maintenance schedule MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 3 of 1273

00-l

GENERAL

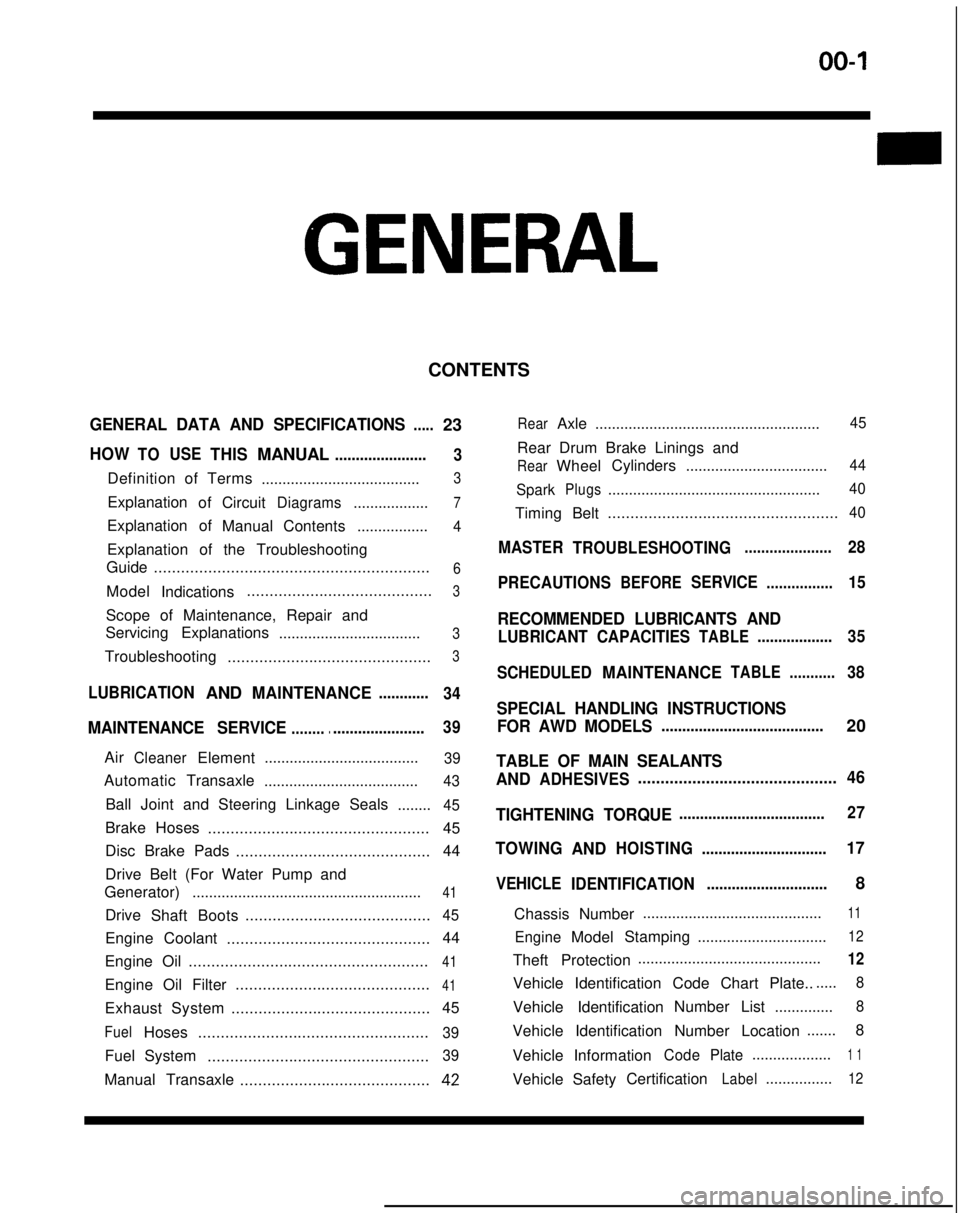

CONTENTS

GENERAL DATA AND SPECIFICATIONS.....23

HOWTOUSETHISMANUAL......................

3

Definition of Terms ......................................3

ExplanationofCircuitDiagrams..................7

Explanation of

ManualContents .................4

Explanation of the Troubleshooting

Guide .............................................................

