ball joint MITSUBISHI LANCER 2006 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 231 of 800

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY CHECK . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13

DRIVE BELT TENSION CHECK. . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-14

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST

COVER CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review th is manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before begi nning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 232 of 800

37-2

STEERING COLUMN SHAFT

ASSEMBLY . . . . . . . . . . . . . . . . . . . .37-20

REMOVAL AND INSTALLATION . . . . . . . . 37-20

DISASSEMBLY AND REASSEMBLY . . . . . 37-22

POWER STEERING GEAR BOX AND

LINKAGE . . . . . . . . . . . . . . . . . . . . . .37-23

REMOVAL AND INSTALLATION . . . . . . . . 37-23

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 37-24

DISASSEMBLY AND REASSEMBLY . . . . . 37-26

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 37-35

POWER STEERING OIL PUMP

ASSEMBLY. . . . . . . . . . . . . . . . . . . . .37-35

REMOVAL AND INSTALLATION . . . . . . . . 37-35

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 37-36

DISASSEMBLY AND REASSEMBLY . . . . . 37-37

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 37-39

POWER STEERING HOSES . . . . . . .37-40

REMOVAL AND INSTALLATION . . . . . . . . 37-40

Page 236 of 800

SERVICE SPECIFICATIONS

POWER STEERING37-6

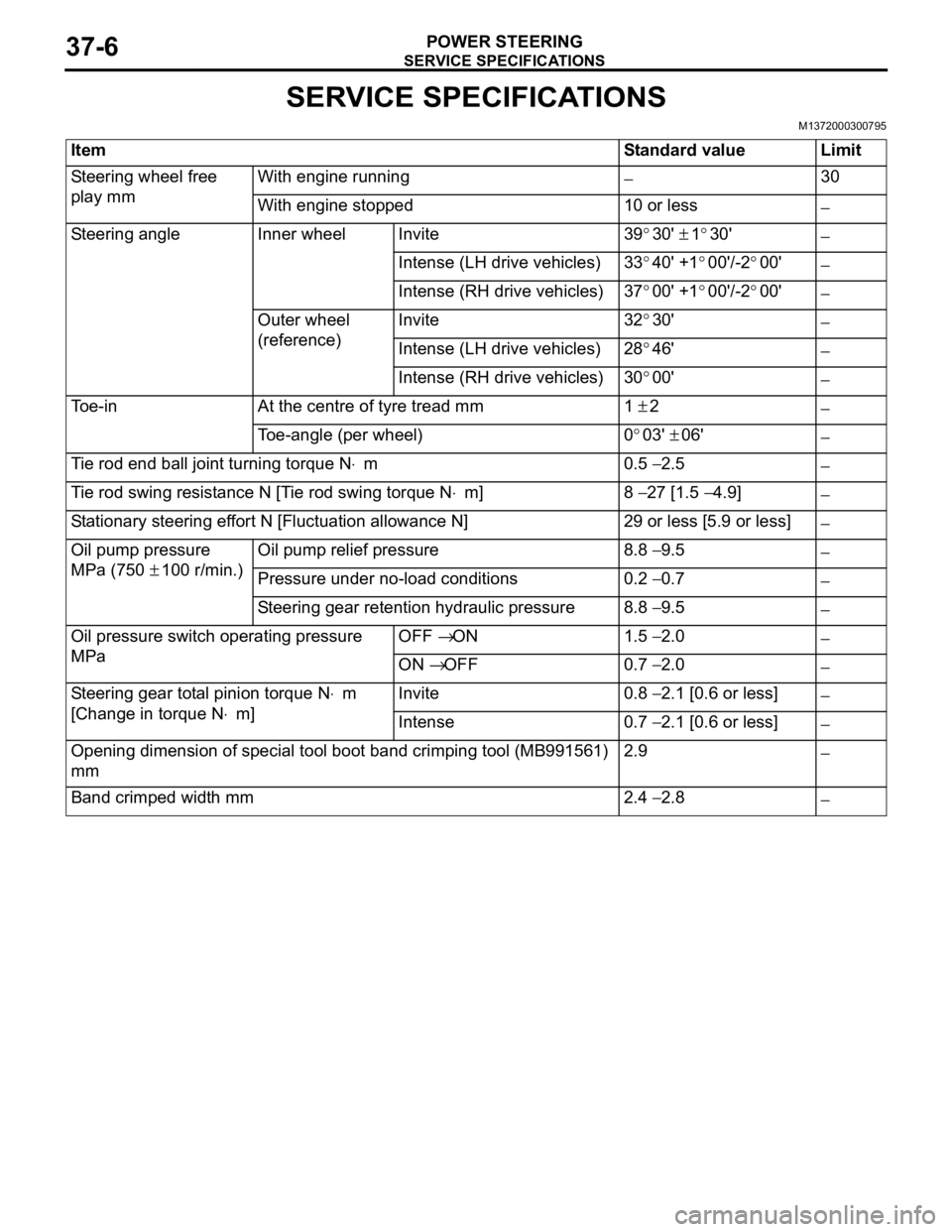

SERVICE SPECIFICATIONS

M1372000300795

ItemStandard valueLimit

Steering wheel free

play mmWith engine running−30

With engine stopped10 or less−

Steering angleInner wheelInvite39°30' ± 1°30'−

Intense (LH drive vehicles)33°40' +1°00'/-2°00'−

Intense (RH drive vehicles)37°00' +1°00'/-2°00'−

Outer wheel

(reference)Invite32°30'−

Intense (LH drive vehicles)28°46'−

Intense (RH drive vehicles)30°00'−

Toe-inAt the centre of tyre tread mm1 ± 2−

Toe-angle (per wheel)0°03' ± 06'−

Tie rod end ball joint turning torque N⋅m0.5 − 2.5−

Tie rod swing resistance N [Tie rod swing torque N⋅m]8 − 27 [1.5 − 4.9]−

Stationary steering effort N [Fluctuation allowance N]29 or less [5.9 or less]−

Oil pump pressure

MPa (750

± 100 r/min.)

Oil pump relief pressure8.8 − 9.5−

Pressure under no-load conditions0.2 − 0.7−

Steering gear retention hydraulic pressure8.8 − 9.5−

Oil pressure switch operating pressure

MPaOFF → ON1.5 − 2.0−

ON → OFF0.7 − 2.0−

Steering gear total pinion torque N⋅m

[Change in torque N

⋅m]

Invite0.8 − 2.1 [0.6 or less]−

Intense0.7 − 2.1 [0.6 or less]−

Opening dimension of special tool boot band crimping tool (MB991561)

