component MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 8 of 800

GENERAL INFORMATION

ENGINE LUBRICATION12-2

GENERAL INFORMATION

M1121000100357

The lubrication method is a fully force-fed, full-flow fil-

tration type. The engine oil pump is a trochoid type

which is driven by the crankshaft <4G1>.The engine

oil pump is a gear type which is driven by the crank

-

shaft via the balancer timing belt <4G6>.

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil will

result in the removal of natural fats from the skin,

leading to dryness, irritation and dermatitis. In addi

-

tion, used engine oil contains potentially harmful con-

taminants which may cause skin cancer. Adequate

means of skin protection and washing facilities must

be provided.

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example by

using enclosed systems for handling used engine oil

and by degreasing components, where practicable,

before handling them. Other precautions:

•Avoid prolonged and repeated contact with oils,

particularly used engine oils.

•Wear protective clothing, including impervious

gloves where practicable.

•Avoid contaminating clothes, particularly under-

pants, with oil.

•Do not put oily rags in pockets, the use of overalls

without pockets will avoid this.

•Do not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from per

-

sonal clothing.

•Where there is a risk of eye contact, eye protec-

tion should be worn, for example, chemical gog-

gles or face shields; in addition an eye wash

facility should be provided.

•Obtain first aid treatment immediately for open

cuts and wounds.

•Wash regularly with soap and water to ensure all

oil is removed, especially before meals (skin

cleansers and nail brushes will help). After clean

-

ing, the application of preparations containing

lanolin to replace the natur al skin oils is advised.

•Do not use petrol, kerosine, diesel fuel, gas oil,

thinners or solvents for cleaning skin.

•Use barrier creams, applying them before each

work period, to help the removal of oil from the

skin after work.

•If skin disorders develop, obtain medical advice

without delay.

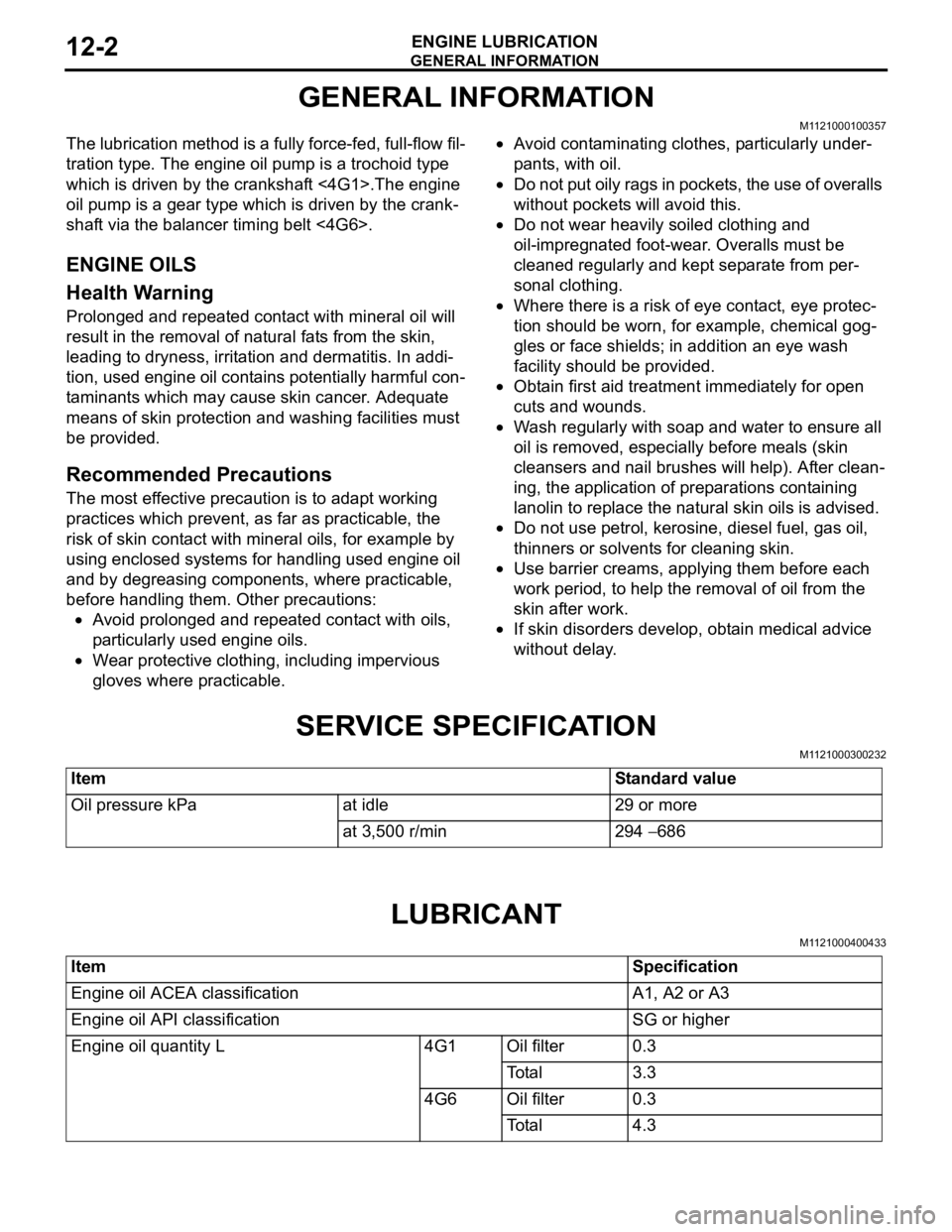

SERVICE SPECIFICATION

M1121000300232

ItemStandard value

Oil pressure kPaat idle29 or more

at 3,500 r/min294 − 686

LUBRICANT

M1121000400433

ItemSpecification

Engine oil ACEA classificationA1, A2 or A3

Engine oil API classificationSG or higher

Engine oil quantity L4G1Oil filter0.3

To t a l3.3

4G6Oil filter0.3

To t a l4.3

Page 21 of 800

TROUBLESHOOTING

ENGINE COOLING14-7

•The engine-ECU

controls the cooling fan motor drive control

unit to activate the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan motor <4G6>.