6

Model

Indications .........................................3

Scope of Maintenance, Repair and

Servicing Explanations

..................................

3

Troubleshooting .............................................3

LUBRICATIONANDMAINTENANCE............

34

MAINTENANCE SERVICE............................... 39

AirCleanerElement

.....................................39

Automatic

Transaxle

.....................................43

Ball Joint and Steering Linkage Seals ........45

Brake Hoses................................................. 45

Disc Brake Pads ........................................... 44

Drive Belt (For Water Pump and

Generator) .......................................................

41

Drive

Shaft Boots .........................................45

Engine Coolant

............................................. 44

Engine Oil .....................................................

41

Engine Oil Filter ...........................................41

Exhaust System

............................................ 45

FuelHoses

...................................................39

Fuel System

.................................................39

Manual Transaxle ..........................................42

RearAxle......................................................45

Rear Drum Brake Linings and

RearWheel Cylinders

..................................44

Spark

Plugs...................................................40

Timing Belt...................................................40

MASTER

TROUBLESHOOTING.....................28

PRECAUTIONS

BEFORESERVICE................15

RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIESTABLE..................35

SCHEDULED

MAINTENANCETABLE ...........38

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS

.......................................20

TABLE OF MAIN SEALANTS

AND

ADHESIVES ............................................46

TIGHTENING TORQUE

................................... 27

TOWING

ANDHOISTING ..............................17

VEHICLE

IDENTIFICATION .............................8

Chassis Number ...........................................

11

EngineModel

Stamping

...............................12

Theft Protection ............................................12

Vehicle Identification Code Chart Plate.......

8

Vehicle Identification Number List

..............8

Vehicle Identification Number Location .......

