idle air control MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 115 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-9

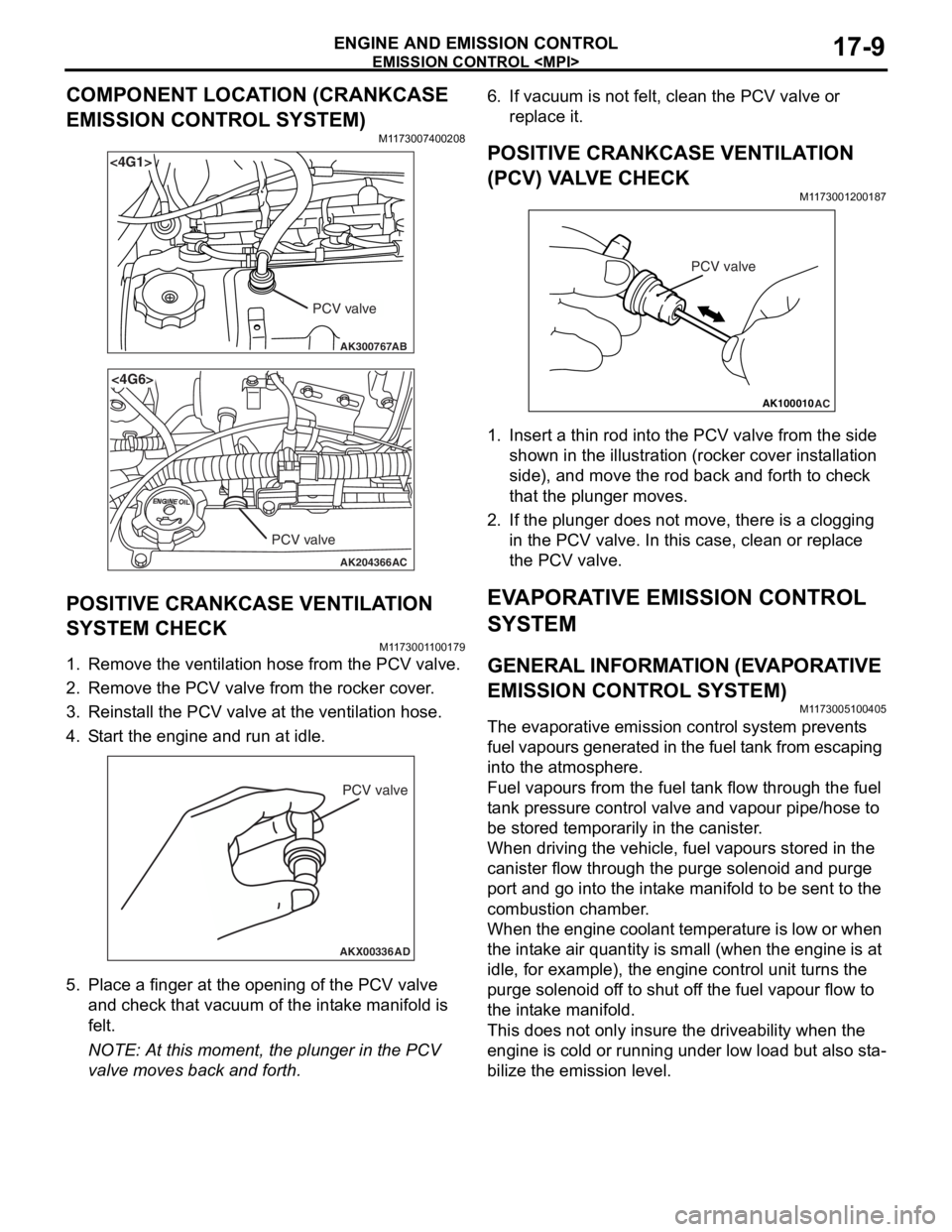

COMPONENT LOCATION (CRANKCASE

EMISSION CONTROL SYSTEM)

M1173007400208

AK300767

<4G1>

AB

PCV valve

AK204366

<4G6>

AC

PCV valve

POSITIVE CRANKCASE VENTILATION

SYSTEM CHECK

M11 7300 1 1 0017 9

1.Remove the ventilatio n hose from the PCV valve.

2.Remove the PCV valve from t he rocker cove r .

3.Reinst all the PCV valve at the ven t ila tion h o se.

4.S t art the engin e and run at idle .

AKX00336

PCV valve

AD

5.Pla c e a fing er at the open ing o f the PCV va lve

an d ch eck that vacu um o f the int a ke manifold is

fe lt.

NOTE: At this mo men t, the p l unge r in t he PCV

valve mo ves back an d forth.

6.If vacuum is not felt, clean t he PCV valve o r

re place it.

POSITIVE CRANKCASE VENTILA TION

(

P CV) V A L VE CHECK

M1173 0012 0018 7

AK100010

PCV valve

AC

1.In sert a thin rod in to the PCV valve from the side

shown in the illu strat i on (ro cke r cover in st allation

side) , and move the ro d back an d forth to ch eck

th at the plung er mo ves.

2.If the plunger does not move , there is a clo ggin g

in the PCV valve. In th is case, clean o r repla c e

th e PCV valve.

EVAPORA T IVE EMISSION CONTROL

SYSTEM

GENERAL INFORMA T ION (EV A PORA TIVE

EMISSION CONTROL SYSTEM)

M1173 0051 0040 5

The evaporat ive emission contro l syste m pre v ent s

f

uel vapours generat ed in t he fuel t ank from escaping

into t

he atmosp here.

Fuel vapours fro m the fuel t a n k flow throug h the f uel

t

a n k pre ssu re co ntrol valve an d vap our pipe/ho se to

be st

ored te mpora r ily in t he ca nister .

When dr iving the veh i cle, fue l va pours stor ed in the

canister

flow thro ugh th e purge solenoid and purge

port an

d go into the int a ke ma nifold to b e sen t to th e

combust

i on chamber .

When the eng ine co ola n t te mp eratu r e is low o r when

the int

a ke air q uantity is small (wh en the engine is at

idle

, for example), t he eng ine contro l unit turns the

purge sole

noid of f to shu t of f the fue l va pour flow to

the in

t a ke manif o ld.