mm2.9−

Band crimped width mm2.4 − 2.8−

Page 237 of 800

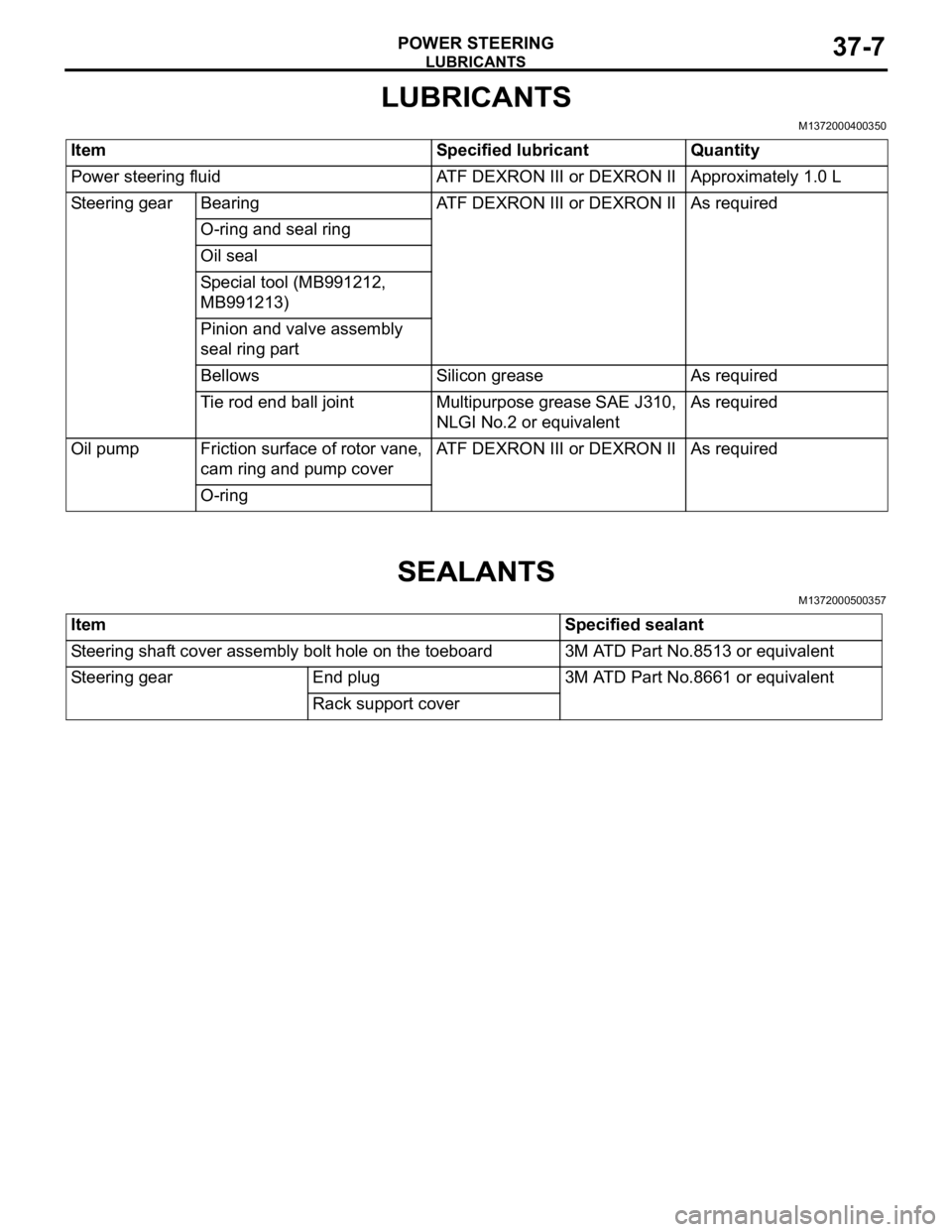

LUBRICANTS

POWER STEERING37-7

LUBRICANTS

M1372000400350

ItemSpecified lubricantQuantity

Power steering fluidATF DEXRON III or DEXRON IIApproximately 1.0 L

Steering gearBearingATF DEXRON III or DEXRON IIAs required

O-ring and seal ring

Oil seal

Special tool (MB991212,

MB991213)

Pinion and valve assembly

seal ring part

BellowsSilicon greaseAs required

Tie rod end ball jointMultipurpose grease SAE J310,

NLGI No.2 or equivalentAs required

Oil pumpFriction surface of rotor vane,

cam ring and pump coverATF DEXRON III or DEXRON IIAs required

O-ring

SEALANTS

M1372000500357

ItemSpecified sealant

Steering shaft cover assembly bolt hole on the toeboard3M ATD Part No.8513 or equivalent

