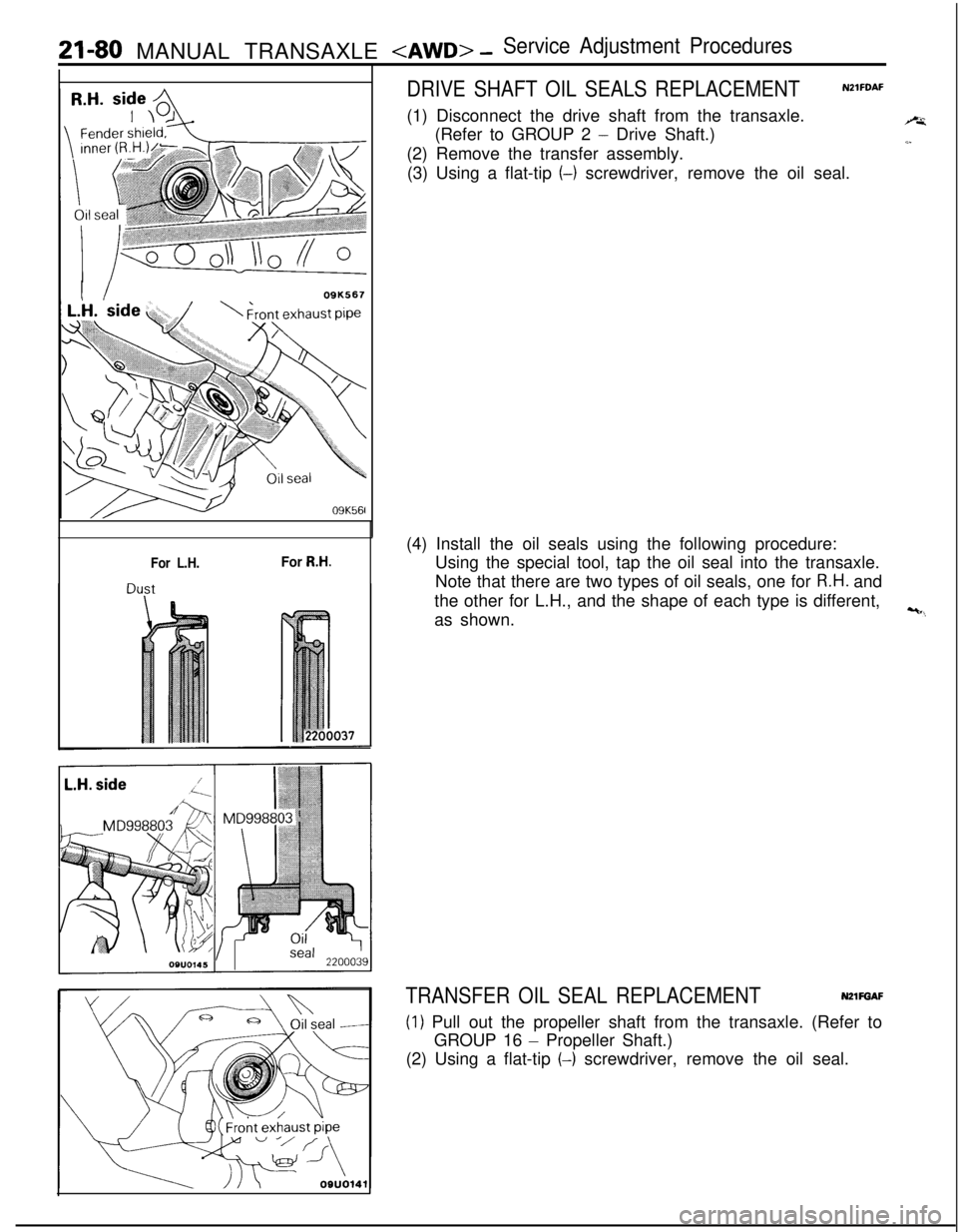

21-80 MANUAL TRANSAXLE

I I09K567

09K561

For L.H.For R.H.

DRIVE SHAFT OIL SEALS REPLACEMENTNZlFDAF(1) Disconnect the drive shaft from the transaxle.

(Refer to GROUP 2

- Drive Shaft.)Pas-(2) Remove the transfer assembly.

(3) Using a flat-tip

(-) screwdriver, remove the oil seal.

