light MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 4 of 3870

LONG STOPPING DISTANCES ON LOOSE ROAD SURFACESWhen braking on loose surfaces like snow-covered or gravel roads, the stopping

distance can be longer for an ABS-equipped vehicle than the stopping distance for a

vehicle with a conventional brake system. SHOCK AT STARTING CHECK Shock may be felt when the brake pedal is lightly pressed while driving at a low

speed. This is a normal characteristic because the ABS system operation check is

carried out when vehicle speed is 8 km/h (5 mph) or less. ANTI-LOCK BRAKING SYSTEM (ABS) DIAGNOSIS INTRODUCTION TO ANTI-LOCK BRAKING SYSTEM DIAGNOSIS The anti-lock braking system (ABS) operates differently from conventional brake

systems. These differences include sounds, sensations, and vehicle performance that

owners and service technicians who are not familiar with ABS may not be used to.

Some operational characteristics may seem to be malfunctions, but they are simply

signs of normal ABS operation. When diagnosing the ABS system, keep these

operational characteristics in mind. Inform the owner of the kind of performance

characteristics to expect from an ABS-equipped vehicle. ABS DIAGNOSTIC TROUBLE CODE DETECTION CONDITIONS ABS diagnostic trouble codes (ABS DTCs) are set under different conditions,

depending on the malfunction detected. Most ABS DTCs will only be set during

vehicle operation. Some ABS DTCs will also be set during the ABS self-check

immediately after the engine is started.

When you check if an ABS DTC will be displayed again after the DTC has been

erased, you should duplicate the ABS DTC set conditions. Depending on the

detection timing and set conditions for the specific ABS DTC, you must either drive

the vehicle or turn the engine off and restart it. To set the proper conditions for that

DTC again, refer to ABS DTC SET CONDITIONS

for each ABS DTC that you

are trying to reset.

ABS DIAGNOSTIC TROUBLESHOOTING STRATEGY

2004 Mitsubishi Endeavor LS

2004 BRAKES Anti-Lock Braking System (ABS) - Endeavor

Page 8 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

4. Connect special tool MB991910 to the V.C.I.

5. Connect special tool to the data link connector.

6. Turn the V.C.I. power switch to the "ON" position.

7. Start the MUT-III system on the personal computer.

HOW TO READ AND ERASE DIAGNOSTIC TROUBLE CODES Required Special Tools:

MB991958: Scan Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.) MB991827: MUT-III USB Cable MB991910: MUT-III Main Harness A

1. Connect scan tool MB991958 to the data link connec

tor. NOTE: When the V.C.I. is energized, the V.C.I. indicator light

will be illuminated in a green color.

NOTE: Disconnect the scan tool in the reverse order of the

connecting sequence, making sure that the ignition

switch is at the "LOCK" (OFF) position.

CAUTION: To prevent damage to scan tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting scan tool

MB991958.

NOTE: If the battery voltage is low, diagnostic trouble codes will

not be set. Check the battery if scan tool MB991958 does

not display.

2004 Mitsubishi Endeavor LS

2004 BRAKES Anti-Lock Braking System (ABS) - Endeavor

Page 230 of 3870

YES: The procedure is complete.

NO: Go to Step 1 .