Steering gearEnd plug3M ATD Part No.8661 or equivalent

Rack support cover

Page 238 of 800

SPECIAL TOOLS

POWER STEERING37-8

SPECIAL TOOLS

M1372000600666

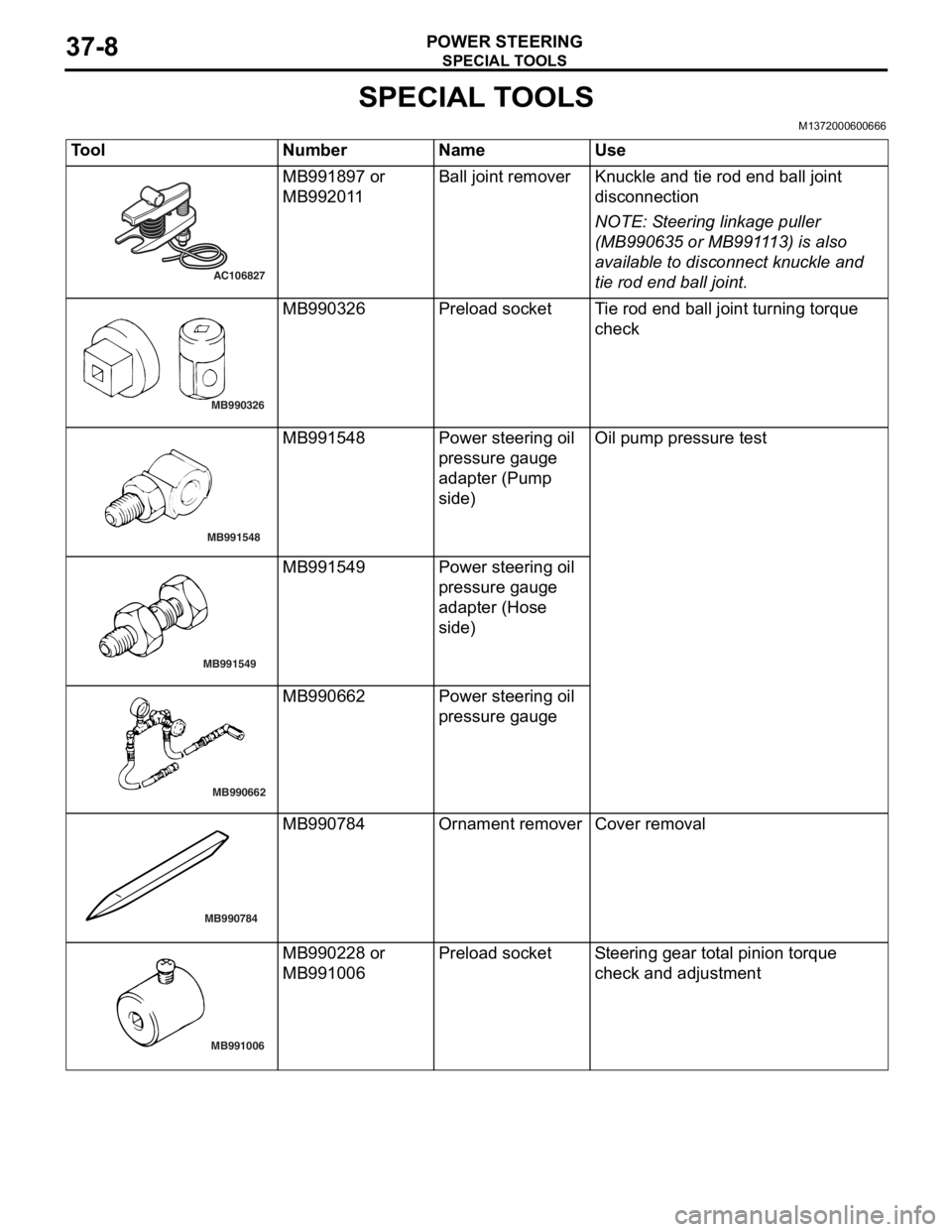

ToolNumberNameUse

AC106827

MB991897 or

MB9920

1 1Ball j o in t remo verKnuckle and tie rod e nd ball joint

discon

nection

NOTE: St eering linkage pu lle r

(MB990 635 o r MB991 1 13) is also

ava

ilab

l e to disconn ect knuckle and

tie ro

d end ball joint.

MB990326

MB9903 26Prel oad socketTi e rod end b a ll join t turning torq ue

che

c k

MB991548

MB9915 48Powe r stee ring oil

pressure g

auge

adapte

r (Pump

sid