(4) Install the oil seals using the following procedure:

Using the special tool, tap the oil seal into the transaxle.

Note that there are two types of oil seals, one for

R.H. and

the other for L.H., and the shape of each type is different,

as shown.

-.

TRANSFER OIL SEAL REPLACEMENTN2lFGAF

(1) Pull out the propeller shaft from the transaxle. (Refer to

GROUP 16

- Propeller Shaft.)

(2) Using a flat-tip

(-) screwdriver, remove the oil seal.

Page 853 of 1216

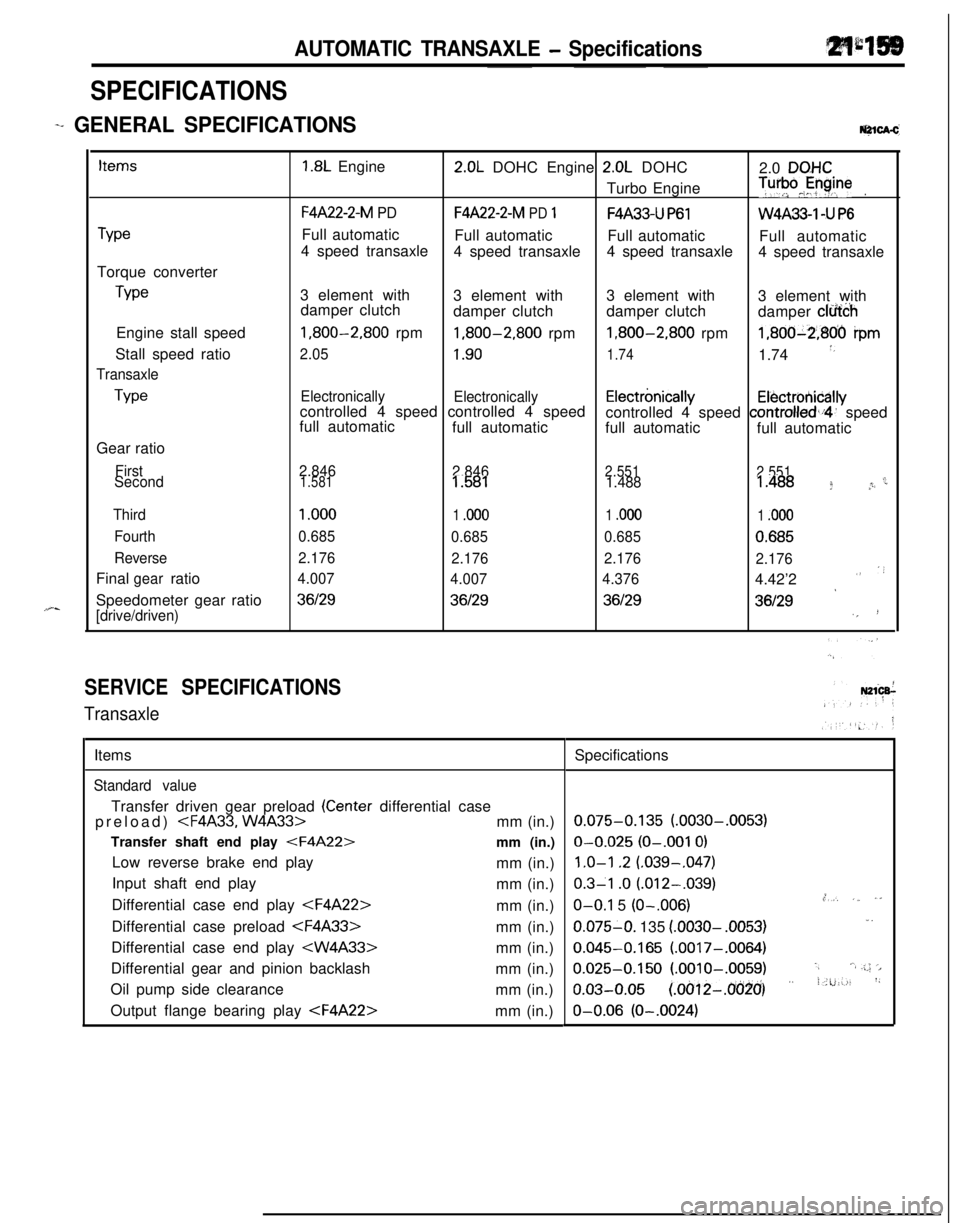

AUTOMATIC TRANSAXLE - Specifications

SPECIFICATIONS

-+ GENERAL [email protected]

TypeTorque converter

TypeEngine stall speed

Stall speed ratio

Transaxle

TypeGear ratio

First

Second

Third

Fourth

ReverseFinal ratio

gearSpeedometer gear ratio

[drive/driven)

1.8L Engine2.0L DOHC Engine 2.0L DOHC

2.0 DQHCTurbo Engine

T”‘pJyine.