TECHNICAL DESCRIPTION

•The cause could be a malfunction of the cooling

fan motor drive control unit power supply or earth

circuit.

•If the communication line wiring harness between

the cooling fan motor drive control unit and the

engine-ECU

short-circuited to earth, the cooling fan motor

(L.H.) and the cooling fan motor (R.H.) <4G1

(Vehicles with A/C)> or the A/C condenser fan

motor <4G6> will not rotate.

•The cause could also be a malfunction of the

cooling fan motor (L.H.).

•The cause could also be a malfunction of imput

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU

•The cause could also be a malfunction of the

cooling fan motor drive control unit or the

engine-ECU

TROUBLESHOOTING HINTS

•Malfunction of fusible link (2)

•Malfunction of fan control relay

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

•Malfunction of engine-ECU

engine-A/T-ECU

•Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

Refer to P.14-24.

Q: Is the cooling fan motor (L.H.) in good condition?

YES : Go to Step 2 .

NO : Replace the cooling fan motor (L.H.) (Refer

to

P.14-33) <4G1> (Refer to P.14-35)

<4G6>. Then go to Step 24 .

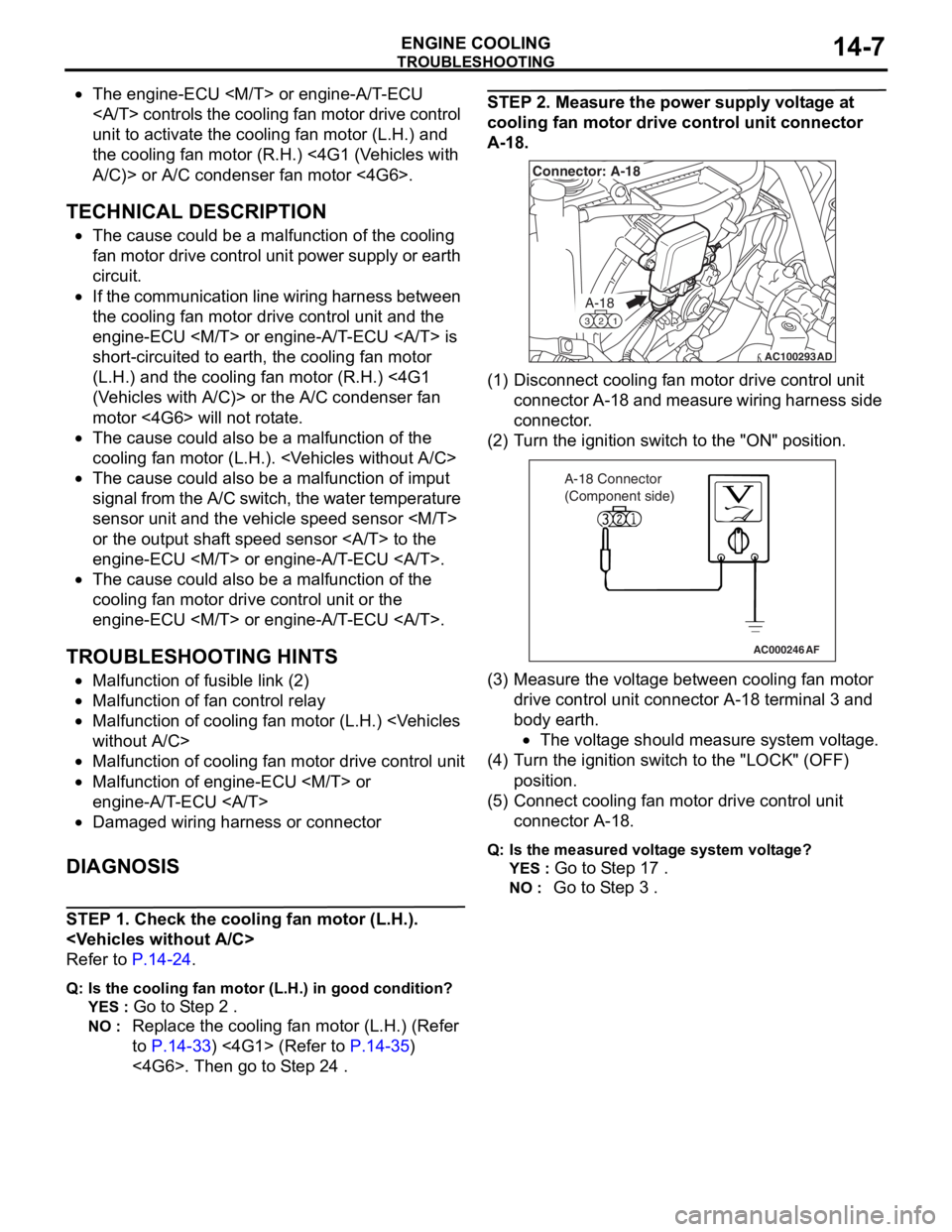

STEP 2. Measure the power supply voltage at

cooling fan motor drive control unit connector

A-18.

