cylinder MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 252 of 800

STEERING COLUMN SHAFT ASSEMBLY

POWER STEERING37-22

DISASSEMBLY AND REASSEMBLY

M1372015000068

AC210967AD

3

2

14

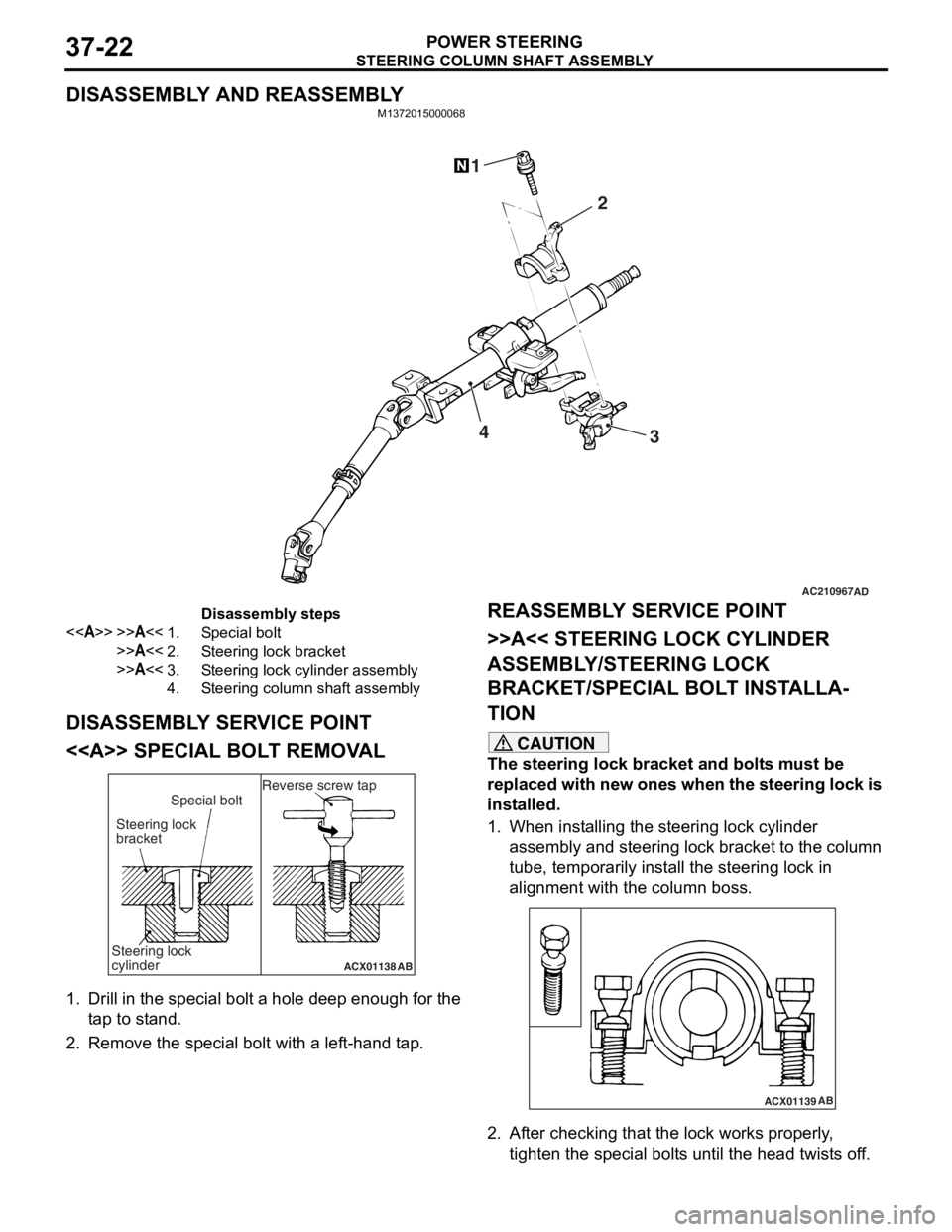

Disassembly steps

<>>>A<<1.Special bolt

>>A<<2.Steering lock bracket

>>A<<3.Steering lock cylinder assembly

4.Steering column shaft assembly

DISASSEMBL

Y SER V ICE POINT

<> SPECIAL BOLT REMOV A L

ACX01138

AB

Steering lock

bracket

Reverse screw tap

Special bolt

Steering lock

cylinder

1. Drill in the special bo lt a ho le de ep enou gh for th e

t ap t o st and.

2.Remove the special b o lt with a lef t -h and t ap.

REASSEMBL Y SER V ICE POINT

>>A<< STEERING LOCK CYLINDER

ASSEMBL

Y /STEERING LOCK

BRACKET/SPECIAL BOL

T INST ALLA

-

TION

CAUTION

The steering lock bracket and bolts must be

replaced with new ones when the steering lock is

installed.

1. When installing the steering lock cylinder assembly and steering lock bracket to the column

tube, temporarily install the steering lock in

alignment with the column boss.

ACX01139 AB

2. After checking that the lock works properly,

tighten the special bolts until the head twists off.

