37-3 MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 231 of 800

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY CHECK . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13

DRIVE BELT TENSION CHECK. . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-14

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST

COVER CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review th is manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before begi nning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 232 of 800

37-2

STEERING COLUMN SHAFT

ASSEMBLY . . . . . . . . . . . . . . . . . . . .37-20

REMOVAL AND INSTALLATION . . . . . . . . 37-20

DISASSEMBLY AND REASSEMBLY . . . . . 37-22

POWER STEERING GEAR BOX AND

LINKAGE . . . . . . . . . . . . . . . . . . . . . .37-23

REMOVAL AND INSTALLATION . . . . . . . . 37-23

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 37-24

DISASSEMBLY AND REASSEMBLY . . . . . 37-26

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 37-35

POWER STEERING OIL PUMP

ASSEMBLY. . . . . . . . . . . . . . . . . . . . .37-35

REMOVAL AND INSTALLATION . . . . . . . . 37-35

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 37-36

DISASSEMBLY AND REASSEMBLY . . . . . 37-37

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 37-39

POWER STEERING HOSES . . . . . . .37-40

REMOVAL AND INSTALLATION . . . . . . . . 37-40

Page 233 of 800

GENERAL INFORMATION

POWER STEERING37-3

GENERAL INFORMATION

M1372000100661

Power steering has been adopted in all vehicles to

make the steering system easier to handle.

FEATURES

•A 4-spoke steering wheel is used.

•MOMO leather-wrapped 3-spoke steering wheel

is used.

•A steering column has a shock absorbing mecha-

nism and a tilt steering mechanism.

•Integral-type rack and pinion gear with high rigid-

ity and excellent response is used.

•A vane type pump with a fluid flow rate control

system which change steering effort according to

the engine speed is used.

•The separate plastic resin oil reservoir is used to

reduce weight and to make the fluid level check

-

ing easier.

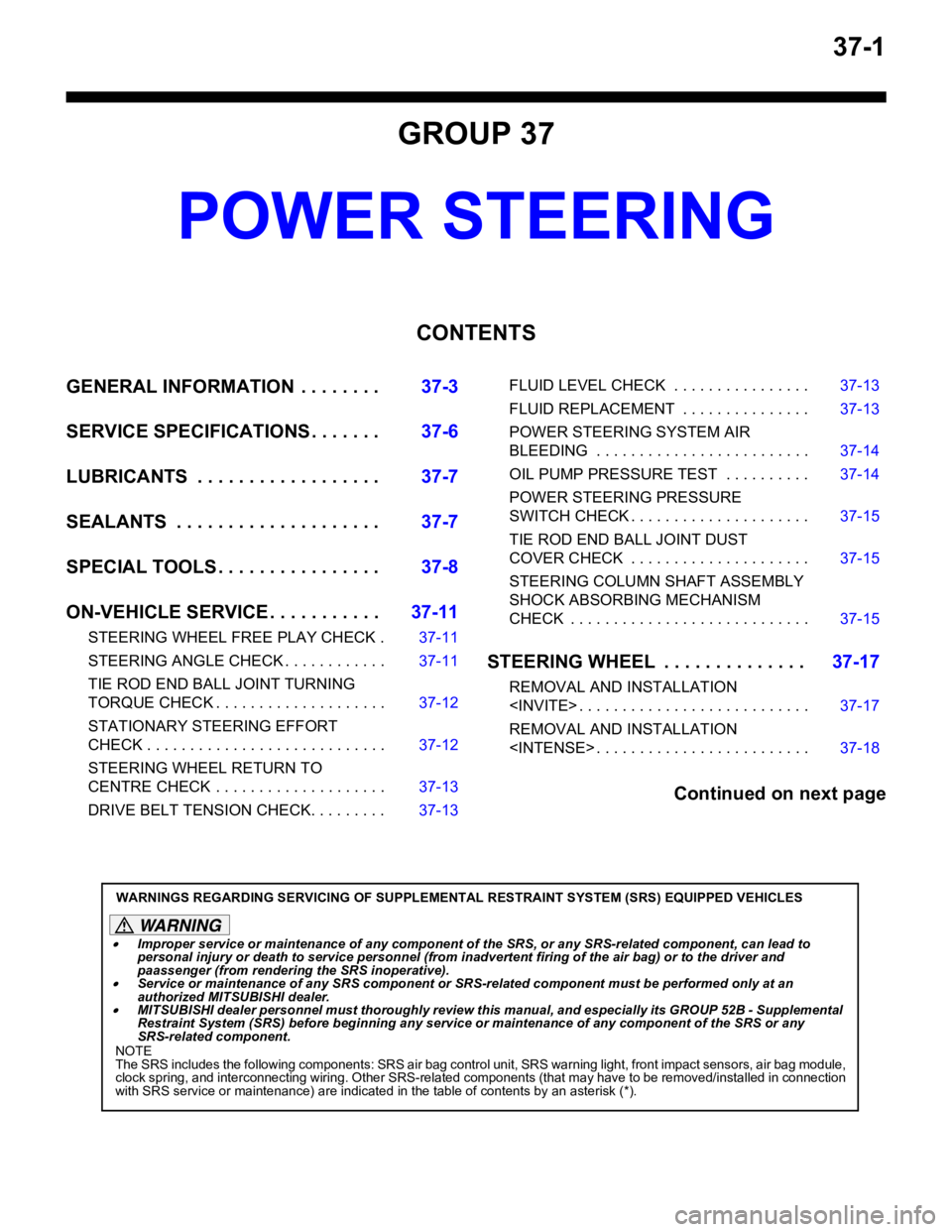

SPECIFICATIONS

ItemInviteIntense

Steering

wheelTy p e4-spoke typeMOMO leather-wrapped

3-spoke type

Outside diameter mm380365

Maximum number of turns3.193.08

Steering

columnColumn mechanismShock absorbing mechanism and Tilt steering mechanism

Power steering typeIntegral type

Oil pumpTy p eVane pump

Basic discharge amount cm3/rev.7.2 <1300, 1600>

8.1 <2000>

7.2 <1300, 1600>

8.1 <2000>

Relief pressure MPa8.88.8

Reservoir typeSeparate type (plastic)