AC100293

A-18

321

Connector: A-18

AD

(1)D isconn ect cooling f an motor drive contro l unit

conne ctor A-18 a nd measure wirin g har ness side

connector .

(2)T urn t he ig nition switch t o the "ON" positio n.

AC000246AF

A-18 Connector

(Component side)

(3)M easu r e the volt age between cooling fan motor

drive control unit con nect o r A-18 te rmin al 3 a nd

bod y ea rth.

•The voltage shou ld measu r e syste m volt age.

(4)T urn t he ig nition switch t o the "L OCK" (OF F )

position.

(5)C onne ct cooling fa n mot o r drive control unit

connector A-18.

Q:Is t h e mea s ure d volt a g e sy ste m v o lt ag e?

YES : Go to S t ep 1 7 .

NO : Go to S t ep 3 .

Page 105 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-43

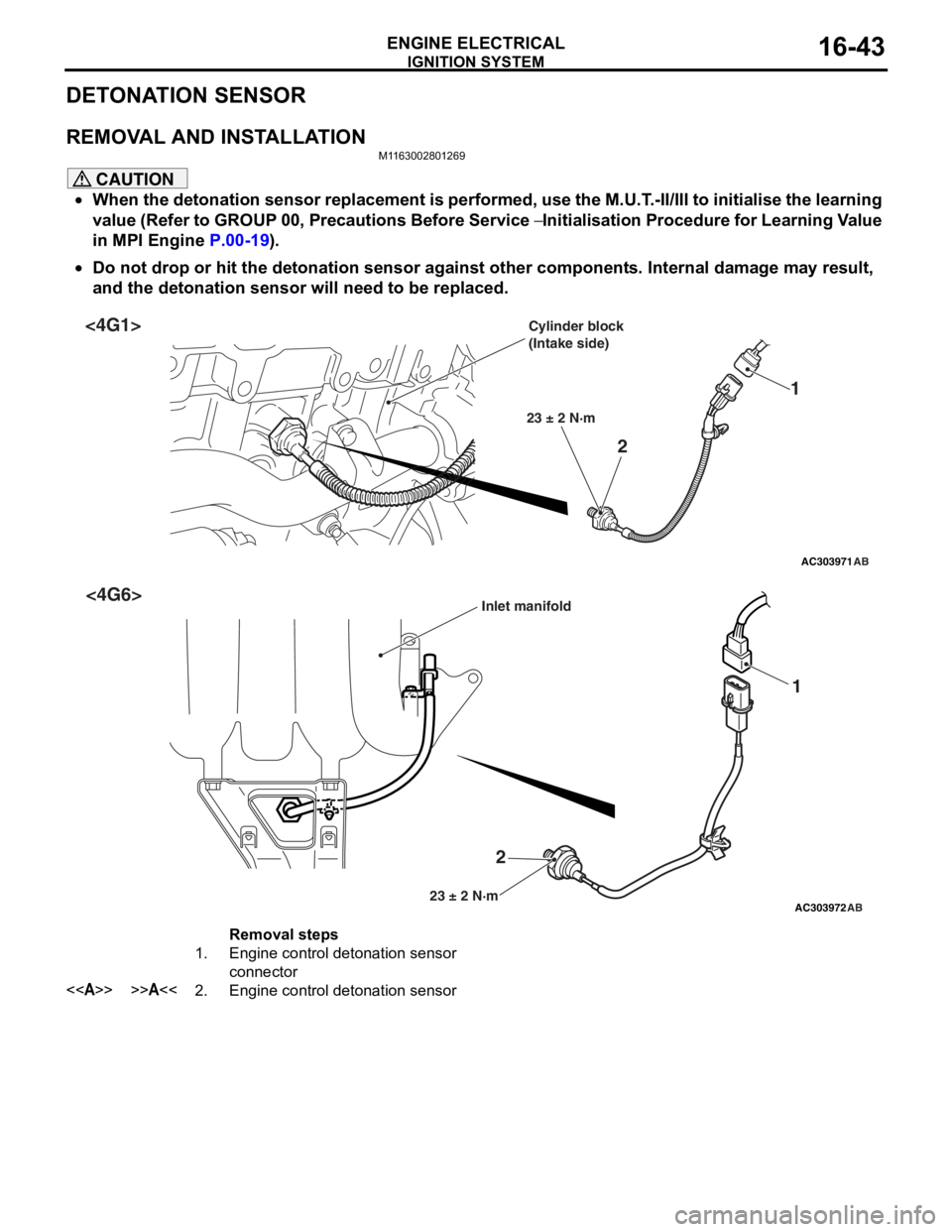

DETONATION SENSOR

REMOVAL AND INSTALLATION

M1163002801269

CAUTION

•When the detonation sensor replacement is performed, use the M.U.T.-II/III to initialise the learning

value (Refer to GROUP 00, Precautions Before Service

− Initialisation Procedure for Learning Value

in MPI Engine

P.00-19).

•

AC303971

2 1

23 ± 2 N·m

AB

<4G1>Cylinder block

(Intake side)

AC303972

2 1

23 ± 2 N·mAB

<4G6>Inlet manifold

Removal steps

1.Engine control detonation sensor

connector

<>>>A<<2.Engine control detonation sensor

Do not drop or hit the detonation sensor against other components. Internal damage may result,

and the detonation sensor will need to be replaced.