This does not on ly insure the driveability when t he

engin

e is cold or runn ing und er low load b u t also st a

-

bilize the emissio n level.

Page 118 of 800

Battery voltageNormal condition

AppliedVacuum leaks

Not appliedVacuum maintained

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-12

5. Measure the resistance between the terminals of the solenoid valve.

Standard value: 30 − 34 Ω (at 20°C)

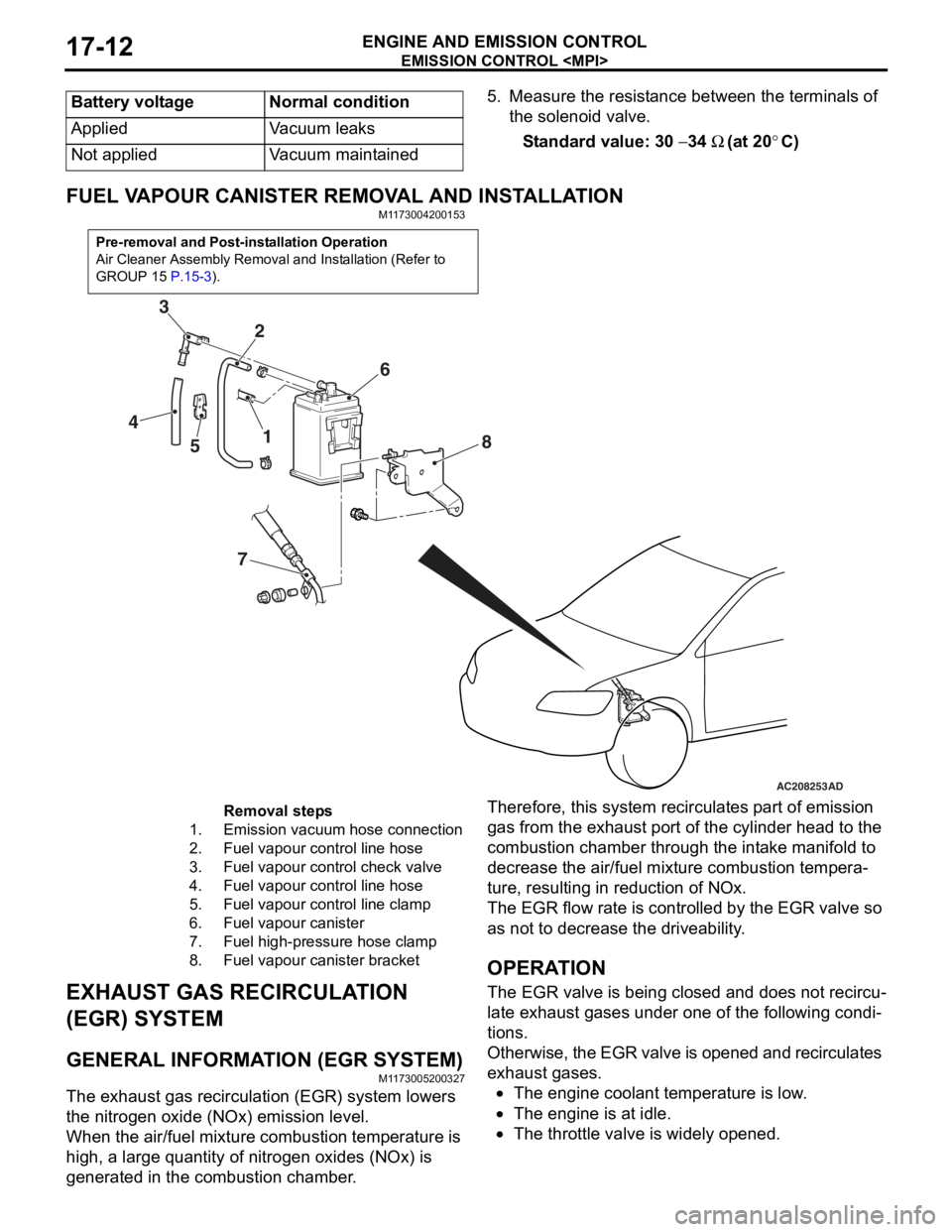

FUEL VAPOUR CANISTER RE MOVAL AND INSTALLATION

M1173004200153

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

AC208253

1

2

3

4 5 6

7 8

AD

Removal steps

1.Emission vacuum hose connection

2.Fuel vapour control line hose

3.Fuel vapour control check valve

4.Fuel vapour control line hose

5.Fuel vapour control line clamp

6.Fuel vapour canister

7.Fuel high-pressure hose clamp

8.Fuel vapour canister bracket

EXHAUST GAS RECIRCULA

T ION

(EGR) SYSTEM

GENERAL INFORMAT ION (EGR SYSTEM)

M1173 0052 0032 7

The exhaust gas recircu l atio n (EGR) system lowers

the nitrogen

oxide (NOx) emission level.

When the air/fuel mixture combus tio n temp erature is

high,

a larg e qua ntity of nitrogen oxides (NOx) is

generat

ed in the comb ustion chamb e r .

Therefor e, this syst em re circulat es p a rt o f emission

gas fro

m the e x ha ust po rt of the cylinder h ead to th e

combust

i on chamber thro ugh th e int a ke ma nifold to

decre

ase the air/fuel mixture combust i on te mpera

-

ture, resulting in redu ctio n of NOx.

The EGR flow rate is cont rolle d by the EGR valve so

as no

t to de crease the driveability .

OPERAT ION

The EGR valve is being clos ed an d does not re circu-

late ex hau st ga ses unde r one o f the fo llo wing condi-

tions.

Otherwise, th e EGR va lve is opene d an d recircul ates

exha

ust g a ses.

•The engine coolan t temperature is low .

•The engine is at idle.

•The throttle va lve is widely ope ned.