INSPECTION PROCEDURE 3: WHEN THE IGNITION KEY IS TURNED TO ON (ENGINE STOPPED), THE

BRAKE/ABS WARNING LIGHT DOES NOT ILLUMINATE, INSPECTION PROCEDURE 4: THE BRAKE/ABS

WARNING LIGHT REMAINS ILLUMINATED AFTER THE ENGINE IS STARTED

2004 Mitsubishi Endeavor LS

2004 BRAKES Anti-Lock Braking System (ABS) - Endeavor

Page 232 of 3870

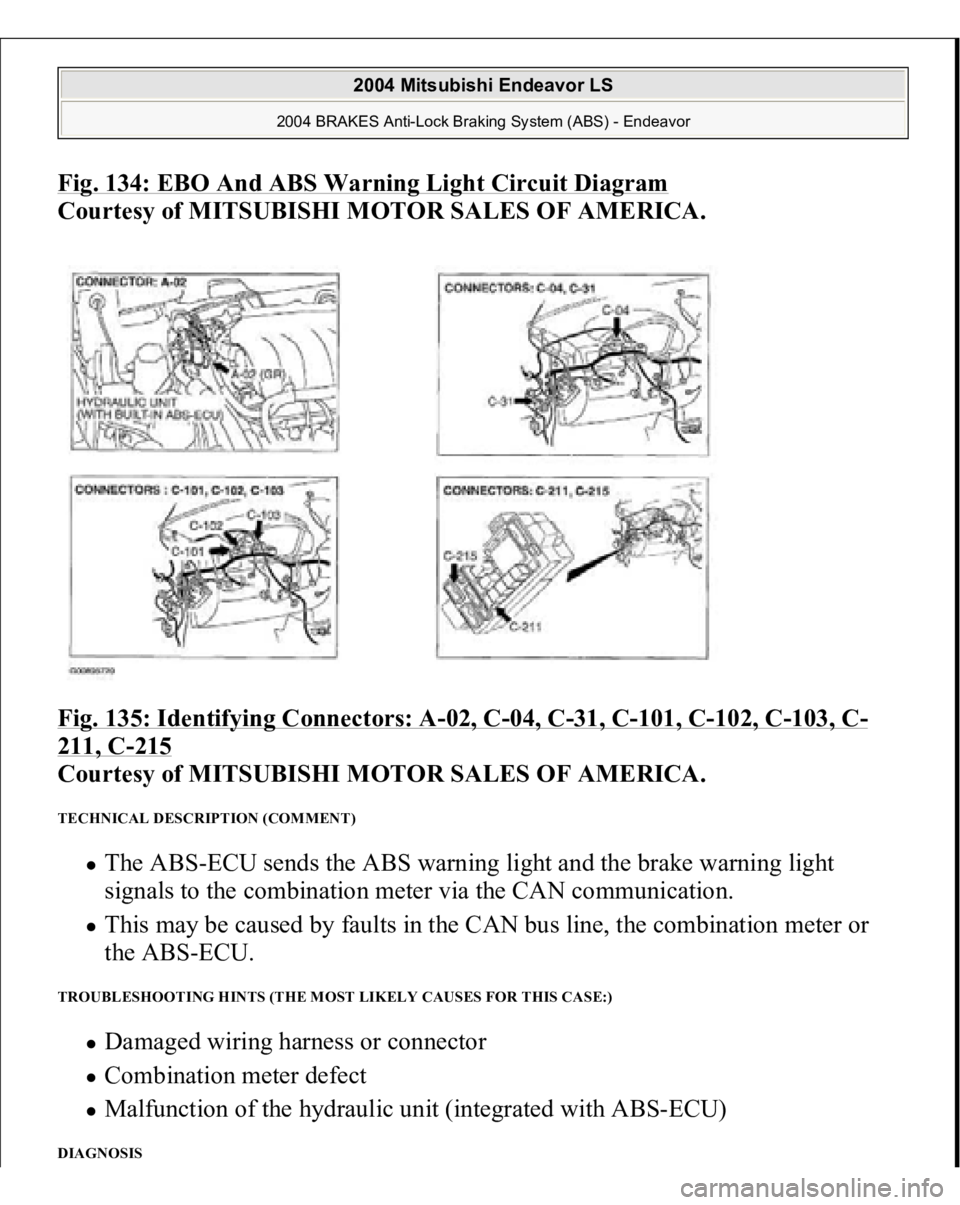

Fig. 134: EBO And ABS Warning Light Circuit Diagram

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Fig. 135: Identifying Connectors: A

-02, C

-04, C

-31, C

-101, C

-102, C

-103, C

-

211, C

-215

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

TECHNICAL DESCRIPTION (COMMENT)