Page 107 of 800

17-1

GROUP 17

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL . . . . . . . . . .17-2

GENERAL INFORMATION . . . . . .17-2

SERVICE SPECIFICATIONS. . . . .17-2

ON-VEHICLE SERVICE. . . . . . . . .17-2

ACCEL CABLE CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 17-2

ACCELERATOR CABLE AND

PEDAL . . . . . . . . . . . . . . . . . . . . . .17-3

REMOVAL AND INSTALLATION . . . . . 17-3

EMISSION CONTROL MPI . . . .17-4

GENERAL INFORMATION . . . . . .17-4

EMISSION CONTROL DEVICE

REFERENCE TABLE . . . . . . . . . .17-4

SERVICE SPECIFICATION(S) . . .17-5

VACUUM HOSE. . . . . . . . . . . . . . .17-5

VACUUM HOSE PIPING DIAGRAM . . . 17-5

VACUUM CIRCUIT DIAGRAM . . . . . . . 17-7

VACUUM HOSE CHECK. . . . . . . . . . . . 17-7

VACUUM HOSE INSTALLATION . . . . . 17-8

CRANKCASE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . .17-8

GENERAL INFORMATION (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-8

COMPONENT LOCATI ON (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-9

POSITIVE CRANKCASE VENTILATION SYSTEM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 17-9

POSITIVE CRANKCASE VENTILATION (PCV)

VALVE CHECK . . . . . . . . . . . . . . . . . . . 17-9

EVAPORATIVE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . .17-9

GENERAL INFORMATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-9

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-10

PURGE CONTROL SYSTEM CHECK . . 17-10

PURGE PORT VACUUM CHECK . . . . . 17-11

PURGE CONTROL SOLENOID VALVE

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 17-11

FUEL VAPOUR CANISTER REMOVAL

AND INSTALLATION . . . . . . . . . . . . . . . 17-12

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM . . . . . . . . . . . . . . .17-12

GENERAL INFORMATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-12

COMPONENT LOCATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-14

EGR SYSTEM CHECK . . . . . . . . . . . . . 17-15

EGR VALVE CHECK . . . . . . . . . . . . . . . 17-15

EGR PORT VACUUM CHECK <4G1>. . 17-16

EGR PORT VACUUM CHECK <4G6>. . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G1> . . . . . . . . . . . . . . . . . . . . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G6> . . . . . . . . . . . . . . . . . . . . 17-17

EXHAUST GAS RECIRCULATION (EGR)

VALVE REMOVAL AND I

NSTALLATION . . . . . . . . . . . . . . . . . . . . 17-18

CATALYTIC CONVERTER . . . . . .17-19

REMOVAL AND INSTALLATION

<4G1, 4G6-M/T> . . . . . . . . . . . . . . . . . . 17-19

REMOVAL AND INSTALLATION

<4G6-A/T> . . . . . . . . . . . . . . . . . . . . . . . 17-19

Page 110 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-4

INSTALLATION SERVICE POINT

>>A<< ACCEL PEDAL PAD INSTALLA-

TION

CAUTION

To prevent damages to the accelerator pedal pad,

warm the thumb area of the accelerator pedal

pad with a dryer, etc. prior to assembling it.

NOTE: If it is difficult to assemble, apply soapy water

to the thumb area to enhance the assembling proc

-

ess.