Page 260 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-30

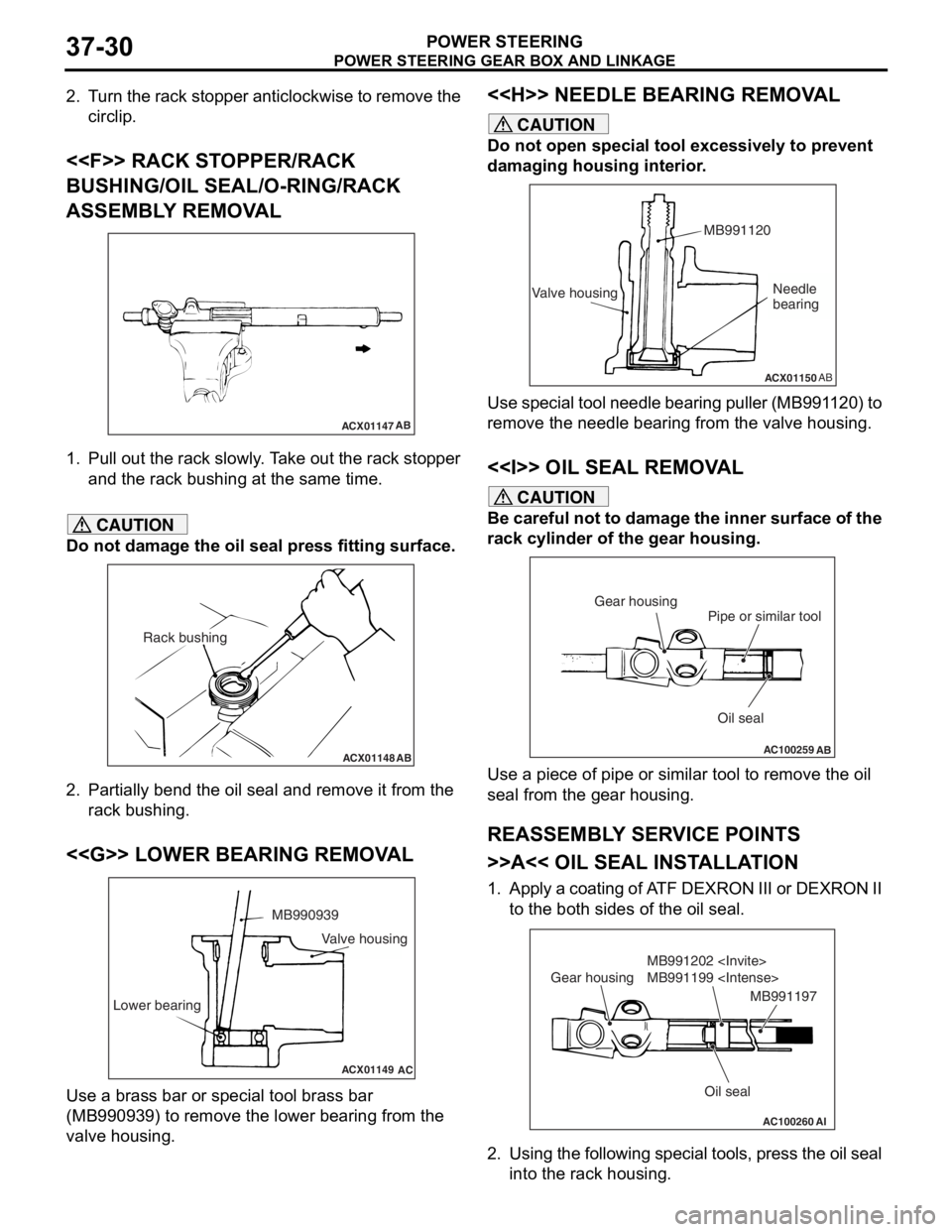

2. Turn the rack stopper anticlockwise to remove the circlip.

<

BUSHING/OIL SEAL/O-RING/RACK

ASSEMBLY REMOVAL

ACX01147 AB

1.

Pull out th e rack slo w ly . T a ke out th e rack stop per

an d the rack bushing at the same time.

CAUTION

Do not damage the oil seal press fitting surface.

ACX01148AB

Rack bushing

2. Partially bend the oil seal and remove it from the

rack bushing.

<

ACX01149

MB990939

Lower bearing

AC

Valve housing

Use a brass bar or special tool brass bar

(MB990939) to remove the lower bearing from the

valve housing.

<

CAUTION

Do not open special tool excessively to prevent

damaging housing interior.

ACX01150 AB

Valve housing MB991120Needle

bearing

Use special tool needle bearing puller (MB991120) to

remove the needle bearing from the valve housing.

<> OIL SEAL REMOVAL

CAUTION

Be careful not to damage the inner surface of the

rack cylinder of the gear housing.

AC100259

Oil seal

Pipe or similar tool

Gear housing

AB

Use a piece of pipe or simila

r tool to remove the oil

seal from the gear housing.

REASSEMBLY SERVICE POINTS

>>A<< OIL SEAL INSTALLATION

1. Apply a coating of ATF DEXRON III or DEXRON II to the both sides of the oil seal.

AC100260AI

Oil seal

MB991202

MB991199

Gear housing

MB991197

2. Using the following special tools, press the oil seal

into the rack housing.