Pressure switchEquipped

Steering

gearTy p eRack and pinion

Stroke ratio (Rack stroke/Steering

wheel maximum turning radius)45.7445.74

Rack stroke mm146141

Page 255 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-25

NOTE: When measuring, remove the bellows from

the rack housing. Measure the pinion torque through

the whole stroke of the rack.

If the measured value is not within the standard

range, first adjust the rack support cover, and then

check the total pinion torque again.

If the total pinion torque cannot be adjusted to within

the standard range by adjusting the rack support

cover, check the rack support cover, rack support

spring, rack support and replace any parts if neces

-

sary.

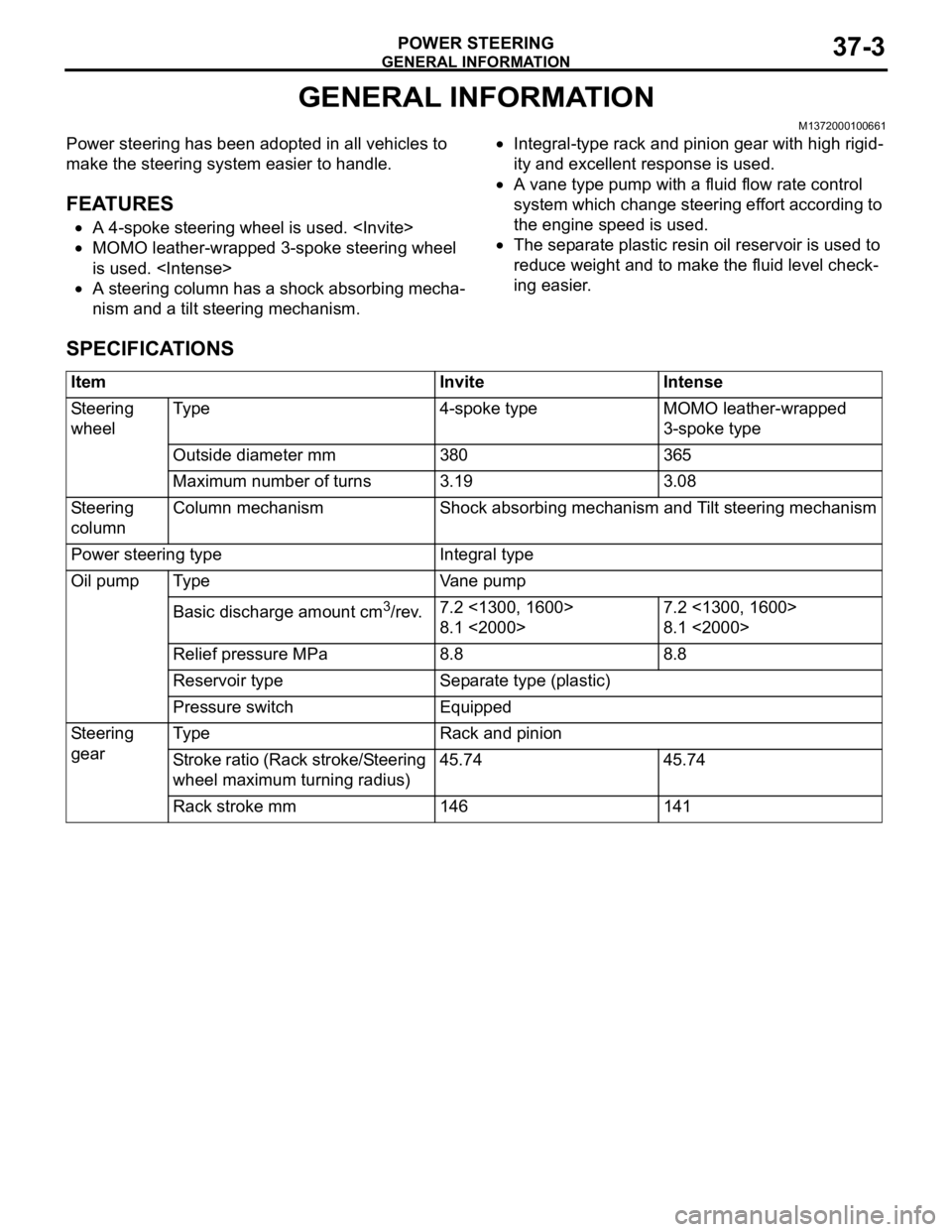

TIE ROD SWING RESISTANCE CHECK

1. Give 10 hard swings to the tie rod.

AC000997

2. Measure the tie ro d swin g resist ance [tie rod

swing to rque] with a spring bala n ce.

St andard va lue: 8 − 27 N [1.5 − 4.9 N⋅m]

3.If the measu r ed value exceeds the st a ndard

value , replace the tie rod.

4. If the measured value is below the st a ndard valu e,

th e tie rod can be re-use d if it swings smo o thly

wit hout e xce ssive play .

