window MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 278 of 3870

On-vehicle Deployment 1. Before proceeding, see

AIR BAG SAFETY PRECAUTIONS

. Move vehicle

to an isolated area. Open all doors and windows. Disconnect and shield

negative battery cable end. Disconnect positive battery cable. Remove battery

from vehicle. Wait at least 60 seconds before continuing.

2. To deploy driver-side air bag module, remove steering column lower cover.

Disconnect lower clockspring Yellow 4-pin connector. Cut harness side of

connector from wire harness and strip ends of driver-side air bag module wires

on harness side of clockspring connector. See

WIRING DIAGRAMS

.

3. To deploy passenger-side air bag module, remove glove box and glove box

outer case. Disconnect passenger-side air bag module Red connector.

4. To deploy side impact air bag module, disconnect appropriate side impact air

bag module Red connector, located under front seat.

5. To deploy seat belt pretensioner, disconnect appropriate seat belt pretensioner

connector, located at seat belt pretensioner.

6. Fabricate a de

ployment harness usin

g two wires at least 20 feet

(6.1 m

) in

WARNING:Air bag modules and seat belt pretensioners make

loud noises during deployment. Air bag module and

seat belt pretensioner deployment could cause

personal injury. Always deploy components

outdoors and away from people. Never deploy air

bag modules with trim cover face down.

NOTE: If vehicle is to be scrapped, perform On-vehicle

deployment. See ON

-VEHICLE DEPLOYMENT

. If vehicle

will continue to be operated, perform Off-vehicle

Deployment. See OFF

-VEHICLE DEPLOYMENT

.

NOTE: Driver-side and passenger-side air bag modules will be

either single-stage or dual-stage. Consult wiring

diagrams to ensure correct wires are cut and spliced

prior to deployment. See WIRING DIAGRAMS

.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 279 of 3870

length. Strip insulation from ends of wires. Connect wires at one end of harness

to clockspring connector stripped wires and cover connections with insulating

tape. Temporarily wrap other end of harness wires together to prevent

unexpected air bag deployment.

7. Stretch deployment harness as far away from vehicle as possible. Roll up

vehicle windows to lessen deployment noise and cover vehicle with car cover,

in case glass should shatter during deployment. Ensure area is clear of people.

Untwist deployment harness wire ends. Touch wire ends to 12 volt battery

terminals to deploy driver-side air bag module.

8. Repeat procedure for remaining air bag modules and seat belt pretensioners.

Use SRS Air Bag Adapter Harness (MB686560) for passenger-side and side

impact air bag modules. Use SRS Adapter Harness (MR991885) for seat belt

pretensioners. If any component fails to deploy, stay away from vehicle and

contact manufacturer for further instructions. Allow 30 minutes for air bag

modules to cool.

Off-vehicle Deployment 1. Before proceeding, see

AIR BAG SAFETY PRECAUTIONS

. Turn ignition

switch to LOCK position. Disconnect negative battery cable. Shield cable end.

Wait at least 60 seconds before continuing. Disconnect positive battery cable.

Remove battery from vehicle.

2. Fabricate a deployment harness using two wires at least 20 feet (6.1 m) in

length. Strip insulation from ends of wires. Twist together one end of wires

temporarily. Remove driver-side air bag module. See

DRIVER

-SIDE AIR

BAG MODULE & CLOCKSPRING

under REMOVAL &

INSTALLATION. Place driver-side air bag module on surface face up. Touch

vehicle body with bare hands to discharge static electricity from body. Cut

driver-side air bag module connector from pigtail leads. Strip insulation from

ends of

pigtail wires. Attach remainin

g ends of de

ployment harness to

pigtail NOTE: Driver-side and passenger-side air bag modules will be

either single-stage or dual-stage. Consult wiring

diagrams to ensure correct wires are cut and spliced

prior to deployment. See WIRING DIAGRAMS

.