Page 261 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-31

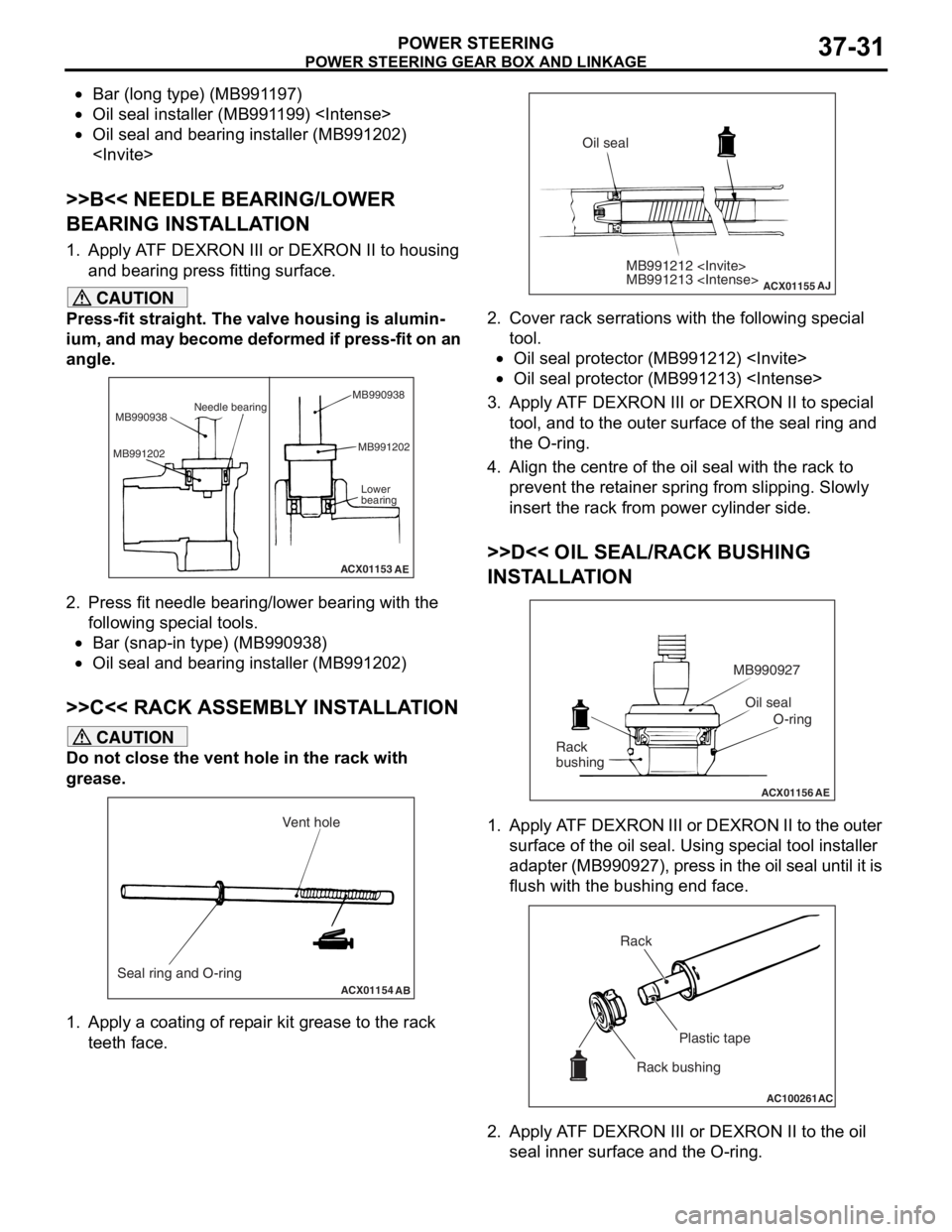

•Bar (long type) (MB991197)

•Oil seal installer (MB991199)

•Oil seal and bearing installer (MB991202)

>>B<< NEEDLE BEARING/LOWER

BEARING INSTALLATION

1. Apply ATF DEXRON III or DEXRON II to housing and bearing press fitting surface.

CAUTION

Press-fit straight. The valve housing is alumin-

ium, and may become deformed if press-fit on an

angle.

ACX01153

Needle bearing

MB990938

MB991202 MB991202

Lower

bearing

AE

MB990938

2. Press fit needle bearing/lower bearing with the

following special tools.

•Bar (snap-in type) (MB990938)

•Oil seal and bearing installer (MB991202)

>>C<< RACK ASSEMBLY INSTALLATION

CAUTION

Do not close the vent hole in the rack with

grease.

ACX01154 AB

Seal ring and O-ring Vent hole

1. Apply a coating of repair kit grease to the rack

teeth face.

ACX01155

MB991212

MB991213

AJ

Oil seal

2. Cover rack serrations with the following special tool.

•Oil seal protector (MB991212)

•Oil seal protector (MB991213)

3. Apply ATF DEXRON III or DEXRON II to special

tool, and to the outer surface of the seal ring and

the O-ring.

4. Align the centre of the oil seal with the rack to prevent the retainer spring from slipping. Slowly

insert the rack from power cylinder side.

>>D<< OIL SEAL/RACK BUSHING

INSTALLATION

ACX01156 AE

Oil seal

O-ring

MB990927

Rack

bushing

1. Apply ATF DEXRON III or DEXRON II to the outer surface of the oil seal. Using special tool installer

adapter (MB990927), press in the oil seal until it is

flush with the bushing end face.