8

Vehicle Information

CodePlate...................1 1

Vehicle SafetyCertificationLabel................12

Page 36 of 1273

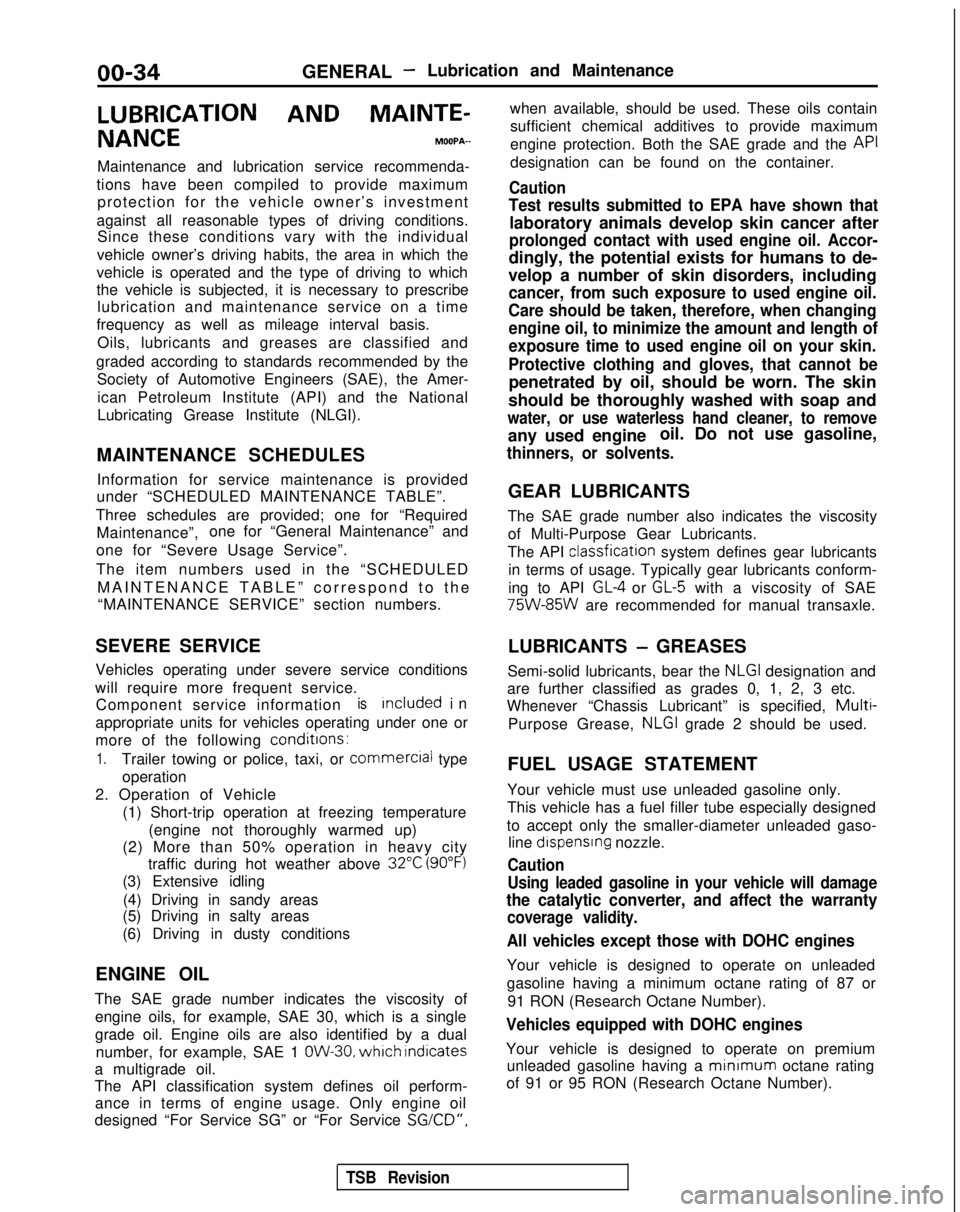

00-34GENERAL- Lubrication and Maintenance

LUBRICATION AND

MAINTE-

NANCEMOOPA-

Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum protection for the vehicle owner’s investment

against all reasonable types of driving conditions. Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by the Society of Automotive Engineers (SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute (NLGI).

MAINTENANCE SCHEDULES Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

The item numbers used in the “SCHEDULED MAINTENANCE TABLE” correspond to th

e

“MAINTENANCE SERVICE” section numbers.

SEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service. Component service information

isIncluded i

n

appropriate units for vehicles operating under one or

more of the following conditrons:

1.Trailer towing or police, taxi, or

commerciai

type

operation

2. Operation of Vehicle (1) Short-trip operation at freezing temperature(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city traffic during hot weather above

32°C (90°F)

(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual number, for example, SAE 1

OW-30, which Indicates

a multigrade oil.

The API classification system defines oil perform- ance in terms of engine usage. Only engine oil

designed “For Service SG” or “For Service

SGKD”,

when available, should be used. These oils contain

sufficient chemical additives to provide maximum

engine protection. Both the SAE grade and the API

designation can be found on the container.

Caution

Test results submitted to EPA have shown that

laboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-

dingly, the potential exists for humans to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be taken, therefore, when changing engine oil, to minimize the amount and length of

exposure time to used engine oil on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to remove

any used engine oil. Do not use gasoline,

thinners, or solvents.

GEAR LUBRICANTS

The SAE grade number also indicates the viscosity of Multi-Purpose Gear Lubricants.

The API classfication

system defines gear lubricants

in terms of usage. Typically gear lubricants conform-

ing to API

GL-4 or GL-5 with a viscosity of SAE 75W-85W

are recommended for manual transaxle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the

NLGI designation and

are further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified,

Multi-

Purpose Grease, NLGI grade 2 should be used.

FUEL USAGE STATEMENT

Your vehicle must use unleaded gasoline only.

This vehicle has a fuel filler tube especially designed

to accept only the smaller-diameter unleaded gaso- line

dispensrng nozzle.

Caution

Using leaded gasoline in your vehicle will damage

the catalytic converter, and affect the warranty

coverage validity.

All vehicles except those with DOHC engines

Your vehicle is designed to operate on unleaded

gasoline having a minimum octane rating of 87 or

91 RON (Research Octane Number).

Vehicles equipped with DOHC engines

Your vehicle is designed to operate on premiumunleaded gasoline having a minimum

octane rating

of 91 or 95 RON (Research Octane Number).

