electrical MITSUBISHI ENDEAVOR 2004 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 295 of 3870

3. To install, reverse removal procedure. Tighten front seat nuts and bolts to

specification. See TORQUE SPECIFICATIONS

. Activate air bag system.

SIDE IMPACT SENSOR Removal & Installation 1. Before proceeding, see AIR BAG SAFETY PRECAUTIONS

. Disable air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

.

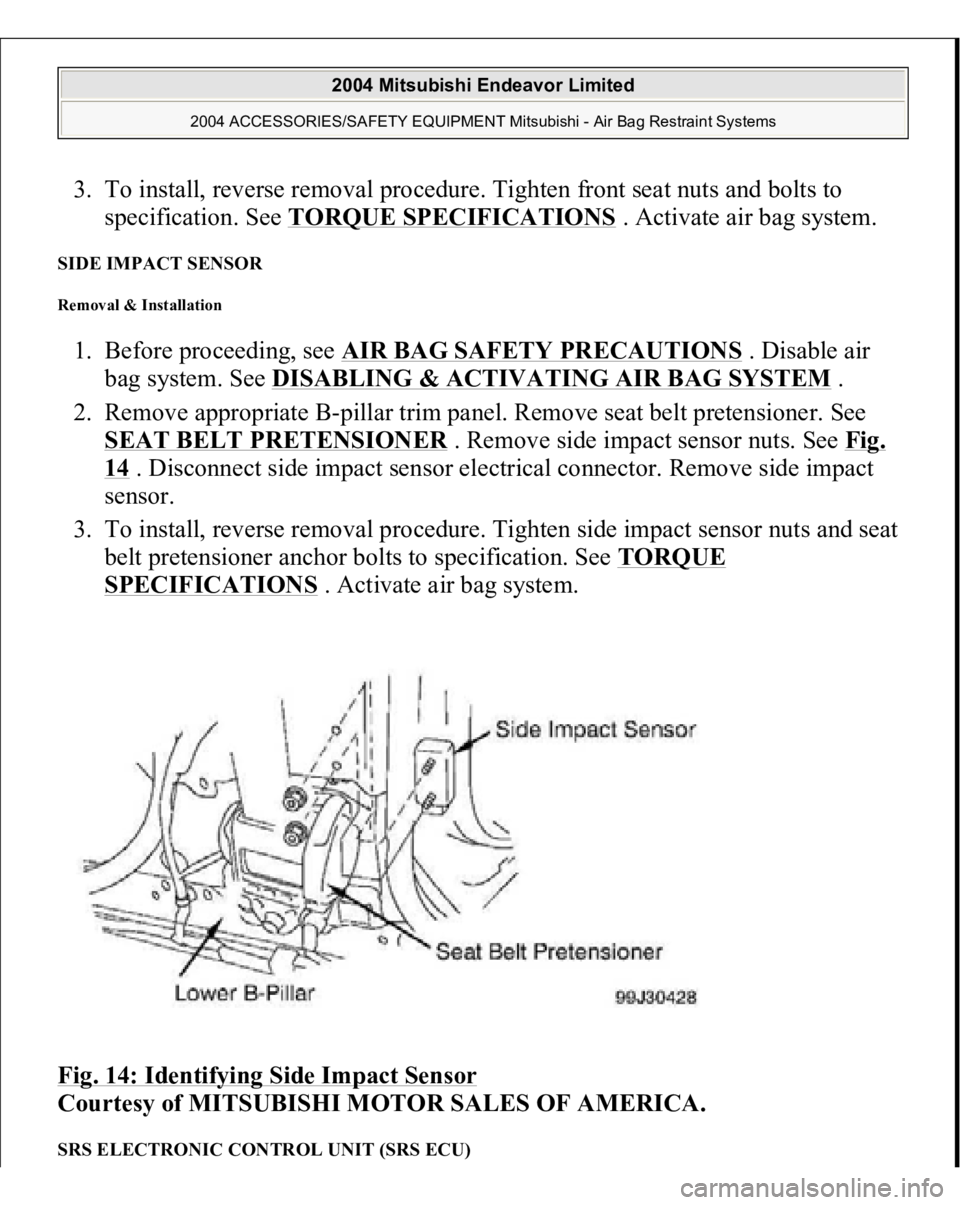

2. Remove appropriate B-pillar trim panel. Remove seat belt pretensioner. See

SEAT BELT PRETENSIONER

. Remove side impact sensor nuts. See Fig.

