engine overheat MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 30 of 1273

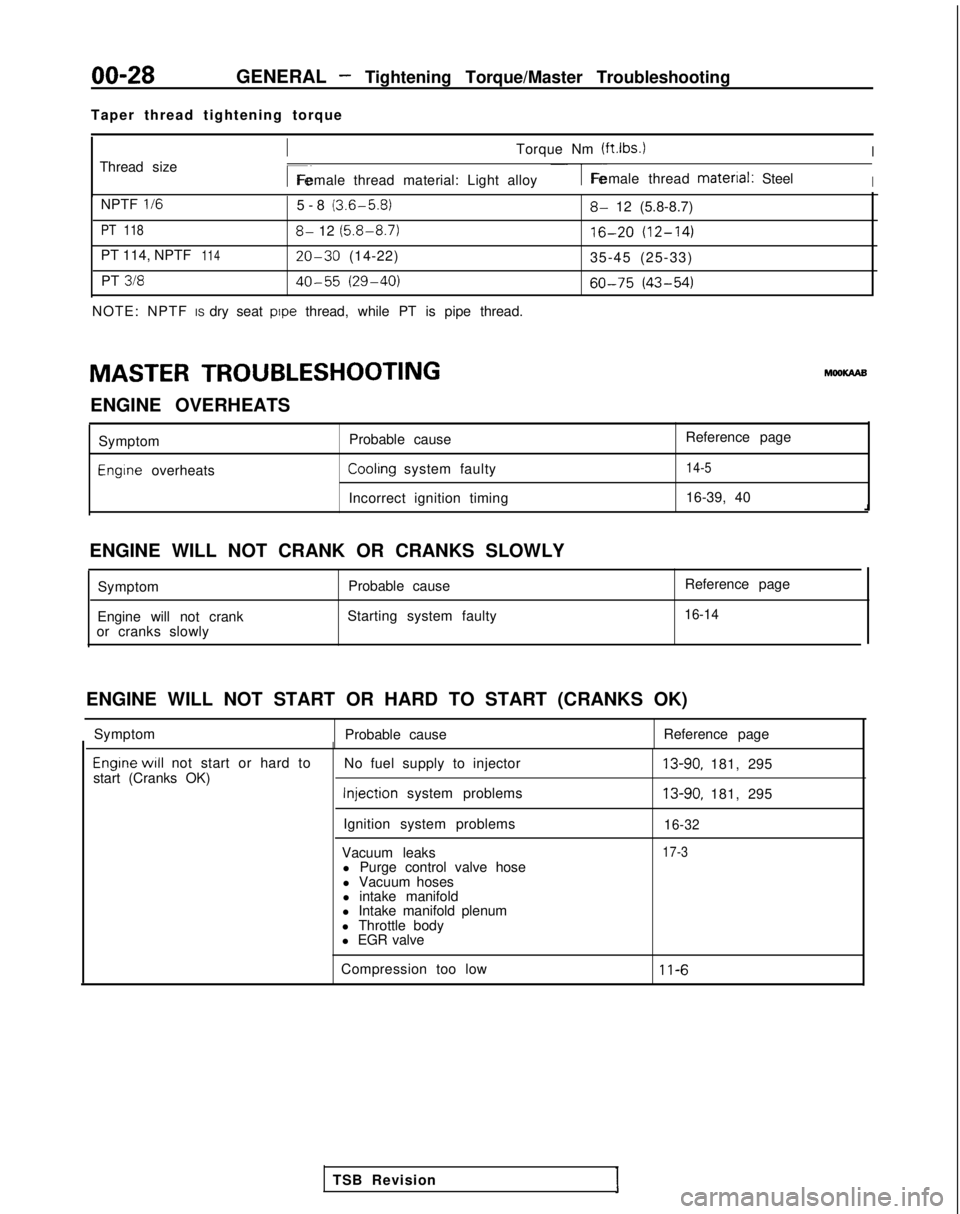

00-28GENERAL - Tightening Torque/Master Troubleshooting

Taper thread tightening torque

Thread size

ITorque Nm (ftlbs.)I

r~Female thread material: Light alloy1-Female thread material: SteelI

NPTF II65-8 (3.6-5.8)

PT 1188- 12 (5.8-8.7)

PT 114, NPTF11420-30 (14-22)

PT

31840-55 (29-40)

NOTE: NPTF IS dry seat pope thread, while PT is pipe thread.