TSB Revision

Page 40 of 1273

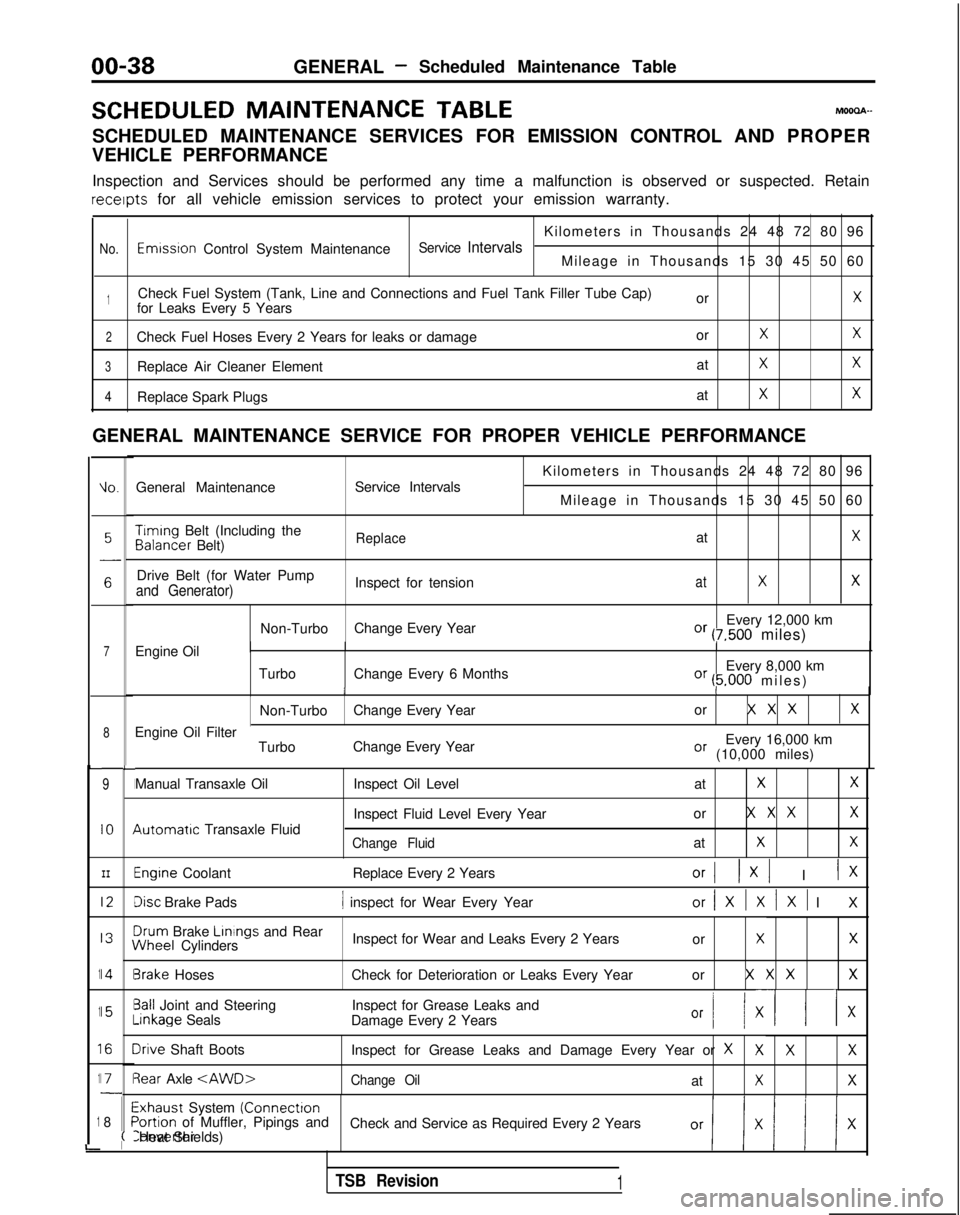

00-38GENERAL- Scheduled Maintenance Table

SCHEDULED MAINTENANCE

TABLEMOOOA-

SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PROPER

VEHICLE PERFORMANCE

Inspection and Services should be performed any time a malfunction is ob\

served or suspected. Retain receipts

for all vehicle emission services to protect your emission warranty.