14 . Disconnect side impact sensor electrical connector. Remove side impact

sensor.

3. To install, reverse removal procedure. Tighten side impact sensor nuts and seat

belt pretensioner anchor bolts to specification. See TORQUE SPECIFICATIONS

. Activate air bag system.

Fig. 14: Identifying Side Impact Sensor

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

SRS ELECTRONIC CONTROL UNIT (SRS ECU)

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 321 of 3870

ohms in each wire, go to next step. If resistance is more than 2 ohms in either

wire, replace wire harness. Go to next step.

4. Reconnect all SRS components. Activate air bag system. Using scan tool, erase

then retrieve DTCs. If DTC 25 is retrieved, go to step 1 . If DTC 25 is not

retrieved, system is normal at this time. Intermittent condition may exist.

DTC 26: DRIVER-SIDE SEAT BELT PRETENSIONER SHORT CIRCUIT 1. Before proceeding, see AIR BAG SAFETY PRECAUTIONS

. Disable SRS.

See DISABLING & ACTIVATING AIR BAG SYSTEM

. If DTC 34 is

retrieved, go to next step. If DTC 34 is not retrieved, go to step 3 .

2. Inspect SRS ECU connector C-25. See SRS ELECTRONIC CONTROL

UNIT (SRS ECU)

under REMOVAL & INSTALLATION. See Fig. 19

. If

connector is connected properly, go to next step. If connector is not connected

properly, connect properly and go to step 7 .

3. Disconnect negative battery cable. Disconnect, then reconnect SRS ECU

connector C-25 and driver-side seat belt pretensioner connector D-24. See

SEAT BELT PRETENSIONER

under REMOVAL & INSTALLATION.

Connect negative battery cable. Using scan tool, check for DTCs. If DTC 26 is

retrieved, go to next step. If DTC 26 is not retrieved, system is normal at this

time.

4. Disconnect negative battery cable. Connect Load Resistor (MB991865) to

Resistor Harness (MB991884). Connect resistor harness to driver-side seat belt

pretensioner connector D-24. Connect negative battery cable. Using scan tool,

check for DTCs. If DTC 26 is retrieved, go to next step. If DTC 26 is not

retrieved, replace driver-side seat belt pretensioner.

5. Disconnect SRS ECU connector C-25 and driver-side seat belt connector D-24.

Insert a cable tie or similar insulator between terminals No. 29 (Red/Blue wire)

and No. 30 (Red/Yellow wire) of SRS ECU connector to release shorting bar.

See Fig. 21

. If continuity exists between terminals No. 29 and 30, go to next

ste

p. If continuit

y does not exist, between terminals No. 29 and 30, erase, then

NOTE: Ensure shorting bar in SRS ECU connector is released by

using a cable tie or similar non conducting item to release

shorting bar before performing electrical measurements.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 322 of 3870

retrieve DTCs using scan tool. If DTC 26 is retrieved, replace SRS ECU. Go to

step 7 .