F4A22-2-M PDF4A22-2-M PD 1F4A33-U P61W4A33-1 -U P6Full automatic

Full automatic

Full automatic

Full automatic

4 speed transaxle

4 speed transaxle4 speed transaxle

4 speed transaxle

3 element with

3 element with3 element with

3 element with

damper clutch

damper clutchdamper clutch

damper clfi&h

1,800-2,800 rpm1,800-2,800 rpm1,800-2,800 rpm1,800-2,806 ipm

2.051.901.741.74 *,

Electronically

Electronicallycontrolled 4 speed controlled 4 speedElectrbnicallyElectrotiicallyfull automaticcontrolled 4 speed controlled,i4’ speed

full automatic

full automatic

full automatic

2.846

2.8462.551

2.551c1.5811.5811.4881.488 f *r

1 .ooo

1 .ooo1 .ooo1 .ooo

0.685

0.6850.6850.685

2.176

2.1762.176

2.176

4.007

4.0074.3764.42’2

””

*36129361293612936129‘,!

SERVICE SPECIFICATIONS

TransaxleItems

Standard valueTransfer driven gear preload

(Center differential case

preload)

Transfer shaft end play

Low reverse brake end play

mm (in.)

Input shaft end play

mm (in.)

Differential case end play

Differential case preload

Differential case end play

Differential gear and pinion backlash

mm (in.)

Oil pump side clearance

mm (in.)

Output flange bearing play

0.075-0.135 (.0030-.0053)O-0.025

(O-.001 0)

1.0-l .2 (.039-,047)

0.3-l .o (.012-.039).,O-O.1 5 (O-.006),*, ,_ ,”0.075-O. 135

(.0030- .0053)1.

0.045-0.165 (.0017-.0064)

0.025-0.150 (.OOlO-.0059).,‘.a .;.; ‘>

o.03-o.05 (~oo12-~o(j~o’) ” i.u:-., ‘~O-0.06

(O-.0024)