AC100261 AC

Rack

Plastic tape

Rack bushing

2. Apply ATF DEXRON III or DEXRON II to the oil seal inner surface and the O-ring.

Page 308 of 800

DOOR

BODY42-36

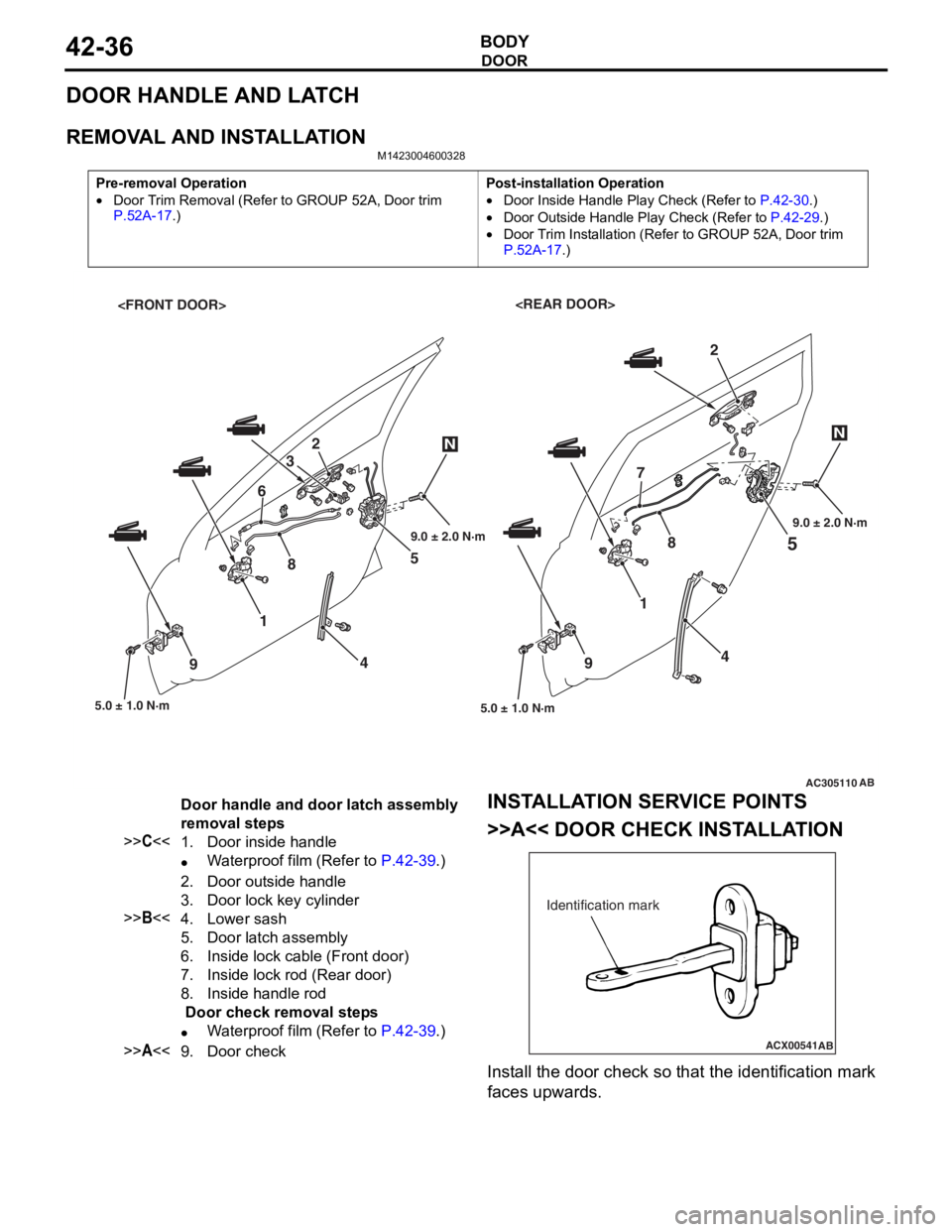

DOOR HANDLE AND LATCH

REMOVAL AND INSTALLATION

M1423004600328

Pre-removal Operation

•Door Trim Removal (Refer to GROUP 52A, Door trim P.52A-17.)

Post-installation Operation

•Door Inside Handle Play Check (Refer to P.42-30.)

•Door Outside Handle Play Check (Refer to P.42-29.)

•Door Trim Installation (Refer to GROUP 52A, Door trim

P.52A-17.)

AC305110

5

5.0 ± 1.0 N·m

1

4

9

2

AB

4 5

2

3

8 7

5.0 ± 1.0 N·m

1

6

9

NN

89.0 ± 2.0 N·m 9.0 ± 2.0 N·m

Door handle and door latch assembly

removal steps

>>C<<1.Door inside handle

•Waterproof film (Refer to P.42-39.)

2.Door outside handle

3.Door lock key cylinder

>>B<<4.Lower sash

5.Door latch assembly

6.Inside lock cable (Front door)

7.Inside lock rod (Rear door)

8.Inside handle rod

Door check removal steps

•Waterproof film (Refer to P.42-39.)

>>A<<9.Door check

INST

ALLA T ION SER VICE POINTS

>>A<< DOOR CHECK INST ALLA TION

ACX00541

Identification mark

AB

Install the d oor check so that th e ide n tification mark

faces upward

s .