8- 12 (5.8-8.7)

16-20 (12-14)

35-45 (25-33)

60-75 (43-54)

MASTER TROUBLESHOOTING hlooKAAB

ENGINE OVERHEATS Symptom

Engine overheats Probable cause

Reference pageCoolrng system faulty14-5

Incorrect ignition timing

16-39, 40

ENGINE WILL NOT CRANK OR CRANKS SLOWLY Symptom Probable cause

Engine will not crank Starting system faulty

or cranks slowly Reference page

16-14

ENGINE WILL NOT START OR HARD TO START (CRANKS OK)

Symptom Probable cause Reference page

Engrne WIII not start or hard to

start (Cranks OK) No fuel supply to injector Injection

system problems

Ignition system problems

Vacuum leaks l Purge control valve hose

l Vacuum hoses

l intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve13-90, 181, 295

13-90, 181, 295

16-32

17-3

Compression too low11-6

TSB Revision

Page 31 of 1273

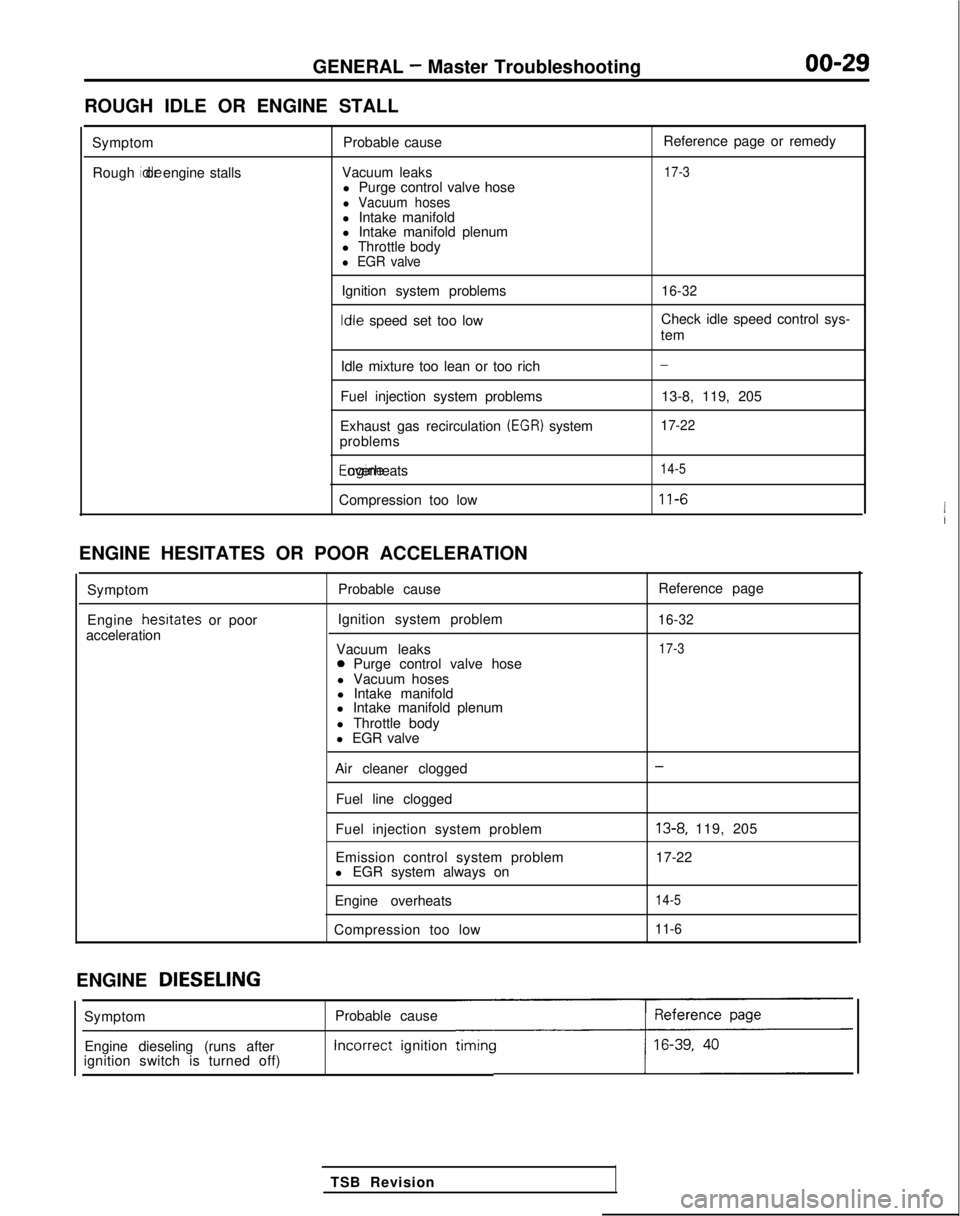

GENERAL - Master Troubleshooting00-29

ROUGH IDLE OR ENGINE STALL

SymptomRough idle or engine stalls

Probable cause

Vacuum leaks l Purge control valve hose

l Vacuum hosesl Intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve

Ignition system problems Idle

speed set too low Reference page or remedy

17-3

16-32

Check idle speed control sys-

tem

Idle mixture too lean or too rich

Fuel injection system problems

Exhaust gas recirculation

(EGR) system

problems Engine overheats

Compression too low

-

13-8, 119, 205

17-22

14-5

11-6

ENGINE HESITATES OR POOR ACCELERATION

Symptom

Engine hesrtates

or poor

acceleration Probable cause

Ignition system problem

Vacuum leaks

0 Purge control valve hose

l Vacuum hoses

l Intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve Reference page

16-32

17-3

Air cleaner clogged

Fuel line clogged

Fuel injection system problem

Emission control system problem

l EGR system always on

Engine overheats

Compression too low-

13-8, 119, 205

17-22

14-5

11-6

ENGINE DIESELING

Probable cause Incorrect

ignition

timincc

TSB Revision

Symptom

Engine dieseling (runs after

ignition switch is turned off)