Page 862 of 1216

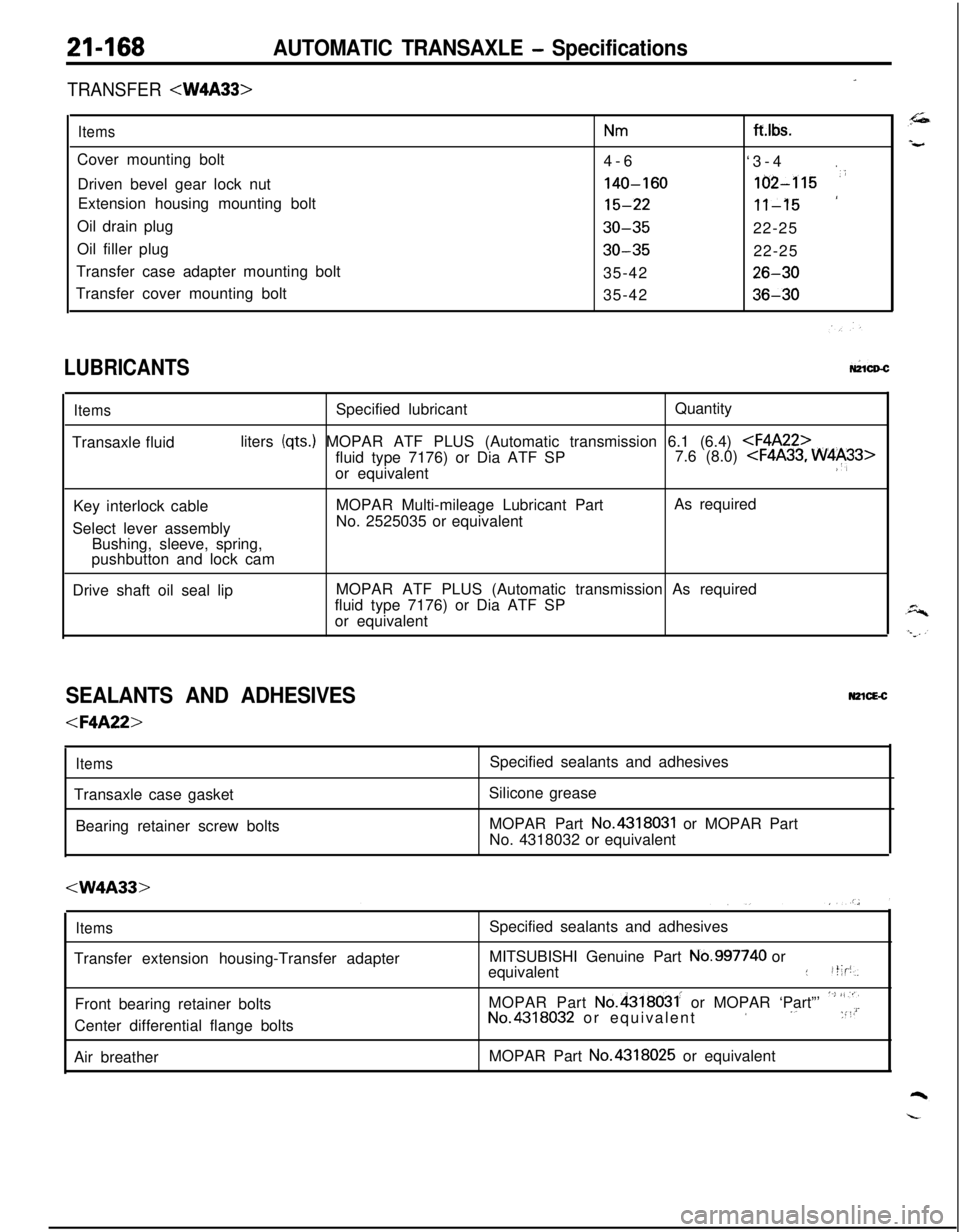

21-168AUTOMATIC TRANSAXLE - Specifications

-TRANSFER

ItemsNmCover mounting bolt

4-6

Driven bevel gear lock nut

140-160Extension housing mounting bolt

15-22Oil drain plug

30-35Oil filler plug

30-35Transfer case adapter mounting bolt

35-42

Transfer cover mounting bolt

35-42ft.lbs.

‘3-4

.

162-115 ‘i

‘11-1522-25

22-25

26-30

36-30

LUBRICANTSW1CD-C

ItemsSpecified lubricantQuantity

Transaxle fluidliters

(qts.) MOPAR ATF PLUS (Automatic transmission 6.1 (6.4)

or equivalent

:‘,Key interlock cableMOPAR Multi-mileage Lubricant PartAs required

Select lever assemblyNo. 2525035 or equivalent

Bushing, sleeve, spring,

pushbutton and lock cam

Drive shaft oil seal lipMOPAR ATF PLUS (Automatic transmission As required

fluid type 7176) or Dia ATF SP

or equivalent

SEALANTS AND ADHESIVESN2lcE-c

ItemsTransaxle case gasket

Bearing retainer screw bolts

Silicone grease

MOPAR Part

No.4318031 or MOPAR Part

No. 4318032 or equivalent

ItemsTransfer extension housing-Transfer adapter

Front bearing retainer bolts

Center differential flange bolts

Air breatherSpecified sealants and adhesives

MITSUBISHI Genuine Part

No.997740 or

equivalent::t;p,

MOPAR Part

No.4318031. or MOPAR ‘Part”’ ‘~’ “,“iNo.4318032 or equivalent’ ‘. :“’MOPAR Part No.4318025 or equivalent