The ABS-ECU sends the ABS warning light and the brake warning light

signals to the combination meter via the CAN communication. This may be caused by faults in the CAN bus line, the combination meter or

the ABS-ECU.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CASE:)

Damaged wiring harness or connector Combination meter defect Malfunction of the hydraulic unit (integrated with ABS-ECU)

DIAGNOSIS

2004 Mitsubishi Endeavor LS

2004 BRAKES Anti-Lock Braking System (ABS) - Endeavor

Page 255 of 3870

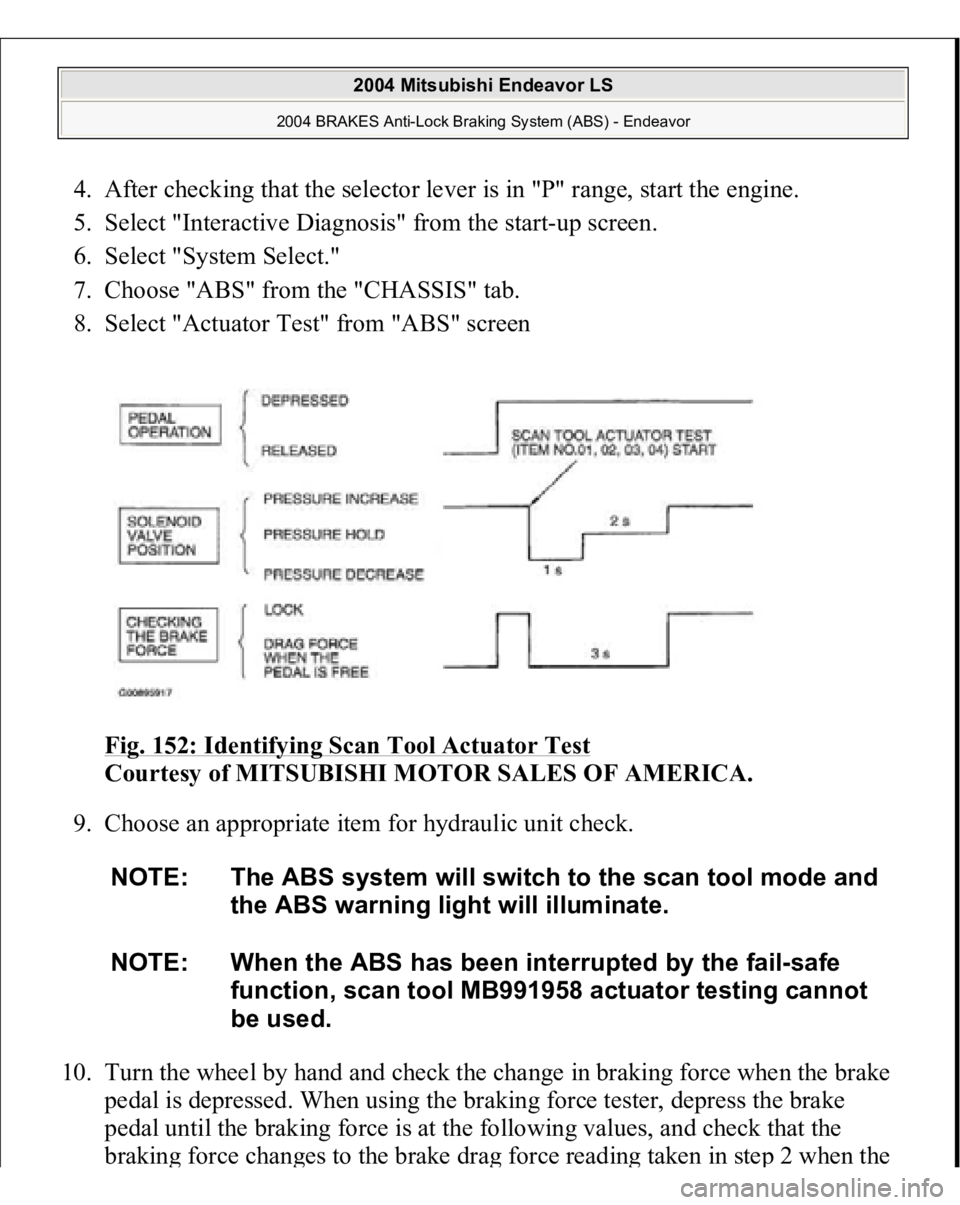

4. After checking that the selector lever is in "P" range, start the engine.

5. Select "Interactive Diagnosis" from the start-up screen.

6. Select "System Select."

7. Choose "ABS" from the "CHASSIS" tab.

8. Select "Actuator Test" from "ABS" screen

Fig. 152: Identifying Scan Tool Actuator Test

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

9. Choose an appropriate item for hydraulic unit check.

10. Turn the wheel by hand and check the change in braking force when the brake

pedal is depressed. When using the braking force tester, depress the brake

pedal until the braking force is at the following values, and check that the

brakin

g force chan

ges to the brake dra

g force readin

g taken in ste

p 2 when the

NOTE: The ABS system will switch to the scan tool mode and

the ABS warning light will illuminate.

NOTE: When the ABS has been interrupted by the fail-safe

function, scan tool MB991958 actuator testing cannot

be used.

2004 Mitsubishi Endeavor LS

2004 BRAKES Anti-Lock Braking System (ABS) - Endeavor

Page 273 of 3870

2004 ACCESSORIES/SAFETY EQUIPMENT

Mitsubishi - Air Bag Restraint Systems

DESCRIPTION & OPERATION Supplemental Restraint System (SRS) components on vehicles with single-stage air

bag systems include single-stage driver-side and passenger-side air bag modules,

side impact air bag modules, seat belt pretensioners, front impact sensors, side

impact sensors, SRS Electronic Control Unit (SRS ECU) and an AIR BAG warning

light or SRS warning light.

SRS components on vehicles with dual-stage air bag systems include dual-stage

driver-side and passenger-side air bag modules, side impact air bag modules, seat