TIE ROD END BALL JOINT DUST COVER

CHECK

1.Check t he dust co ver f o r cracks or da mage by

p u shing it with your finger .

2.If the du st cover is cracked o r damaged, repla c e

th e tie rod end (Refer to

P.37-26).

NOTE: Cracks or dama ge of t he dust co ver may

d

a

mag

e the ball joint. If it is da mag ed du ring serv

-

ice work, replace the du st cove r (Re f er to

P.37-35).

Page 260 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-30

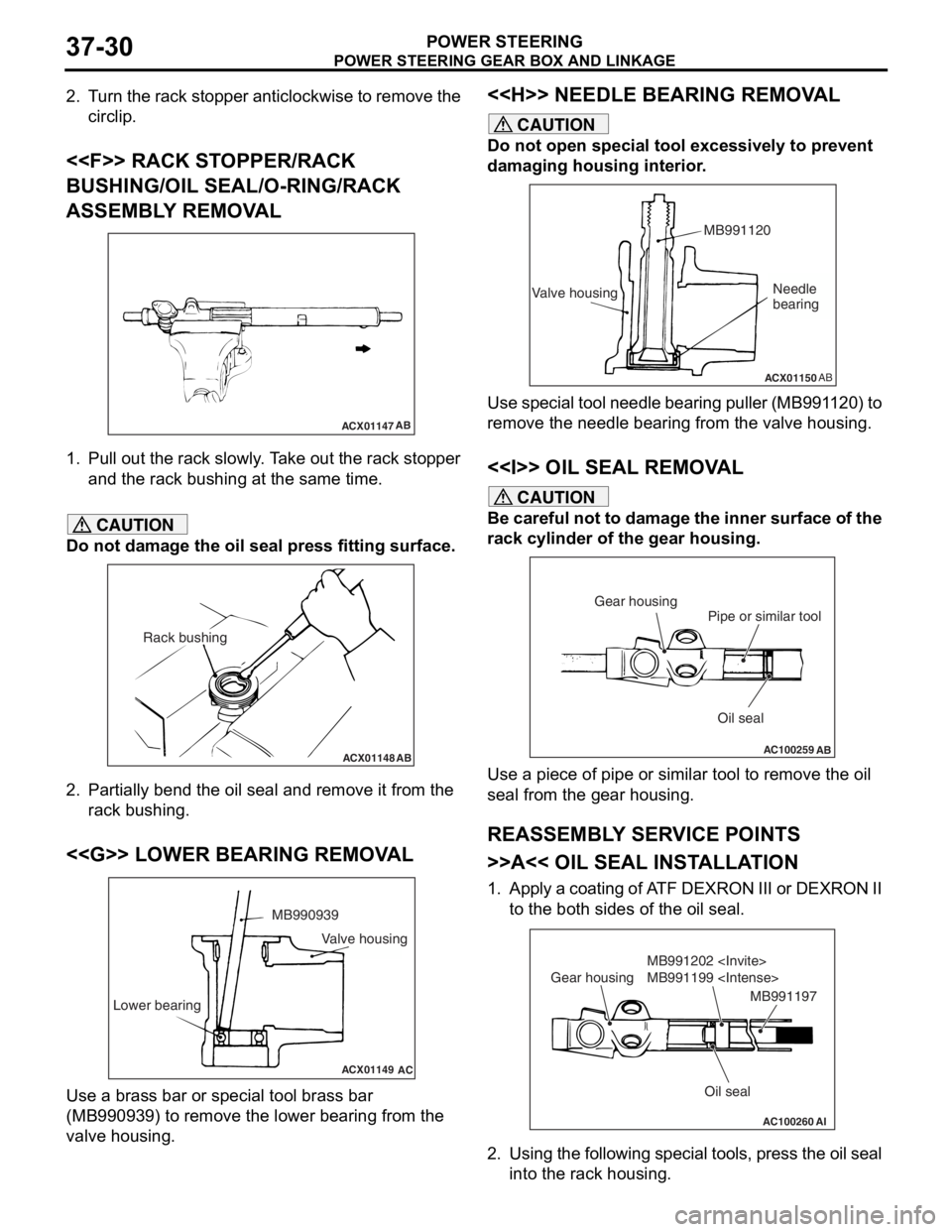

2. Turn the rack stopper anticlockwise to remove the circlip.

<

BUSHING/OIL SEAL/O-RING/RACK

ASSEMBLY REMOVAL

ACX01147 AB

1.

Pull out th e rack slo w ly . T a ke out th e rack stop per

an d the rack bushing at the same time.

CAUTION

Do not damage the oil seal press fitting surface.

ACX01148AB

Rack bushing

2. Partially bend the oil seal and remove it from the

rack bushing.

<

ACX01149

MB990939

Lower bearing

AC

Valve housing

Use a brass bar or special tool brass bar

(MB990939) to remove the lower bearing from the

valve housing.

<

CAUTION

Do not open special tool excessively to prevent

damaging housing interior.

ACX01150 AB

Valve housing MB991120Needle

bearing

Use special tool needle bearing puller (MB991120) to

remove the needle bearing from the valve housing.

<> OIL SEAL REMOVAL

CAUTION

Be careful not to damage the inner surface of the

rack cylinder of the gear housing.

AC100259

Oil seal

Pipe or similar tool

Gear housing

AB

Use a piece of pipe or simila

r tool to remove the oil

seal from the gear housing.

