differential MITSUBISHI ENDEAVOR 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 648 of 3870

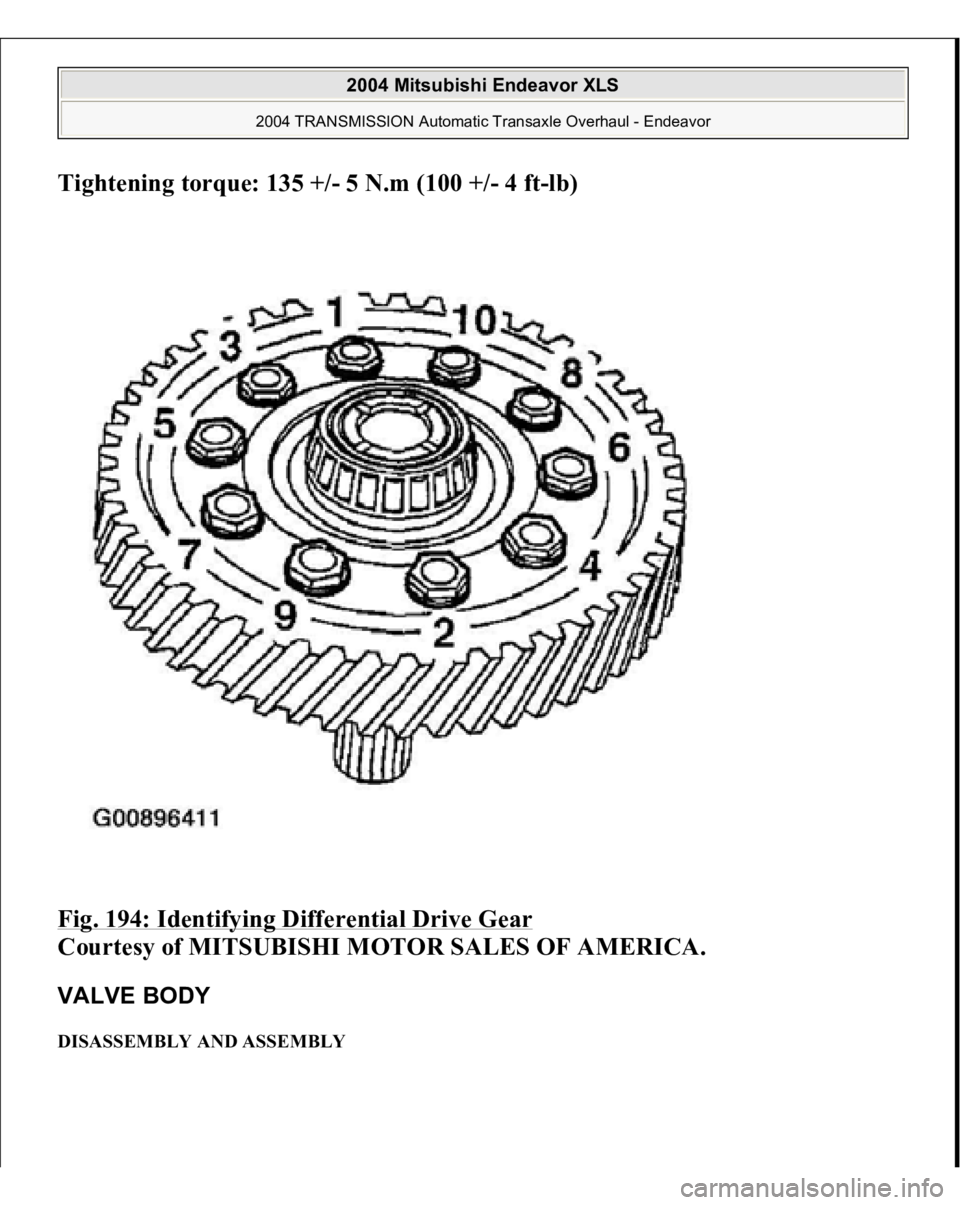

Tightening torque: 135 +/- 5 N.m (100 +/- 4 f

t-lb)