2004 Mitsubishi Endeavor Limited

2004 ACCESSORIES/SAFETY EQUIPMENT Mitsubishi - Air Bag Restraint Systems

Page 987 of 3870

2004 BODY & ACCESSORIES

Rear Window Defogger - Endeavor

REAR WINDOW DEFOGGER GENERAL DESCRIPTION Rear Defogger operation The defogger relay turns ON if the defogger switch built-in the A/C-ECU is turned

ON when the ignition switch is in the "ON" position. When the defogger relay turns

ON, power is supplied to the defogger and the defogger is activated. The defogger

comes with a timer function that causes the defogger switch to automatically turn

OFF in about 17 minutes after the defogger switch is turned ON. EQUIPMENT DIAGNOSIS REAR WINDOW DEFOGGER DIAGNOSIS The rear window defogger is controlled by the A/C-ECU. For troubleshooting, refer

to MANUAL A/C DIAGNOSIS

.

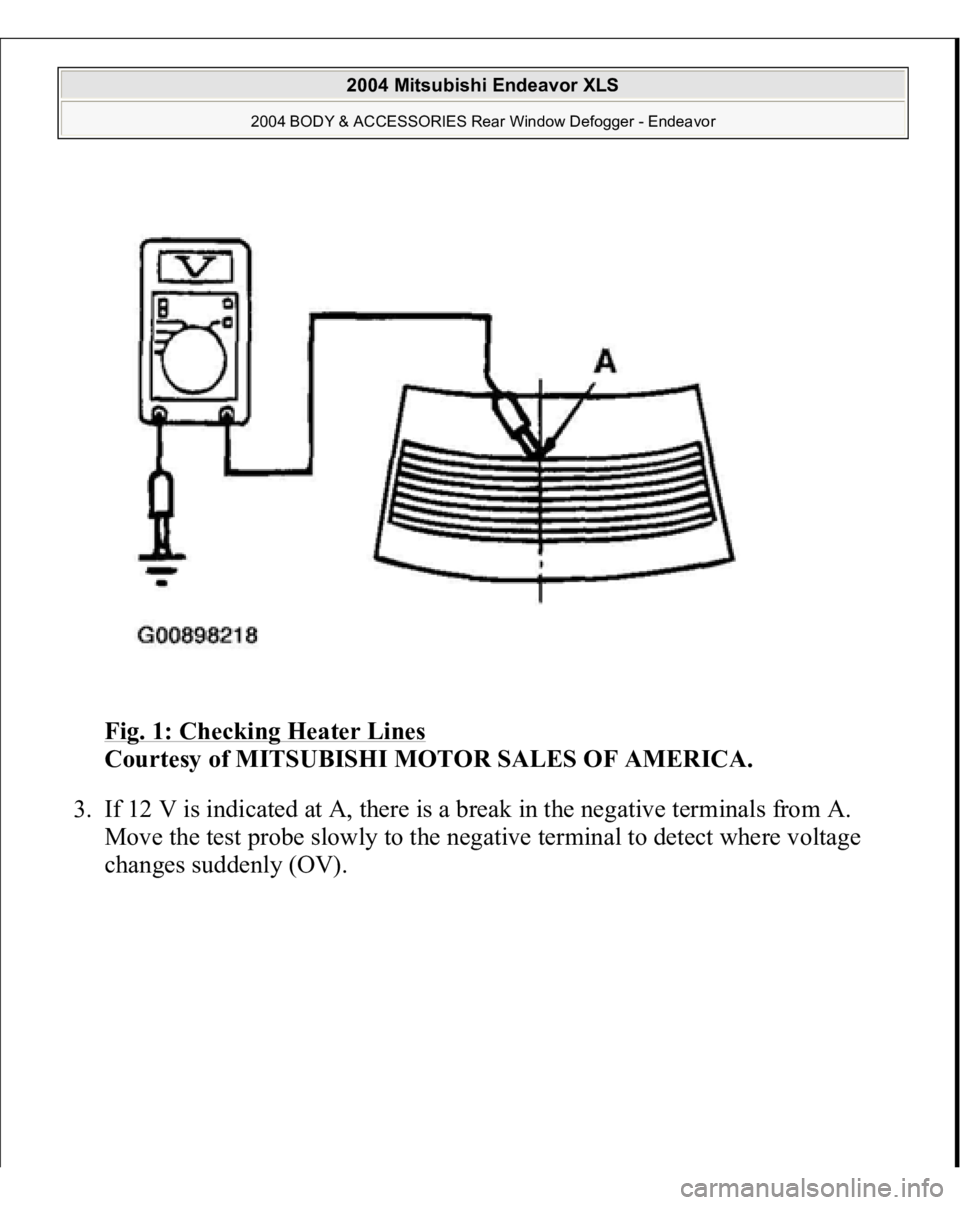

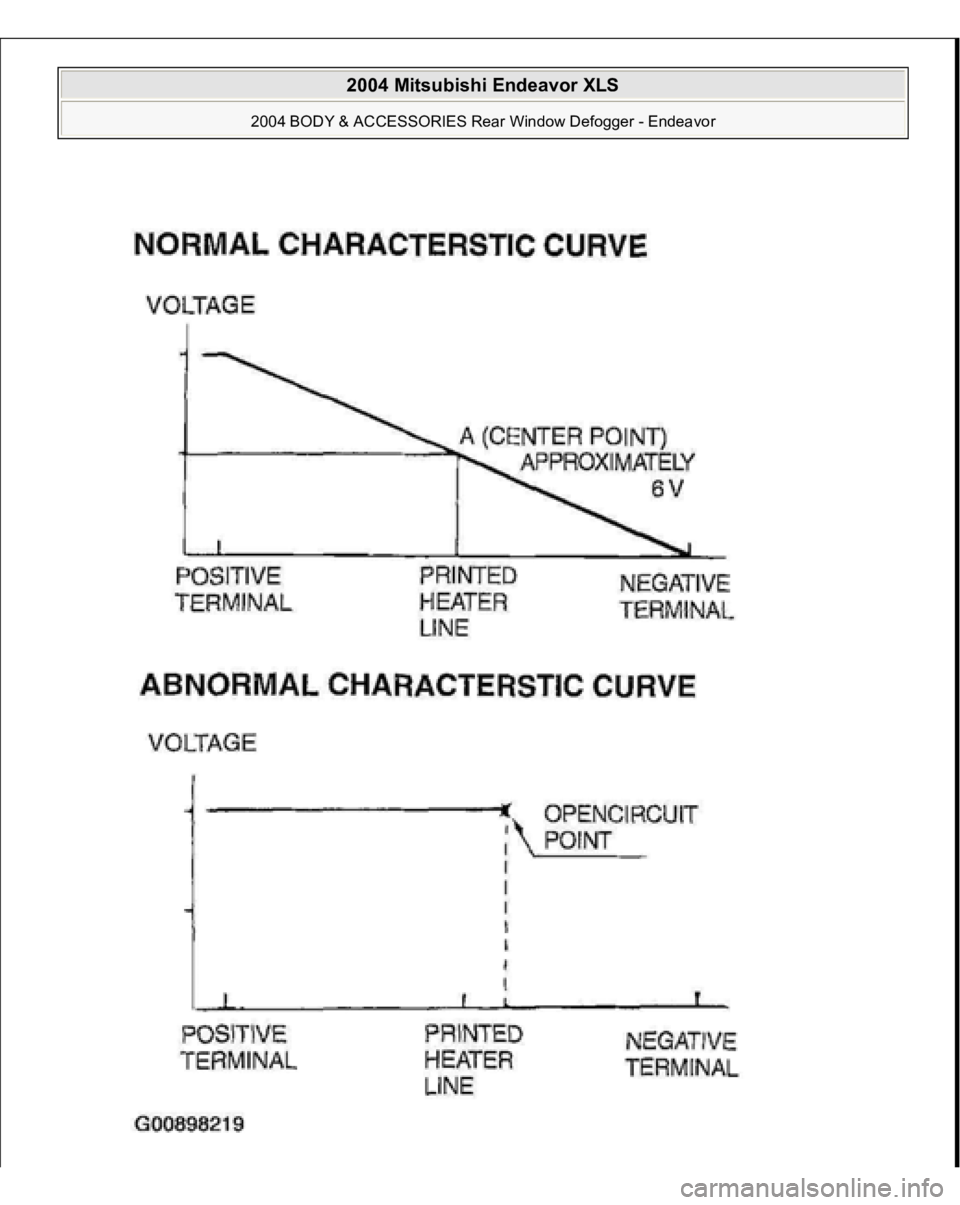

ON-VEHICLE SERVICE PRINTED-HEATER LINES CHECK 1. Run the engine at 2,000 r/min. Check the heater element with the battery at

full.