e )Oil pump pre ssu re test

MB991549

MB991549Powe r stee ring oil

pressure g

auge

adapte

r (Hose

sid

e )

MB990662

MB9906 62Powe r stee ring oil

pressure g

auge

MB990784

MB990784Ornament removerCover removal

MB991006

MB9902 28 or

MB9910

06Prel oad socketSt e e ring gear to t a l pinion torque

che

ck and ad justmen t

Page 242 of 800

ON-VEHICLE SERVICE

POWER STEERING37-12

TIE ROD END BALL JOINT TURNING

TORQUE CHECK

M1372001500554

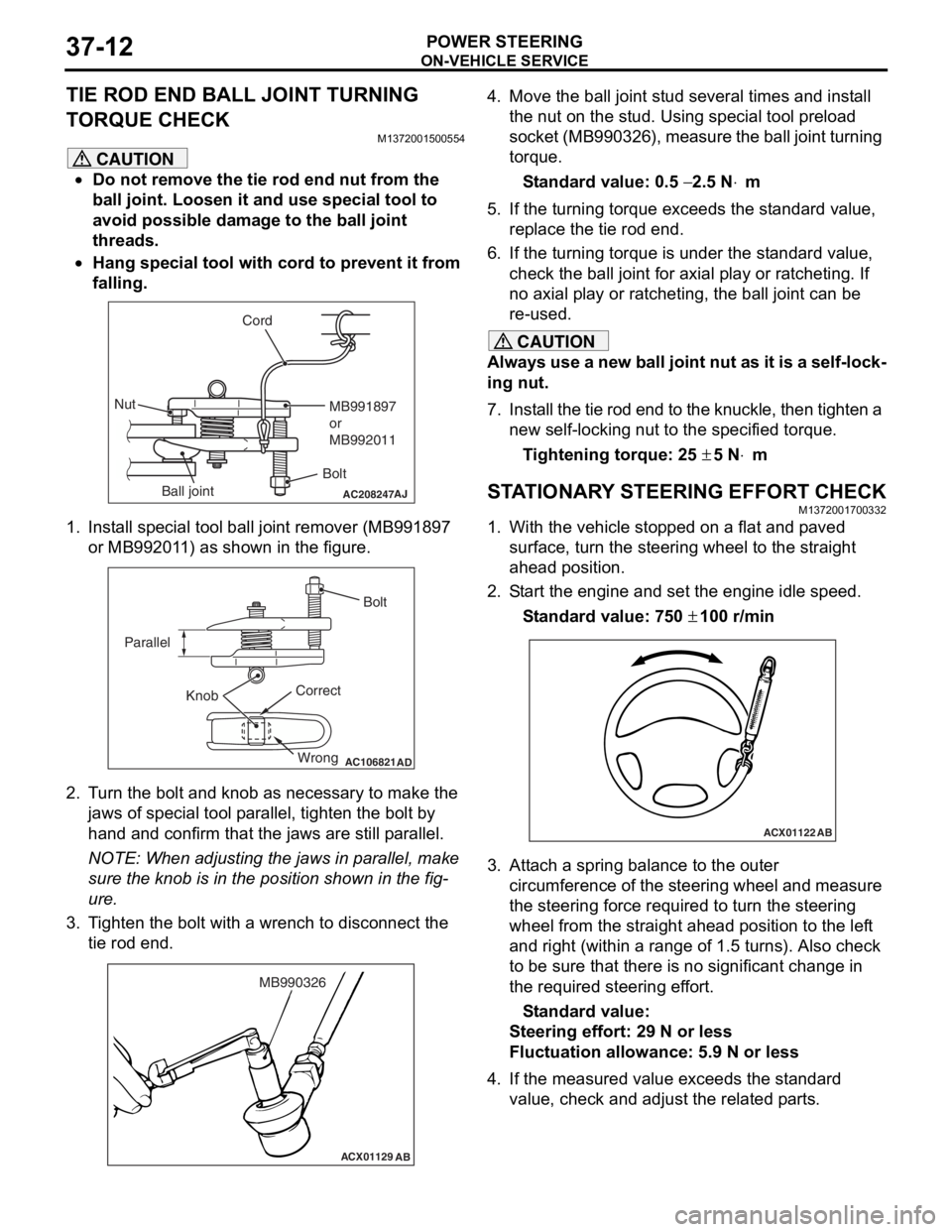

CAUTION

•Do not remove the tie rod end nut from the

ball joint. Loosen it and use special tool to

avoid possible damage to the ball joint

threads.