Page 310 of 800

DOOR

BODY42-38

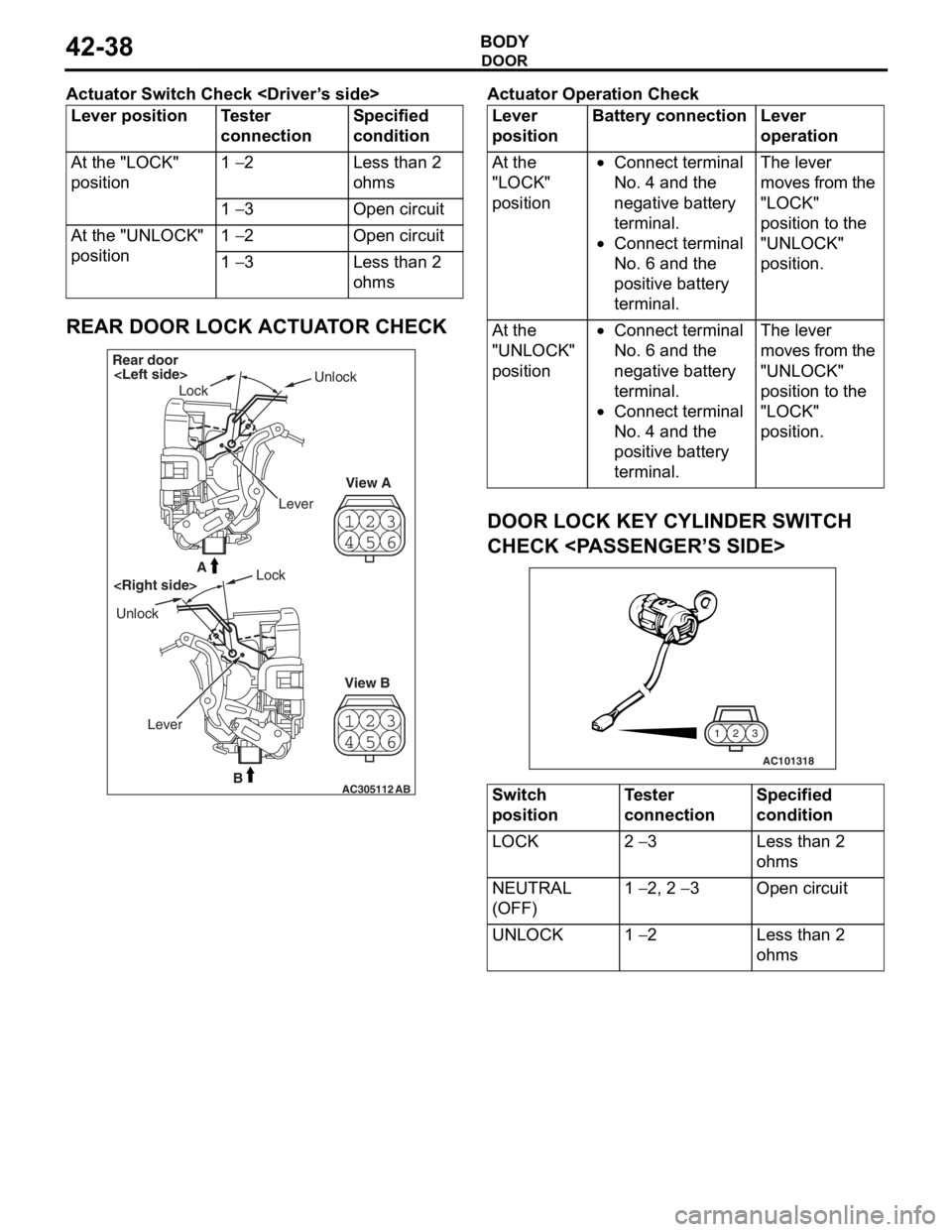

Actuator Switch Check

Lever positionTester

connectionSpecified

condition

At the "LOCK"

position1 − 2Less than 2

ohms

1 − 3Open circuit

At the "UNLOCK"

position1 − 2Open circuit

1 − 3Less than 2

ohms

REAR DOOR LOCK ACTUATOR CHECK

23

4 1

56

23

4 1

56

AC305112B

A

AB

Rear door

Lock Unlock

View A

View B

Unlock

Lock

Lever

Ac tuator Op era t ion Check

Lever

positionBattery connectionLever

operation

At the

"LOCK"

position•Connect terminal

No. 4 and the

negative battery

terminal.

•Connect terminal

No. 6 and the

positive battery

terminal.

The lever

moves from the

"LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position•Connect terminal

No. 6 and the

negative battery

terminal.

•Connect terminal

No. 4 and the

positive battery

terminal.

The lever

moves from the

"UNLOCK"

position to the

"LOCK"

position.

DOOR LOCK KEY CYLINDER SWITCH

CHECK

AC101318

3

2

1

Switch

positionTester

connectionSpecified

condition

LOCK2 − 3Less than 2

ohms

NEUTRAL

(OFF)1 − 2, 2 − 3Open circuit

UNLOCK1 − 2Less than 2

ohms

Page 315 of 800

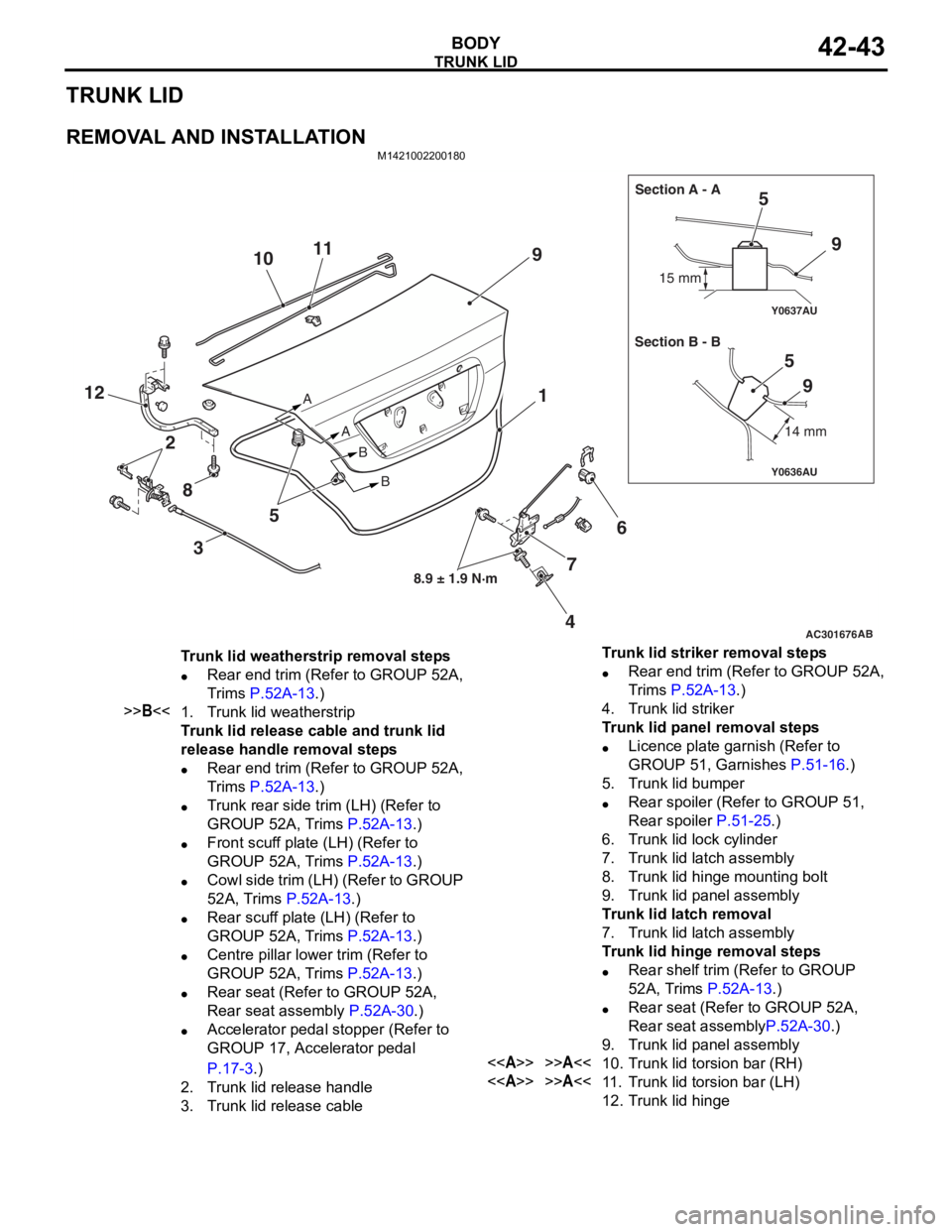

TRUNK LID

BODY42-43

TRUNK LID

REMOVAL AND INSTALLATION

M1421002200180

AC301676

Y0636AU

Y0637AU

AB

8.9 ± 1.9 N·m

A

AB

B 15 mm

14 mm

Section A - A

Section B - B

9

5

6

4

12

9

59

7

11

10

8 3 5 1

2

Trunk lid weatherstrip removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

>>B<<1.Trunk lid weatherstrip

Trunk lid release cable and trunk lid

release handle removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

•Trunk rear side trim (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Front scuff plate (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Cowl side trim (LH) (Refer to GROUP

52A, Trims

P.52A-13.)