REASSEMBLY SERVICE POINTS

>>A<< OIL SEAL INSTALLATION

1. Apply a coating of ATF DEXRON III or DEXRON II to the both sides of the oil seal.

AC100260AI

Oil seal

MB991202

MB991199

Gear housing

MB991197

2. Using the following special tools, press the oil seal

into the rack housing.

Page 261 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-31

•Bar (long type) (MB991197)

•Oil seal installer (MB991199)

•Oil seal and bearing installer (MB991202)

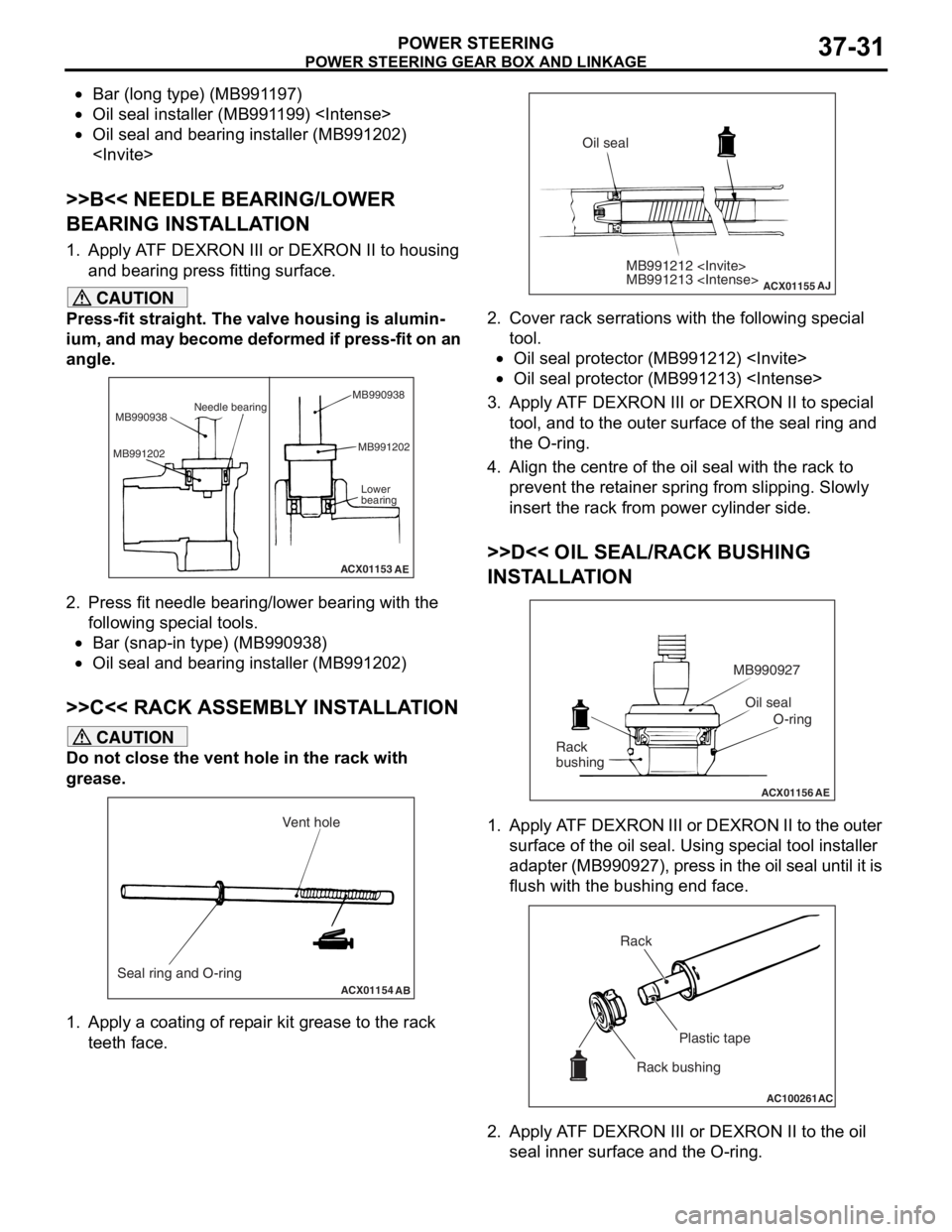

>>B<< NEEDLE BEARING/LOWER

BEARING INSTALLATION

1. Apply ATF DEXRON III or DEXRON II to housing and bearing press fitting surface.

CAUTION

Press-fit straight. The valve housing is alumin-

ium, and may become deformed if press-fit on an

angle.

ACX01153

Needle bearing

MB990938

MB991202 MB991202

Lower

bearing

AE

MB990938

2. Press fit needle bearing/lower bearing with the

following special tools.

•Bar (snap-in type) (MB990938)

•Oil seal and bearing installer (MB991202)

>>C<< RACK ASSEMBLY INSTALLATION

CAUTION

Do not close the vent hole in the rack with

grease.

ACX01154 AB

Seal ring and O-ring Vent hole

1. Apply a coating of repair kit grease to the rack

teeth face.

ACX01155

MB991212

MB991213

AJ

Oil seal

2. Cover rack serrations with the following special tool.

•Oil seal protector (MB991212)

•Oil seal protector (MB991213)

3. Apply ATF DEXRON III or DEXRON II to special

tool, and to the outer surface of the seal ring and

the O-ring.

4. Align the centre of the oil seal with the rack to prevent the retainer spring from slipping. Slowly

insert the rack from power cylinder side.

>>D<< OIL SEAL/RACK BUSHING

INSTALLATION

ACX01156 AE

Oil seal

O-ring

MB990927

Rack

bushing

1. Apply ATF DEXRON III or DEXRON II to the outer surface of the oil seal. Using special tool installer

adapter (MB990927), press in the oil seal until it is

flush with the bushing end face.