Page 267 of 1273

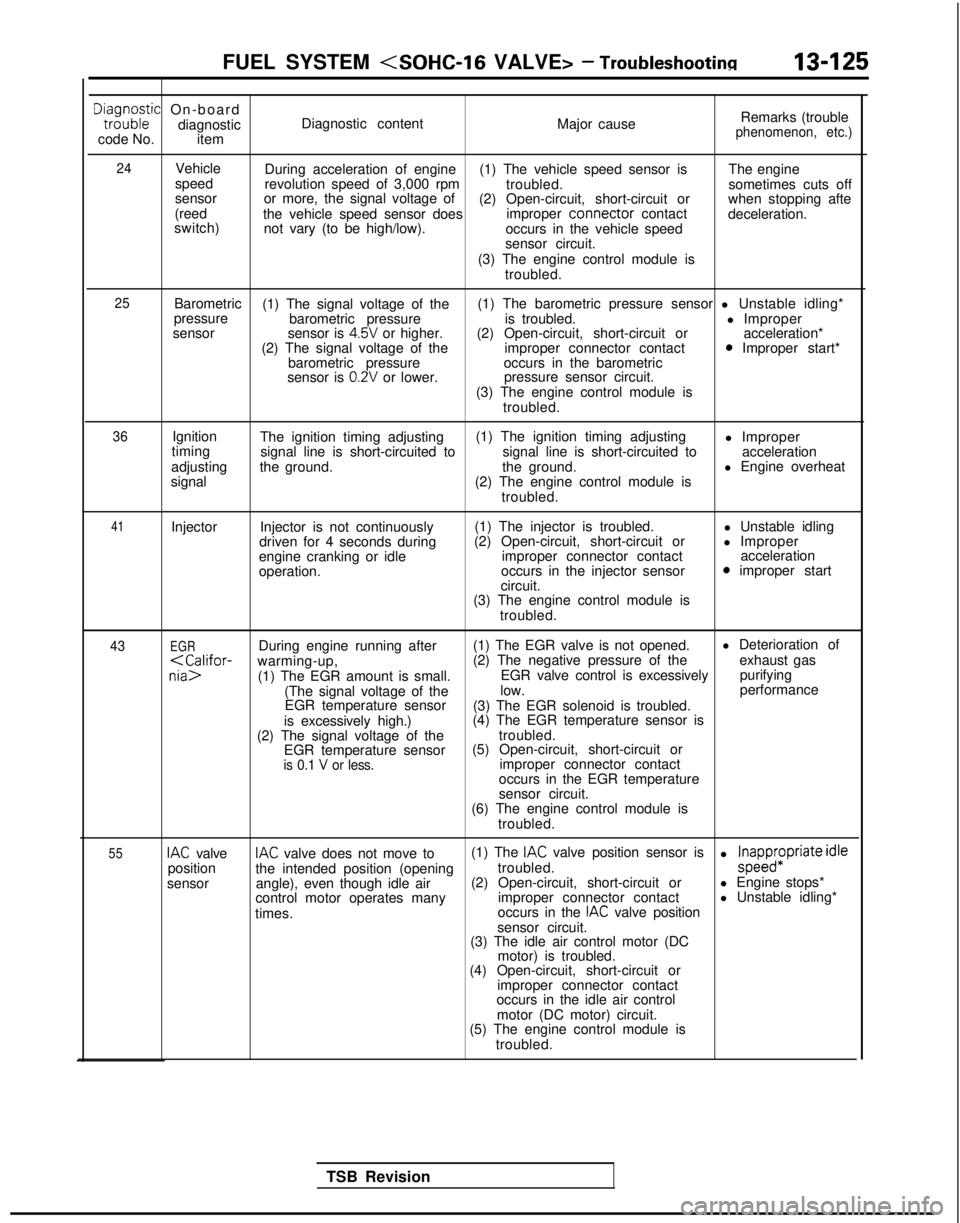

FUEL SYSTEM

Dta,i;o;ic On-board

diagnostic

code No. item Diagnostic content

Major causeRemarks (trouble

phenomenon, etc.)

24

Vehicle

speed

sensor

(reed

switch) During acceleration of engine

(1) The vehicle speed sensor is The engine

revolution speed of 3,000 rpm troubled.sometimes cuts off

or more, the signal voltage of (2) Open-circuit, short-circuit or when stopping afte

the vehicle speed sensor does improper connector

contact

deceleration.

not vary (to be high/low). occurs in the vehicle speed

sensor circuit.

(3) The engine control module is troubled.

25Barometric (1) The signal voltage of the (1) The barometric pressure sensor l Unstable idling*

pressure barometric pressure is troubled. l Improper

sensor sensor is

4.5V or higher.(2) Open-circuit, short-circuit or acceleration*

(2) The signal voltage of the improper connector contact0 Improper start*

barometric pressure occurs in the barometric

sensor is

0.2V or lower. pressure sensor circuit.

(3) The engine control module is troubled.

36Ignition

timing

adjusting

signal The ignition timing adjusting

(1) The ignition timing adjusting

l Improper

signal line is short-circuited to signal line is short-circuited toacceleration

the ground. the ground.l Engine overheat

(2) The engine control module is troubled.

41Injector Injector is not continuously

driven for 4 seconds during

engine cranking or idle

operation. (1) The injector is troubled.

(2) Open-circuit, short-circuit or improper connector contact

occurs in the injector sensor

circuit. l Unstable idling

l Improper acceleration

0 improper start

(3) The engine control module is troubled.

43EGRDuring engine running after (1) The EGR valve is not opened. l Deterioration of

purifying

(The signal voltage of the low. performance

EGR temperature sensor (3) The EGR solenoid is troubled.

is excessively high.) (4) The EGR temperature sensor is

(2) The signal voltage of the troubled.

