Reverse sensor MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 95 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-33

SPARK PLUG CHECK AND CLEANING

<4G6>

M1163004300353

CAUTION

When pulling off the spark plug cable from the

plug always hold the cable cap, not the cable.

1. Remove the spark plug cables.

2. Remove the spark plugs.

CAUTION

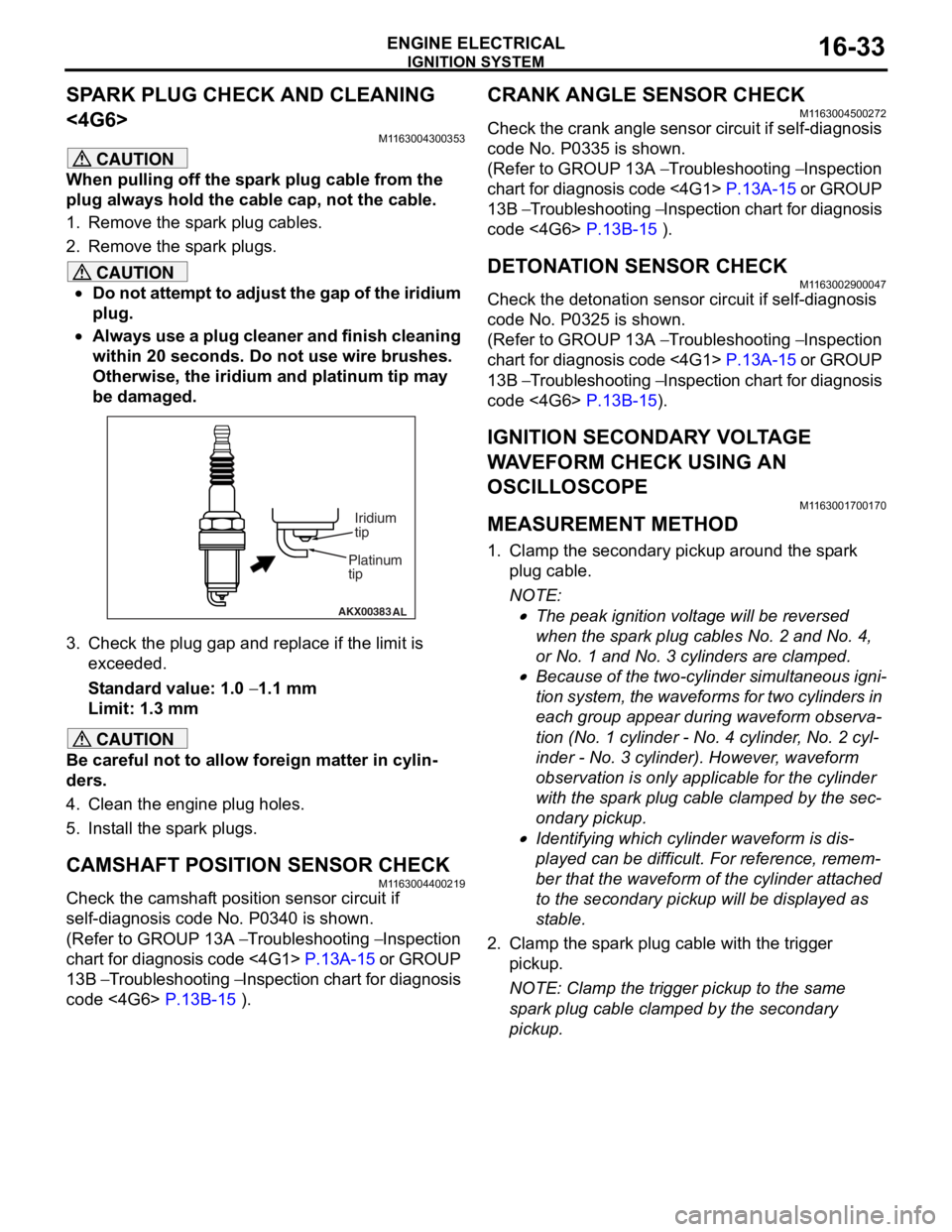

•Do not attempt to adjust the gap of the iridium

plug.