EMISSION CONTROL

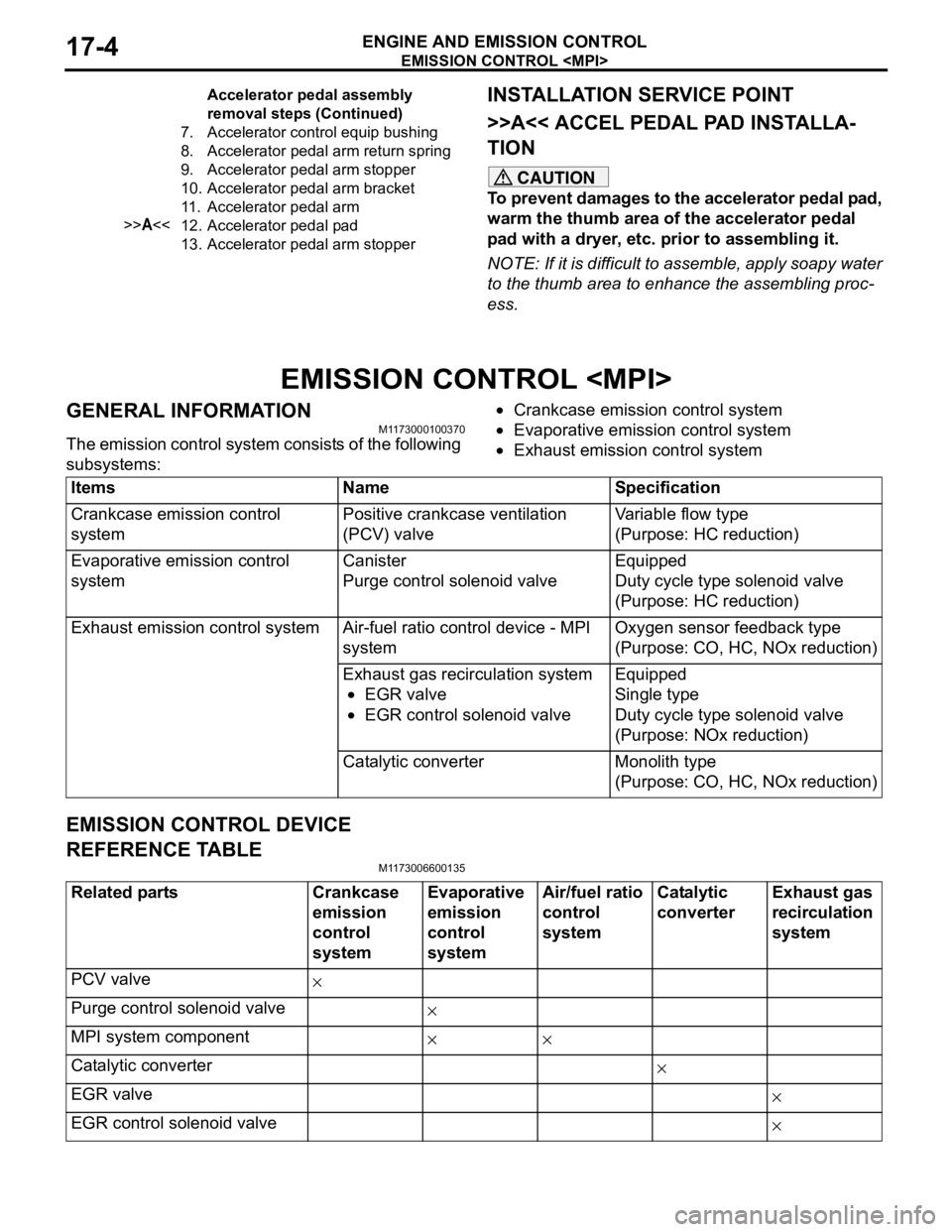

GENERAL INFORMATION

M1173000100370

The emission control system consists of the following

subsystems:

•Crankcase emission control system

•Evaporative emission control system

•

ItemsNameSpecification

Crankcase emission control

systemPositive crankcase ventilation

(PCV) valveVariable flow type

(Purpose: HC reduction)

Evaporative emission control

systemCanister

Purge control solenoid valve

Equipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Exhaust emission control systemAir-fuel ratio control device - MPI

systemOxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

•EGR valve

•EGR control solenoid valve

Equipped

Single type

Duty cycle type solenoid valve

(Purpose: NOx reduction)

Catalytic converterMonolith type

(Purpose: CO, HC, NOx reduction)

Exhaust emission control system

EMISSION CONTROL DEVICE

REFERENCE TABLE

M1173006600135

Related partsCrankcase

emission

control

systemEvaporative

emission

control

systemAir/fuel ratio

control

systemCatalytic

converterExhaust gas

recirculation

system

PCV valve×

Purge control solenoid valve×

MPI system component××

Catalytic converter×

EGR valve×

EGR control solenoid valve×

7.Accelerator control equip bushing

8.Accelerator pedal arm return spring

9.Accelerator pedal arm stopper

10.Accelerator pedal arm bracket

11 .Accelerator pedal arm

>>A<<12.Accelerator pedal pad

13.Accelerator pedal arm stopper

Accelerator pedal assembly

removal steps (Continued)