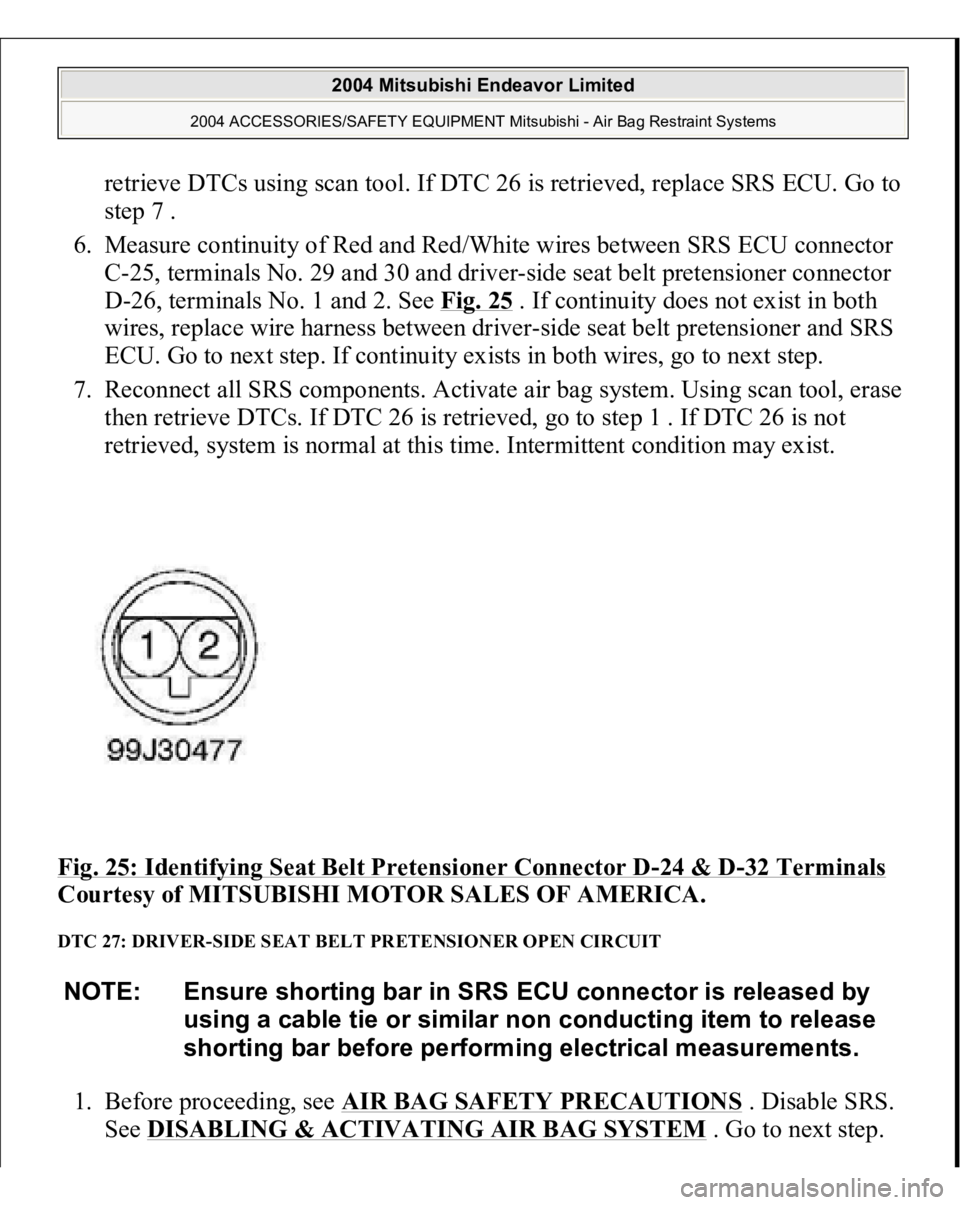

6. Measure continuity of Red and Red/White wires between SRS ECU connector

C-25, terminals No. 29 and 30 and driver-side seat belt pretensioner connector

D-26, terminals No. 1 and 2. See Fig. 25

. If continuity does not exist in both

wires, replace wire harness between driver-side seat belt pretensioner and SRS

ECU. Go to next step. If continuity exists in both wires, go to next step.

7. Reconnect all SRS components. Activate air bag system. Using scan tool, erase

then retrieve DTCs. If DTC 26 is retrieved, go to step 1 . If DTC 26 is not

retrieved, system is normal at this time. Intermittent condition may exist.