•

AC208247AJ

CordBoltMB991897

or

MB992011

Nut

Ball joint

Hang special tool with cord to prevent it from

falling.

1. Install special tool ball joint remover (MB991897 or MB992011) as shown in the figure.

AC106821

Knob

Parallel

Bolt

Correct Wrong

AD

2. Turn the bolt and knob as necessary to make the jaws of special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the fig

-

ure.

3. Tighten the bolt with a wrench to disconnect the tie rod end.

ACX01129 AB

MB990326

4. Move the ball joint stud several times and install

the nut on the stud. Using special tool preload

socket (MB990326), measure the ball joint turning

torque.

Standard value: 0.5 − 2.5 N⋅m

5. If the turning torque exceeds the standard value, replace the tie rod end.

6. If the turning torque is under the standard value, check the ball joint for axial play or ratcheting. If

no axial play or ratcheting, the ball joint can be

re-used.

CAUTION

Always use a new ball joint nut as it is a self-lock-

ing nut.

7. Install the tie rod end to the knuckle, then tighten a new self-locking nut to the specified torque.

Tightening torque: 25 ± 5 N⋅m

STATIONARY STEERING EFFORT CHECKM1372001700332

1. With the vehicle stopped on a flat and paved

surface, turn the steering wheel to the straight

ahead position.

2. Start the engine and set the engine idle speed.

Standard value: 750 ± 100 r/min

ACX01122 AB

3. Attach a spring balance to the outer

circumference of the steering wheel and measure

the steering force required to turn the steering

wheel from the straight ahead position to the left

and right (within a range of 1.5 turns). Also check

to be sure that there is no significant change in

the required steering effort.

Standard value:

Steering effort: 29 N or less

Fluctuation allowance: 5.9 N or less

4. If the measured value exceeds the standard value, check and adjust the related parts.

Page 245 of 800

ON-VEHICLE SERVICE

POWER STEERING37-15

6. Check whether or not the hydraulic pressure is the standard value when no-load conditions are

created by fully opening the shut-off valve of the

pressure gauge.

Standard value: 0.2 − 0.7 MPa

7. If it is not within the standard value, the probable cause is a malfunction of the oil line or steering

gear, so check these parts and repair as

necessary.

8. Turn the steering wheel all the way to the left or right; then check whether or not the retention

hydraulic pressure is the standard value.