AC100261 AC

Rack

Plastic tape

Rack bushing

2. Apply ATF DEXRON III or DEXRON II to the oil seal inner surface and the O-ring.

Page 262 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-32

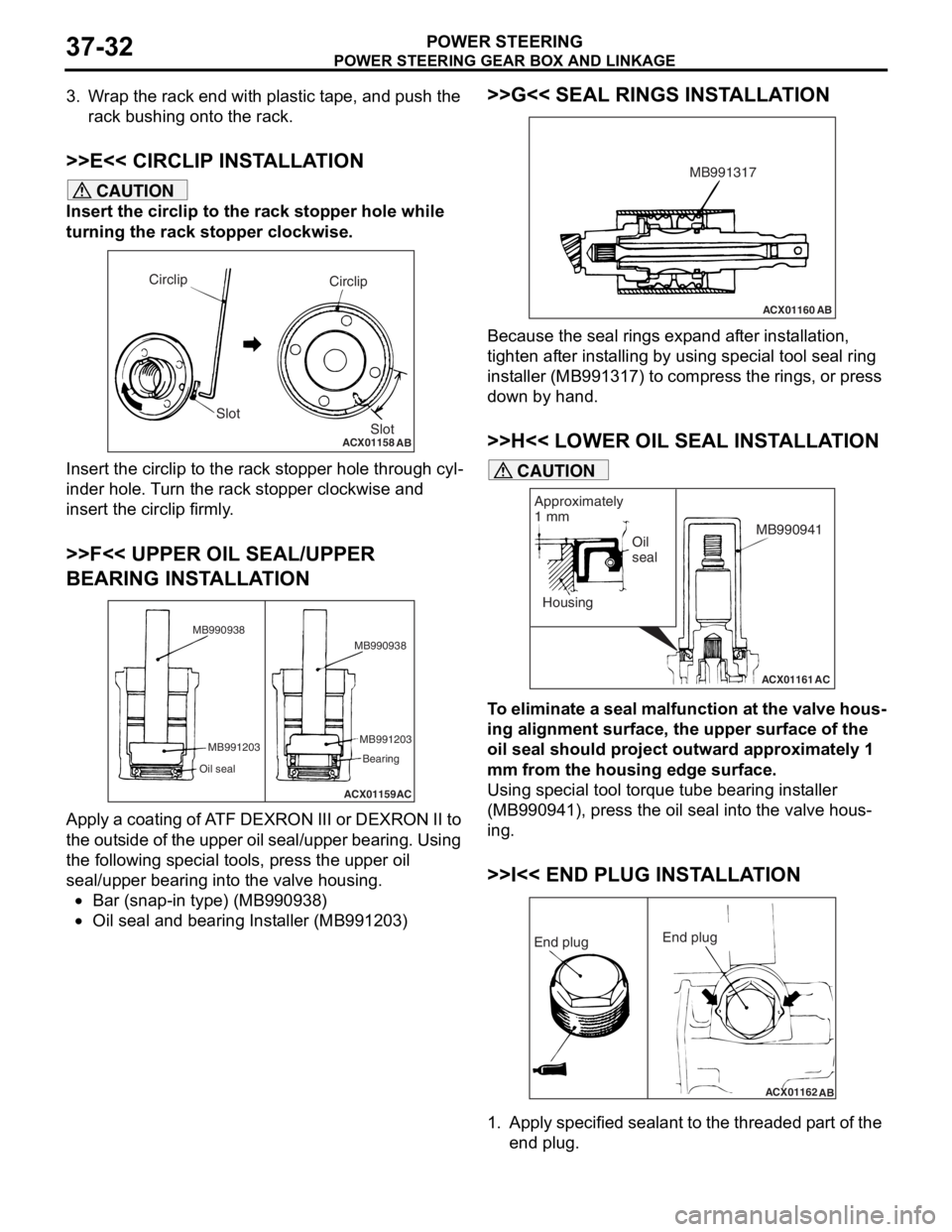

3. Wrap the rack end with plastic tape, and push the rack bushing onto the rack.

>>E<< CIRCLIP INSTALLATION

CAUTION

Insert the circlip to the rack stopper hole while

turning the rack stopper clockwise.

ACX01158

Circlip

Slot

AB

Circlip

Slot

Insert the circlip to the rack stopper hole through cyl-

inder hole. Turn the rack stopper clockwise and

insert the circlip firmly.

>>F<< UPPER OIL SEAL/UPPER

BEARING INSTALLATION

ACX01159AC

MB990938

MB991203

Oil seal

MB991203 Bearing

MB990938

Apply a coating of ATF DEXRON III or DEXRON II to

the outside of the upper oil seal/upper bearing. Using

the following special tools, press the upper oil

seal/upper bearing into the valve housing.

•Bar (snap-in type) (MB990938)

•Oil seal and bearing Installer (MB991203)

>>G<< SEAL RINGS INSTALLATION

ACX01160

AB

MB991317

Because the seal rings expand after installation,

tighten after installing by using special tool seal ring

installer (MB991317) to compress the rings, or press

down by hand.

>>H<< LOWER OIL SEAL INSTALLATION

ACX01161

Housing

AC

Oil

seal

Approximately

1 mm

MB990941

CAUTION

To eliminate a seal malfunction at the valve hous-

ing alignment surface, the upper surface of the

oil seal should project outward approximately 1

mm from the housing edge surface.

Using special tool torque tube bearing installer

(MB990941), press the oil seal into the valve hous

-

ing.