Page 244 of 800

ON-VEHICLE SERVICE

POWER STEERING37-14

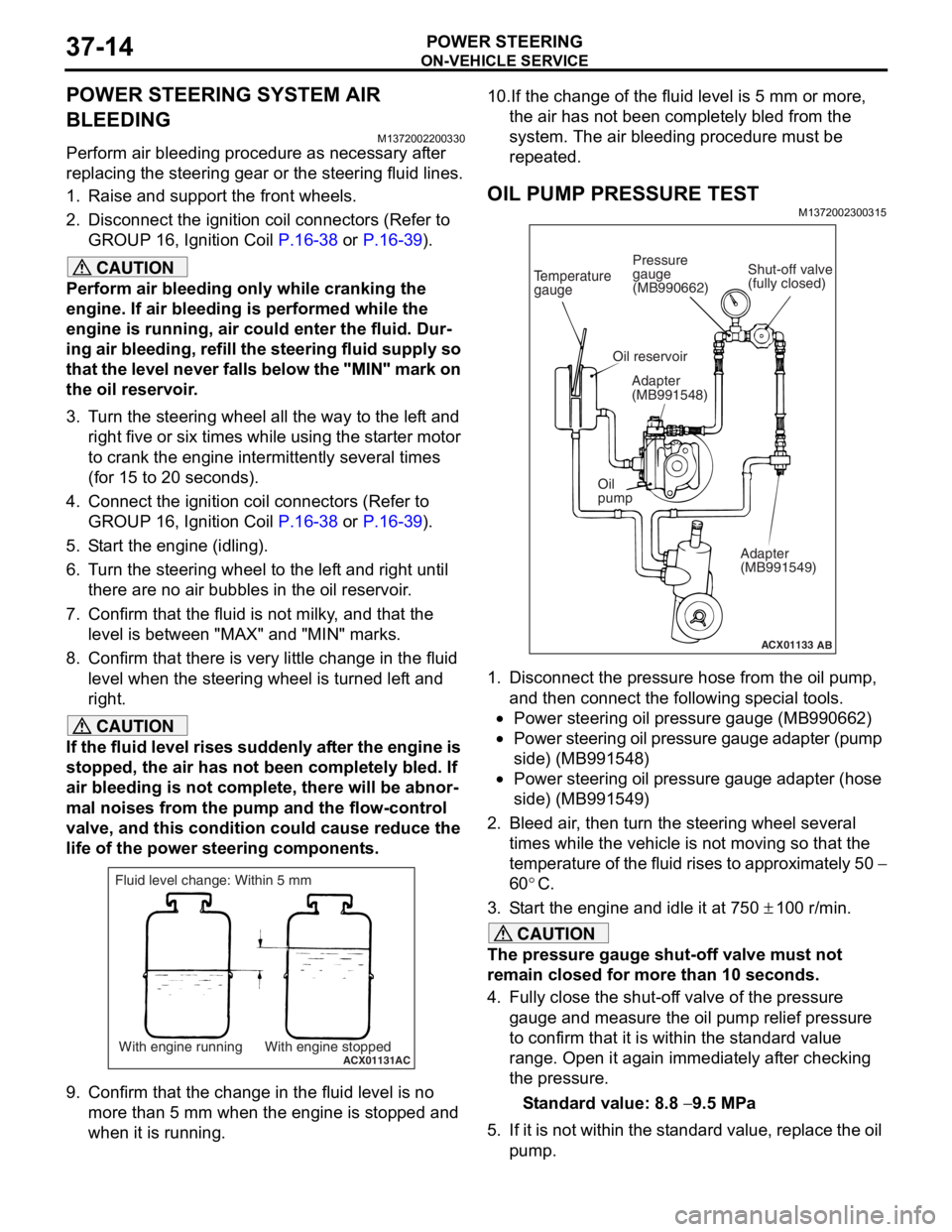

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid. Dur

-

ing air bleeding, refill the steering fluid supply so

that the level never falls below the "MIN" mark on

the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times wh ile using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be abnor

-

mal noises from the pump and the flow-control

valve, and this condition could cause reduce the

life of the power steering components.

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

9. Confirm that the change in the fluid level is no more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

OIL PUMP PRESSURE TEST

M1372002300315

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump Adapter

(MB991549)

AB

Shut-off valve

(fully closed)

Pressure

gauge

(MB990662)

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•Power steering oil pressure gauge (MB990662)

•Power steering oil pressure gauge adapter (pump

side) (MB991548)

•Power steering oil pressure gauge adapter (hose

side) (MB991549)

2. Bleed air, then turn the steering wheel several times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

−

60

°C.