Page 115 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-9

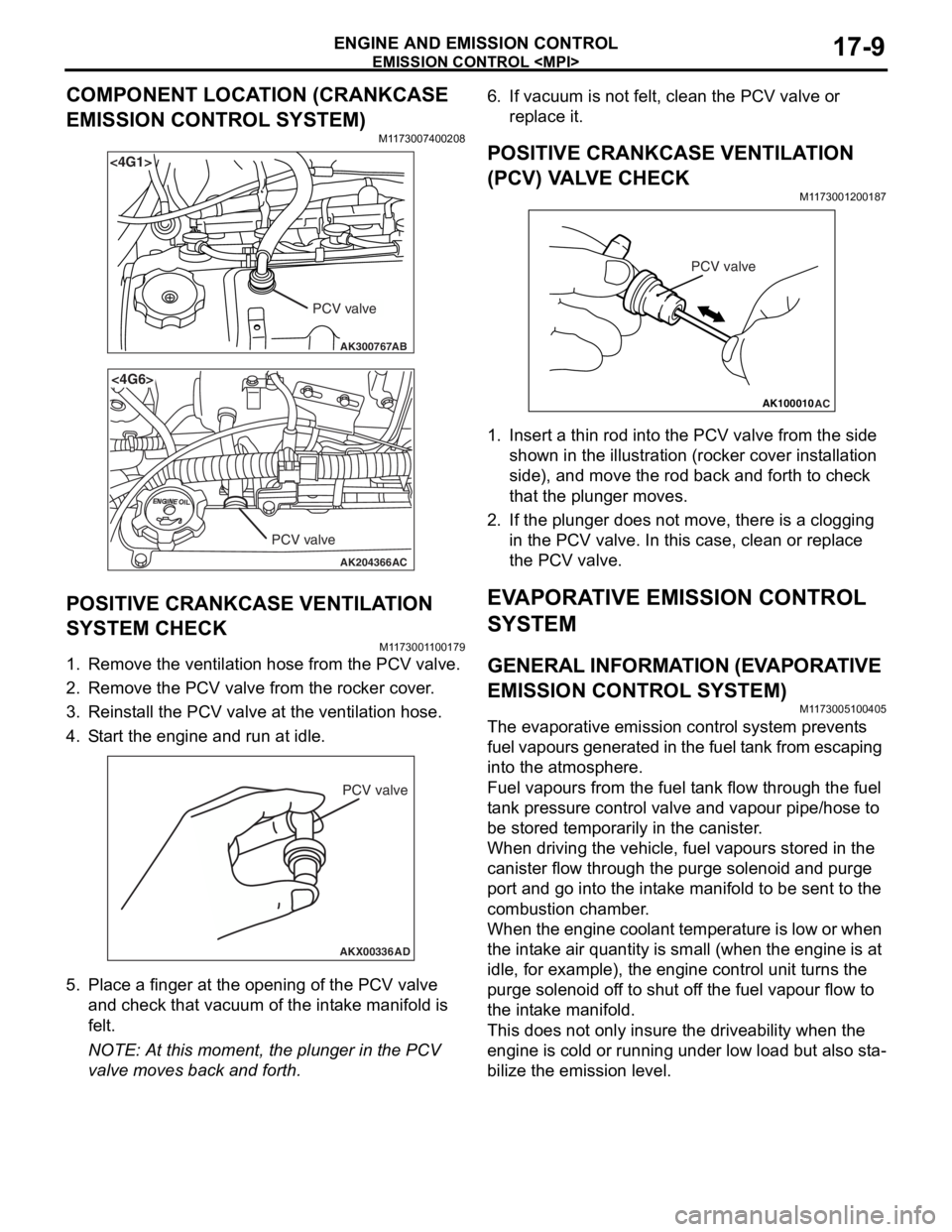

COMPONENT LOCATION (CRANKCASE

EMISSION CONTROL SYSTEM)

M1173007400208

AK300767

<4G1>

AB

PCV valve

AK204366

<4G6>

AC

PCV valve

POSITIVE CRANKCASE VENTILATION

SYSTEM CHECK

M11 7300 1 1 0017 9

1.Remove the ventilatio n hose from the PCV valve.

2.Remove the PCV valve from t he rocker cove r .

3.Reinst all the PCV valve at the ven t ila tion h o se.

4.S t art the engin e and run at idle .

AKX00336

PCV valve

AD

5.Pla c e a fing er at the open ing o f the PCV va lve

an d ch eck that vacu um o f the int a ke manifold is

fe lt.

NOTE: At this mo men t, the p l unge r in t he PCV

valve mo ves back an d forth.

6.If vacuum is not felt, clean t he PCV valve o r

re place it.

POSITIVE CRANKCASE VENTILA TION

(

P CV) V A L VE CHECK

M1173 0012 0018 7

AK100010

PCV valve

AC

1.In sert a thin rod in to the PCV valve from the side

shown in the illu strat i on (ro cke r cover in st allation

side) , and move the ro d back an d forth to ch eck

th at the plung er mo ves.

2.If the plunger does not move , there is a clo ggin g

in the PCV valve. In th is case, clean o r repla c e

th e PCV valve.

EVAPORA T IVE EMISSION CONTROL

SYSTEM

GENERAL INFORMA T ION (EV A PORA TIVE

EMISSION CONTROL SYSTEM)

M1173 0051 0040 5

The evaporat ive emission contro l syste m pre v ent s

f

uel vapours generat ed in t he fuel t ank from escaping

into t

he atmosp here.

Fuel vapours fro m the fuel t a n k flow throug h the f uel

t

a n k pre ssu re co ntrol valve an d vap our pipe/ho se to

be st

ored te mpora r ily in t he ca nister .

When dr iving the veh i cle, fue l va pours stor ed in the

canister

flow thro ugh th e purge solenoid and purge

port an

d go into the int a ke ma nifold to b e sen t to th e

combust

i on chamber .

When the eng ine co ola n t te mp eratu r e is low o r when

the int

a ke air q uantity is small (wh en the engine is at

idle

, for example), t he eng ine contro l unit turns the

purge sole

noid of f to shu t of f the fue l va pour flow to

the in

t a ke manif o ld.

This does not on ly insure the driveability when t he

engin

e is cold or runn ing und er low load b u t also st a

-

bilize the emissio n level.