>>I<< END PLUG INSTALLATION

ACX01162

AB

End plug End plug

1. Apply specified sealant to the threaded part of the

end plug.

Page 263 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-33

Specified sealant: 3M ATD Part No.8661 or

equivalent

2. Secure the threaded portion of the end plug at two places by using a punch.

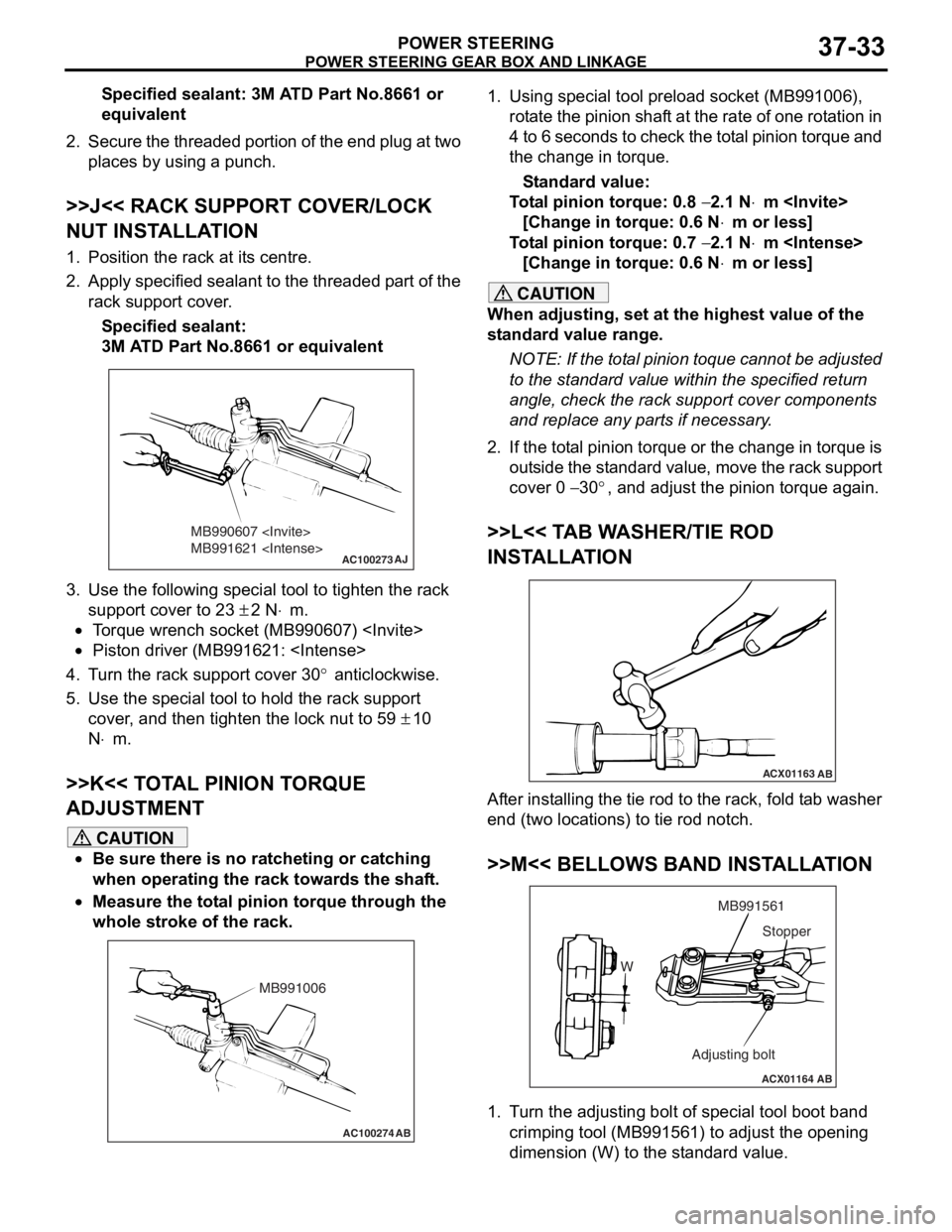

>>J<< RACK SUPPORT COVER/LOCK

NUT INSTALLATION

1. Position the rack at its centre.

2. Apply specified sealant to the threaded part of the

rack support cover.

Specified sealant:

3M ATD Part No.8661 or equivalent

AC100273

MB990607

MB991621

AJ

3.Use the fo llo wing special to ol to tigh ten the rack

suppor t cover to 2 3

± 2 N⋅m.

•To rque wren ch socket (MB990607 )

•Piston driver (MB9916 21:

4.T u rn the rack suppo rt cover 30° anticlockwise .

5.Use the special tool to hold the r a ck sup port

cove r , and t hen tighten the lock nut to 59

± 10

N

⋅m.

>>K<< T O T A L PINION T O RQUE

ADJUSTMENT

CAUTION

•Be sure there is no ratcheting or catching

when operating the rack towards the shaft.

•

AC100274 AB

MB991006

Measure the total pinion torque through the

whole stroke of the rack.

1. Using special tool preload socket (MB991006),

rotate the pinion shaft at the rate of one rotation in

4 to 6 seconds to check the total pinion torque and

the change in torque.

Standard value:

Total pinion torque: 0.8 − 2.1 N⋅m

[Change in torque: 0.6 N

⋅m or less]

Total pinion torque: 0.7 − 2.1 N⋅m

[Change in torque: 0.6 N

⋅m or less]

CAUTION

When adjusting, set at the highest value of the

standard value range.