2. Turn "ON" the rear window defogger switch. Measure the heater element

voltage with an ohmmeter at the rear window glass center A. Condition is good

if it indicates about 6 V.

2004 Mitsubishi Endeavor XLS

2004 BODY & ACCESSORIES Rear Window Defogger - Endeavor

2004 Mitsubishi Endeavor XLS

2004 BODY & ACCESSORIES Rear Window Defogger - Endeavor

Page 988 of 3870

Fig. 1: Checking Heater Lines

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. If 12 V is indicated at A, there is a break in the negative terminals from A.

Move the test probe slowly to the negative terminal to detect where voltage

changes suddenly (OV).

2004 Mitsubishi Endeavor XLS

2004 BODY & ACCESSORIES Rear Window Defogger - Endeavor

Page 989 of 3870

2004 Mitsubishi Endeavor XLS

2004 BODY & ACCESSORIES Rear Window Defogger - Endeavor

Page 990 of 3870

Fig. 2: Identifying Normal And Abnormal Characteristic Curve

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. If 0 V is indicated at A, there is a break in the positive terminals from A.

Defect where the voltage changes suddenly (12 V) in the same method

described above.

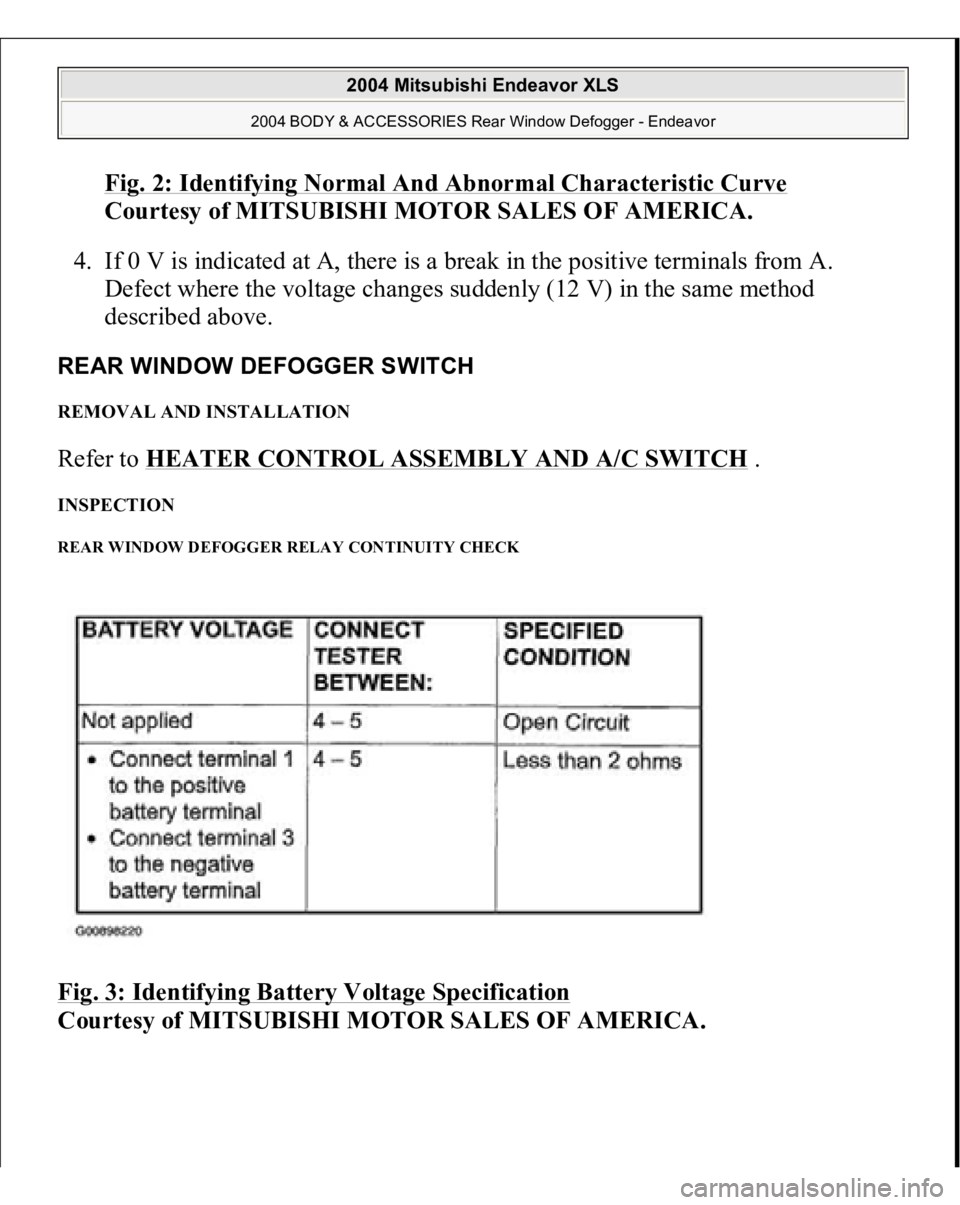

REAR WINDOW DEFOGGER SWITCH REMOVAL AND INSTALLATION Refer to HEATER CONTROL ASSEMBLY AND A/C SWITCH

.

INSPECTION REAR WINDOW DEFOGGER RELAY CONTINUITY CHECK Fig. 3: Identifying Battery Voltage Specification