EGR temperature sensor (5) Open-circuit, short-circuit or

is 0.1 V or less.improper connector contact

occurs in the EGR temperature

sensor circuit.

(6) The engine control module is

troubled.

55IAC valveIAC valve does not move to (1) The IAC valve position sensor is

position the intended position (opening troubled.l ;papp$Priate idle

sensor angle), even though idle air (2) Open-circuit, short-circuit or

l Engine stops*

control motor operates many improper connector contactl Unstable idling*

times. occurs in the

IAC valve position

sensor circuit.

(3) The idle air control motor (DC

motor) is troubled.

(4) Open-circuit, short-circuit or

improper connector contact

occurs in the idle air control

motor (DC motor) circuit.

(5) The engine control module is

troubled.

TSB Revision

Page 553 of 1273

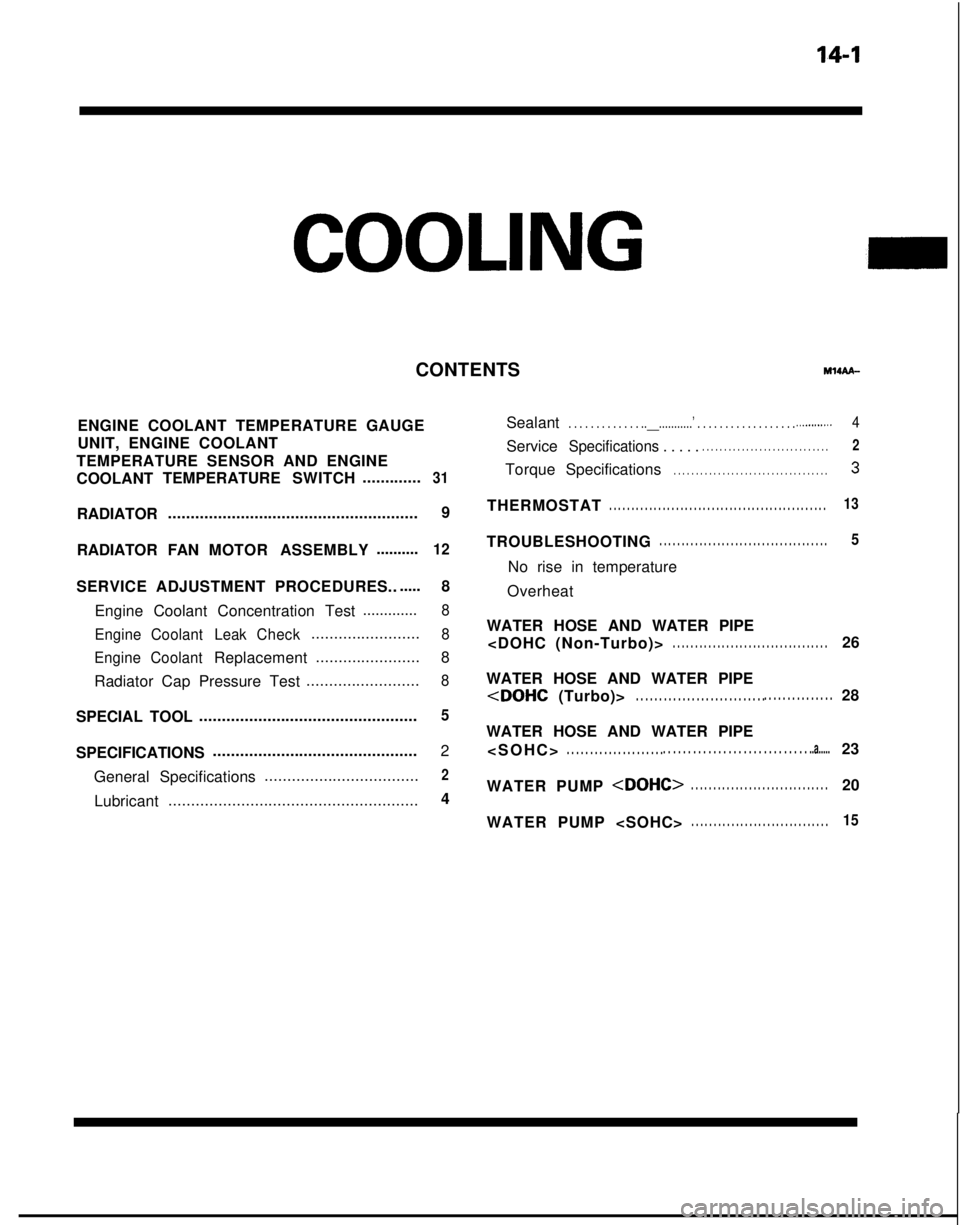

14-1

COOLING

ENGINE COOLANT TEMPERATURE GAUGE

UNIT, ENGINE COOLANT

TEMPERATURE SENSOR AND ENGINE

COOLANT TEMPERATURE

SWITCH.............

31

RADIATOR ....................................................... 9

RADIATOR FAN MOTOR ASSEMBLY ..........

12

SERVICE ADJUSTMENT PROCEDURES..

.....

8

Engine Coolant Concentration Test .............

8

Engine Coolant LeakCheck

........................8

Engine Coolant

Replacement .......................

8

Radiator Cap Pressure Test .........................

8

SPECIAL TOOL................................................5

SPECIFICATIONS .............................................

2

General Specifications ..................................

2

Lubricant

....................................................... 4

CONTENTS

IM14AA-

Sealant. . . . . . . . . . . . . ..__...........’ . . . . . . . . . . . . . \

. . . . . .._.........4

ServiceSpecifications . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Torque