3. Start the engine and idle it at 750 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil pump.

Page 398 of 800

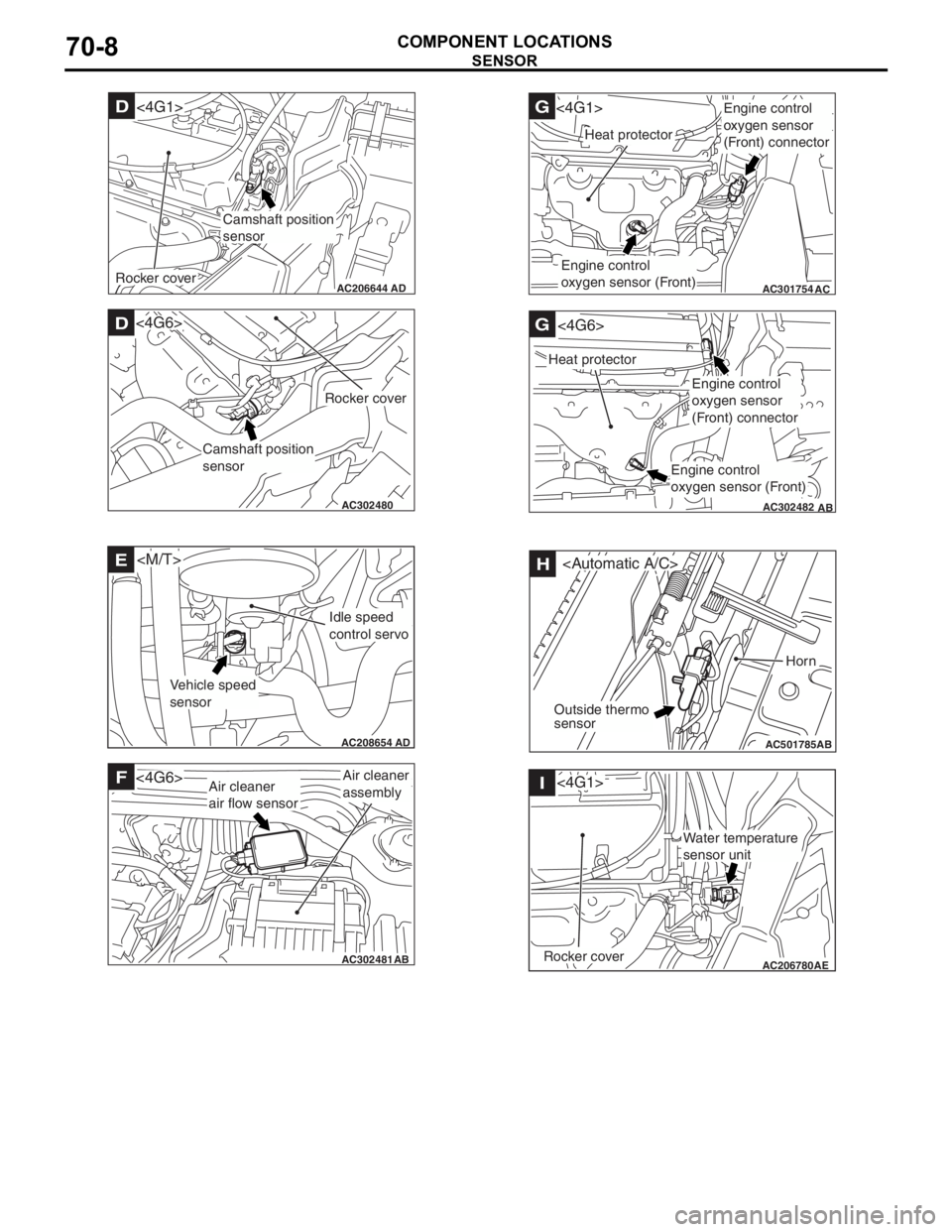

AC206644AD

Camshaft position

sensor

D<4G1>

Rocker cover

AC302480AB

D

Camshaft position

sensor

Rocker cover

<4G6>

AC208654

AD

E

Vehicle speed

sensor

Idle speed

control servo

AC302481AB

FAir cleaner

assembly<4G6>Air cleaner

air flow sensor

AB

AC301754

G<4G1>

AC

Heat protector

Engine control

oxygen sensor (Front)

Engine control

oxygen sensor

(Front) connector

AC302482

G

AB

Heat protector

<4G6>

Engine control

oxygen sensor

(Front) connector

Engine control

oxygen sensor (Front)