•

AKX00383 AL

Platinum

tipIridium

tip

Always use a plug cleaner and finish cleaning

within 20 seconds. Do not use wire brushes.

Otherwise, the iridium and platinum tip may

be damaged.

3. Check the plug gap and re

place if the limit is

exceeded.

Standard value: 1.0 − 1.1 mm

Limit: 1.3 mm

CAUTION

Be careful not to allow foreign matter in cylin-

ders.

4. Clean the engine plug holes.

5. Install the spark plugs.

CAMSHAFT POSITION SENSOR CHECK

M1163004400219

Check the camshaft position sensor circuit if

self-diagnosis code No. P0340 is shown.

(Refer to GROUP 13A − Troubleshooting − Inspection

chart for diagnosis code <4G1>

P.13A-15 or GROUP

13B − Troubleshooting − Inspection chart for diagnosis

code <4G6>

P.13B-15 ).

CRANK ANGLE SENSOR CHECK

M1163004500272

Check the crank angle sensor circuit if self-diagnosis

code No. P0335 is shown.

(Refer to GROUP 13A − Troubleshooting − Inspection

chart for diagnosis code <4G1>

P.13A-15 or GROUP

13B − Troubleshooting − Inspection chart for diagnosis

code <4G6>

P.13B-15 ).

DETONATION SENSOR CHECKM1163002900047

Check the detonation sensor circuit if self-diagnosis

code No. P0325 is shown.

(Refer to GROUP 13A − Troubleshooting − Inspection

chart for diagnosis code <4G1>

P.13A-15 or GROUP

13B − Troubleshooting − Inspection chart for diagnosis

code <4G6>

P.13B-15).

IGNITION SECONDARY VOLTAGE

WAVEFORM CHECK USING AN

OSCILLOSCOPE

M1163001700170

MEASUREMENT METHOD

1. Clamp the secondary pickup around the spark

plug cable.

NOTE: .

•The peak ignition voltage will be reversed

when the spark plug cables No. 2 and No. 4,

or No. 1 and No. 3 cylinders are clamped.

•Because of the two-cylinder simultaneous igni-

tion system, the waveforms for two cylinders in

each group appear during waveform observa

-

tion (No. 1 cylinder - No. 4 cylinder, No. 2 cyl-

inder - No. 3 cylinder). However, waveform

observation is only applicable for the cylinder

with the spark plug cable clamped by the sec

-

ondary pickup.

•Identifying which cylinder waveform is dis-

played can be difficult. For reference, remem-

ber that the waveform of the cylinder attached

to the secondary pickup will be displayed as

stable.

2. Clamp the spark plug cable with the trigger pickup.

NOTE: Clamp the trigger pickup to the same

spark plug cable clamped by the secondary

pickup.