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor XLS

2004 BODY & ACCESSORIES Rear Window Defogger - Endeavor

Page 991 of 3870

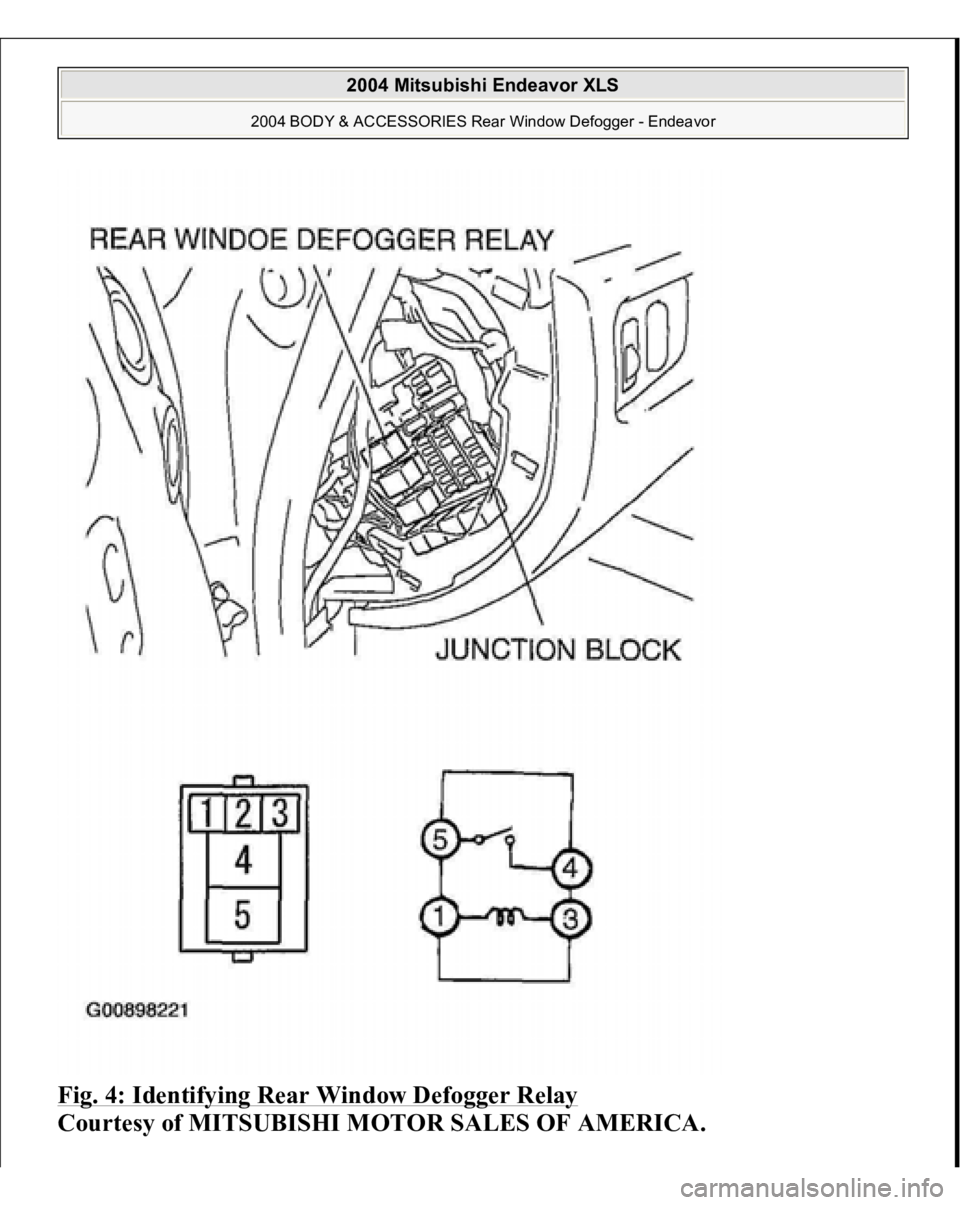

Fig. 4: Identifying Rear Window Defogger Relay

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor XLS

2004 BODY & ACCESSORIES Rear Window Defogger - Endeavor

Page 992 of 3870

2004 BODY & ACCESSORIES

Door - Endeavor

GENERAL DESCRIPTION OPERATION CENTRAL DOOR LOCKING SYSTEM The central door locking system operates the door lock actuator to lock or unlock

the doors and liftgate using the door lock switch built into the front power window

(main or sub) switch or key built into the driver's side door outside handle. The

system has the following operations and features:

All doors and liftgate can be locked using the door lock switch built into the

front power window (main or sub) switch. Insert the key into the driver's key cylinder and turn once to the unlock side to

unlock the driver's door. Turn the key once again to the unlock side to unlock

all doors and the liftgate. The key reminder function automatically unlocks all doors and liftgate when

door lock operation is performed and the front doors are opened while the key

is inserted into the ignition switch.

POWER WINDOWS When the power window (main or sub) switch is operated, the door windows will

open or close. This system has the following operations and features:

A power window lock switch on the power window main switch prevents the

door window glass from opening/closing with the front passenger's and rear

power window sub switch. The power window of the door window glass can be opened/closed for 30

seconds with the timer function after the ignition switch is turned OFF. (The

timer expires if the front door < LH or RH> is opened when the timer is in

operation). The power window main switch contains a one-touch down switch that will

automatically open the driver's side door window only.