AC501785AB

H

Horn

Outside thermo

sensor

AC206780 AE

I

Rocker cover

<4G1>

Water temperature

sensor unit

SE

NSOR

COMPONENT LOCA TIONS70-8

Page 482 of 800

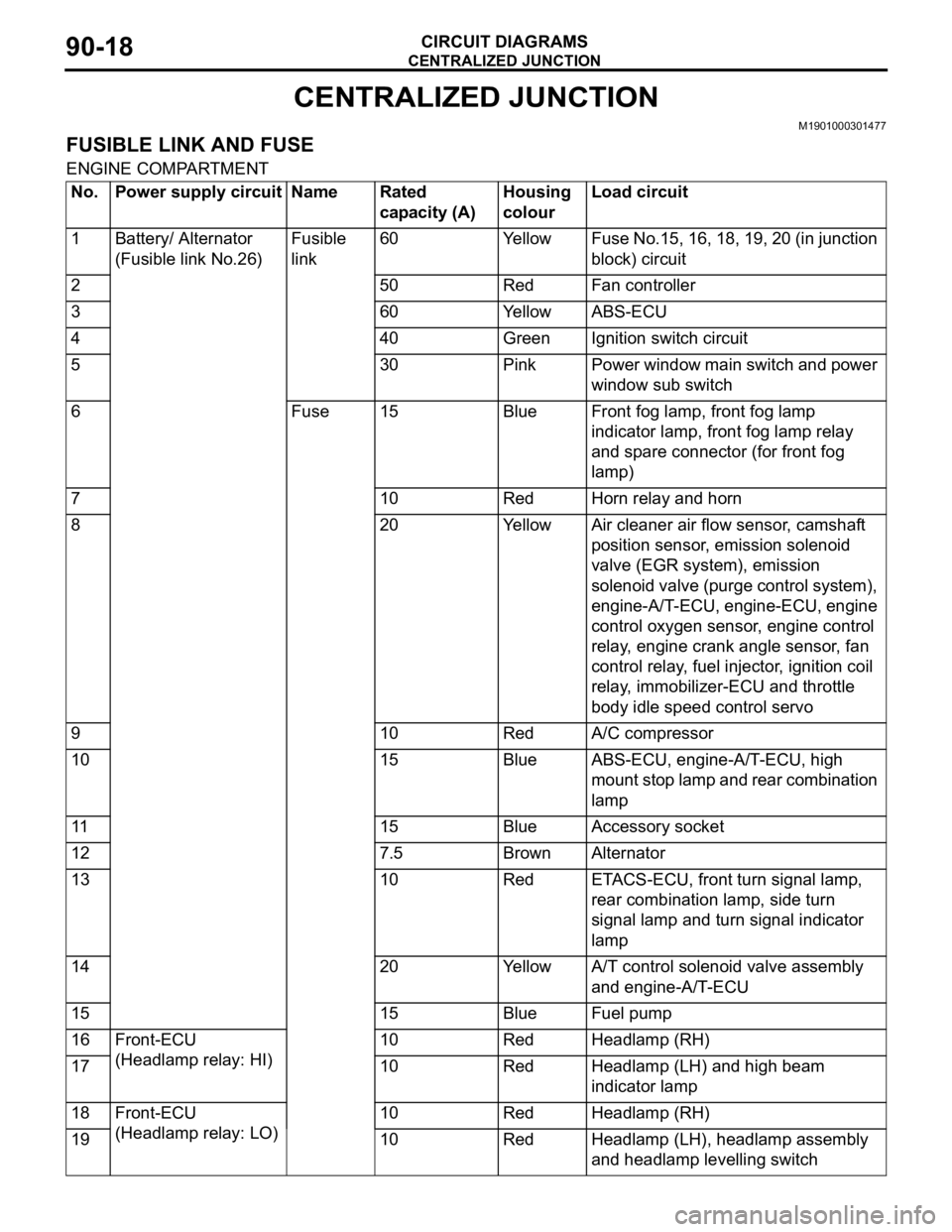

CENTRALIZED JUNCTION

CIRCUIT DIAGRAMS90-18

CENTRALIZED JUNCTION

M1901000301477

FUSIBLE LINK AND FUSE

ENGINE COMPARTMENT

No.Power supply circuitNameRated

capacity (A)Housing

colourLoad circuit

1Battery/ Alternator

(Fusible link No.26)Fusible

link60YellowFuse No.15, 16, 18, 19, 20 (in junction

block) circuit

250RedFan controller

360YellowABS-ECU

440GreenIgnition switch circuit

530PinkPower window main switch and power

window sub switch

6Fuse15BlueFront fog lamp, front fog lamp

indicator lamp, front fog lamp relay

and spare connector (for front fog

lamp)

710RedHorn relay and horn

820YellowAir cleaner air flow sensor, camshaft

position sensor, emission solenoid

valve (EGR system), emission

solenoid valve (purge control system),

engine-A/T-ECU, engine-ECU, engine

control oxygen sensor, engine control

relay, engine crank angle sensor, fan

control relay, fuel injector, ignition coil

relay, immobilizer-ECU and throttle

body idle speed control servo

910RedA/C compressor

1015BlueABS-ECU, engine-A/T-ECU, high

mount stop lamp and rear combination

lamp

1115BlueAccessory socket

127.5BrownAlternator

1310RedETACS-ECU, front turn signal lamp,

rear combination lamp, side turn

signal lamp and turn signal indicator

lamp

1420YellowA/T control solenoid valve assembly

and engine-A/T-ECU

1515BlueFuel pump

16Front-ECU

(Headlamp relay: HI)10RedHeadlamp (RH)

1710RedHeadlamp (LH) and high beam

indicator lamp

18Front-ECU

(Headlamp relay: LO)10RedHeadlamp (RH)

1910RedHeadlamp (LH), headlamp assembly

and headlamp levelling switch

Page 516 of 800

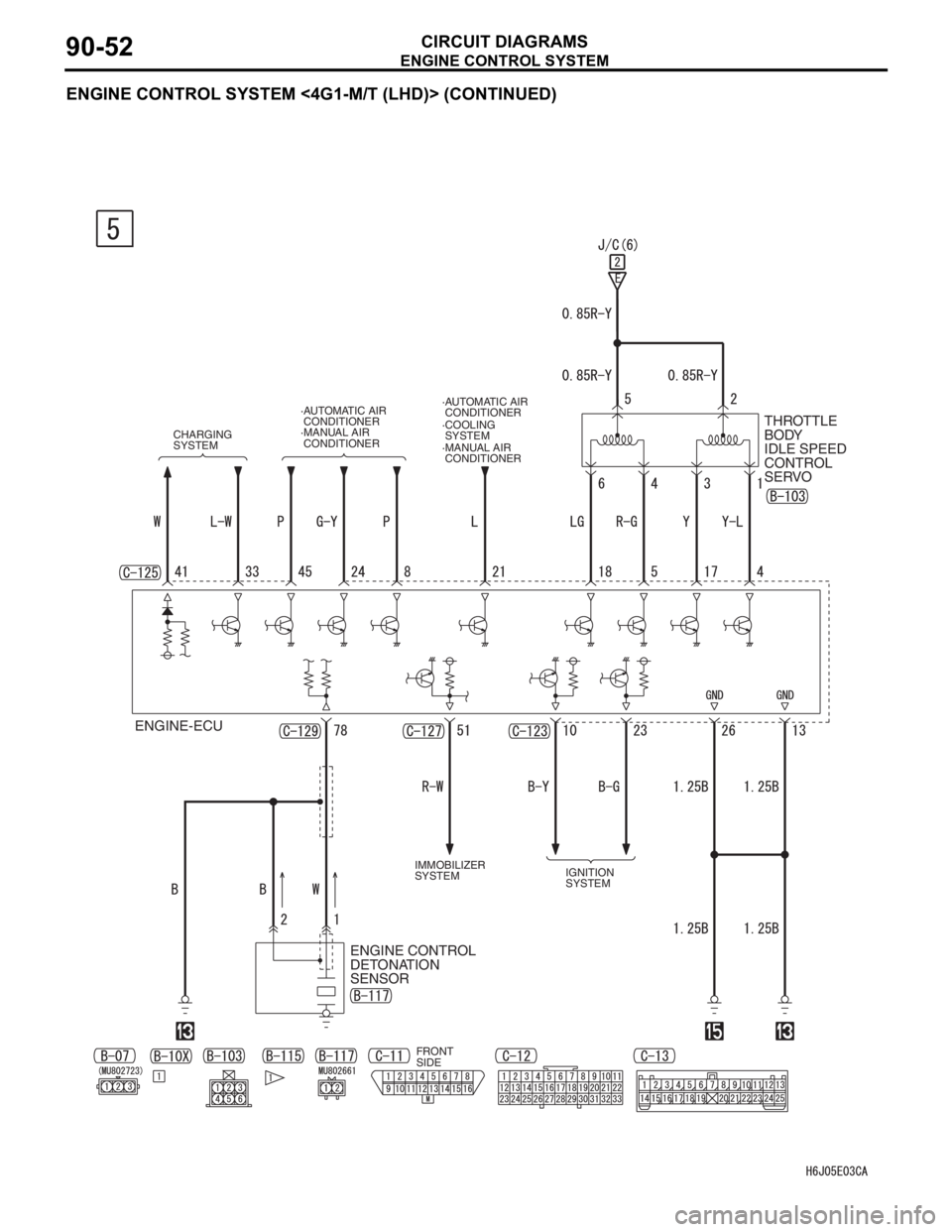

ENGINE CONTROL SYSTEM

CIRCUIT DIAGRAMS90-52

ENGINE CONTROL SYSTEM <4G1-M/T (LHD)> (CONTINUED)