Kilometers in Thousands 24 48 72 80 96

No.Emwsron Control System MaintenanceService IntervalsMileage in Thousands 15 30 45 50 60

1Check Fuel System (Tank, Line and Connections and Fuel Tank Filler Tube\

Cap) orXfor Leaks Every 5 Years

2Check Fuel Hoses Every 2 Years for leaks or damage orXX

3Replace Air Cleaner ElementatXX

4Replace Spark PlugsatXX

GENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

L

1

1

1

1

1

i

IO.General Maintenance

Service Intervals

7Engine Oil

8

9

IO

III2

I3

14

15

I6

I71

8

L

I

I

I

I

I\

I

II

I

I

;(

Kilometers in Thousands 24 48 72 80 96

Mileage in Thousands 15 30 45 50 60 Timing

Belt (Including the Balancer

Belt)

ReplaceatX

Drive Belt (for Water Pump

Inspect for tensionatXXand Generator)

Non-TurboChange Every Year Every 12,000 kmOr (7,500 miles)

Turbo Change Every 6 Months Every 8,000 km

Or (5.000 miles

)

II

Non-Turbo

Change Every Year or X X XX

Every 16,000 kmOr (10,000 miles)

Engine Oil Filter

TurboChange Every Year

Manual Transaxle Oil 4utomatrc

Transaxle Fluid Inspect Oil Level

at

XX

Inspect Fluid Level Every Yearor X X XX

Change FluidatXX

Engine Coolant

Replace Every 2 YearsOrI 1x1 I IX

Disc Brake Pads1 inspect for Wear Every Yearor/XlXlXl I

X

3rum

Brake Linings

and Rear iNheel

Cylinders Inspect for Wear and Leaks Every 2 Years

or

XX

3rake HosesCheck for Deterioration or Leaks Every Year or X X XX

3all Joint and SteeringInspect for Grease Leaks and-inkage

Seals

Damage Every 2 Years

Or I/ XII x

Irive Shaft Boots Inspect for Grease Leaks and Damage Every Year or XXXX

3ear Axle

Exhaust System (Connectron>ortion of Muffler, Pipings and

Check and Service as Required Every 2 YearsConverter Heat Shields)