Fig. 25: Identifying Seat Belt Pretensioner Connector D

-24 & D

-32 Terminals

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

DTC 27: DRIVER-SIDE SEAT BELT PRETENSIONER OPEN CIRCUIT 1. Before proceeding, see AIR BAG SAFETY PRECAUTIONS

. Disable SRS.

See DISABLING & ACTIVATING AIR BAG SYSTEM

. Go to next ste

p.

NOTE: Ensure shorting bar in SRS ECU connector is released by

using a cable tie or similar non conducting item to release

shorting bar before performing electrical measurements.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 323 of 3870

2. Disconnect driver-side seat belt pretensioner connector D-24. See SEAT

BELT PRETENSIONER

under REMOVAL & INSTALLATION. See Fig.

19 . Connect Load Resistor (MB991865) to Resistor Harness (MB991884).

Connect resistor harness to driver-side seat belt pretensioner connector.

Connect negative battery cable. Using scan tool, check for DTCs. If DTC 27 is

retrieved, go to next step. If DTC 27 is not retrieved, replace driver-side seat

belt pretensioner.

3. Disconnect SRS ECU connector C-25. See SRS ELECTRONIC CONTROL UNIT (SRS ECU)

under REMOVAL & INSTALLATION. Measure

resistance of Red/Blue wire between SRS ECU connector C-25, terminal No.

29 and driver-side seat belt pretensioner connector D-26, terminal No. 1. See

Fig. 21

& Fig. 25

. Measure resistance of Red/Yellow wire between SRS ECU

connector terminal No. 30 and driver-side seat belt pretensioner connector D-

26, terminal No. 2. If resistance is 2 ohms or less in both wires, erase, then

retrieve DTCs using scan tool. If DTC 27 is retrieved, replace SRS ECU. Go to

next step. If resistance is more than 2 ohms in either wire, replace wire harness

between SRS ECU and seat belt pretensioner. Go to next step.

4. Reconnect all SRS components. Activate air bag system. Using scan tool, erase

then retrieve DTCs. If DTC 27 is retrieved, go to step 1 . If DTC 27 is not

retrieved, system is normal at this time. Intermittent condition may exist.

DTC 28: PASSENGER-SIDE SEAT BELT PRETENSIONER SHORT CIRCUIT 1. Before proceeding, see AIR BAG SAFETY PRECAUTIONS

. Disable SRS.

See DISABLING & ACTIVATING AIR BAG SYSTEM

. If DTC 34 is

retrieved, go to next step. If DTC 34 is not retrieved, go to step 3 .

2. Inspect SRS ECU connector C-25. See SRS ELECTRONIC CONTROL

UNIT (SRS ECU)

under REMOVAL & INSTALLATION. See Fig. 19

. If

connector is connected properly, go to next step. If connector is not connected

properly, connect properly. Go to step 7 .

3. Disconnect ne

gative batter

y cable. Disconnect SRS ECU connector

C-25 and

NOTE: Ensure shorting bar in SRS ECU connector is released by

using a cable tie or similar non conducting item to release

shorting bar before performing electrical measurements.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 324 of 3870

passenger-side seat belt pretensioner connector D-32. See SEAT BELT PRETENSIONER

under REMOVAL & INSTALLATION. Reconnect

connectors. Connect negative battery cable. Using scan tool, check for DTCs.

If DTC 28 is retrieved, go to next step. If DTC 28 is not retrieved, system is

normal at this time.

4. Disconnect negative battery cable. Connect Load Resistor (MB991865) to

Resistor Harness (MB991884). Connect resistor harness to driver-side seat belt

pretensioner connector D-32. Connect negative battery cable. Using scan tool,

check for DTCs. If DTC 28 is retrieved, go to next step. If DTC 28 is not

retrieved, replace passenger-side seat belt pretensioner.