•Rear scuff plate (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Centre pillar lower trim (Refer to

GROUP 52A, Trims

P.52A-13.)

•Rear seat (Refer to GROUP 52A,

Rear seat assembly

P.52A-30.)

•Accelerator pedal stopper (Refer to

GROUP 17, Accelerator pedal

P.17-3.)

2.Trunk lid release handle

3.Trunk lid release cable

Trunk lid striker removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

4.Trunk lid striker

Trunk lid panel removal steps

•Licence plate garnish (Refer to

GROUP 51, Garnishes

P.51-16.)

5.Trunk lid bumper

•Rear spoiler (Refer to GROUP 51,

Rear spoiler

P.51-25.)

6.Trunk lid lock cylinder

7.Trunk lid latch assembly

8.Trunk lid hinge mounting bolt

9.Trunk lid panel assembly

Trunk lid latch removal

7.Trunk lid latch assembly

Trunk lid hinge removal steps

•Rear shelf trim (Refer to GROUP

52A, Trims

P.52A-13.)

•Rear seat (Refer to GROUP 52A,

Rear seat assembly

P.52A-30.)

9.Trunk lid panel assembly

<>>>A<<10.Trunk lid torsion bar (RH)

<>>>A<<11 .Trunk lid torsion bar (LH)

12.Trunk lid hinge

Page 322 of 800

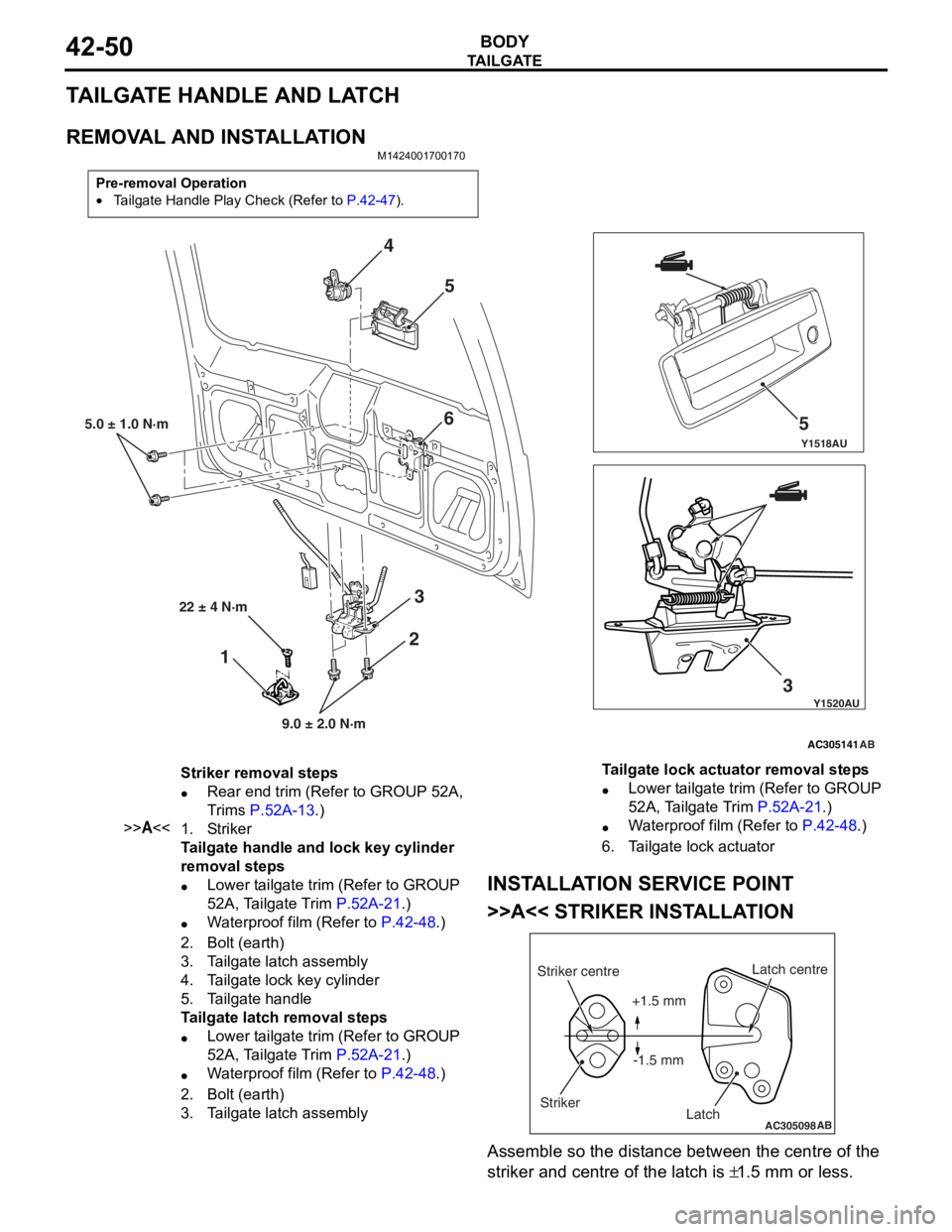

TAILGATE

BODY42-50

TAILGATE HANDLE AND LATCH

REMOVAL AND INSTALLATION

M1424001700170

Pre-removal Operation

•Tailgate Handle Play Check (Refer to P.42-47).