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

THERMOSTAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . .13

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. .5

No rise in temperature

Overheat

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

WATER HOSE AND WATER PIPE

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..a.....23

WATER PUMP

WATER PUMP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Page 557 of 1273

COOLING - Special TooVTroubleshooting

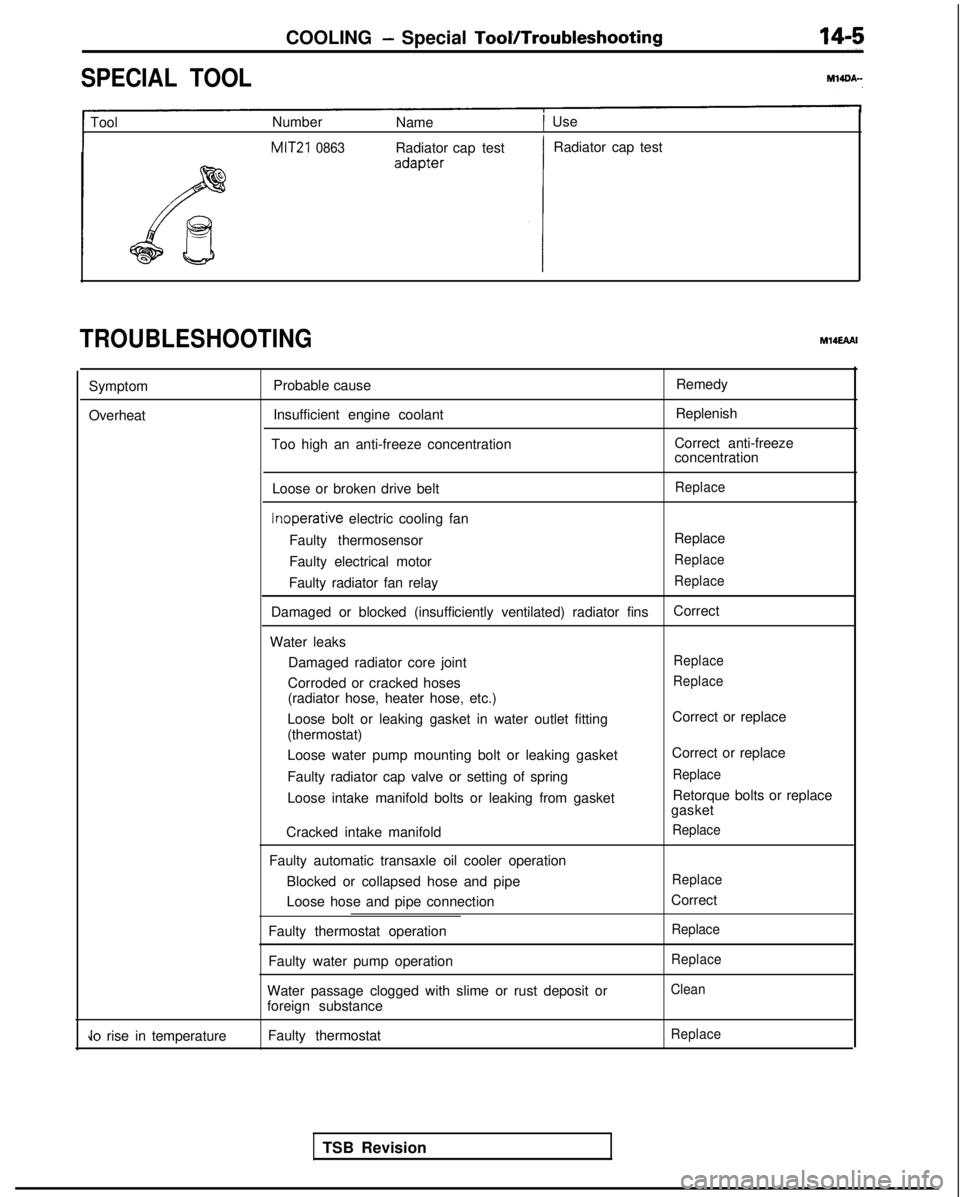

SPECIAL TOOL

1 Tool

Number

Name1 Use

MIT21 0863Radiator cap test Radiator cap test

TROUBLESHOOTINGM14EAAI

Symptom

Overheat Probable cause

Insufficient engine coolant

Too high an anti-freeze concentration Remedy

Replenish

Correct anti-freeze

concentration

Loose or broken drive belt

Replace Inoperative

electric cooling fan

Faulty thermosensor Replace

Faulty electrical motor

Replace

Faulty radiator fan relayReplace

Damaged or blocked (insufficiently ventilated) radiator fins Correct

Water leaks Damaged radiator core joint

Replace

Corroded or cracked hosesReplace

(radiator hose, heater hose, etc.)

Loose bolt or leaking gasket in water outlet fitting

(thermostat)

Loose water pump mounting bolt or leaking gasket

Faulty radiator cap valve or setting of spring

Loose intake manifold bolts or leaking from gasket

Cracked intake manifold

Faulty automatic transaxle oil cooler operation Blocked or collapsed hose and pipe

Loose hose and pipe connection

Faulty thermostat operation

Faulty water pump operation

Water passage clogged with slime or rust deposit or

foreign substance Correct or replace

Correct or replace

Replace

Retorque bolts or replace

gasket

Replace

Replace

Correct

Replace

Replace

Clean

Jo rise in temperature Faulty thermostatReplace

TSB Revision

Page 649 of 1273

I6EM0187

EMISSION CONTROL SYSTEMSExhaust Gas Recirculation (EGR) System/- Catalytic Converter/Air-fuel Ratio Control (MPI) System17-29