NOTE: If the total pinion toque cannot be adjusted

to the standard value within the specified return

angle, check the rack support cover components

and replace any parts if necessary.

2. If the total pinion torque or the change in torque is outside the standard value, move the rack support

cover 0

− 30°, and adjust the pinion torque again.

>>L<< TAB WASHER/TIE ROD

INSTALLATION

ACX01163 AB

After installing the tie rod to the rack, fold tab washer

end (two locations) to tie rod notch.

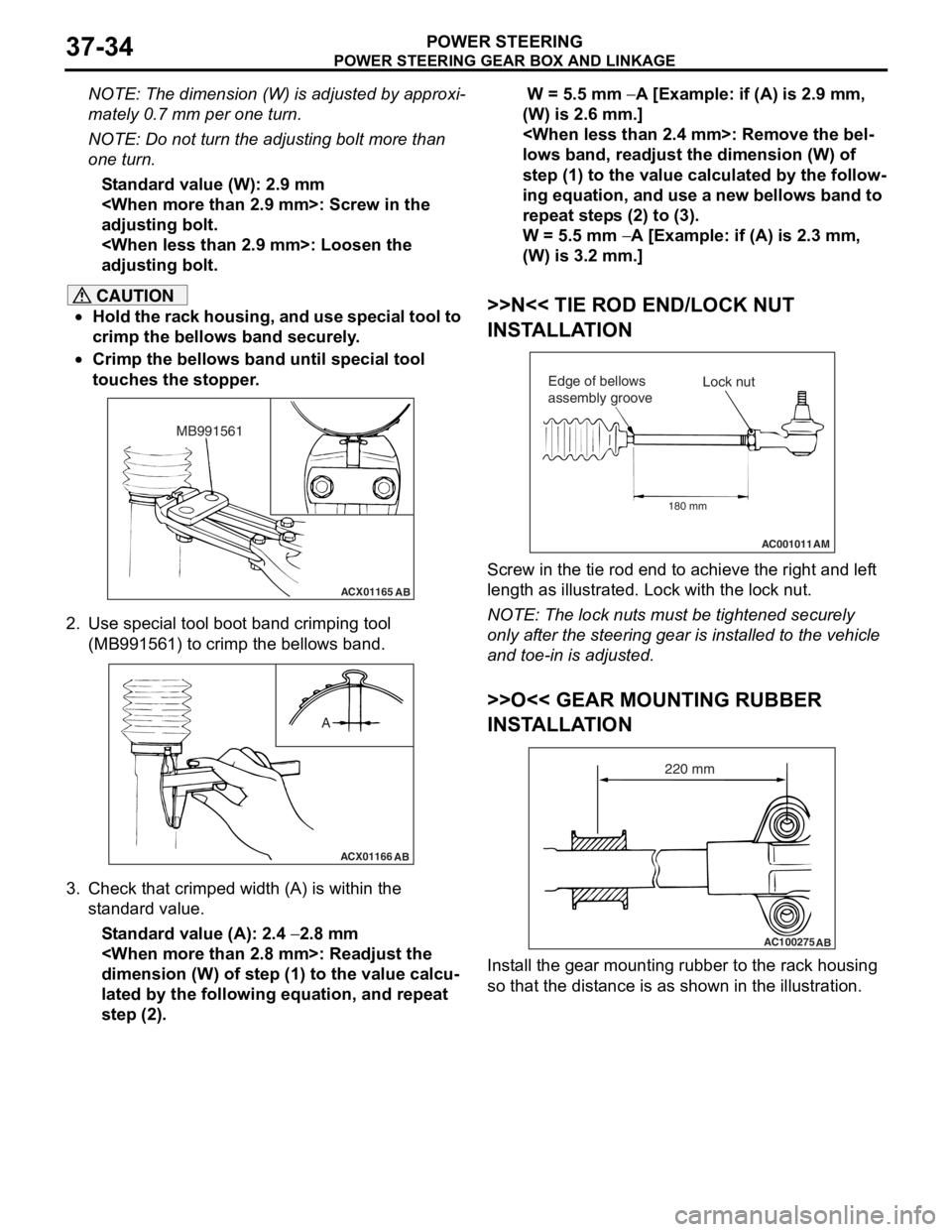

>>M<< BELLOWS BAND INSTALLATION

ACX01164 AB

W MB991561

Adjusting bolt Stopper

1. Turn the adjusting bolt of special tool boot band

crimping tool (MB991561) to adjust the opening

dimension (W) to the standard value.

Page 264 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-34

NOTE: The dimension (W) is adjusted by approxi-

mately 0.7 mm per one turn.

NOTE: Do not turn the adjusting bolt more than

one turn.

Standard value (W): 2.9 mm

adjusting bolt.

adjusting bolt.

CAUTION

•Hold the rack housing, and use special tool to

crimp the bellows band securely.

•

ACX01165AB

MB991561

Crimp the bellows band until special tool

touches the stopper.

2. Use special tool boot band crimping tool (MB991561) to crimp the bellows band.

ACX01166 AB

A

3. Check that crimped width (A) is within the

standard value.

Standard value (A): 2.4 − 2.8 mm

dimension (W) of step (1) to the value calcu

-

lated by the following equation, and repeat

step (2).

W = 5.5 mm − A [Example: if (A) is 2.9 mm,

(W) is 2.6 mm.]

lows band, readjust the dimension (W) of

step (1) to the value calculated by the follow

-

ing equation, and use a new bellows band to

repeat steps (2) to (3).

W = 5.5 mm − A [Example: if (A) is 2.3 mm,

(W) is 3.2 mm.]