Y1518AU

Y1520AU

AC305141

4 5

6

3

3 5

5.0 ± 1.0 N·m

9.0 ± 2.0 N·m

AB

2

1

22 ± 4 N·m

Striker removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

>>A<<1.Strik er

Tailgate handle and lock key cylinder

removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim

P.52A-21.)

•Waterproof film (Refer to P.42-48.)

2.Bolt (earth)

3.Tailgate latch assembly

4.Tailgate lock key cylinder

5.Tailgate handle

Tailgate latch removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim

P.52A-21.)

•Waterproof film (Refer to P.42-48.)

2.Bolt (earth)

3.Tailgate latch assembly

Tailgate lock actuator removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim

P.52A-21.)

•Waterproof film (Refer to P.42-48.)

6.Tailgate lock actuator

INSTALLA T ION SER VICE POINT

>>A<< STRIKER INST ALLA TION

AC305098AB

Striker centre

Striker Latch centre

Latch

+1.5 mm

-1.5 mm

Assemble so the dist ance between the centre of the

striker an

d ce ntre of t he la tch is

±1.5 mm or less.

Page 328 of 800

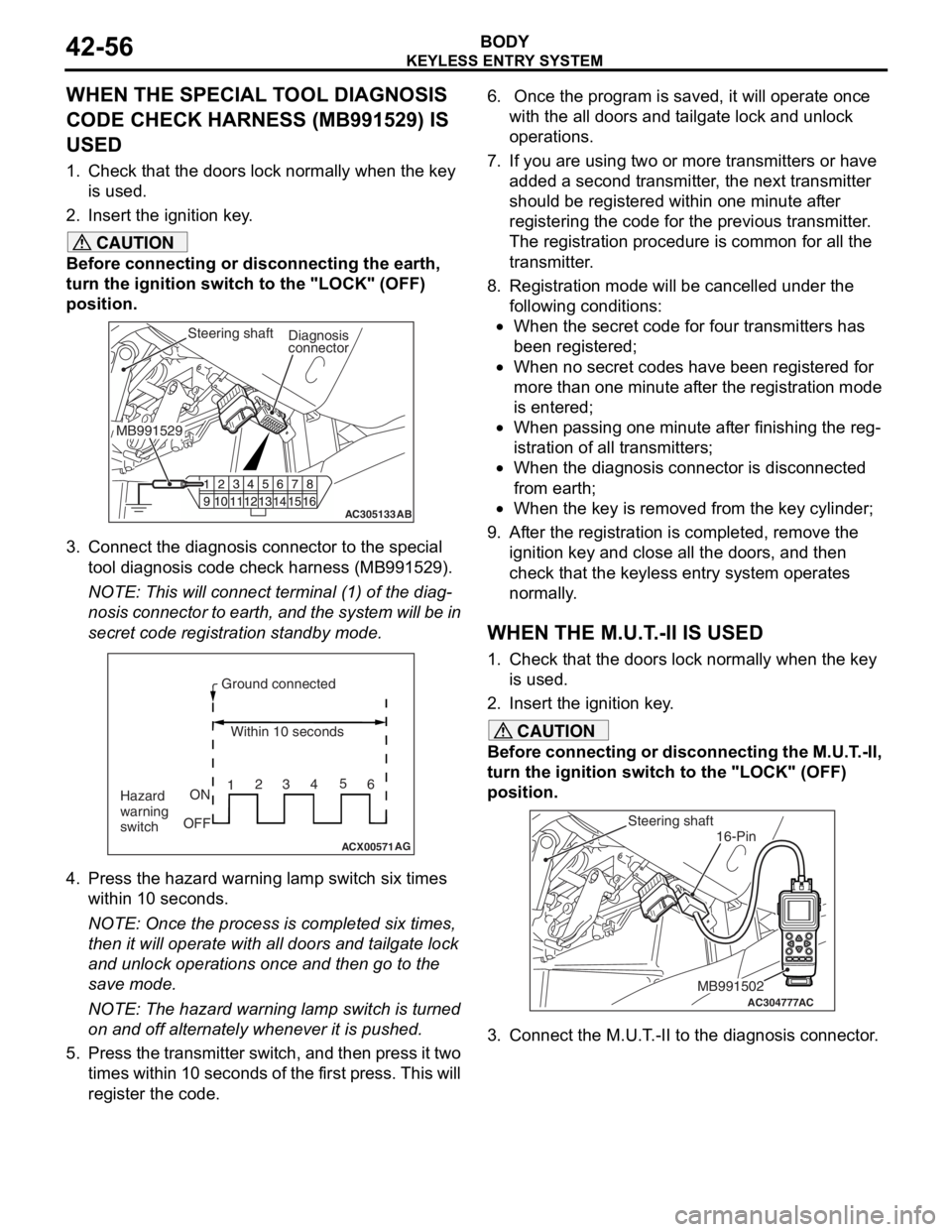

KEYLESS ENTRY SYSTEM

BODY42-56

WHEN THE SPECIAL TOOL DIAGNOSIS

CODE CHECK HARNESS (MB991529) IS

USED

1. Check that the doors lock normally when the key is used.

2. Insert the ignition key.

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305133AB

Diagnosis

connector

MB991529Steering shaft

3. Connect the diagnosis connector to the special tool diagnosis code check harness (MB991529).

NOTE: This will connect terminal (1) of the diag-

nosis connector to earth, and the system will be in

secret code registration standby mode.

ACX00571

Ground connected

Within 10 seconds

Hazard

warning

switch ON

OFF 1

23

45

6

AG

4. Press the hazard warning lamp switch six times

within 10 seconds.

NOTE: Once the process is completed six times,

then it will operate with al l doors and tailgate lock

and unlock operations once and then go to the

save mode.

NOTE: The hazard warning lamp switch is turned

on and off alternately whenever it is pushed.

5. Press the transmitter switch, and then press it two times within 10 seconds of the first press. This will

register the code.

6. Once the program is saved, it will operate once

with the all doors and tailgate lock and unlock

operations.