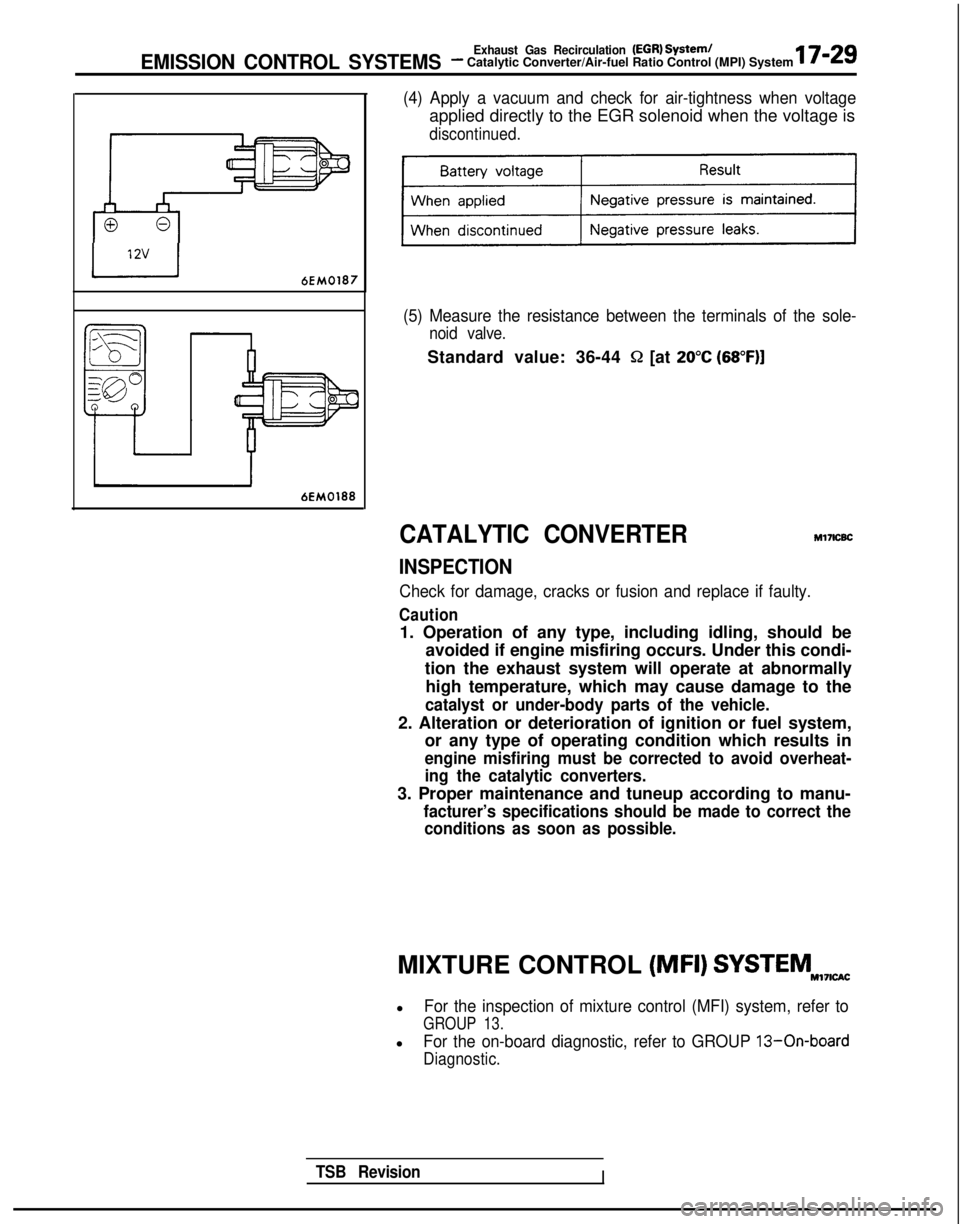

(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the EGR solenoid when the voltage is

discontinued.

(5) Measure the resistance between the terminals of the sole-

noid valve.

Standard value: 36-44 Q [at 20°C (68”F)]

CATALYTIC CONVERTERMl7lcBc

INSPECTION

Check for damage, cracks or fusion and replace if faulty.

Caution

1. Operation of any type, including idling, should be

avoided if engine misfiring occurs. Under this condi-

tion the exhaust system will operate at abnormally high temperature, which may cause damage to the

catalyst or under-body parts of the vehicle.

2. Alteration or deterioration of ignition or fuel system, or any type of operating condition which results in

engine misfiring must be corrected to avoid overheat-

ing the catalytic converters.

3. Proper maintenance and tuneup according to manu-

facturer’s specifications should be made to correct theconditions as soon as possible.

TSB RevisionI

MIXTURE CONTROL (MFI) SYSTEMNI,I,w

lFor the inspection of mixture control (MFI) system, refer to

GROUP 13.

lFor the on-board diagnostic, refer to GROUP 13-On-board

Diagnostic.