5. Disconnect SRS ECU connector C-25 and passenger-side seat belt connector

D-32. Insert a cable tie or similar insulator between terminals No. 27 (Red

wire) and 28 (Red/White wire) of SRS ECU connector to release shorting bar.

See Fig. 21

. Check for continuity between terminals. If continuity exists, go to

next step. If continuity does not exist, erase, then retrieve DTCs using scan

tool. If DTC 28 is retrieved, replace SRS ECU. Go to step 7 .

6. Measure continuity of Red and Red/White wires between SRS ECU connector

C-25, terminals No. 27 and 28 and passenger-side seat belt pretensioner

connector D-39, terminals No. 1 and 2. See Fig. 25

. If continuity does not

exist in both wires, replace wire harness between SRS ECU and passenger-side

seat belt pretensioner. Go to next step. If continuity exists in both wires, go to

next step.

7. Reconnect all SRS components. Activate air bag system. Using scan tool, erase

then retrieve DTCs. If DTC 28 is retrieved, go to step 1 . If DTC 28 is not

retrieved, system is normal at this time. Intermittent condition may exist.

DTC 29: PASSENGER-SIDE SEAT BELT PRETENSIONER OPEN CIRCUIT 1. Before proceeding, see AIR BAG SAFETY PRECAUTIONS

. Disable SRS.

See DISABLING & ACTIVATING AIR BAG SYSTEM

. Go to next step.

2. Disconnect

passen

ger-side seat belt

pretensioner connector D-32. See SEAT

NOTE: Ensure shorting bar in SRS ECU connector is released by

using a cable tie or similar non conducting item to release

shorting bar before performing electrical measurements,

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 380 of 3870

diagnose CAN bus lines and CAN bus lines are satisfactory, go to next step. If

scan tool cannot diagnose CAN bus lines, repair CAN bus lines. Go to next

step.

2. Erase, then retrieve DTCs. If DTC B1435 is retrieved, replace SRS ECU. See

SRS ELECTRONIC CONTROL UNIT (SRS ECU)

under REMOVAL &

INSTALLATION. If DTC B1435 is not retrieved, an intermittent condition

may exist.

DTCB1436: SIDE IMPACT SENSOR (LH) FAILURE 1. Connect scan tool to Data Link Connector (DLC). See INITIAL SRS

DIAGNOSTIC PROCEDURE

under DIAGNOSTICS. If scan tool is able to

diagnose CAN bus lines and CAN bus lines are satisfactory, go to next step. If

scan tool cannot diagnose CAN bus lines, repair CAN bus lines.

2. Erase, then retrieve DTCs. If DTC B1466 is retrieved, go to next step. If DTC

B1436 is not retrieved, an intermittent condition may exist.

3. Replace driver-side impact sensor. See FRONT IMPACT SENSOR

under

REMOVAL & INSTALLATION. Reconnect SRS components. Erase, then

retrieve DTCs. If DTC B1436 is retrieved, replace SRS ECU. See SRS

ELECTRONIC CONTROL UNIT (SRS ECU)

under REMOVAL &

INSTALLATION. If DTC B1436 is not retrieved, system is normal at this

time.

DTCB1437: FRONT IMPACT SENSOR (LH) VOLTAGE ERROR 1. Connect scan tool to Data Link Connector (DLC). See INITIAL SRS

DIAGNOSTIC PROCEDURE

under DIAGNOSTICS. If scan tool is able to

diagnose CAN bus lines and CAN bus lines are satisfactory, go to next step. If

scan tool cannot diagnose CAN bus lines, repair CAN bus lines. Go to next

step.

2. Erase, then retrieve DTCs. Turn ignition off. If DTC B1437 is retrieved,

go to

NOTE: When making electrical measurements at SRS ECU

connector, use a cable tie to ensure shorting bar in SRS

ECU connector is released and does not interfere with

electrical measurements.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 456 of 3870

2004 TRANSMISSION

Automatic Transaxle Overhaul - Endeavor

GENERAL INFORMATION This automatic transaxle is made up of the following main parts.