2004 Mitsubishi Endeavor LS

2004 BODY & ACCESSORIES Door - Endeavor

2004 Mitsubishi Endeavor LS

2004 BODY & ACCESSORIES Door - Endeavor

Page 993 of 3870

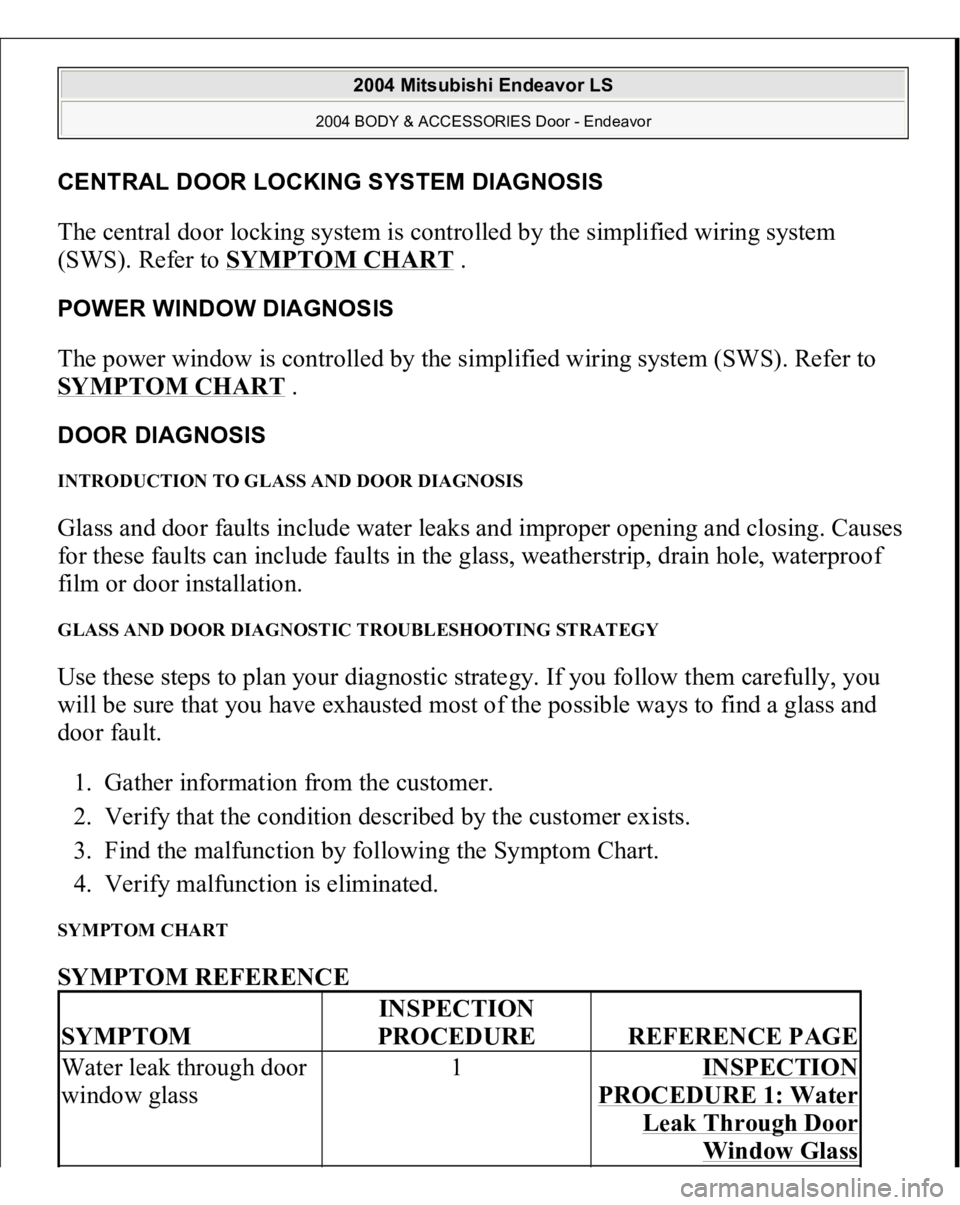

CENTRAL DOOR LOCKING SYSTEM DIAGNOSIS The central door locking system is controlled by the simplified wiring system

(SWS). Refer to SYMPTOM CHART

.

POWER WINDOW DIAGNOSIS The power window is controlled by the simplified wiring system (SWS). Refer to

SYMPTOM CHART

.

DOOR DIAGNOSIS INTRODUCTION TO GLASS AND DOOR DIAGNOSIS Glass and door faults include water leaks and improper opening and closing. Causes

for these faults can include faults in the glass, weatherstrip, drain hole, waterproof

film or door installation. GLASS AND DOOR DIAGNOSTIC TROUBLESHOOTING STRATEGY Use these steps to plan your diagnostic strategy. If you follow them carefully, you

will be sure that you have exhausted most of the possible ways to find a glass and

door fault.