Standard value: 8.8 − 9.5 MPa

9. If not the standard value, overhaul the steering gear. Remeasure fluid pressure.

10. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

11. Bleed the system (Refer to P.37-14).

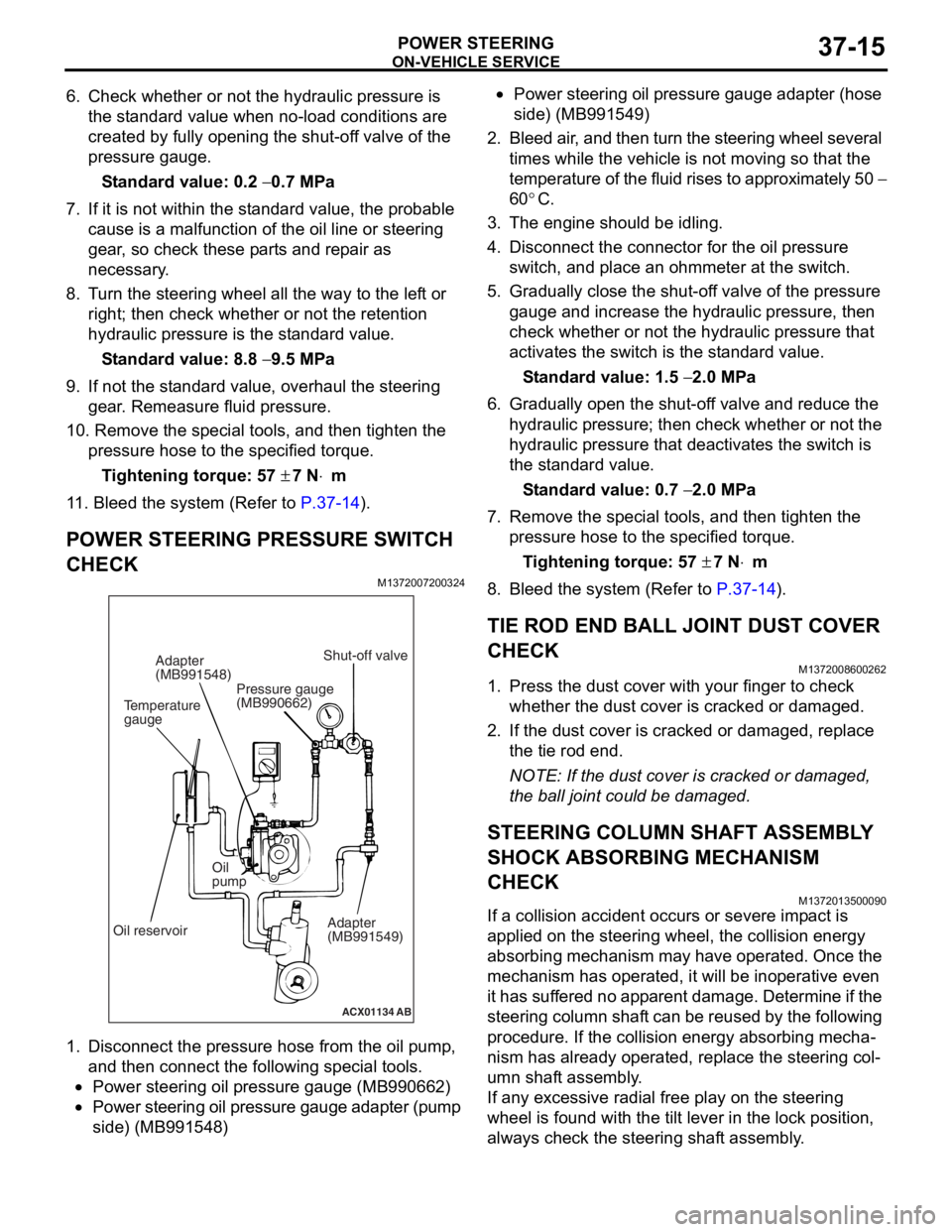

POWER STEERING PRESSURE SWITCH

CHECK

M1372007200324

ACX01134 AB

Temperature

gaugeAdapter

(MB991548)

Oil reservoir Oil

pump

Adapter

(MB991549)

Shut-off valve

Pressure gauge

(MB990662)

1. Disco nnect the pre s sure hose from the oil pump ,

an d then con nect the followin g sp ecial too l s.

•Power steering oil pressure gauge (MB990 662)

•Power steering oil pressure gauge ad apter (pump

side) (MB99154

8)

•Power steering oil pressure gaug e a dapte r (ho s e

side) (MB99154

9)

2. Bleed air , and the n turn t he steering wheel several

times while the vehicle is not moving so that the

tempe r atu r e o f th e flu i d rise s to approximately 50

−

60

°C.

3. Th e engine should be idling.

4.Disco nnect the conne ctor fo r the o il pr essure

switch , and p l ace an o h mmeter a t the switch .

5.Gradua lly close the shut-of f valve of the pressure

g auge a nd in crease the hyd r aulic pre ssu re, the n

check wheth e r or no t the h y drau lic pressure that

a c tivates the switch is the st a ndard valu e.

St andard va lue: 1.5 − 2.0 MPa

6.Gradua lly open the shut-of f va lve and re duce the

h y drau lic p r essure; then check whethe r o r n o t the

h y drau lic pressure that de activate s the switch is

th e st and ard va lue.

St andard va lue: 0.7 − 2.0 MPa

7.Remove the special tools, and then tighten the

p r essure hose to the specified torque .

Ti ghte n ing torque: 57 ± 7 N⋅m

8.Bleed the system (Refer to P.37-14).

TIE ROD END BALL JOINT DUST COVER

CHECK

M13720086 0026 2

1.Press th e dust co ver wit h you r fing er to check

whet her the dust cover is cra cke d or da mage d.

2.If the du st cover is cracked o r damaged, repla c e

th e tie rod end .

NOTE: If the dust cover is cra cke d or da mag ed,

th

e ball jo int could be da mage d.

STEERING COLUMN SHAFT ASSEMBL Y

SHOCK ABSORBING MECHANISM

CHECK

M13720135 0009 0

If a collision accid ent occu rs or seve re imp a ct is

applied on

the steering w heel, the collision energy

abso

r bing mechanism ma y h a ve opera t ed. Once the

mechanism

has o perate d , it will b e ino perative e v en

it has

suf f er ed no app a r en t d a mage . De termin e if the

steering colu

mn shaf t can b e reused b y th e following

proce

dure. If the collision en ergy a b sor b ing mecha

-

nism has already operated, rep l ace the steering col-

umn shaft assembly .

If any excessive radial fre e pla y on the steering

wh

eel is fo und with the tilt lever in the lock po sit i on,

always ch

eck the steering shaf t assembly .

Page 255 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-25

NOTE: When measuring, remove the bellows from

the rack housing. Measure the pinion torque through

the whole stroke of the rack.

If the measured value is not within the standard

range, first adjust the rack support cover, and then

check the total pinion torque again.