belt pretensioners, front impact sensors, side impact sensors, SRS Electronic

Control Unit (SRS ECU), occupant classification sensor, occupant classification

sensor ECU, seat belt switches, AIR BAG warning light or SRS warning light,

PASSENGER AIR BAG OFF warning light and a PASSENGER SEAT BELT

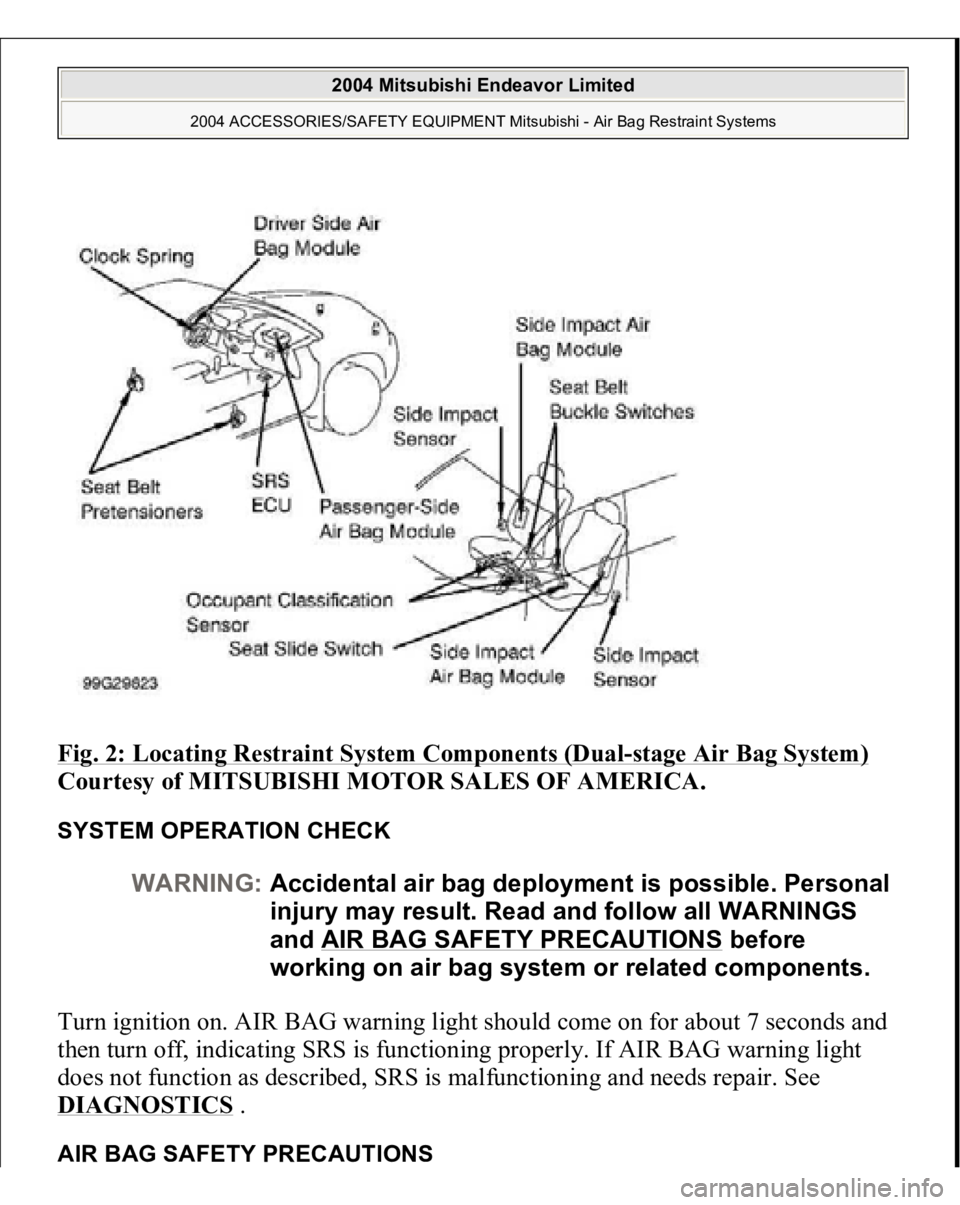

warning light. COMPONENT LOCATIONS Refer to illustration for SRS com

ponent locations. See

Fig. 1

&

Fig. 2

.

WARNING:Accidental air bag deployment is possible. Personal

injury may result. Read and follow all WARNINGS

and AIR BAG SAFETY PRECAUTIONS

before

working on air bag system or related components.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 275 of 3870

Fig. 2: Locating Restraint System Components (Dual

-stage Air Bag System)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

SYSTEM OPERATION CHECK Turn ignition on. AIR BAG warning light should come on for about 7 seconds and

then turn off, indicating SRS is functioning properly. If AIR BAG warning light

does not function as described, SRS is malfunctioning and needs repair. See DIAGNOSTICS

.

AIR BAG SAFETY PRECAUTION

S

WARNING:Accidental air bag deployment is possible. Personal

injury may result. Read and follow all WARNINGS

and AIR BAG SAFETY PRECAUTIONS

before

working on air bag system or related components.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 276 of 3870

Observe these precautions when servicing the air bag system:

Disable SRS before servicing any SRS component. Failure to do this may

result in accidental air bag deployment and possible personal injury. See DISABLING & ACTIVATING AIR BAG SYSTEM

.

After disabling SRS, wait at least 60 seconds before servicing SRS. After servicing, always turn ignition on from outside of vehicle in case of

accidental air bag module deployment. After servicing, check AIR BAG warning light to verify system operation. See SYSTEM OPERATION CHECK

.