The gear train is made up of 3 multi-plate clutches, 2 multi-plate brakes and 2

planetary gears made up of a sun gear, carrier, pinion gear and annulus gear.

The torque converter employs a 3 element, 1 step, 2 phase lock-up clutch.

The cases consist of a converter housing, transaxle case, rear cover and a valve

body cover.

Parts related to oil pressure regulation are the oil pump, which pressurizes the oil;

the regulator, which controls the pressure setting; the solenoid valves, which

changes the oil pressure with electrical signals; the pressure control valve, which

controls the oil pressure coming from the solenoid valve that effects each clutch and

brake; each kind of valve, which carry out the retention of the oil pressure through

the lines; and finally the valve body, which houses all the valves. SECTIONAL VIEW < F4A5A >

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 695 of 3870

2004 ELECTRICAL

Battery - Endeavor

BATTERY ON-VEHICLE SERVICE BATTERY CHECK

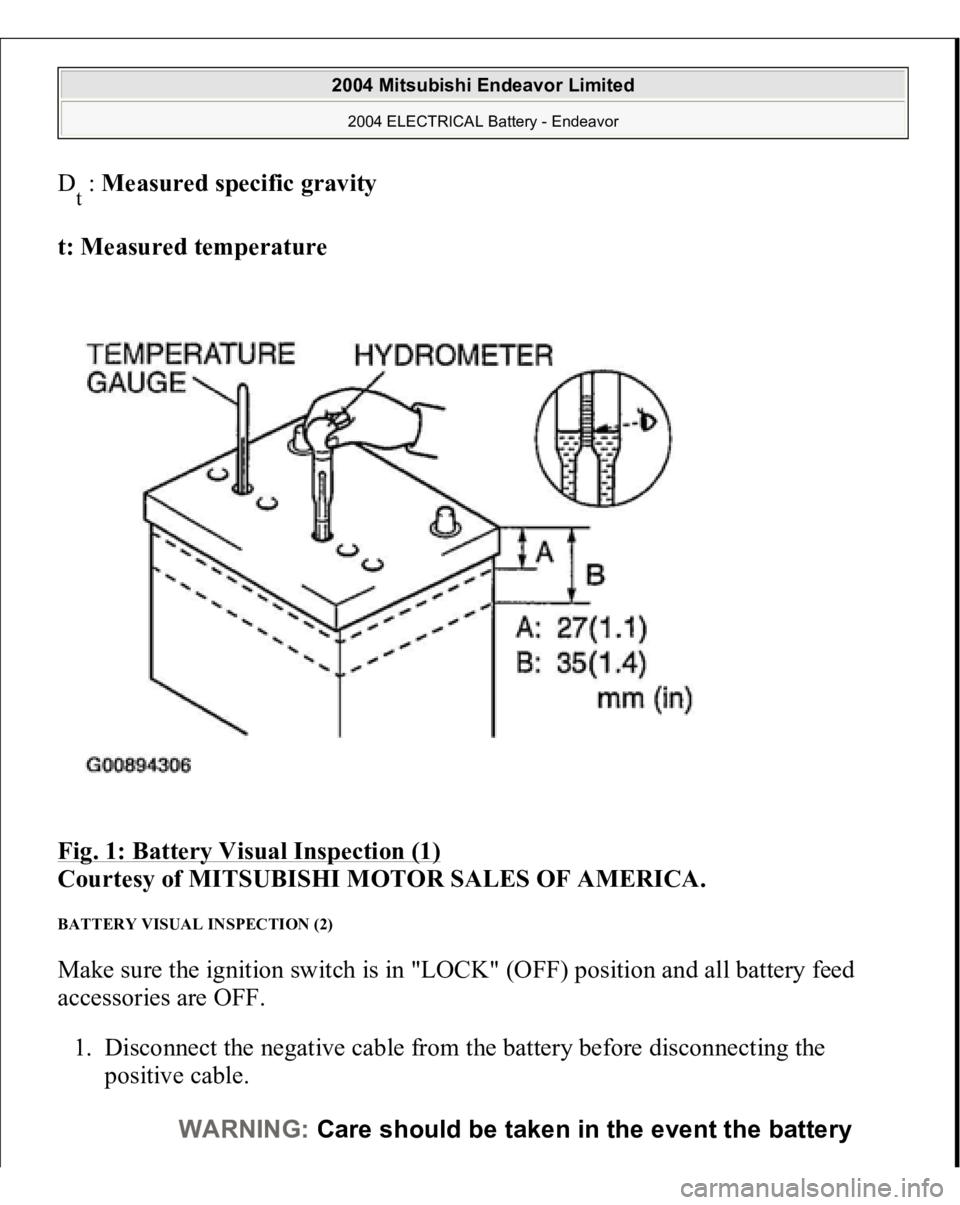

BATTERY VISUAL INSPECTION (1) 1. Ensure that the battery electrolyte level is between A and B shown in the

figure. Add if the level is lower than the specified range.

2. Use a hydrometer and temperature gauge to check the specific gravity of the

electrolyte.

Standard value:

1.220 - 1.290 [at 20°C (68°F)]

The specific gravity of electrolyte depends on its temperature. Use the formula

below to determine the proper value.

Conversion on centigrade

D20 =(t - 20) x 0.0007 + Dt

Conversion on Fahrenheit

D20 =(t - 68) x 0.0007 + Dt

D20 : Specific gravity as if electrolyte temperature is 20°C (68°F)

WARNING:Battery posts, terminals and related accessories

contain lead and lead compounds. WASH HANDS

AFTER HANDLING.

2004 Mitsubishi Endeavor Limited 2004 ELECTRICAL Battery - Endeavor

2004 Mitsubishi Endeavor Limited 2004 ELECTRICAL Battery - Endeavor

Page 696 of 3870

Dt : Measured specific gravity

t: Measured temperature

Fig. 1: Battery Visual Inspection (1)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