CHARGING

SYSTEM

·MANUAL AIR

CONDITIONER ·MANUAL AIR

CONDITIONER·COOLING

SYSTEMTHROTTLE

BODY

IDLE SPEED

CONTROL

SERVO

ENGINE-ECU

ENGINE CONTROL

DETONATION

SENSOR

IMMOBILIZER

SYSTEMIGNITION

SYSTEM

FRONT

SIDE·AUTOMATIC AIR

CONDITIONER ·AUTOMATIC AIR

CONDITIONER

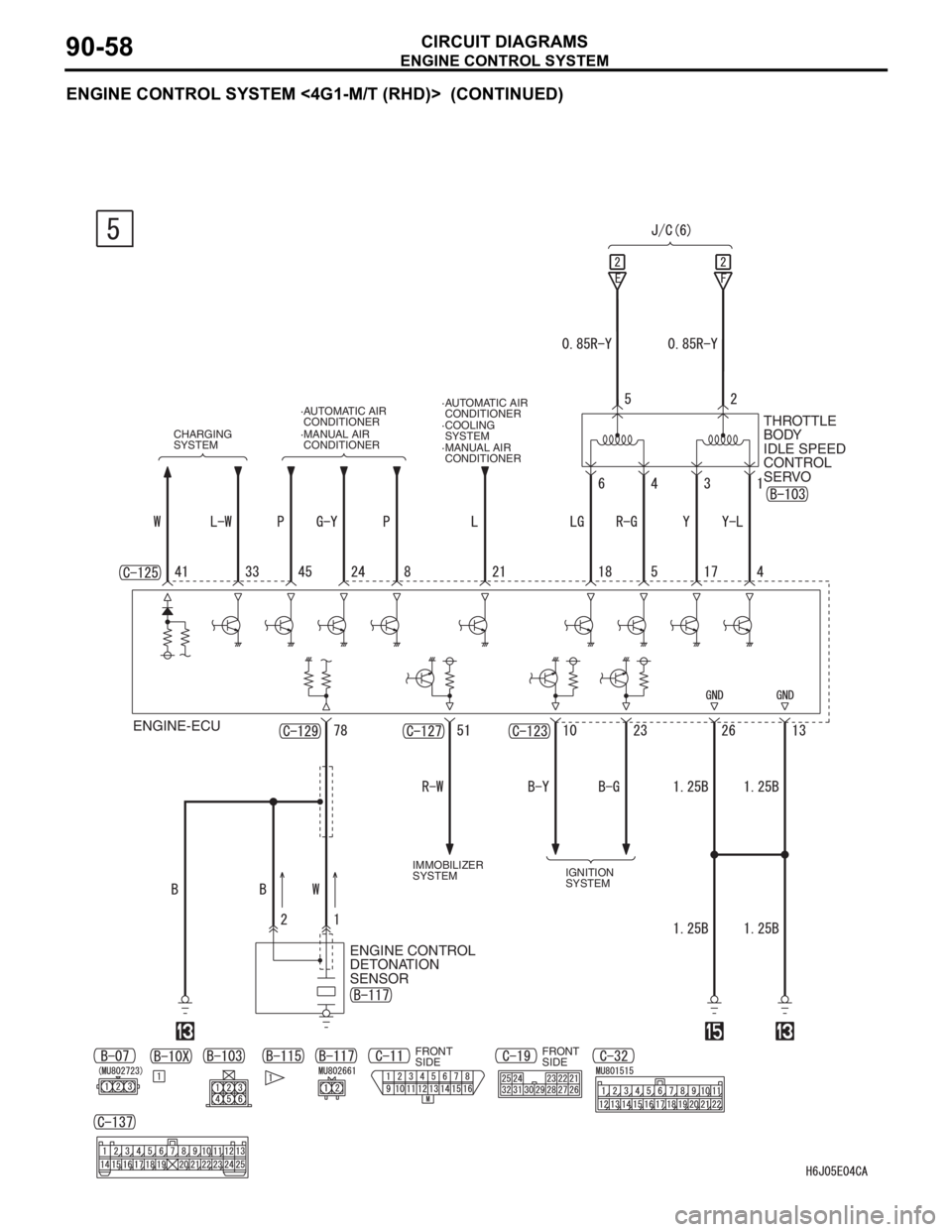

Page 522 of 800

ENGINE CONTROL SYSTEM

CIRCUIT DIAGRAMS90-58

ENGINE CONTROL SYSTEM <4G1-M/T (RHD)> (CONTINUED)