If the total pinion torque cannot be adjusted to within

the standard range by adjusting the rack support

cover, check the rack support cover, rack support

spring, rack support and replace any parts if neces

-

sary.

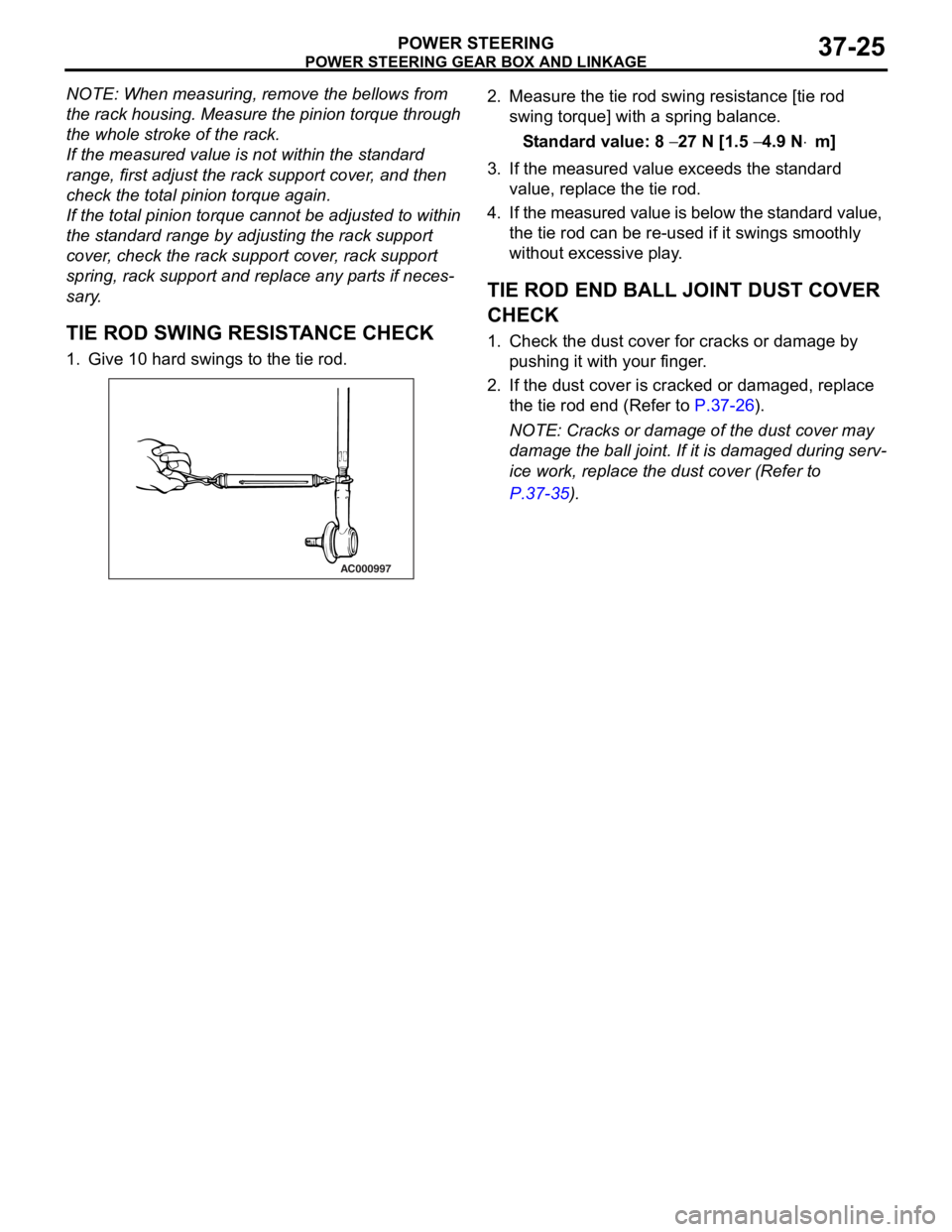

TIE ROD SWING RESISTANCE CHECK

1. Give 10 hard swings to the tie rod.

AC000997

2. Measure the tie ro d swin g resist ance [tie rod

swing to rque] with a spring bala n ce.

St andard va lue: 8 − 27 N [1.5 − 4.9 N⋅m]

3.If the measu r ed value exceeds the st a ndard

value , replace the tie rod.

4. If the measured value is below the st a ndard valu e,

th e tie rod can be re-use d if it swings smo o thly

wit hout e xce ssive play .

TIE ROD END BALL JOINT DUST COVER

CHECK

1.Check t he dust co ver f o r cracks or da mage by

p u shing it with your finger .

2.If the du st cover is cracked o r damaged, repla c e

th e tie rod end (Refer to

P.37-26).

NOTE: Cracks or dama ge of t he dust co ver may

d

a

mag

e the ball joint. If it is da mag ed du ring serv

-

ice work, replace the du st cove r (Re f er to

P.37-35).