7. If you are using two or more transmitters or have

added a second transmitter, the next transmitter

should be registered within one minute after

registering the code for the previous transmitter.

The registration procedure is common for all the

transmitter.

8. Registration mode will be cancelled under the following conditions:

•When the secret code for four transmitters has

been registered;

•When no secret codes have been registered for

more than one minute after the registration mode

is entered;

•When passing one minute after finishing the reg-

istration of all transmitters;

•When the diagnosis connector is disconnected

from earth;

•When the key is removed from the key cylinder;

9. After the registration is completed, remove the ignition key and close all the doors, and then

check that the keyless entry system operates

normally.

WHEN THE M.U.T.-II IS USED

1. Check that the doors lock normally when the key

is used.

2. Insert the ignition key.

CAUTION

Before connecting or disconnecting the M.U.T.-II,

turn the ignition switch to the "LOCK" (OFF)

position.

AC304777

Steering shaft

ACMB991502

16-Pin

3. Connect the M.U.T.-II to the diagnosis connector.

Page 330 of 800

KEYLESS ENTRY SYSTEM

BODY42-58

7. If you are using two or more transmitters or have added a second transmitter, the next transmitter

should be registered within one minute after

registering the code for the previous transmitter.

The registration procedure is common for all the

transmitter.

8. Registration mode will be cancelled under the following conditions:

•When the secret code for four transmitters has

been registered;

•When no secret codes have been registered for

more than one minute after the registration mode

is entered;

•When passing one minute after finishing the reg-

istration of all transmitters;

•When the V.C.I. is disconnected from the diagno-

sis connector;

•When the key is removed from the key cylinder;

9. After the registration is completed, remove the ignition key and close all the doors, and then

check that the keyless entry system operates

normally.

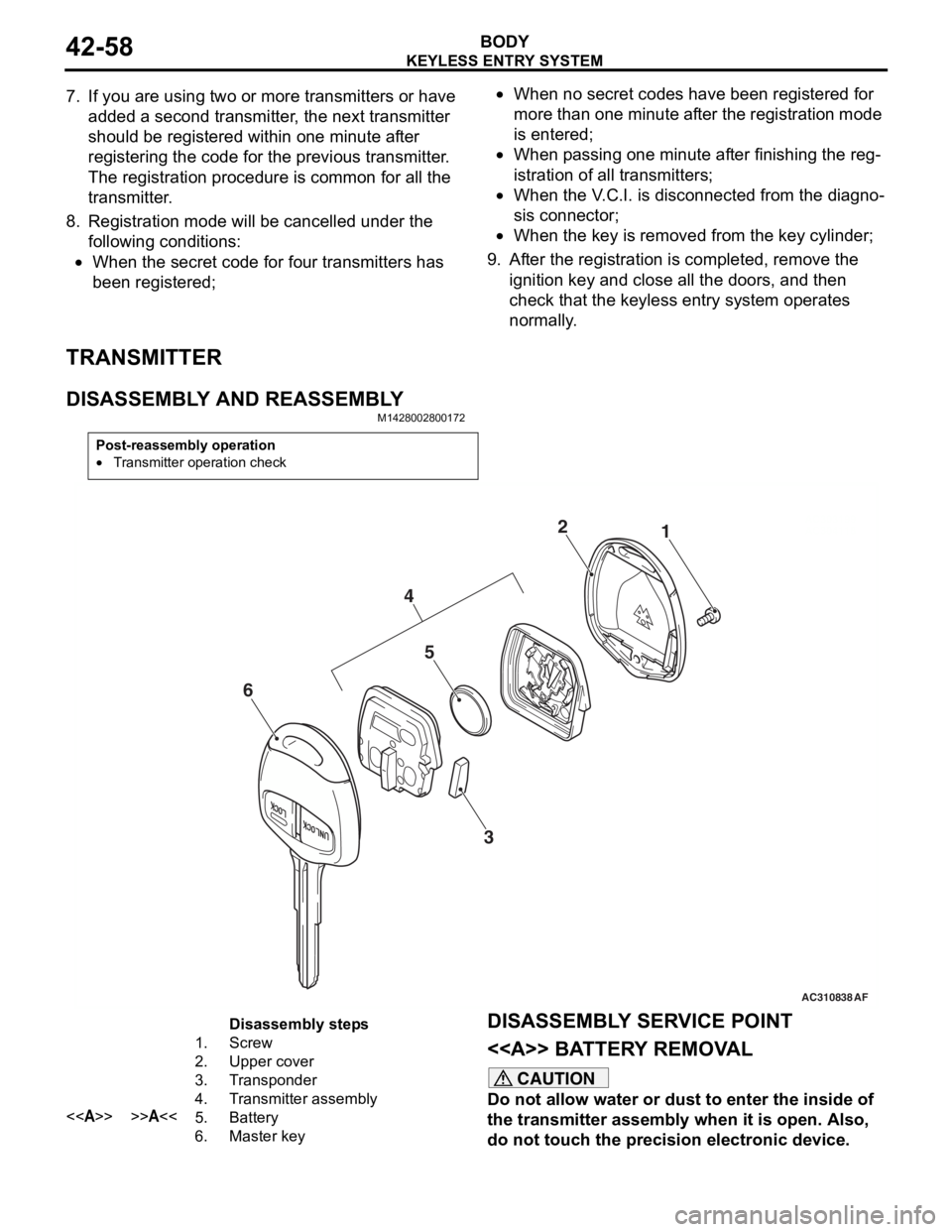

TRANSMITTER

DISASSEMBLY AND REASSEMBLY

M1428002800172

Post-reassembly operation

•Transmitter operation check

AC310838AC303199

AC3041181

2

AF

5

3

4

6

Disassembly steps

1.Screw

2.Upper cover

3.Transponder

4.Transmitter assembly

<>>>A<<5.Battery

6.Master key

DISASSEMBL Y SER V ICE POINT

<> BATTER Y REMOV A L

CAUTION

Do not allow water or dust to enter the inside of

the transmitter assembly when it is open. Also,

do not touch the precision electronic device.