MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Page 1350 of 3870

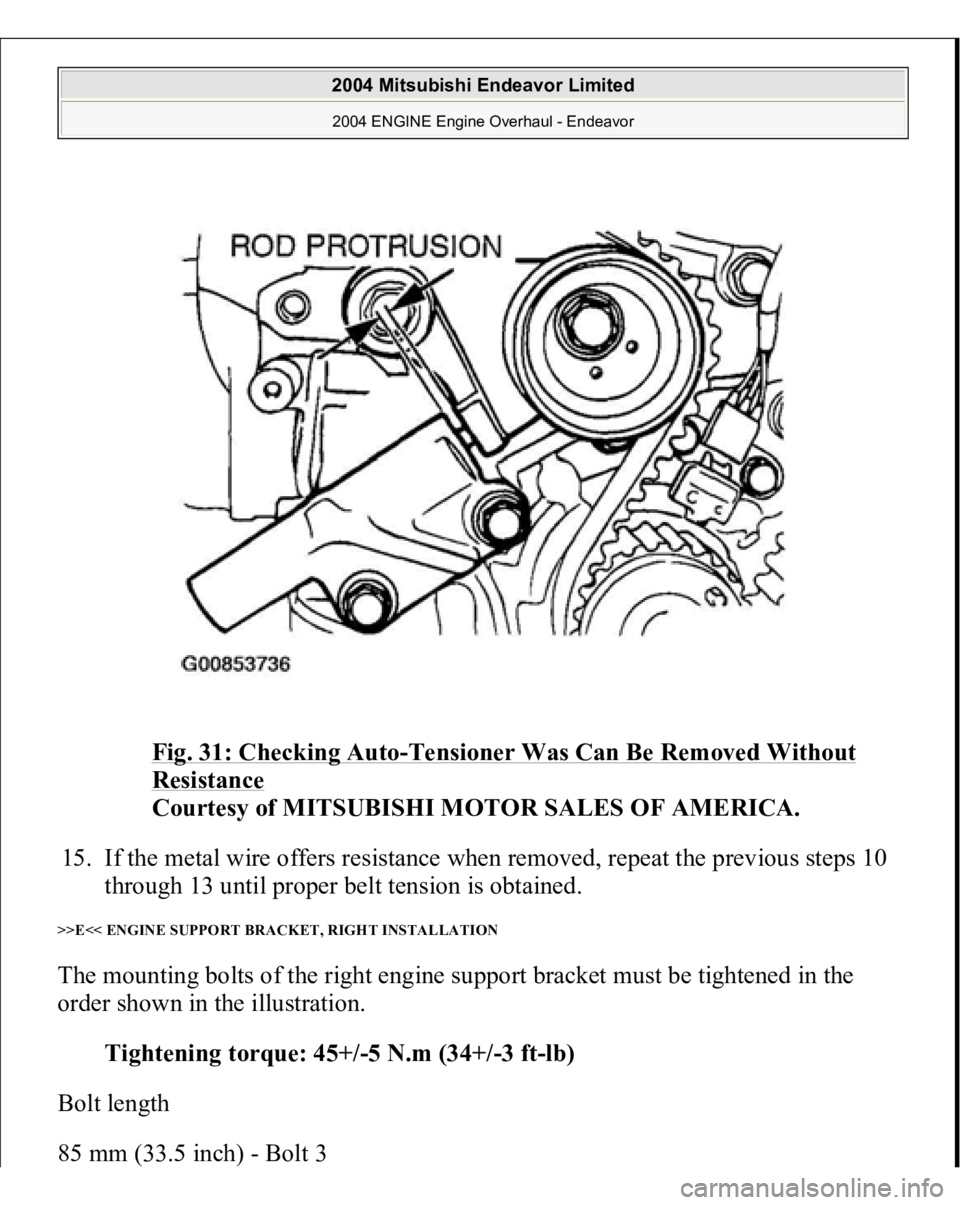

Fig. 31: Checking Auto

-Tensioner Was Can Be Removed Without

Resistance

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

15. If the metal wire offers resistance when removed, repeat the previous steps 10

through 13 until proper belt tension is obtained.

>>E<< ENGINE SUPPORT BRACKET, RIGHT INSTALLATION The mounting bolts of the right engine support bracket must be tightened in the

order shown in the illustration.