Page 265 of 800

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-35

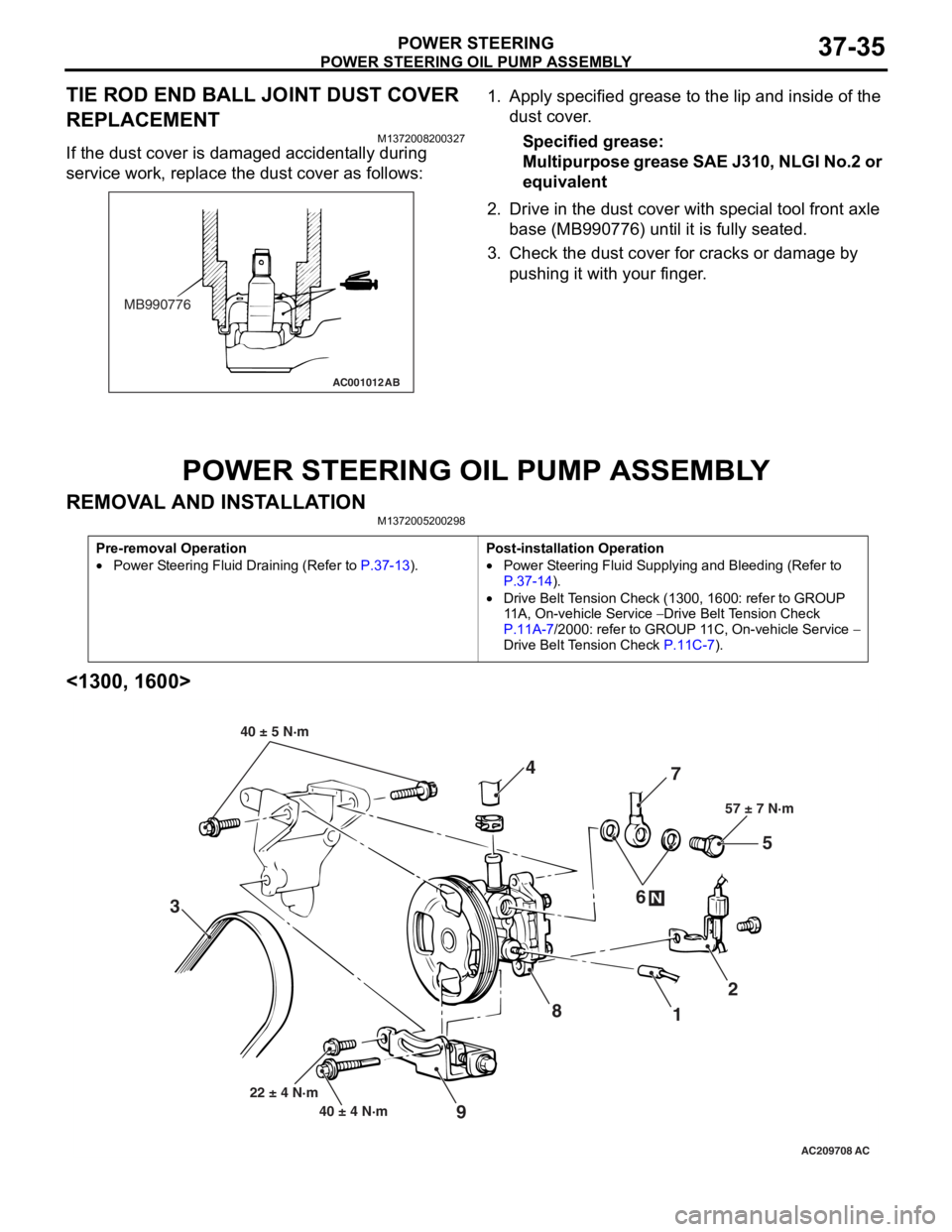

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT

M1372008200327

If the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

AC001012AB

MB990776

1.App l y specified grea se to the lip an d inside of the

d u st c o ve r .

Specified grease:

Mu l t i p u r po se g r ea se SAE J3 10 , NL GI No .2 or

equival

ent

2.Drive in the d u st cover with special tool f r ont axle

b a se (MB9907 76) unt il it is fully seated .

3.Check t he dust co ver f o r cracks or da mage by

p u shing it with your finger .

POWER STEERING OIL PUMP ASSEMBL Y

REMOVA L AND INST ALLA TIONM13720052 0029 8

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13).

Post-installation Operation

•Power Steering Fluid Supplying and Bleeding (Refer to

P.37-14).

•Drive Belt Tension Check (1300, 1600: refer to GROUP

11A, On-vehicle Service

− Drive Belt Tension Check

P.11A-7/2000: refer to GROUP 11C, On-vehicle Service − Drive Belt Tension Check P.11C-7).

<1300, 1600>

AC209708

87

1 2

3 4

5

6

57 ± 7 N·m

40 ± 4 N·m

22 ± 4 N·m

N

9

40 ± 5 N·m

AC