Page 560 of 800

INVECS-II 4A/T

CIRCUIT DIAGRAMS90-96

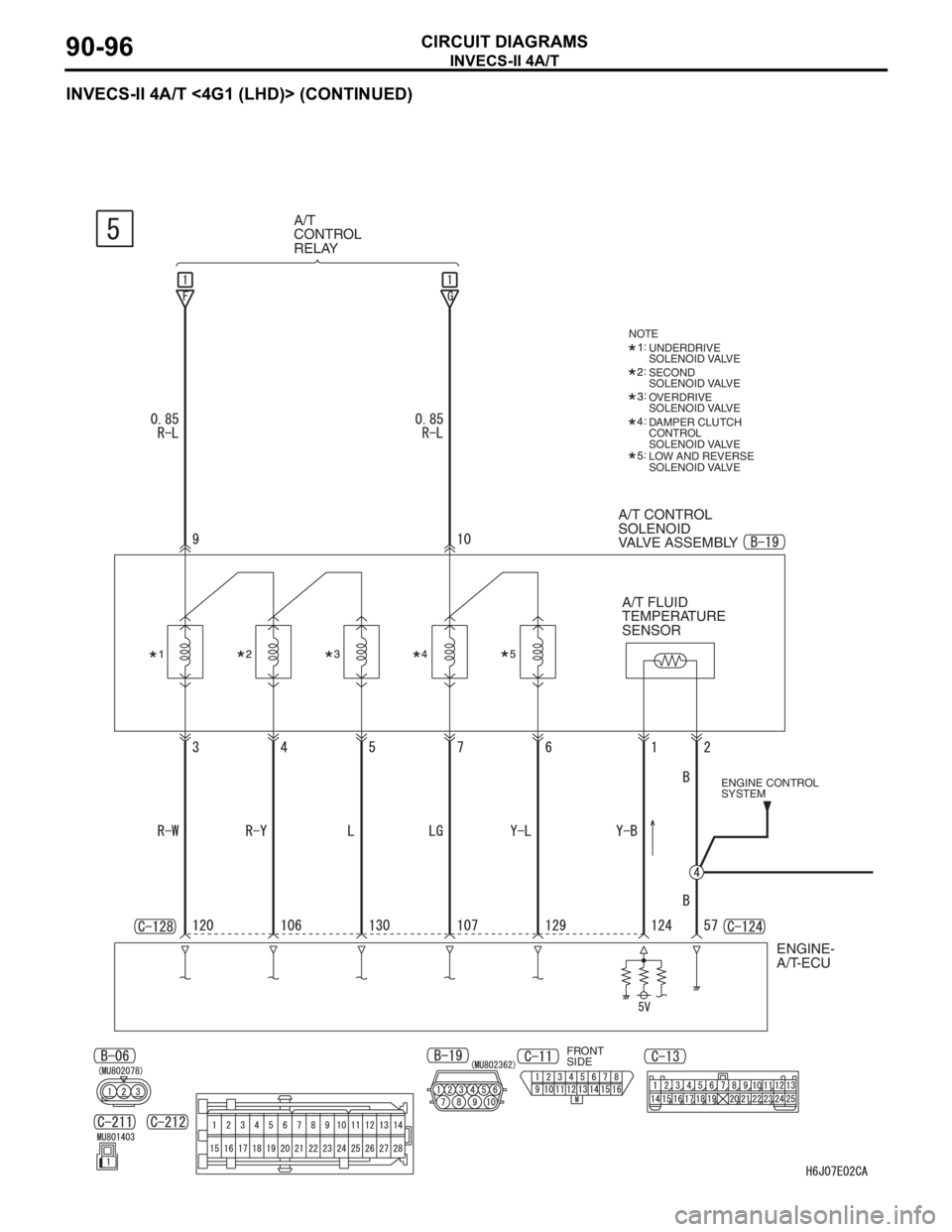

INVECS-II 4A/T <4G1 (LHD)> (CONTINUED)

A/T

CONTROL

RELAY

A/T CONTROL

SOLENOID

VALVE ASSEMBLY

ENGINE CONTROL

SYSTEM

ENGINE-

A/T-ECU

NOTE

:

:

:

:

: UNDERDRIVE

SOLENOID VALVE

SECOND

SOLENOID VALVE

DAMPER CLUTCH

CONTROL

SOLENOID VALVE OVERDRIVE

SOLENOID VALVE

LOW AND REVERSE

SOLENOID VALVE

A/T FLUID

TEMPERATURE

SENSOR

FRONT

SIDE

Page 566 of 800

INVECS-II 4A/T

CIRCUIT DIAGRAMS90-102

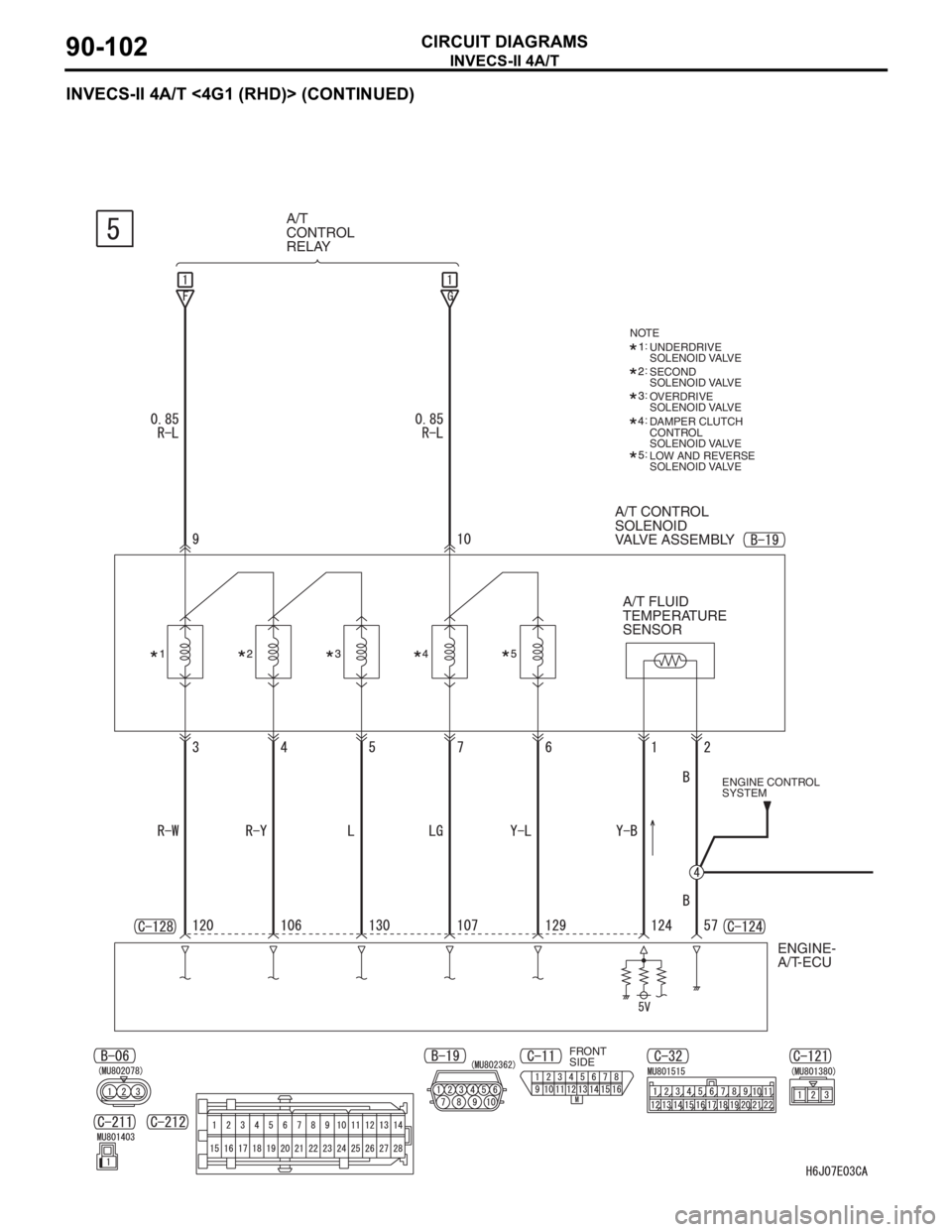

INVECS-II 4A/T <4G1 (RHD)> (CONTINUED)

A/T CONTROL

SOLENOID

VALVE ASSEMBLY

NOTE

:

:

:

:

: UNDERDRIVE

SOLENOID VALVE

SECOND

SOLENOID VALVE

DAMPER CLUTCH

CONTROL

SOLENOID VALVE OVERDRIVE

SOLENOID VALVE

LOW AND REVERSE

SOLENOID VALVE

A/T

CONTROL

RELAY

ENGINE CONTROL

SYSTEM

ENGINE-

A/T-ECU

FRONT

SIDE

A/T FLUID

TEMPERATURE

SENSOR

Page 572 of 800

INVECS-II 4A/T

CIRCUIT DIAGRAMS90-108

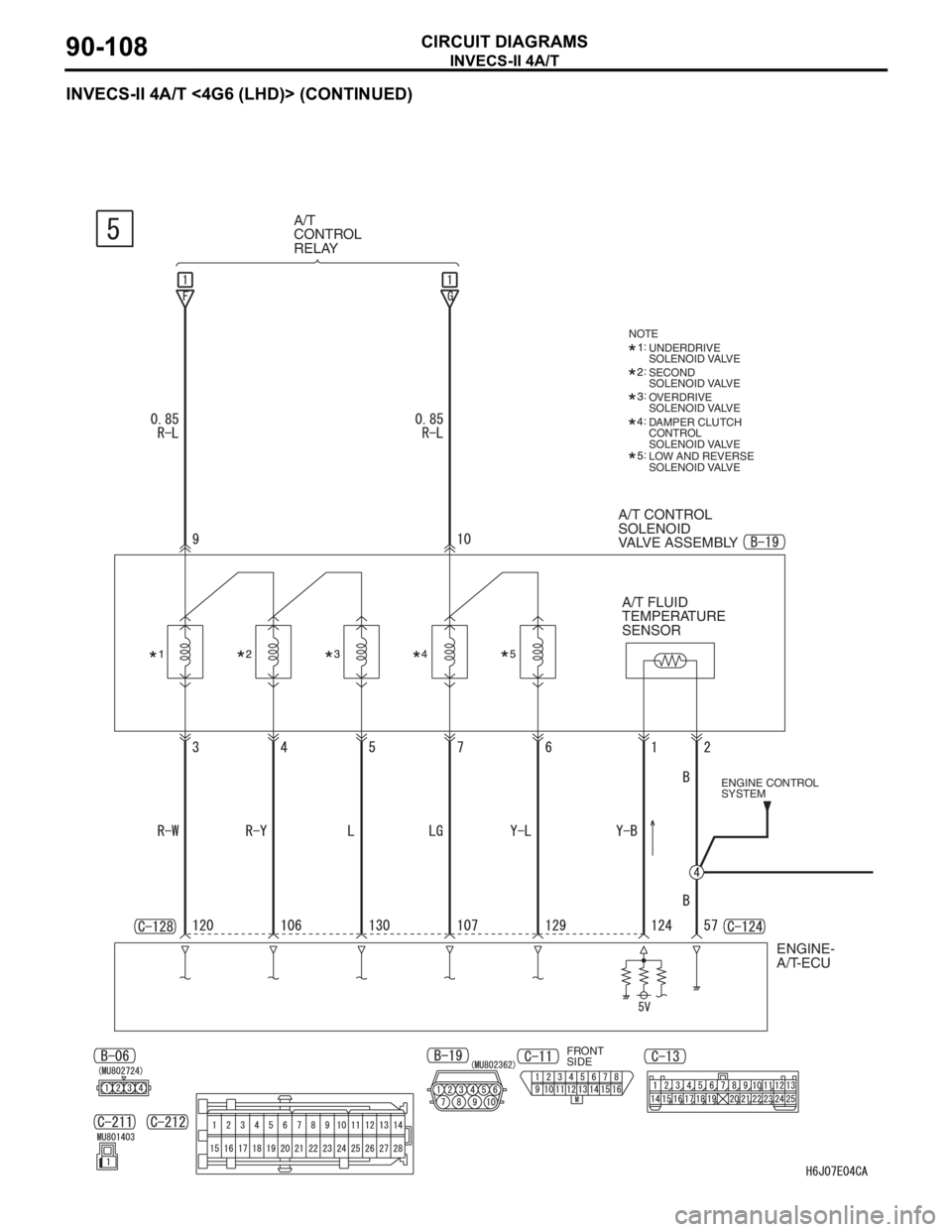

INVECS-II 4A/T <4G6 (LHD)> (CONTINUED)

A/T

CONTROL

RELAY

A/T CONTROL

SOLENOID

VALVE ASSEMBLY

ENGINE CONTROL

SYSTEM

ENGINE-

A/T-ECU

NOTE

:

:

:

:

: UNDERDRIVE

SOLENOID VALVE

SECOND

SOLENOID VALVE

DAMPER CLUTCH

CONTROL

SOLENOID VALVE OVERDRIVE

SOLENOID VALVE

LOW AND REVERSE

SOLENOID VALVE

A/T FLUID

TEMPERATURE

SENSOR

FRONT

SIDE