Page 889 of 1216

AUTOMATIC TRANSAXLE - Troubleshooting21'495

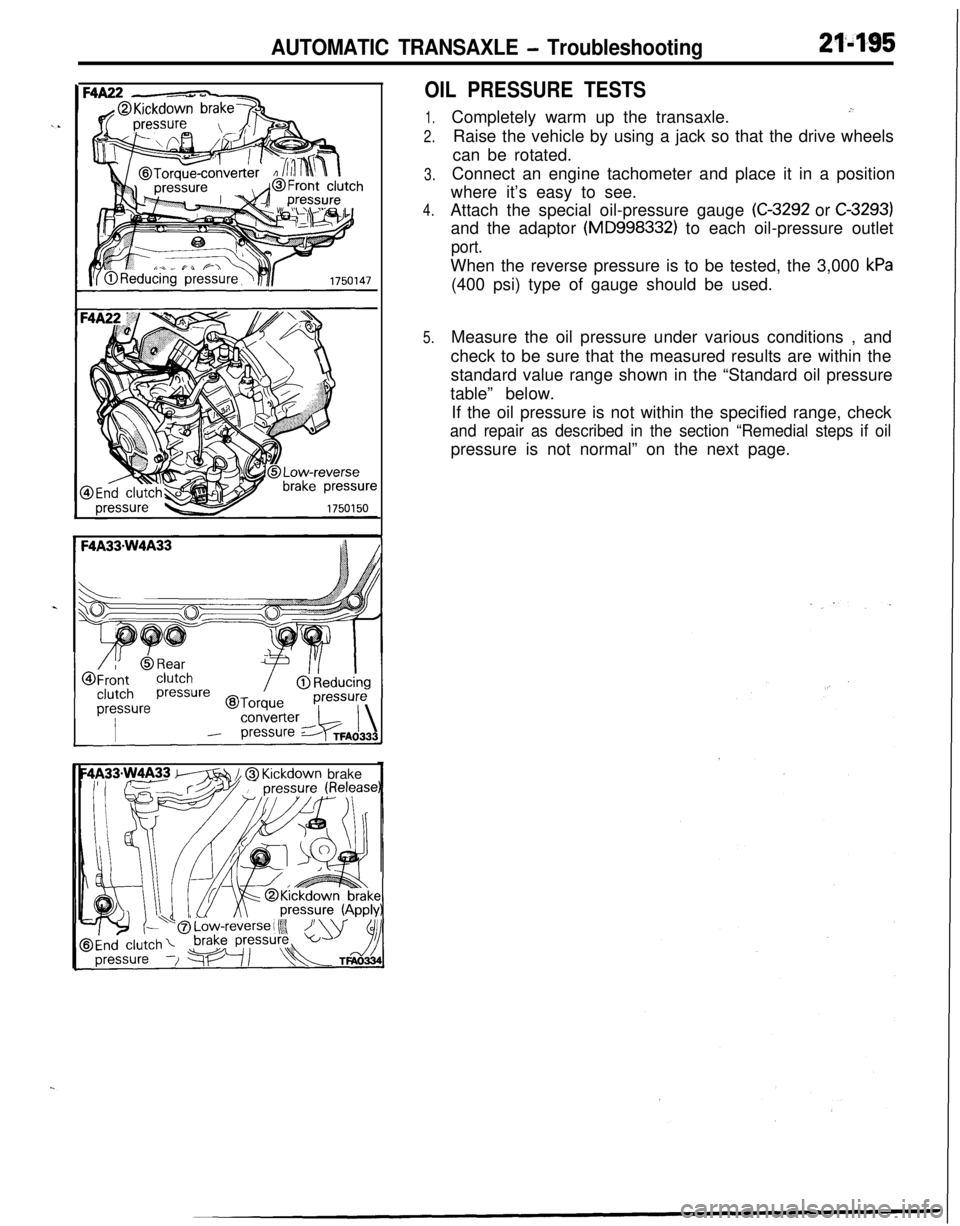

OIL PRESSURE TESTS

1.

2.

3.

4.

5.Completely warm up the transaxle.

.”Raise the vehicle by using a jack so that the drive wheels

can be rotated.

Connect an engine tachometer and place it in a position

where it’s easy to see.

Attach the special oil-pressure gauge

(C-3292 or C-3293)and the adaptor

(MD998332) to each oil-pressure outlet

port.When the reverse pressure is to be tested, the 3,000

kPa(400 psi) type of gauge should be used.

Measure the oil pressure under various conditions , and

check to be sure that the measured results are within the

standard value range shown in the “Standard oil pressure

table” below.

If the oil pressure is not within the specified range, check

and repair as described in the section “Remedial steps if oilpressure is not normal” on the next page.

m // @ Kickdown brake