Fig. 194: Identifying Differential Drive Gear

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

VALVE BODY DISASSEMBLY AND ASSEMBLY

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 671 of 3870

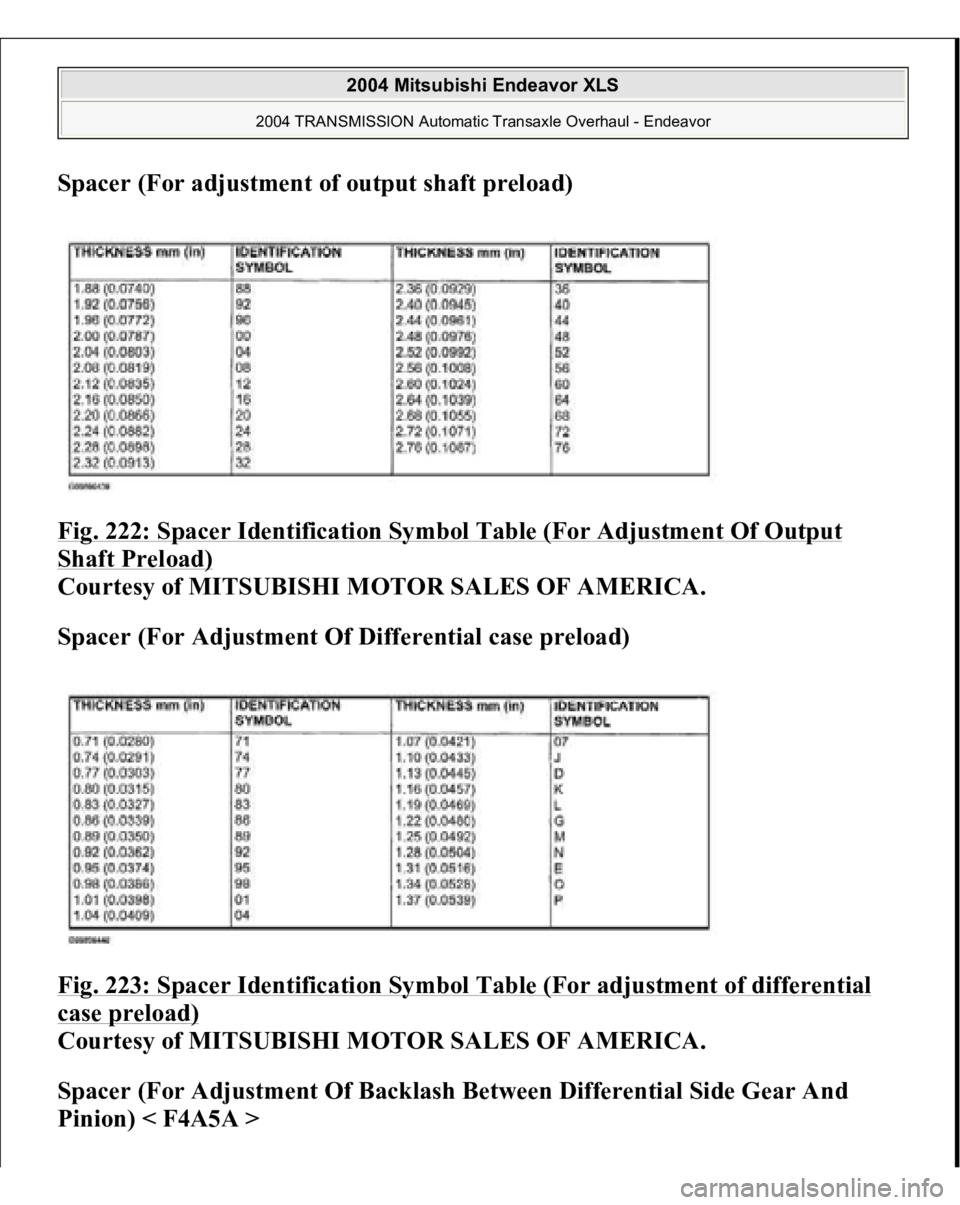

Spacer (For adjustment of output shaft preload)

Fig. 222: Spacer Identification Symbol Table (For Adjustment Of Output Shaft Preload)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Spacer (For Adjustment Of Differential case preload)

Fig. 223: Spacer Identification Symbol Table (For adjustment of differential

case preload)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Spacer (For Adjustment Of Backlash Between Differential Side Gear And