>>N<< TIE ROD END/LOCK NUT

INSTALLATION

AC001011 AM

Lock nut

Edge of bellows

assembly groove

180 mm

Screw in the tie rod end to achieve the right and left

length as illustrated. Lock with the lock nut.

NOTE: The lock nuts must be tightened securely

only after the steering gear is installed to the vehicle

and toe-in is adjusted.

>>O<< GEAR MOUNTING RUBBER

INSTALLATION

AC100275 AB

220 mm

Install the gear mounting rubber to the rack housing

so that the distance is as shown in the illustration.

Page 265 of 800

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-35

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT

M1372008200327

If the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

AC001012AB

MB990776

1.App l y specified grea se to the lip an d inside of the

d u st c o ve r .

Specified grease:

Mu l t i p u r po se g r ea se SAE J3 10 , NL GI No .2 or

equival

ent

2.Drive in the d u st cover with special tool f r ont axle

b a se (MB9907 76) unt il it is fully seated .

3.Check t he dust co ver f o r cracks or da mage by

p u shing it with your finger .

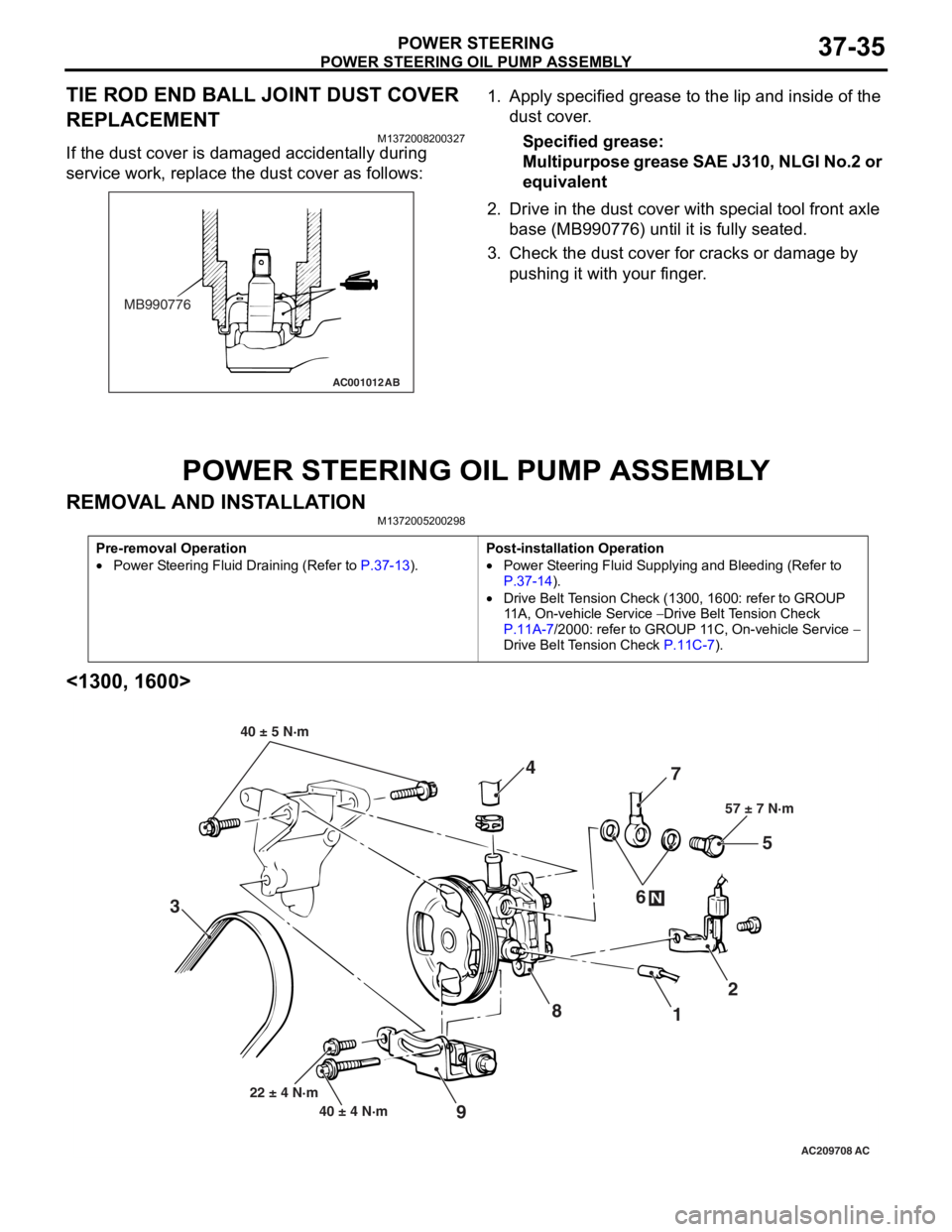

POWER STEERING OIL PUMP ASSEMBL Y

REMOVA L AND INST ALLA TIONM13720052 0029 8

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13).

Post-installation Operation

•Power Steering Fluid Supplying and Bleeding (Refer to

P.37-14).

•Drive Belt Tension Check (1300, 1600: refer to GROUP

11A, On-vehicle Service

− Drive Belt Tension Check

P.11A-7/2000: refer to GROUP 11C, On-vehicle Service − Drive Belt Tension Check P.11C-7).

<1300, 1600>

AC209708

87

1 2

3 4

5

6

57 ± 7 N·m

40 ± 4 N·m

22 ± 4 N·m

N

9

40 ± 5 N·m

AC