Tightening torque: 45+/-5 N.m (34+/-3 ft-lb)

Bolt length

85 mm

(33.5 inch

) - Bolt

3

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1586 of 3870

Fig. 72: Tightening Bolts In Order

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

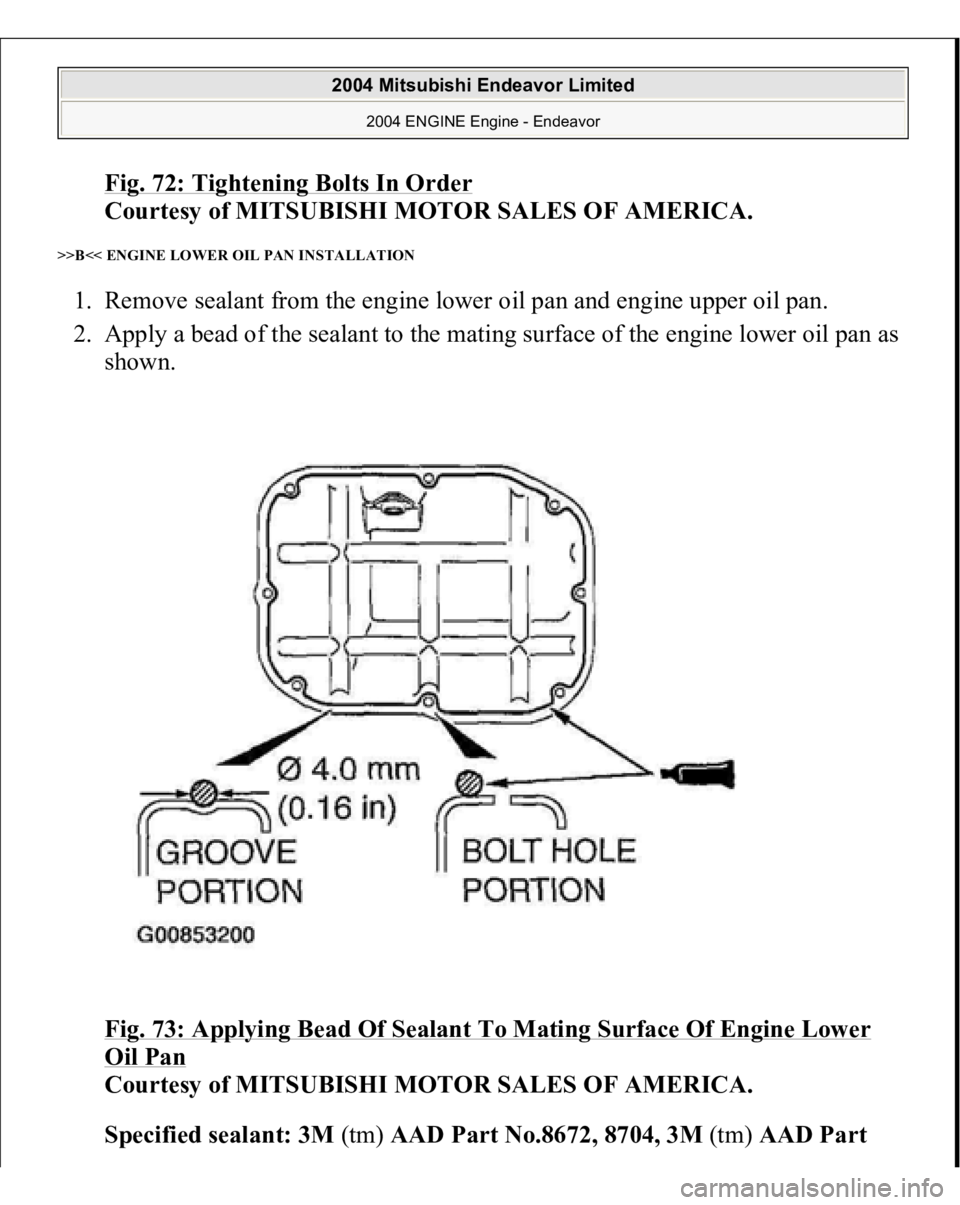

>>B<< ENGINE LOWER OIL PAN INSTALLATION 1. Remove sealant from the engine lower oil pan and engine upper oil pan.

2. Apply a bead of the sealant to the mating surface of the engine lower oil pan as

shown.

Fig. 73: Applying Bead Of Sealant To Mating Surface Of Engine Lower

Oil Pan

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Specified sealant: 3M(tm) AAD Part No.8672, 8704, 3M(tm) AAD Part