CHARGING

SYSTEM

·MANUAL AIR

CONDITIONER ·MANUAL AIR

CONDITIONER·AUTOMATIC AIR

CONDITIONER ·AUTOMATIC AIR

CONDITIONER

·COOLING

SYSTEMTHROTTLE

BODY

IDLE SPEED

CONTROL

SERVO

ENGINE-ECU

ENGINE CONTROL

DETONATION

SENSOR

IMMOBILIZER

SYSTEMIGNITION

SYSTEM

FRONT

SIDEFRONT

SIDE

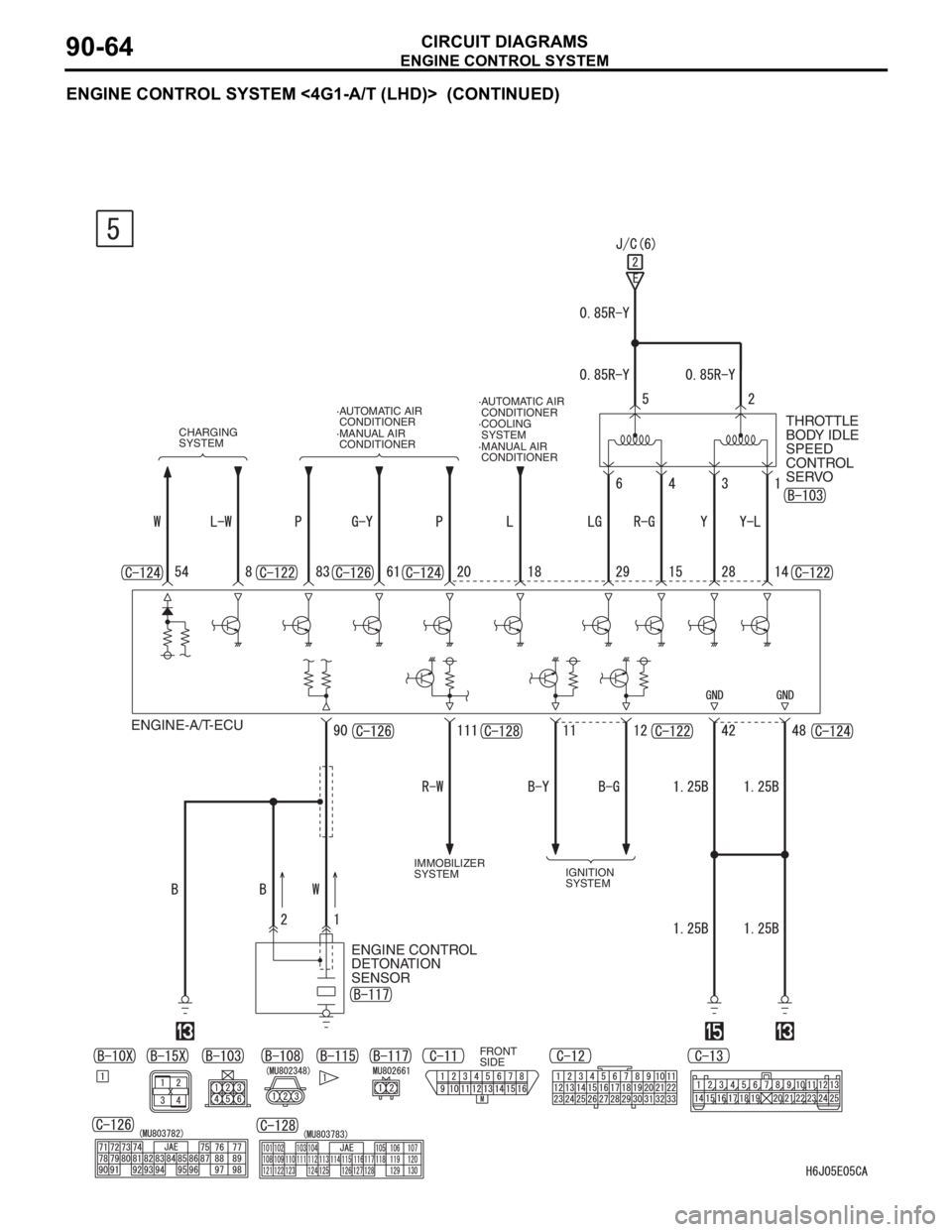

Page 528 of 800

ENGINE CONTROL SYSTEM

CIRCUIT DIAGRAMS90-64

ENGINE CONTROL SYSTEM <4G1-A/T (LHD)> (CONTINUED)