Page 116 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-10

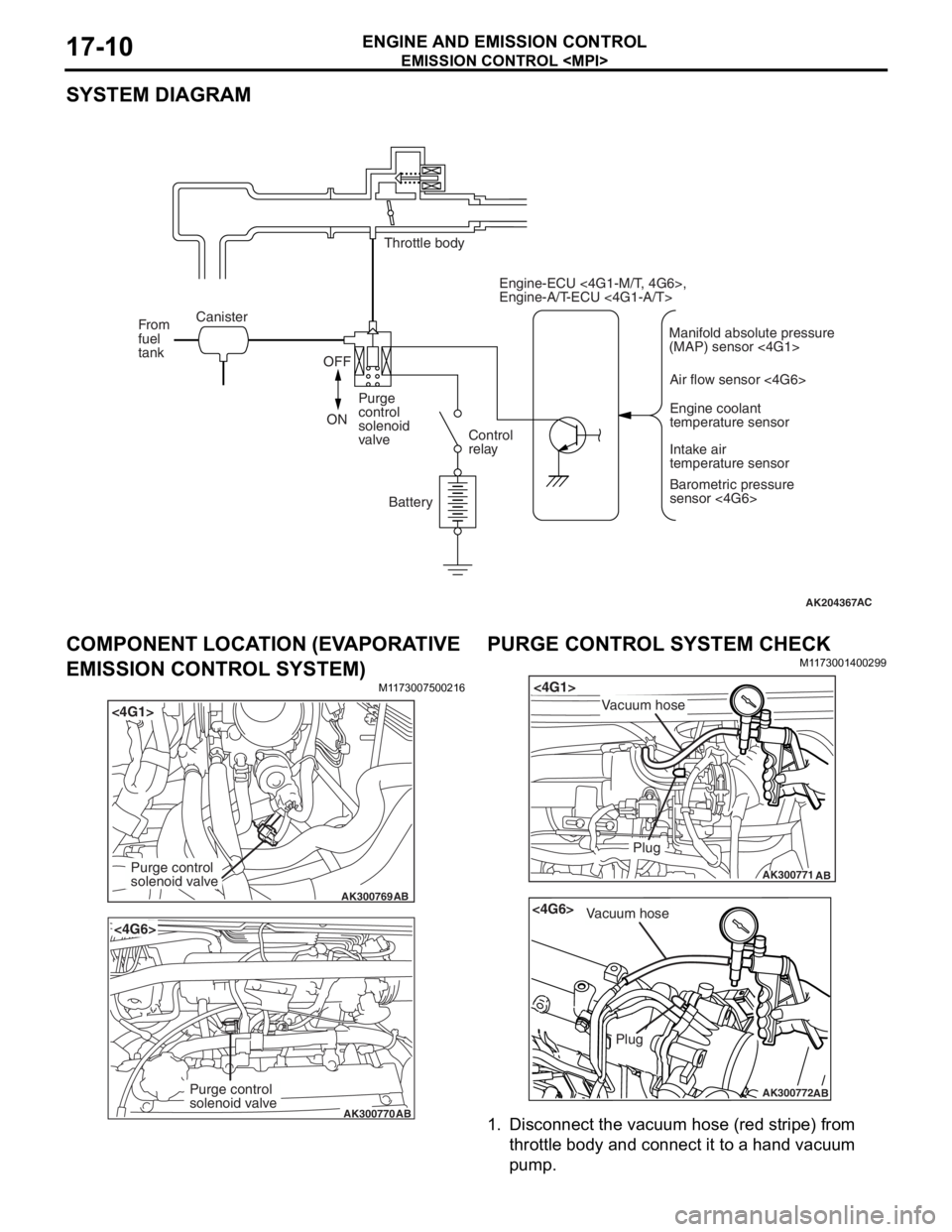

SYSTEM DIAGRAM

AK204367AC

Throttle body

Canister

From

fuel

tank

OFF

ON Purge

control

solenoid

valve

Control

relay

Battery Engine-ECU <4G1-M/T, 4G6>,

Engine-A/T-ECU <4G1-A/T>

Air flow sensor <4G6>Engine coolant

temperature sensor

Intake air

temperature sensor

Barometric pressure

sensor <4G6>

Manifold absolute pressure

(MAP) sensor <4G1>

COMPONENT LOCA

TION (EV A PORA TIVE

EMISSION CONTROL SYSTEM)

M1173 0075 0021 6

AK300769

<4G1>

AB

Purge control

solenoid valve

AK300770

<4G6>

AB

Purge control

solenoid valve

PURGE CONTROL SYSTEM CHECK

M1173 0014 0029 9

AK300771

<4G1>

AB

Plug

Vacuum hose

AK300772

<4G6>

AB

Plug

Vacuum hose

1.Disco nnect the vacu um h o se (re d str i pe) fro m

th rottle body and conne ct it to a h and vacu um

pu m p .