TSB Revision1

Page 41 of 1273

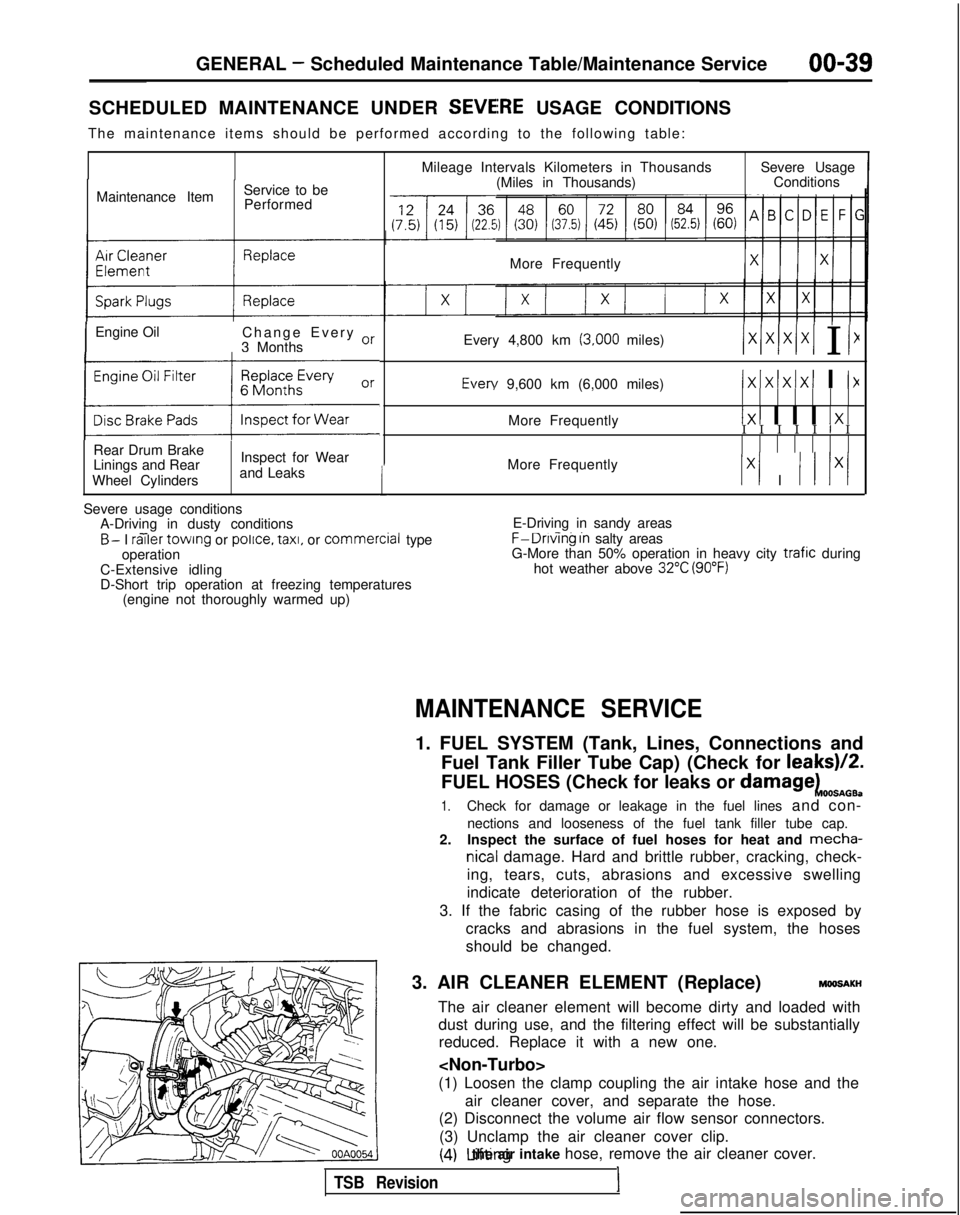

GENERAL - Scheduled Maintenance Table/Maintenance Service00-39

SCHEDULED MAINTENANCE UNDER SEVEiRE USAGE CONDITIONS

The maintenance items should be performed according to the following tab\

le:

Maintenance Item Service to be

Performed

IEngine Oil Change Every or

3 Months

(:z:.:a::I

Rear Drum Brake

Linings and Rear

Wheel Cylinders Inspect for Wear

and Leaks

1

Mileage Intervals Kilometers in Thousands (Miles in Thousands) Severe Usage

Conditions

More Frequently

Every 4,800 km

(3,000 miles)/xlxlx/xI I I1 Every

9,600 km (6,000 miles)

IxIxlxIxI I I>(

More Frequently1x1 I I I 1x1I I I I I I I

More Frequently

Ix1 I I I lx/

Severe usage conditions A-Driving in dusty conditions

- -B- I railer

towing or police.

taxi,

or commercial

type

operation

C-Extensive idling

D-Short trip operation at freezing temperatures (engine not thoroughly warmed up) E-Driving in sandy areas- -..F-Dnvlng In salty areas

G-More than 50% operation in heavy city trafic during

hot weather above 32°C (90°F)

MAINTENANCE SERVICE

1. FUEL SYSTEM (Tank, Lines, Connections and

Fuel Tank Filler Tube Cap) (Check for leaks)/2.

FUEL HOSES (Check for leaks or

damagekOOSnOB.

1.Check for damage or leakage in the fuel lines and con-

nections and looseness of the fuel tank filler tube cap.

2. Inspect the surface of fuel hoses for heat and mecha-

nicall damage. Hard and brittle rubber, cracking, check-

ing, tears, cuts, abrasions and excessive swelling

indicate deterioration of the rubber.

3. If the fabric casing of the rubber hose is exposed by cracks and abrasions in the fuel system, the hoses

should be changed.

3. AIR CLEANER ELEMENT (Replace)

MMlSAKH

The air cleaner element will become dirty and loaded with dust during use, and the filtering effect will be substantiallyreduced. Replace it with a new one.

(1) Loosen the clamp coupling the air intake hose and the air cleaner cover, and separate the hose.

(2) Disconnect the volume air flow sensor connectors.

(3) Unclamp the air cleaner cover clip.

(4) Lifting the air intake hose, remove the air cleaner cover.

TSB Revision1