CHARGING

SYSTEM

·MANUAL AIR

CONDITIONER ·MANUAL AIR

CONDITIONER·AUTOMATIC AIR

CONDITIONER ·AUTOMATIC AIR

CONDITIONER

·COOLING

SYSTEMTHROTTLE

BODY IDLE

SPEED

CONTROL

SERVO

ENGINE-A/T-ECU

ENGINE CONTROL

DETONATION

SENSOR

IMMOBILIZER

SYSTEMIGNITION

SYSTEM

FRONT

SIDE

Page 534 of 800

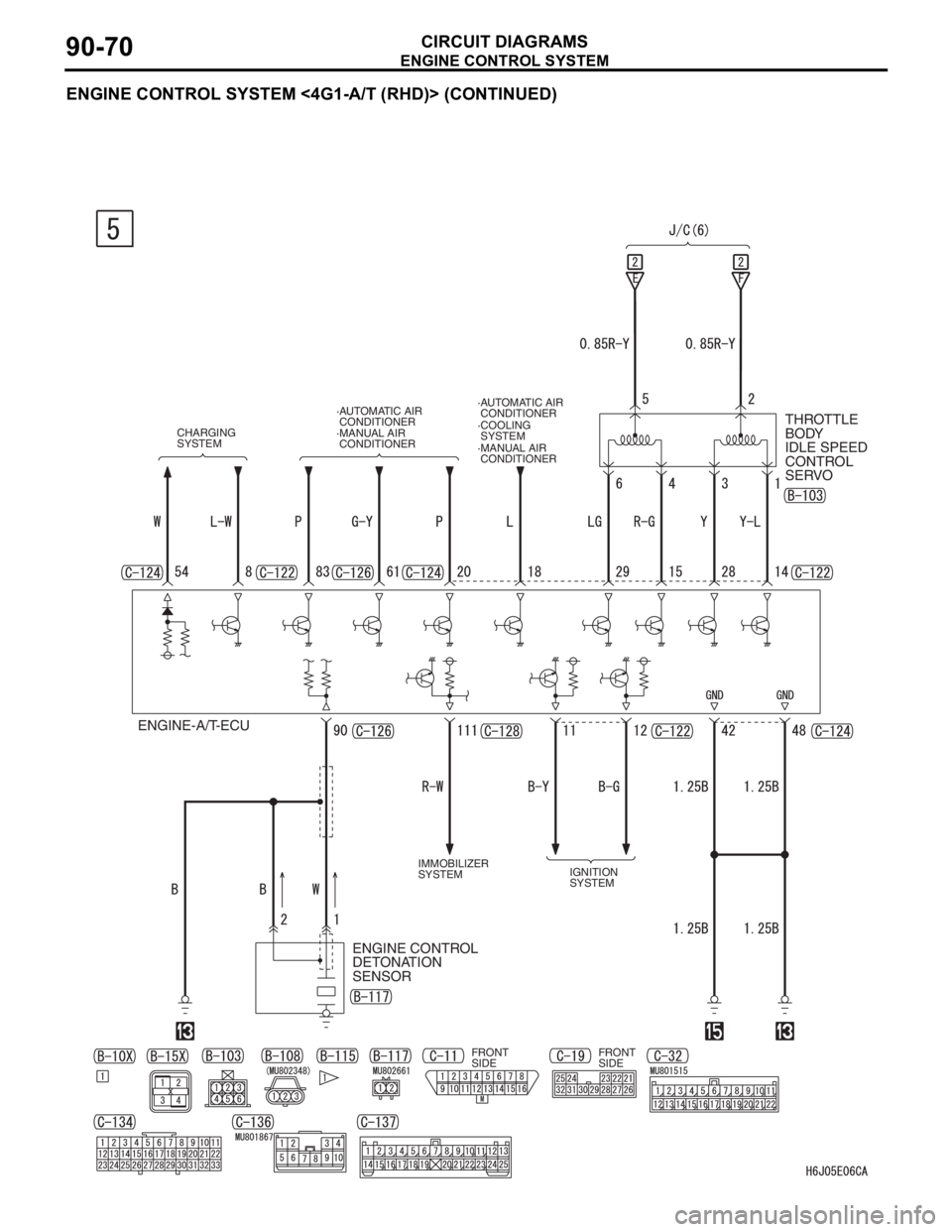

ENGINE CONTROL SYSTEM

CIRCUIT DIAGRAMS90-70

ENGINE CONTROL SYSTEM <4G1-A/T (RHD)> (CONTINUED)

CHARGING

SYSTEM

·MANUAL AIR

CONDITIONER ·MANUAL AIR

CONDITIONER·AUTOMATIC AIR

CONDITIONER ·AUTOMATIC AIR

CONDITIONER

·COOLING

SYSTEMTHROTTLE

BODY

IDLE SPEED

CONTROL

SERVO

ENGINE-A/T-ECU

ENGINE CONTROL

DETONATION

SENSOR

IMMOBILIZER

SYSTEMIGNITION

SYSTEM

FRONT

SIDEFRONT

SIDE

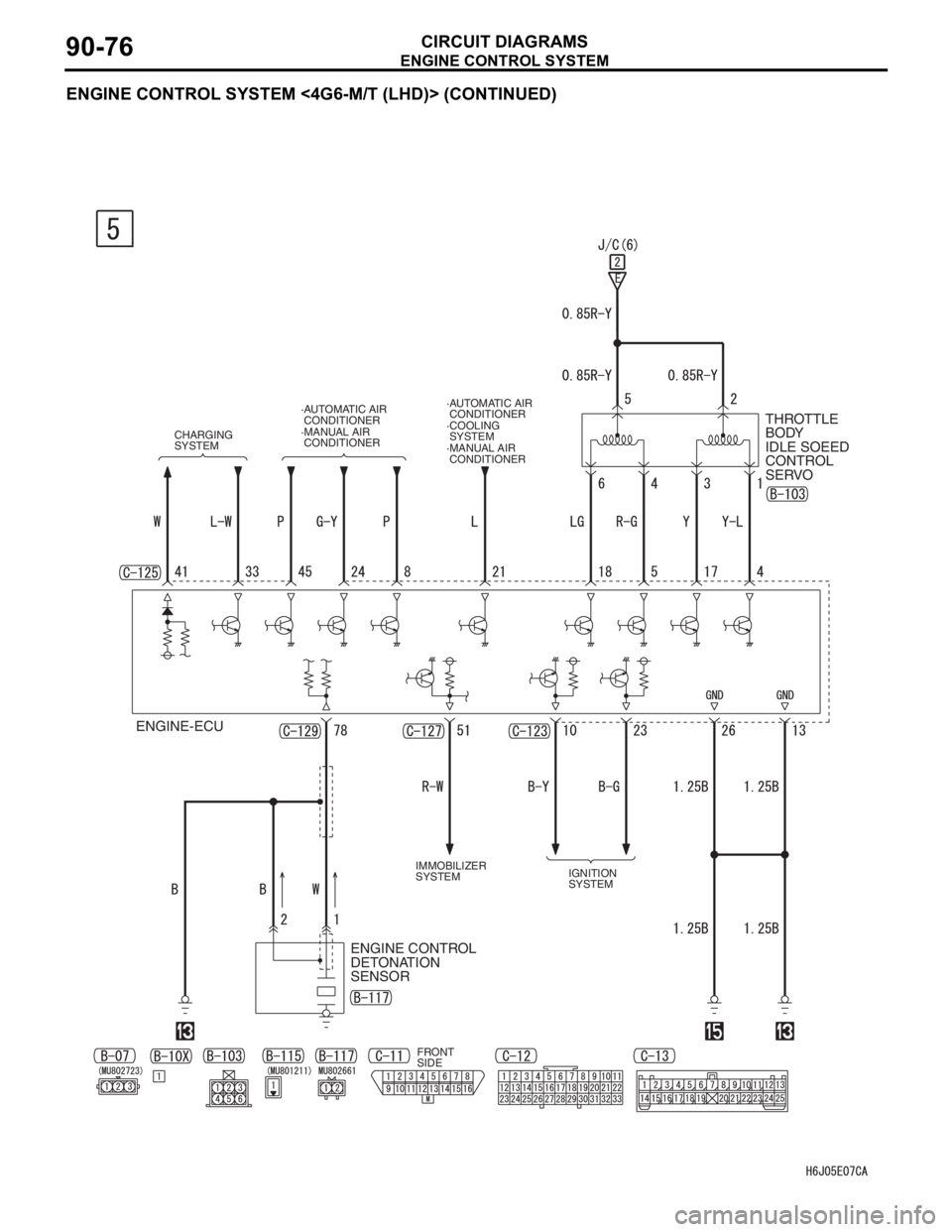

Page 540 of 800

ENGINE CONTROL SYSTEM

CIRCUIT DIAGRAMS90-76

ENGINE CONTROL SYSTEM <4G6-M/T (LHD)> (CONTINUED)

CHARGING

SYSTEM

·MANUAL AIR

CONDITIONER ·MANUAL AIR

CONDITIONER·AUTOMATIC AIR

CONDITIONER ·AUTOMATIC AIR

CONDITIONER

·COOLING

SYSTEMTHROTTLE

BODY

IDLE SOEED

CONTROL

SERVO

ENGINE-ECU

ENGINE CONTROL

DETONATION

SENSOR

IMMOBILIZER

SYSTEMIGNITION

SYSTEM

FRONT

SIDE