Page 120 of 800

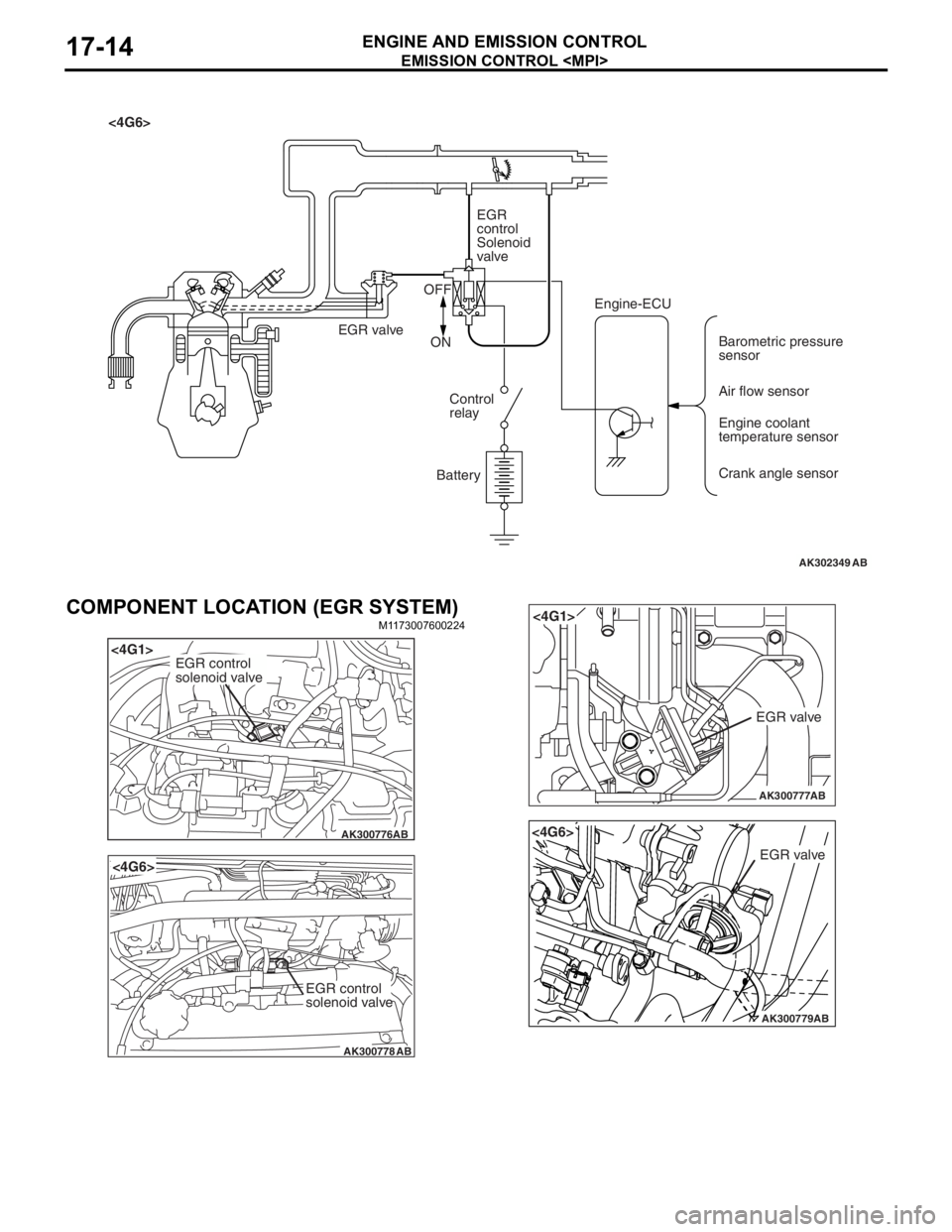

AK302349AB

<4G6>EGR

control

Solenoid

valve

EGR valve OFF

ON

Control

relay

Battery Engine-ECU

Barometric pressure

sensor

Air flow sensor

Engine coolant

temperature sensor

Crank angle sensor

EMISSION CONTROL

ENGINE AND E M ISSION CON T ROL17-14

COMPONENT LOCATION (EGR SYSTEM)

M1173 0076 0022 4

AK300776

<4G1>

AB

EGR control

solenoid valve

AK300778

<4G6>

AB

EGR control

solenoid valve

AK300777

<4G1>

AB

EGR valve

AK300779AB

<4G6>

EGR valve

Page 166 of 800

TROUBLESHOOTING

WHEEL AND TYRE31-4

WHEEL BALANCE ACCURACY

M1311001700247

PURPOSE

This section contains tips and procedures for achiev-

ing accurate wheel balance. Steering wheel vibration

and/or body shake can result if any of these proce

-

dures are not carefully observed.

1. Wheels and tyres must be properly mounted on a balancer in order to achieve correct balance.

Centring the wheel on the shaft of the balancer is

essential for proper mounting.

2. Off-the-car wheel balancers must be calibrated periodically to ensure good balancing results. An

inaccurately calibrated balancer could cause

unnecessary replacement of tyres, shocks,

suspension components, or steering components.

Check your balancer's calibration approximately

every 100 balances. Your wheel balancer's instruc

-

tion manual should include calibration procedures. If

the calibration procedures specifically for your bal

-

ancer are missing, use the generic steps in this sec-

tion for zero calibration, static balance, and dynamic

balance checks. The wheel balancer calibration

checks are also described in the flowchart. (Refer to

P.31-6).

PROCEDURE

1. Confirm that the balancer's cone and the wheel

mounting cone are undamaged and free of dirt

and rust.

2. On this vehicle, the wheel's centre hole on the hub side has a chamfered edge. Use a

back-mounting cone on your wheel balancer to

centre the wheel on the balancer shaft.

3. Install a wheel mounting cone. The appropriate size cone for this vehicle is 67.0 mm.

4. Before balancing the wheel, remove any wheel weights from both sides. Also check both sides for

any damage.

5. When installing wheel weights, hammer them at a straight (not diagonal) angle.

Scalloped

wear

ACX00934

Lack of rot a tio n of tyres or worn

or out-of-a

lign m ent suspensionRota te th e tyre s, an d

check the f

r ont or

rea

r suspension

alignment

s.

Refer to GROUP

33

, On -vehicle

serv

ic e

− Front

whee

l alignment

check and

ad

justmen t

P.33-6.

Refer to GROUP

34

, On -vehicle

serv

ic e

− Rear

whee

l alignment

check and

ad

justmen t

P.34-6.

Sy mptom P robable cause Reme dy Referen ce p a g e

Page 183 of 800

33-1

GROUP 33

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATIO N . . . . . . . .33-2

SERVICE SPECIFICATIONS . . . . . . .33-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .33-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .33-4

ON-VEHICLE SERVICE . . . . . . . . . . .33-6

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 33-6

LOWER ARM BALL JOINT AXIAL PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

LOWER ARM BALL JOINT COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

STRUT ASSEMBLY . . . . . . . . . . . . . .33-7

REMOVAL AND INSTALLATION . . . . . . . . 33-7

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-7

DISASSEMBLY AND REASSEMBLY . . . . . 33-8

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-10

LOWER ARM . . . . . . . . . . . . . . . . . . .33-11

REMOVAL AND INSTALLATION . . . . . . . . 33-11

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BALL JOINT COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BUSHING (REAR)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-13

STABILIZER BAR. . . . . . . . . . . . . . . .33-14

REMOVAL AND INSTALLATION . . . . . . . . 33-14

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-16

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).