1. Gather information from the customer.

2. Verify that the condition described by the customer exists.

3. Find the malfunction by following the Symptom Chart.

4. Verify malfunction is eliminated. SYMPTOM CHART SYMPTOM REFERENCE SYMPTOM

INSPECTION

PROCEDURE

REFERENCE PAGE

Water leak through door

window glass

1

INSPECTION

PROCEDURE 1: Water

Leak Throu

gh Door

Window Glass

2004 Mitsubishi Endeavor LS

2004 BODY & ACCESSORIES Door - Endeavor

Page 994 of 3870

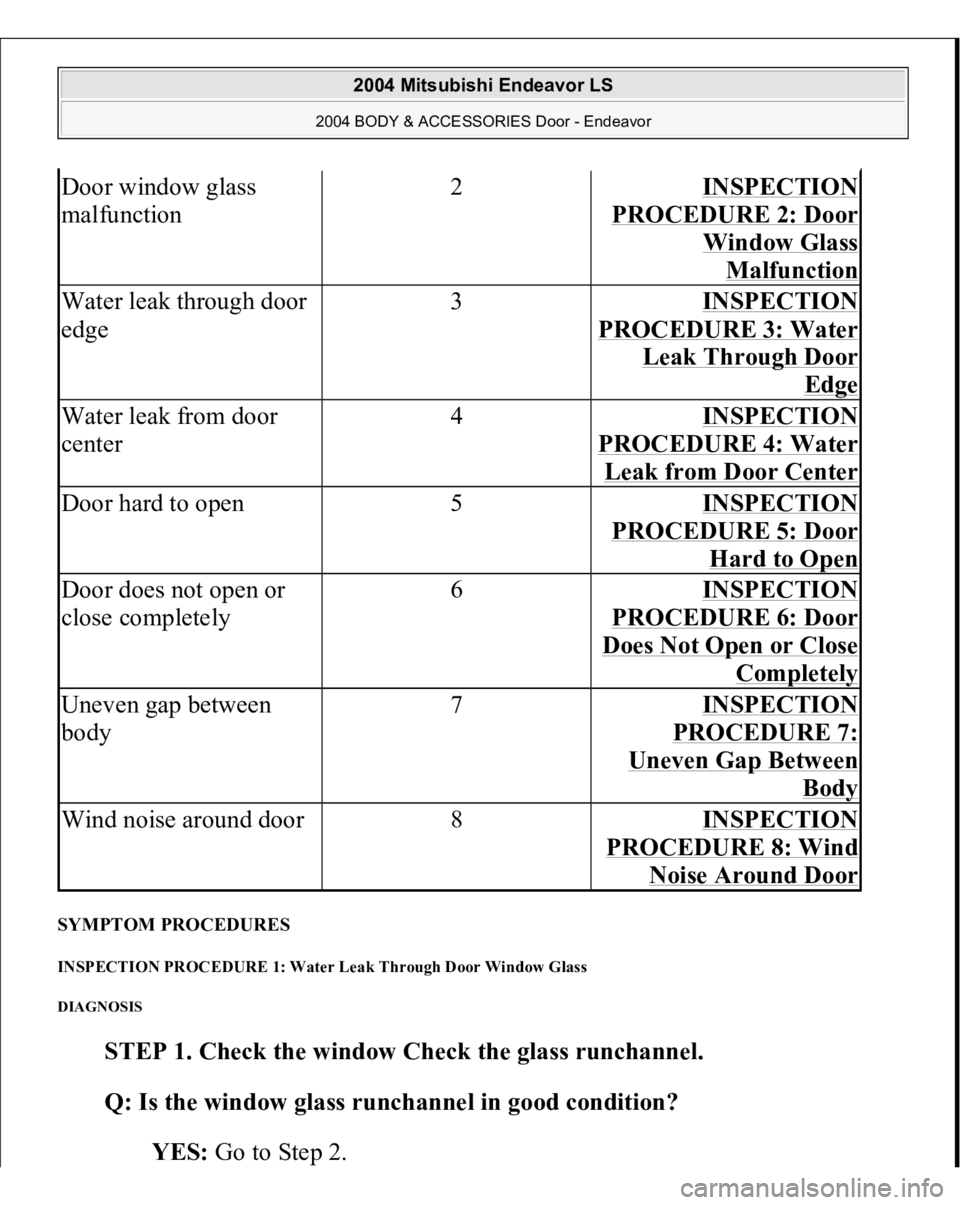

SYMPTOM PROCEDURES INSPECTION PROCEDURE 1: Water Leak Through Door Window Glass DIAGNOSIS

STEP 1. Check the window Check the glass runchannel.

Q: Is the window glass runchannel in good condition?

YES: Go to Step 2.

Door window glass

malfunction

2

INSPECTION

PROCEDURE 2: Door

Window Glass Malfunction

Water leak through door

edge

3

INSPECTION

PROCEDURE 3: Water

Leak Throu

gh Door Edge

Water leak from door

center

4

INSPECTION

PROCEDURE 4: Water Leak from Door Center

Door hard to open

5

INSPECTION

PROCEDURE 5: Door

Hard to Open

Door does not open or

close completely

6

INSPECTION

PROCEDURE 6: Door Does Not Open or Close

Completely

Uneven gap between

body

7

INSPECTION

PROCEDURE 7:

Uneven Gap Between

Body

Wind noise around door

8

INSPECTION

PROCEDURE 8: Wind

Noise Around Door

2004 Mitsubishi Endeavor LS

2004 BODY & ACCESSORIES Door - Endeavor