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1588 of 3870

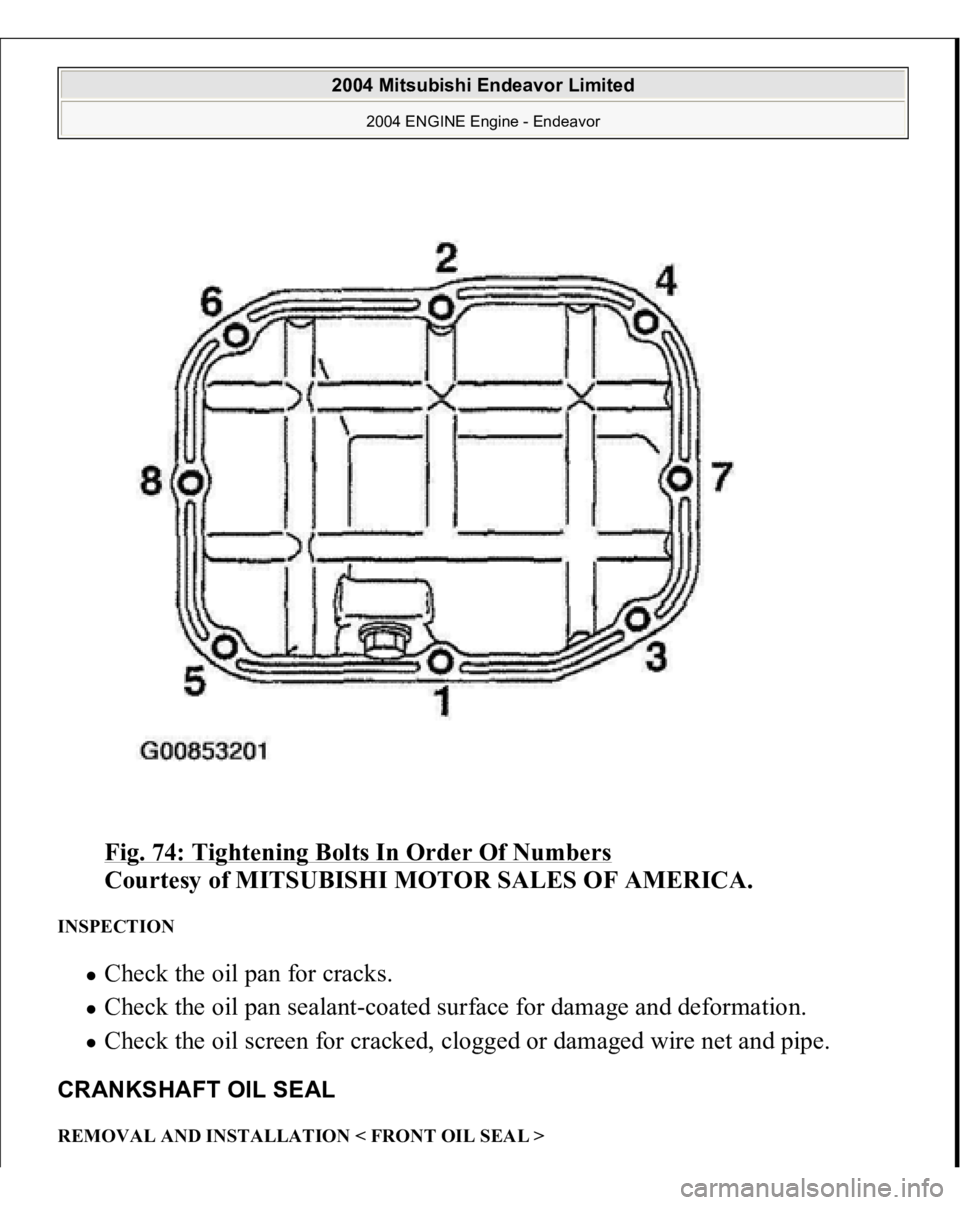

Fig. 74: Tightening Bolts In Order Of Numbers

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSPECTION

Check the oil pan for cracks. Check the oil pan sealant-coated surface for damage and deformation. Check the oil screen for cracked, clogged or damaged wire net and pipe.

CRANKSHAFT OIL SEAL REMOVAL AND INSTALLATION < FRONT OIL SEAL >

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1600 of 3870

1. Use a scraper to clean the gasket surface of the cylinder head assembly.

2. Using special tool MD998051 and a torque wrench, tighten the bolts to the

specified torque in the order shown in the illustration. (in two or three cycles)

Tightening torque: 108 +/- 5 N.m (80 +/- 3 ft-lb) +/- 0 N.m (0 in-lb) +/-

108 +/- 5 N.m (80 +/- 3 ft-lb)

damage may result.

CAUTION: Install the head bolt washers with the beveled

side facing upwards as shown in the illustration.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 2875 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

INSTALLATION SERVICE POINT >>A<< STEERING COLUMN SHAFT ASSEMBLY INSTALLATION Ensure that the tilt lever is in the lock position, and install the steering column.

Tighten the four bolts finger-tight in the order shown in illustration, and then

tighten them to the specified torque in the order shown in illustration.

Tightening torque: 12 +/- 2 N.m (102 +/- 22 in-lb)

CAUTION:

1. If reusin

g the steerin

g column, do not release the

tilt lever until the steering column shaft has been

installed.

2. If a new steering column is being installed, do

not release the tilt lever until it has been

installed. Do not remove the tilt lever fixing band

until the installation is completed.