BATTERY VISUAL INSPECTION (2) Make sure the ignition switch is in "LOCK" (OFF) position and all battery feed

accessories are OFF.

1. Disconnect the negative cable from the battery before disconnecting the

positive cable.

WARNING:Care should be taken in the event the battery

2004 Mitsubishi Endeavor Limited 2004 ELECTRICAL Battery - Endeavor

Page 697 of 3870

2. Remove the battery from the vehicle.

3. Inspect battery carrier for damage caused by loss of acid from the battery. If

acid damage is present, it is necessary to clean area with a solution of clean

warm water and baking soda. Scrub area with a stiff bristle brush. Wipe clean

with a cloth moistened with ammonia or baking soda in water.

4. Clean the battery, especially the top with same solutions as described in step 3.

5. Inspect the battery case and cover for cracks. If cracks are present, battery must

be replaced.

6. Clean the battery post with a suitable battery post cleaning tool.

7. Clean the inside surfaces of the terminal clamps with a suitable battery

terminal cleaning tool. Replace damaged or frayed cables and broken terminal

clamps.

8. Install the battery in the vehicle.

9. Connect the positive and negative cables to the battery in the order of mention.

10. Tighten the clamp nut securely. BATTERY CHARGING Battery electrolyte temperature may temporarily be allowed to rise to 55°C (131°F).

Increase of electrolyte temperature above 55°C (131°F) is harmful to the battery,

causing deformation of battery cell, decrease in life of battery, etc.

case is cracked or leaking to protect hands from

the electrolyte. A suitable pair of rubber gloves

(not the household type) should be worn when

removing battery by hand.

WARNING:When batteries are being charged, an explosive gas

forms beneath the cover of each cell. Do not smoke

near batteries on charge or which have recently

been charged. Do not break live circuits at the

terminals of the batteries on charge. A spark will

occur where the live circuit is broken. Keep all open

flames away from the battery.

2004 Mitsubishi Endeavor Limited 2004 ELECTRICAL Battery - Endeavor