Pinion) < F4A5A >

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 672 of 3870

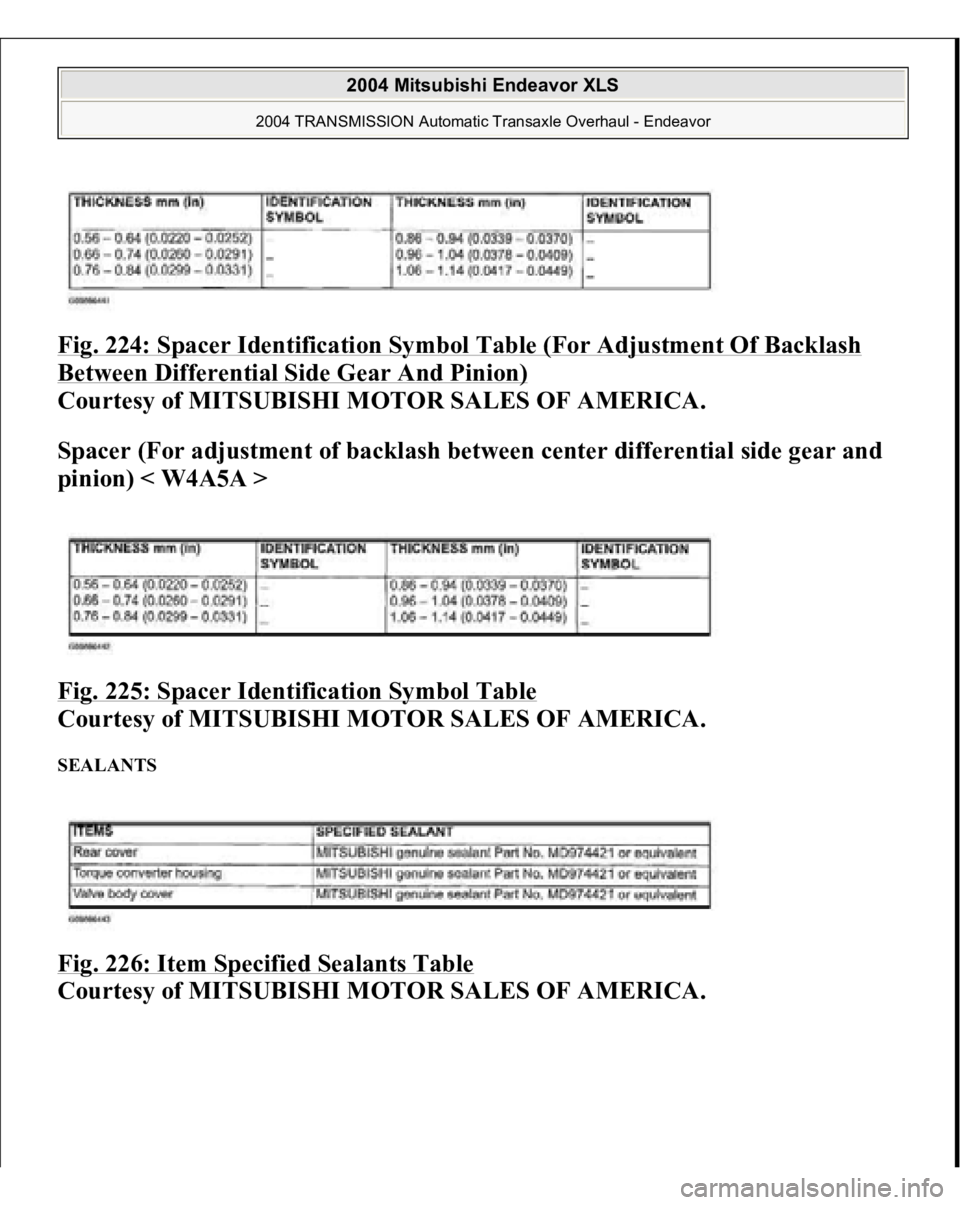

Fig. 224: Spacer Identification Symbol Table (For Adjustment Of Backlash Between Differential Side Gear And Pinion)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Spacer (For adjustment of backlash between center differential side gear and

pinion) < W4A5A >

Fig. 225: Spacer Identification Symbol Table

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

SEALANTS Fig. 226: Item Specified Sealants Table

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 687 of 3870

B. Using Puller Shaft (MB990242), Puller Bar (MB990244), Puller Body

(MB991354), and End Yoke Holder (MB990767), push out the axle shaft from

the hub. Using Sliding Hammer (MB991721), Drive Shaft Puller (MB991833),

and Adapter (MB991961), remove the axle shaft from the differential carrier.

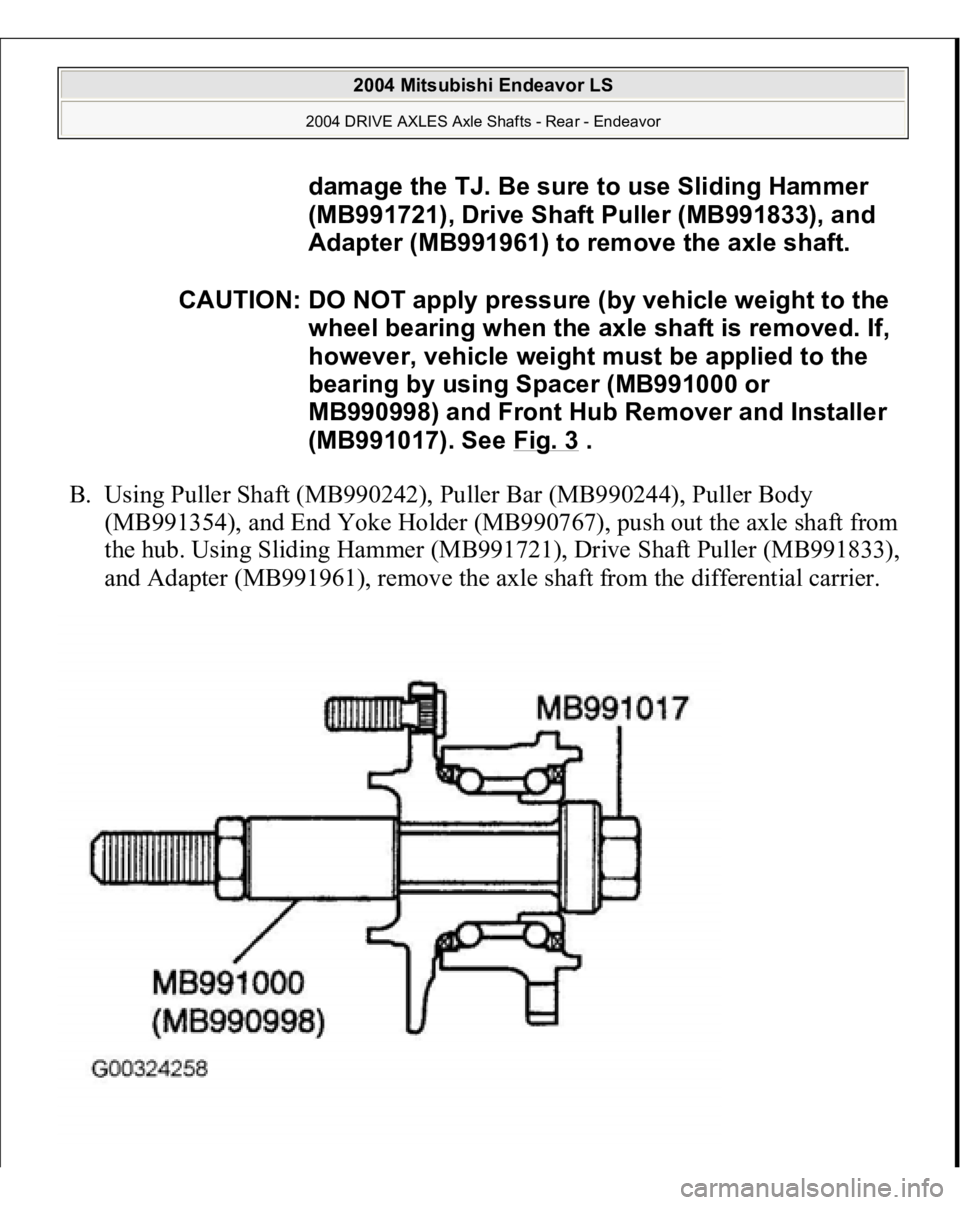

damage the TJ. Be sure to use Sliding Hammer

(MB991721), Drive Shaft Puller (MB991833), and

Adapter (MB991961) to remove the axle shaft.

CAUTION: DO NOT apply pressure (by vehicle weight to the

wheel bearing when the axle shaft is removed. If,

however, vehicle weight must be applied to the

bearing by using Spacer (MB991000 or

MB990998) and Front Hub Remover and Installer

(MB991017). See Fig. 3

.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Rear - Endeavor

Page 1083 of 3870

PROPELLER SHAFT DIAGNOSTIC TROUBLESHOOTING STRATEGYUse these steps to plan your diagnostic strategy. If you follow them carefully, you

will be sure that you have exhausted all of the possible ways to find a propeller

shaft fault.

1. Gather information from the customer.

2. Verify that the condition described by the customer exists.

3. Find the malfunction by following the Symptom Chart.

4. Verify malfunction is eliminated. SYMPTOM CHART Fig. 2: Propeller Shaft Troubleshooting Symptom Chart

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

SYMPTOM PROCEDURES INSPECTION PROCEDURE 1: Noise at Start DIAGNOSIS

STEP 1. Check if the propeller shaft and differential companion flange

connecting nuts and the center bearing mounting nuts are loose.

Connecting nuts tightening torque: 32 +/- 2 N.m (24 +/- 1 ft-lb)

Mounting nuts tightening torque: 30 +/- 4 N.m (22 +/- 3 ft-lb)

Q: Are the connecting nuts and mounting nuts tightened to the specified

torque?

YES: Go to Ste

p 2.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLE Propeller Shaft - Endeavor

Page 1086 of 3870

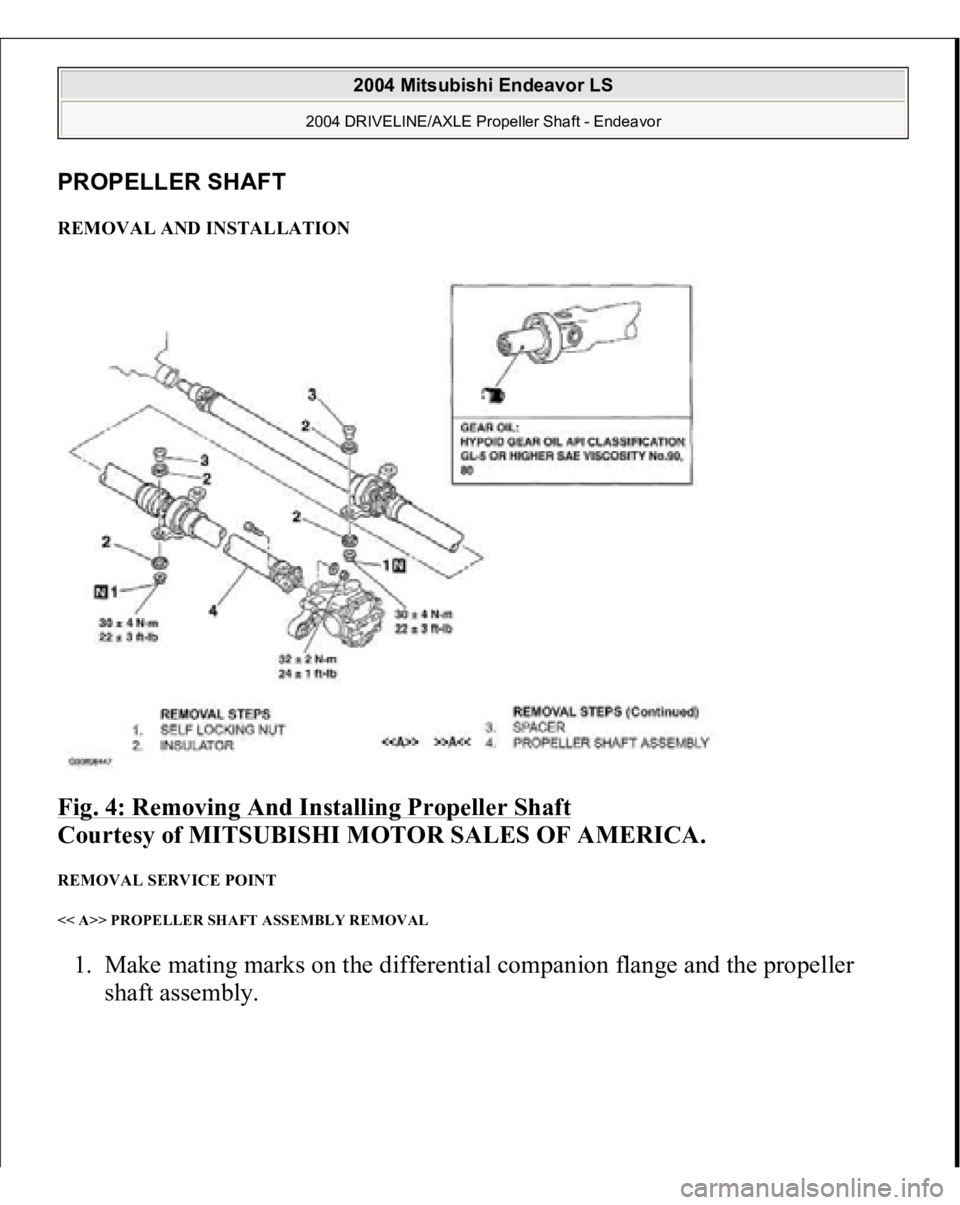

PROPELLER SHAFT REMOVAL AND INSTALLATION Fig. 4: Removing And Installing Propeller Shaft

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

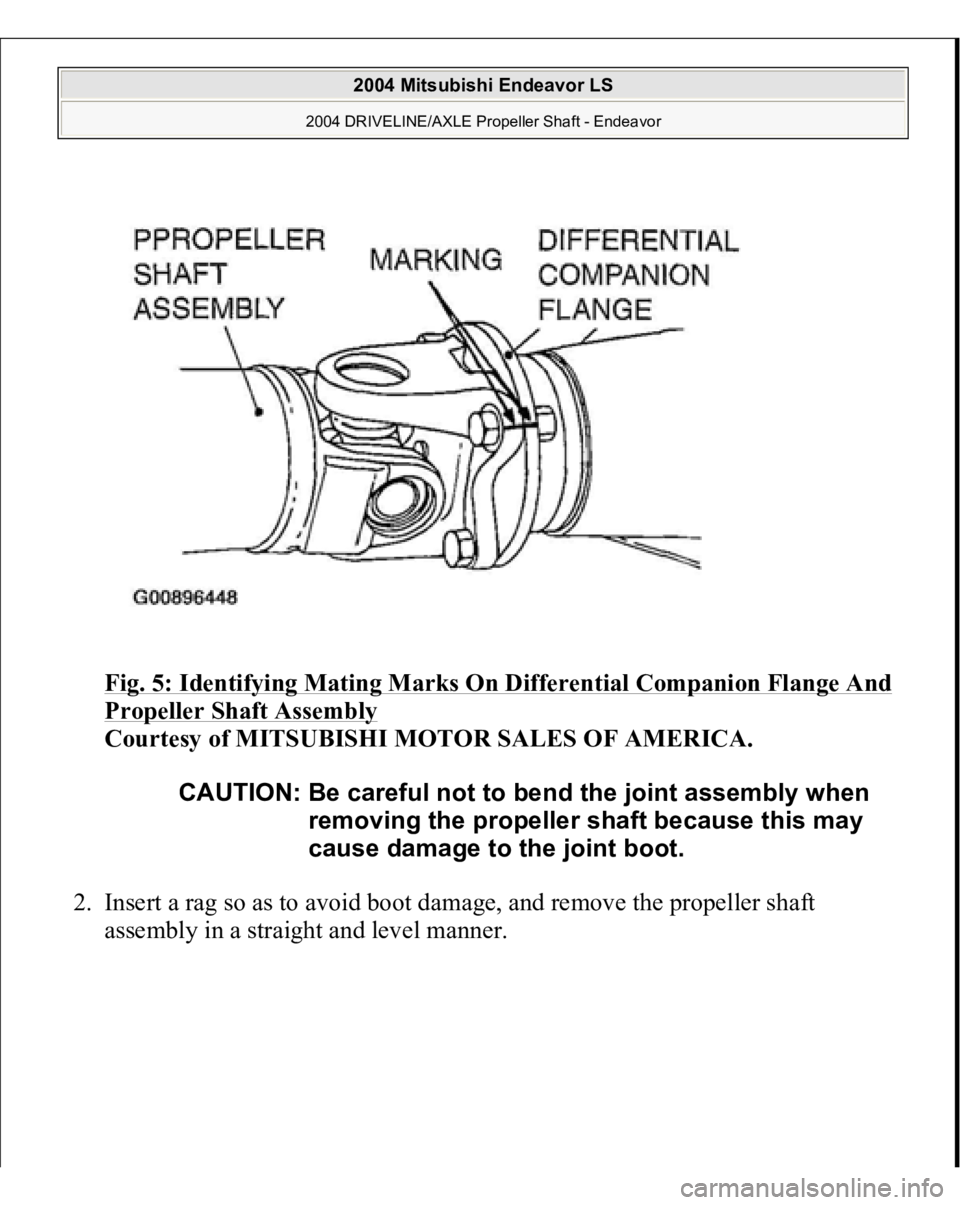

REMOVAL SERVICE POINT << A>> PROPELLER SHAFT ASSEMBLY REMOVAL 1. Make mating marks on the differential companion flange and the propeller

shaft assembl

y.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLE Propeller Shaft - Endeavor

Page 1087 of 3870

Fig. 5: Identifying Mating Marks On Differential Companion Flange And Propeller Shaft Assembly

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Insert a rag so as to avoid boot damage, and remove the propeller shaft

assembly in a straight and level manner.

CAUTION: Be careful not to bend the joint assembly when

removing the propeller shaft because this may

cause damage to the joint boot.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLE Propeller Shaft - Endeavor

Page 1089 of 3870

If reusing the propeller shaft, align the mating marks of differential companion

flan

ge and

propeller shaft assembl

y to install.

Fig. 7: Locating Oil Seal Lips On Transfer Case

Courtes

y of MITSUBISHI MOTOR SALES OF AME

R

Remove oil and grease from the threads of the

mounting bolts and nuts before ti

ghtenin

g, or the

y

loosen. Be careful not to bend the

joint portion when rem

o

the propeller shaft, because this will damage the j

o

boot.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLE Propeller Shaft - Endeavor

Page 1090 of 3870

Fig. 8: Aligning Mating Marks Of Differential Companion Flange And Propeller Shaft Assembly

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSPECTION

Check the sleeve yoke and center yoke for wear, damage or cracks. Check the propeller shaft for bends, twisting or damage. Check the universal joint for smooth operation in all directions. Check the center bearing for smooth movement.

PROPELLER SHAFT RUNOUT

Limit: 0.6 mm (0.02 inch)

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLE Propeller Shaft - Endeavor

Page 1096 of 3870

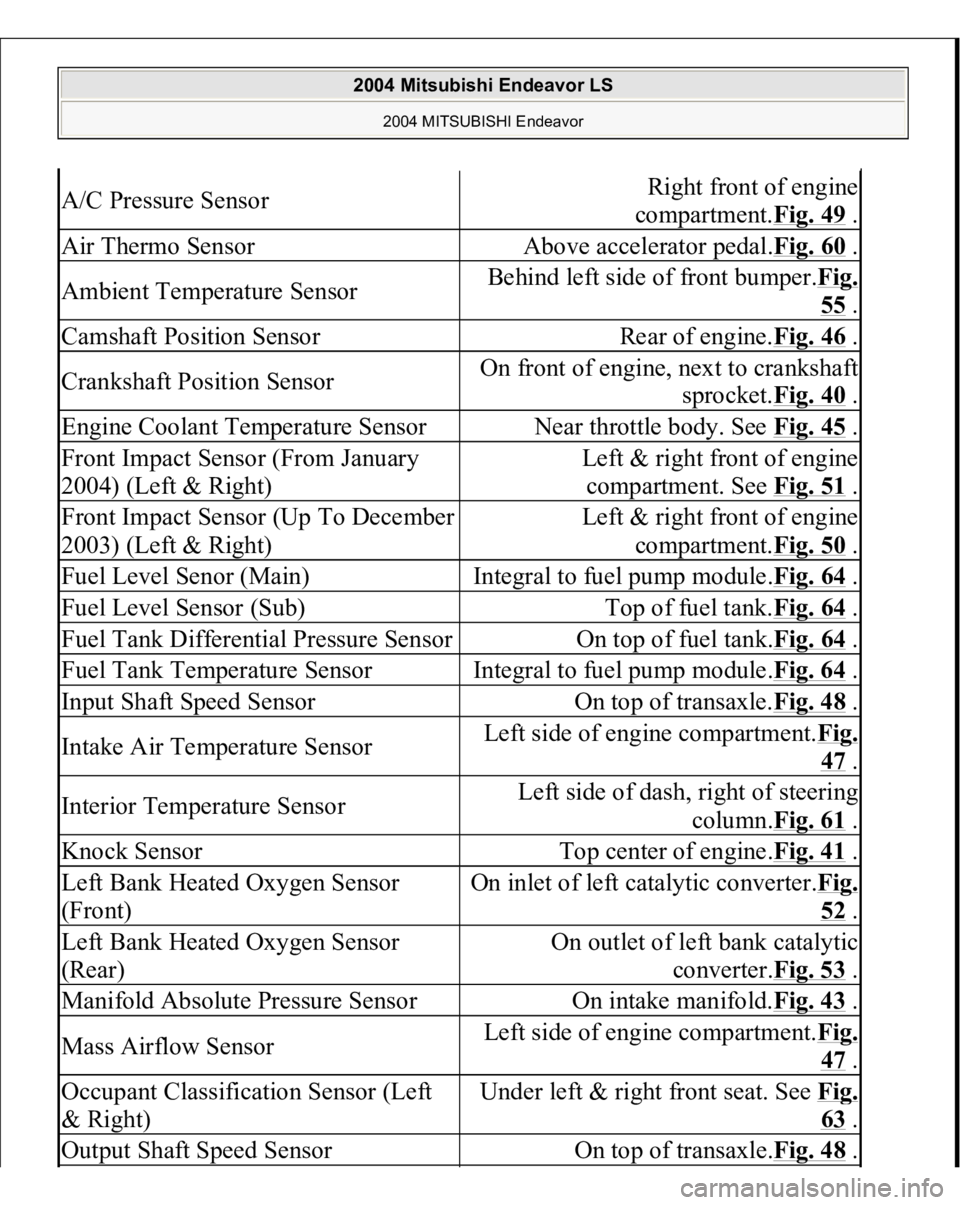

A/C Pressure Sensor

Right front of engine

compartment.Fig. 49

.

Air Thermo Sensor

Above accelerator pedal.Fig. 60

.

Ambient Temperature Sensor

Behind left side of front bumper.Fig.

55 .

Camshaft Position Sensor

Rear of engine.Fig. 46

.

Crankshaft Position Sensor

On front of engine, next to crankshaft

sprocket.Fig. 40

.

Engine Coolant Temperature Sensor

Near throttle body. See Fig. 45

.

Front Impact Sensor (From January

2004) (Left & Right)

Left & right front of engine

compartment. See Fig. 51

.

Front Impact Sensor (Up To December

2003) (Left & Right)

Left & right front of engine

compartment.Fig. 50

.

Fuel Level Senor (Main)

Integral to fuel pump module.Fig. 64

.

Fuel Level Sensor (Sub)

Top of fuel tank.Fig. 64

.

Fuel Tank Differential Pressure Sensor

On top of fuel tank.Fig. 64

.

Fuel Tank Temperature Sensor

Integral to fuel pump module.Fig. 64

.

Input Shaft Speed Sensor

On top of transaxle.Fig. 48

.

Intake Air Temperature Sensor

Left side of engine compartment.Fi

g.

47 .

Interior Temperature Sensor

Left side of dash, right of steering

column.Fig. 61

.

Knock Sensor

Top center of engine.Fig. 41

.

Left Bank Heated Oxygen Sensor

(Front)

On inlet of left catalytic converter.Fi

g.

52 .

Left Bank Heated Oxygen Sensor

(Rear)

On outlet of left bank catalytic

converter.Fig. 53

.

Manifold Absolute Pressure Sensor

On intake manifold.Fig. 43

.

Mass Airflow Sensor

Left side of engine compartment.Fi

g.

47 .

Occupant Classification Sensor (Left

& Right)

Under left & right front seat. See Fi

g.

63 .

Output Shaft Speed Sensor

On top of transaxle.Fig. 48

.

2004 Mitsubishi Endeavor LS

2004 MITSUBISHI Endeavor