3. When installing the steering column, do not leave

it fixed temporarily at only one point and make

sure the column shaft is not shaken strongly. If

this happens, the collision absorbing mechanism

at the column shaft mounting location may be

damaged.

2004 Mitsubishi Endeavor LS

2004 STEERING Power Steering - Endeavor

Page 2891 of 3870

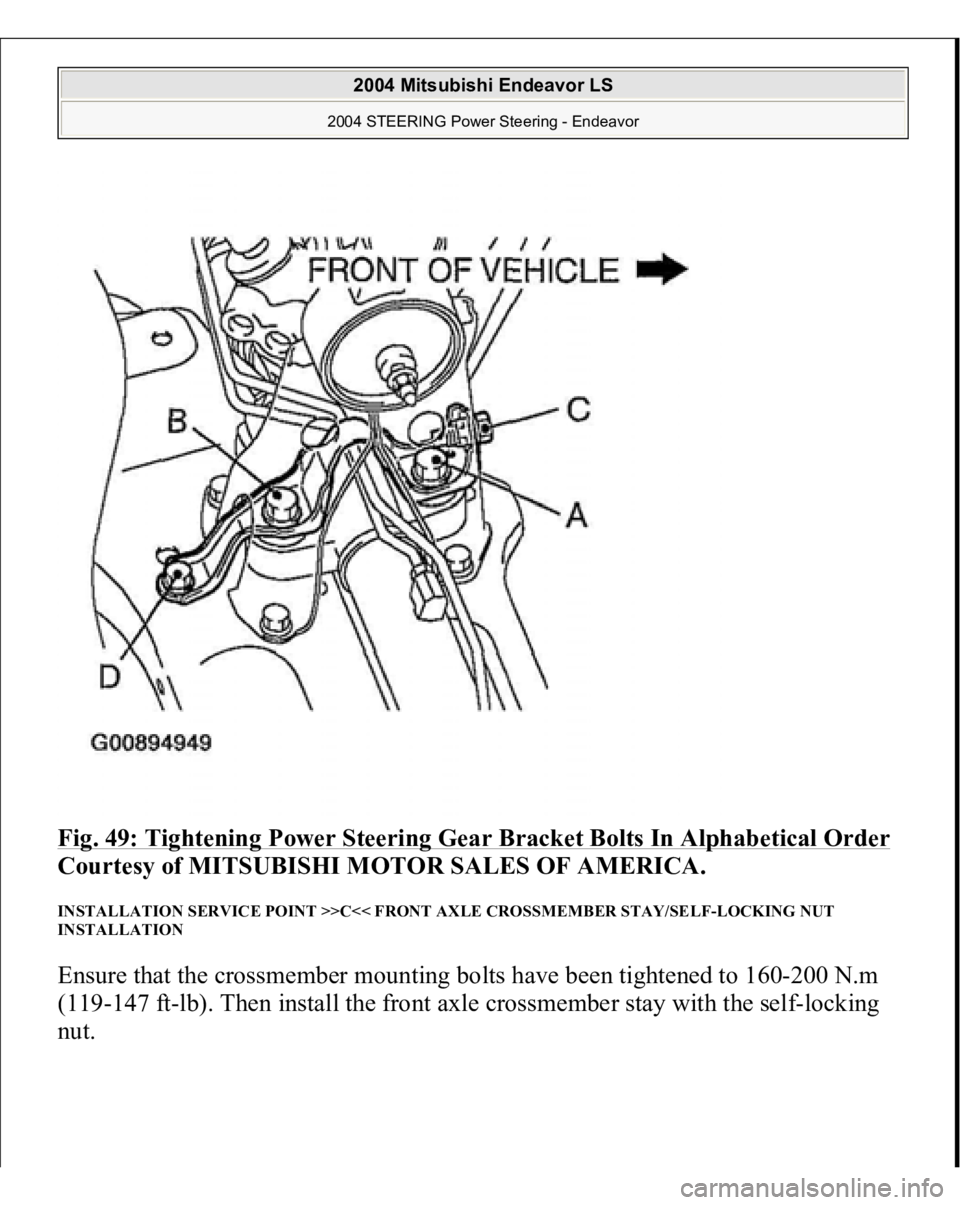

Fig. 49: Tightening Power Steering Gear Bracket Bolts In Alphabetical Order

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSTALLATION SERVICE POINT >>C<< FRONT AXLE CROSSMEMBER STAY/SELF-LOCKING NUT

INSTALLATION Ensure that the crossmember mounting bolts have been tightened to 160-200 N.m

(119-147 ft-lb). Then install the front axle crossmember stay with the self-locking

nut.

2004 Mitsubishi Endeavor LS

2004 STEERING Power Steering - Endeavor