Always wear safety glasses when servicing or handling an SRS component. Hearing protection must be worn when performing deployment procedures. DO NOT expose air bag modules, clockspring or SRS ECU to temperatures

greater than 200°F (93°C ). DO NOT expose seat belt pretensioners to temperatures greater than 194°F

(90°C ). When placing a live air bag module on a bench or other surface, always place

air bag module with trim cover facing up and away from surface. This will

reduce motion of air bag module if accidental deployment occurs. After air bag module deploys, surrounding surfaces may contain deposits of

sodium hydroxide, which irritates skin. Always wear safety glasses, rubber

gloves and a long-sleeved shirt during clean-up. Wash hands using mild soap

and water. Follow correct clean-up and disposal procedures. See

DISPOSAL

PROCEDURES

.

Because of critical system operating requirements, DO NOT service any SRS

components. Repairs are only made by replacing defective components. DO NOT allow any electrical source near inflator on back of air bag module. When carrying a live (undeployed) air bag module, trim cover must be pointed

away from body to minimize injury in case of accidental air bag deployment. If instructed to probe wire harness, do so from harness side of connector. DO NOT probe a wire through insulator. Wire will be damaged and eventually

fail due to corrosion. When

performin

g electrical tests,

prevent accidental shortin

g of terminals.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 277 of 3870

Such shorts can damage fuses or components and may cause a second

Diagnostic Trouble Code (DTC) to set, making diagnosis of original problem

more difficult. Never use an analog volt/ohm meter or test light in place of a Digital Volt/Ohm

Meter (DVOM). Use only a DVOM with a maximum test current of 2 mA

(milliamps) at minimum range of resistance measurement. If SRS is not fully functional for any reason, DO NOT drive vehicle until

system is repaired and fully functional. DO NOT remove bulbs, modules,

sensors, or other components or in any way disable system from operating

normally. If SRS is not functional, park vehicle until repairs are made.

DISABLING & ACTIVATING AIR BAG SYSTEM To disable system, turn ignition off. Disconnect negative battery cable. Shield cable

end with electrical tape. Wait at least 60 seconds before servicing air bag system.

To activate system, reconnect negative battery cable. Check system operation. See SYSTEM OPERATION CHECK

.

DISPOSAL PROCEDURES DEPLOYED AIR BAG OR SEAT BELT PRETENSIONER Place deployed component in a strong plastic bag and seal tightly. Dispose of

component as you would any other part. No other special disposal procedure is

required. UNDEPLOYED AIR BAG OR SEAT BELT PRETENSIONER

WARNING:Accidental air bag deployment is possible. Personal

injury may result. Read and follow all WARNINGS

and AIR BAG SAFETY PRECAUTIONS

before

working on air bag system or related components.

NOTE: Undeployed air bag modules must be deployed before

disposal. Disposing of an undeployed air bag may violate

federal, state and/or local laws. This also applies to vehicles

that are to be scrapped.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 287 of 3870

CONSOLE ASSEMBL

Y . Remove left and right A-pillar trim panels.

Remove hood lock release handle.

3. Remove end panel. See Fig. 8

. Remove driver-side knee bolster. Remove fog

light switch. Remove steering column upper and lower covers. Remove

combination meter assembly. Remove center panel assembly. Remove air

vents. Remove radio panel. Remove AC-heater control assembly.

4. Remove hazard warning switch. Remove console meter hood. Remove multi-

center display unit. Remove audio components. Remove glove box assembly.

Remove left and right speaker covers. Remove speakers. Disconnect

clockspring and steering column switch connectors. Remove photo sensor and

photo sensor clamp.

5. Remove interior temperature sensor. Disconnect passenger-side air bag module

connector. Remove left and right center instrument panel brackets. Disconnect

remaining electrical connectors. Remove instrument panel nuts and bolts.

Remove instrument panel.

6. To install, reverse removal procedure. Tighten NEW steering wheel nut and

drive

r-side air ba

g module bolts to s

pecification. Activate air ba

g system.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems