position light MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 66 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-4

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0

‚ąí 120 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is pos

-

sibly not found the problem that the output current

is dropping due to the insufficient connection

between terminal "B" and the output wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the battery (+)

terminal. [Connect the (+) lead of the voltmeter to

the "B" terminal and the connect the (-) lead of the

voltmeter to the battery (+) cable].

6. Reconnect the negative battery cable.

7. Connect a tachometer or the M.U.T.-II/III (Refer to

GROUP 11A

‚ąí On-vehicle Service ‚ąí Idle speed

check <4G1>

P.11A-11 or GROUP 11C ‚ąí

On-vehicle Service ‚ąí Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlamps and other lamps on and off to adjust

the alternator load so that the value displayed on

the ammeter is slightly above 30 A.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

Limit: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease until 30 A, set the value to 40 A. Read

the value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is maxi

-

mum 0.4 V.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire, so check the wiring

between the alternator "B" terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lamps and the ignition switch.

14.Remove the tachometer or the M.U.T.-II/III.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

Page 68 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-6

9. Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery (+) ter

-

minal.

10.Turn the light switch on to turn on headlamps and

then start the engine.

11.Immediately after setting the headlamps to high

beam and turning the heater blower switch to the

high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current output

NOTE: .

‚ÄĘFor the nominal current output, refer to the

Alternator Specifications.

‚ÄĘBecause the current from the battery will soon

drop after the engine is started, the above step

should be carried out as quickly as possible in

order to obtain the maximum current output

value.

‚ÄĘThe current output value will depend on the

electrical load and the temperature of the

alternator body.

‚ÄĘIf the electrical load is small while testing, the

specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving

the headlamps turned on for some time to dis

-

charge the battery or by using the lighting sys-

tem in another vehicle, and then test again.

‚ÄĘThe specified level of current also may not be

output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Remove the tachometer or the M.U.T.-II/III.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter.

18.Connect the negative battery cable.

Page 92 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

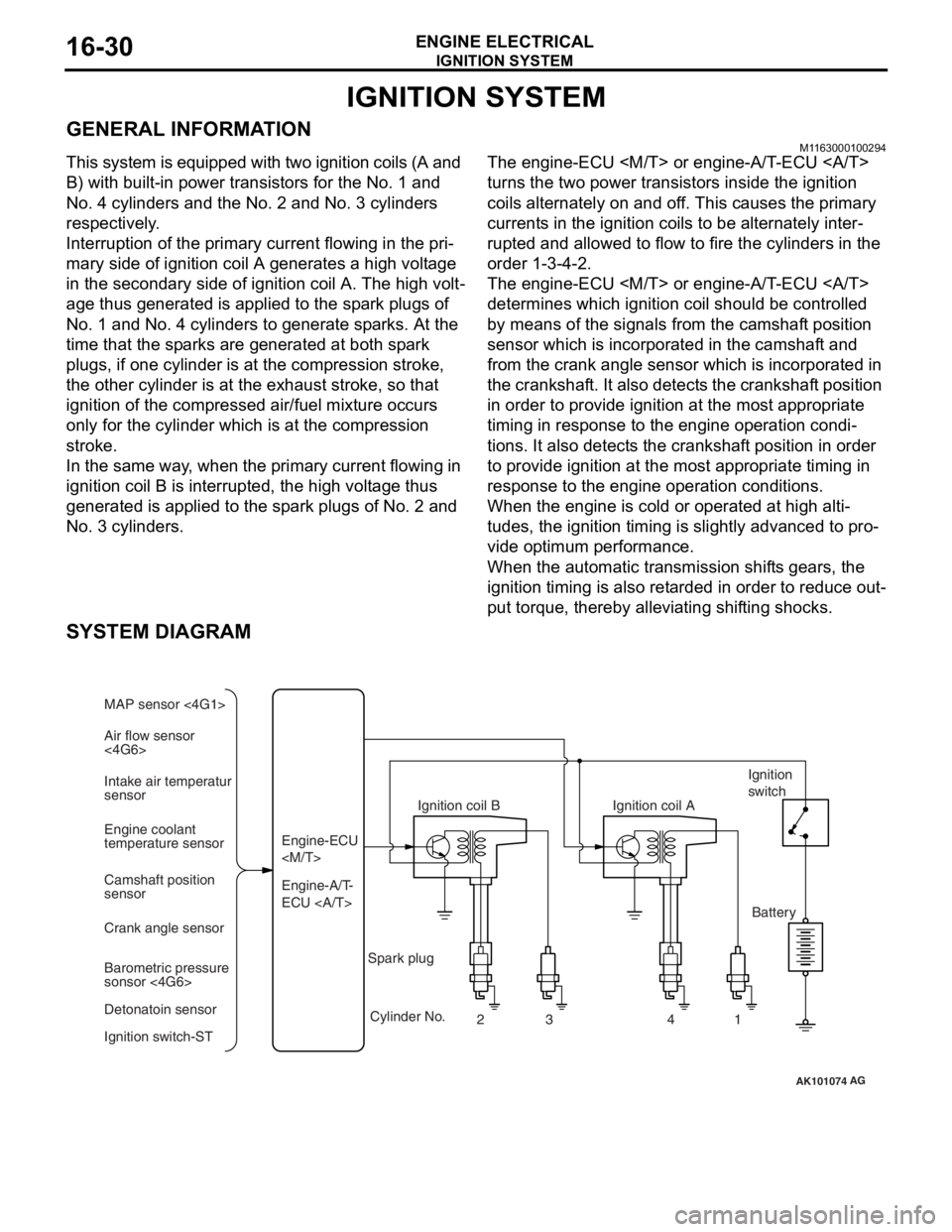

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the pri-

mary side of ignition coil A generates a high voltage

in the secondary side of ignition coil A. The high volt

-

age thus generated is applied to the spark plugs of

No. 1 and No. 4 cylinders to generate sparks. At the

time that the sparks are generated at both spark

plugs, if one cylinder is at the compression stroke,

the other cylinder is at the exhaust stroke, so that

ignition of the compressed air/fuel mixture occurs

only for the cylinder which is at the compression

stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.

The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately inter

-

rupted and allowed to flow to fire the cylinders in the

order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation condi

-

tions. It also detects the crankshaft position in order

to provide ignition at the most appropriate timing in

response to the engine operation conditions.

When the engine is cold or operated at high alti-

tudes, the ignition timing is slightly advanced to pro-

vide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce out

-

put torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-ST Engine-A/T-

ECU Engine-ECU

Ignition coil B

Cylinder No. 23 4

AG

1

Spark plug Ignition coil A

Ignition

switch

Battery

Page 108 of 800

ENGINE CONTROL

ENGINE AND EMISSION CONTROL17-2

ENGINE CONTROL

GENERAL INFORMATIONM1171000100277

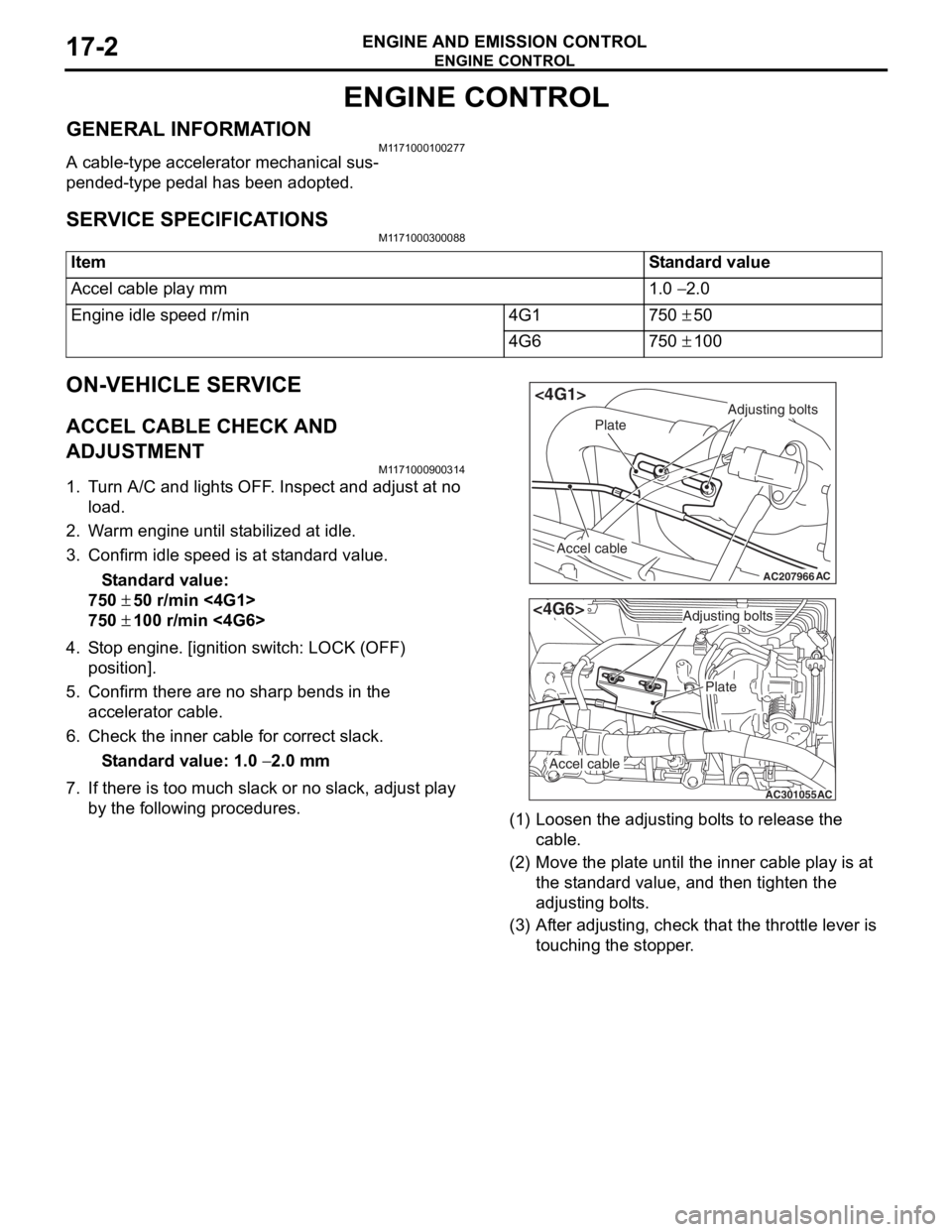

A cable-type accelerator mechanical sus-

pended-type pedal has been adopted.

SERVICE SPECIFICATIONS

M1171000300088

ItemStandard value

Accel cable play mm1.0 ‚ąí 2.0

Engine idle speed r/min4G1750 ¬Ī 50

4G6750 ¬Ī 100

ON-VEHICLE SERVICE

ACCEL CABLE CHECK AND

ADJUSTMENT

M1171000900314

1. Turn A/C and lights OFF. Inspect and adjust at no load.

2. Warm engine until stabilized at idle.

3. Confirm idle speed is at standard value.

Standard value:

750 ¬Ī 50 r/min <4G1>

750 ¬Ī 100 r/min <4G6>

4. Stop engine. [ignition switch: LOCK (OFF)

position].

5. Confirm there are no sharp bends in the accelerator cable.

6. Check the inner cable for correct slack.

Standard value: 1.0 ‚ąí 2.0 mm

7. If there is too much slack or no slack, adjust play by the following procedures.

AC207966

Adjusting bolts

Plate

Accel cable

AC

<4G1>

AC301055

Adjusting bolts

Plate

Accel cable

AC

<4G6>

(1) Loosen th e adjusting bo lt s to re lease the

cab l e.

(2) M o v e th e pla t e until the inne r cab l e play is a t

the st andard value, an d then tighte n the

adjusting bo lt s.

(3) A f t e r adju s ting, check that the thro ttle leve r is

touching the stoppe r .

Page 283 of 800

WINDOW GLASS

BODY42-11

HANDLING OF AUTO WINDOW SEALER

Keep the sealant in a cool place, not exposed to the

direct rays of the sun. Do not place any heavy article

on the sealant nor press it, otherwise it will become

deformed. Avoid storing the sealant for more than 6

months, because it will lose its sealing effect.

BODY PINCH-WELD FLANGE SERVICING

Before servicing the body pinch-weld flange, remove

old adhesive completely. If the flange requires paint

-

ing, bake it after painting is completed.

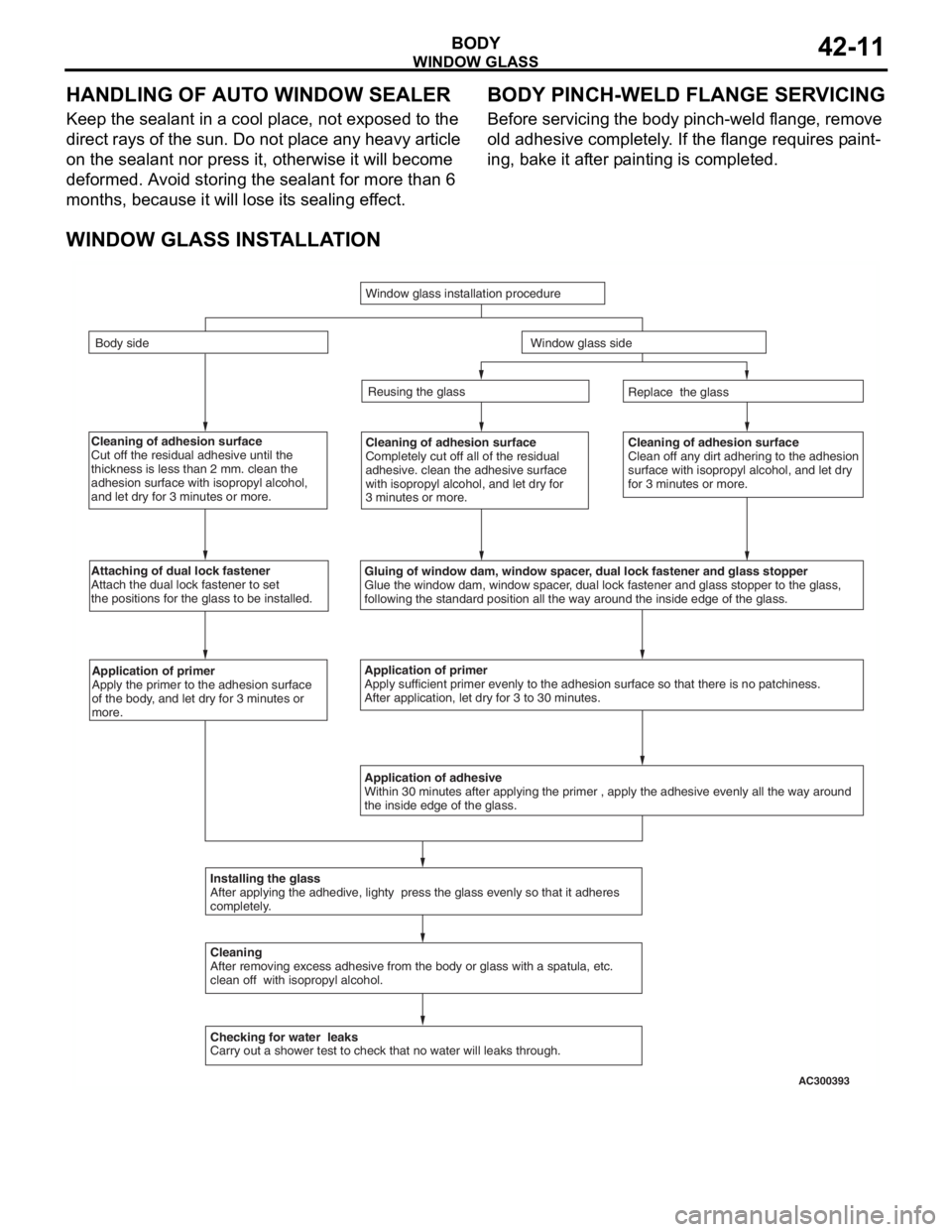

WINDOW GLASS INSTALLATION

Cleaning of adhesion surface

Cut off the residual adhesive until the

thickness is less than 2 mm. clean the

adhesion surface with isopropyl alcohol,

and let dry for 3 minutes or more.Cleaning of adhesion surface

Completely cut off all of the residual

adhesive. clean the adhesive surface

with isopropyl alcohol, and let dry for

3 minutes or more.Cleaning of adhesion surface

Clean off any dirt adhering to the adhesion

surface with isopropyl alcohol, and let dry

for 3 minutes or more.

Attaching of dual lock fastener

Attach the dual lock fastener to set

the positions for the glass to be installed.

Gluing of window dam, window spacer, dual lock fastener and glass stopper

Glue the window dam, window spacer, dual lock fastener and glass stopper to the glass,

following the standard position all the way around the inside edge of th\

e glass.

Application of primer

Apply the primer to the adhesion surface

of the body, and let dry for 3 minutes or

more.Application of primer

Apply sufficient primer evenly to the adhesion surface so that there is \

no patchiness.

After application, let dry for 3 to 30 minutes.

Application of adhesive

Within 30 minutes after applying the primer , apply the adhesive evenly \

all the way around

the inside edge of the glass.

Installing the glass

After applying the adhedive, lighty press the glass evenly so that it a\

dheres

completely.

Cleaning

After removing excess adhesive from the body or glass with a spatula, et\

c.

clean off with isopropyl alcohol.

Checking for water leaks

Carry out a shower test to check that no water will leaks through. Replace the glass

Reusing the glass

Window glass installation procedure

Body side

Window glass side

AC300393

Page 314 of 800

TRUNK LID

BODY42-42

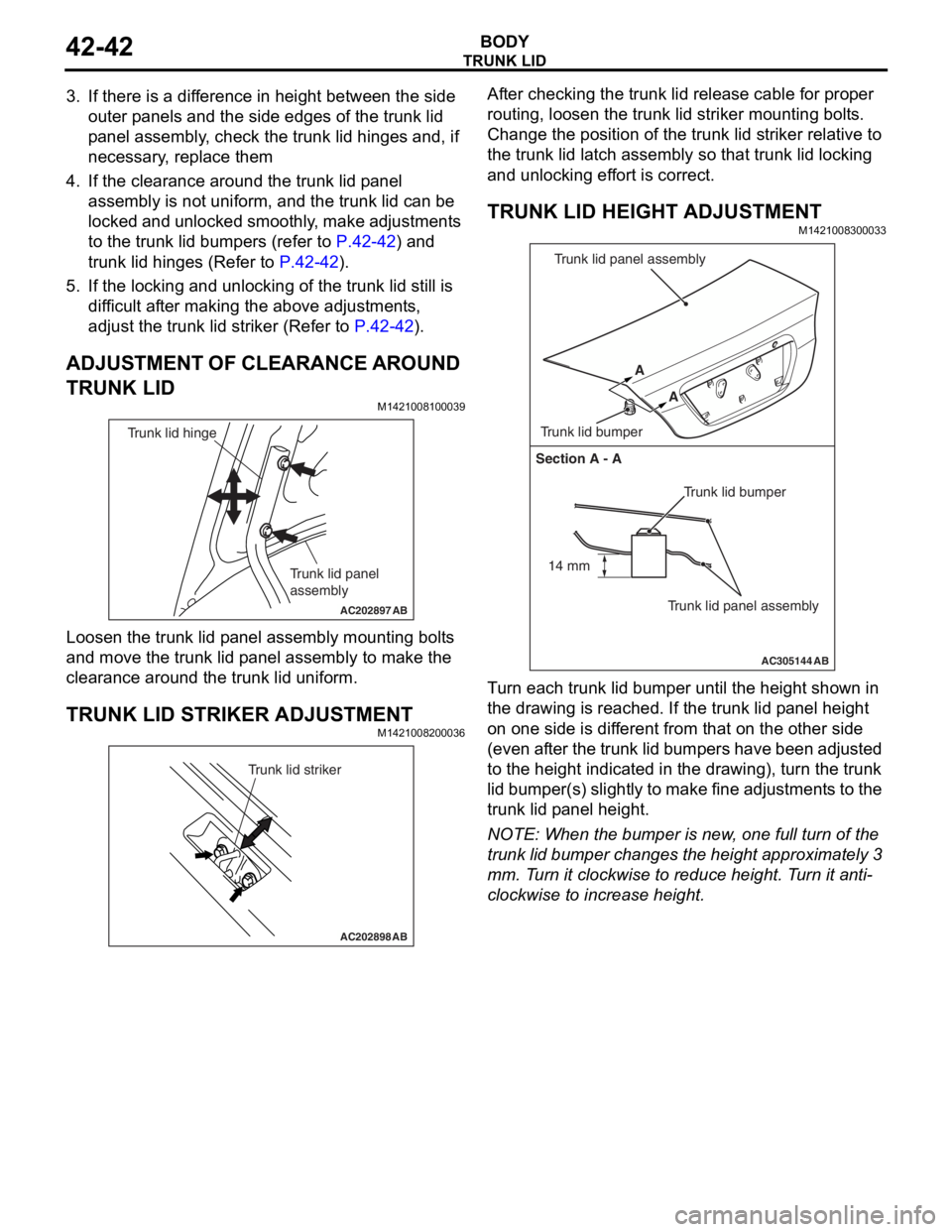

3. If there is a difference in height between the side outer panels and the side edges of the trunk lid

panel assembly, check the trunk lid hinges and, if

necessary, replace them

4. If the clearance around the trunk lid panel assembly is not uniform, and the trunk lid can be

locked and unlocked smoothly, make adjustments

to the trunk lid bumpers (refer to

P.42-42) and

trunk lid hinges (Refer to P.42-42).

5. If the locking and unlocking of the trunk lid still is difficult after making the above adjustments,

adjust the trunk lid striker (Refer to

P.42-42).

ADJUSTMENT OF CLEARANCE AROUND

TRUNK LID

M1421008100039

AC202897

Trunk lid panel

assembly

Trunk lid hinge

AB

Loosen the trunk lid p a nel a sse mbly mounting bolt s

and move

the trun k lid p anel assembly to make t he

clea

rance aroun d the t r unk lid u n iform.

TRUNK LID STRIKER ADJUSTMENT

M14210082 0003 6

AC202898

Trunk lid striker

AB

After checking the trunk lid relea s e cable for pro per

routin

g, lo osen the trun k lid striker mo untin g bolt s .

Ch

ange th e position of t he trunk lid st rike r relat i ve to

the trun

k lid la tch a s sembly so tha t trunk lid lockin g

and un

lockin g ef f o rt is corre ct.

TRUNK LID HEIGHT ADJUSTMENT

M14210083 0003 3

AC305144

Section A - A

Trunk lid bumper

Trunk lid panel assembly

A

A

Trunk lid bumper Trunk lid panel assembly

AB

14 mm

T

u rn each trun k lid bumper u n til the he ight shown in

the dra

w ing is reached. If the t r unk lid p a n e l he ight

on one

sid e is dif f erent from that on the oth e r side

(even

a f t e r th e t r un k lid bu mp ers have be en ad ju st ed

to the h

e igh t ind i ca ted in the dra w ing), tu rn the trunk

lid bumper(s)

slight ly to make fine adjustment s to the

trunk lid p

a nel h e ight .

NOTE: Whe n the b u mpe r is new , one full turn o f the

trunk lid bumper ch anges t he height appro x imately 3

mm.

T

u

rn it clockwise to r educe height. T u rn it anti

-

clockwise to increase height.

Page 329 of 800

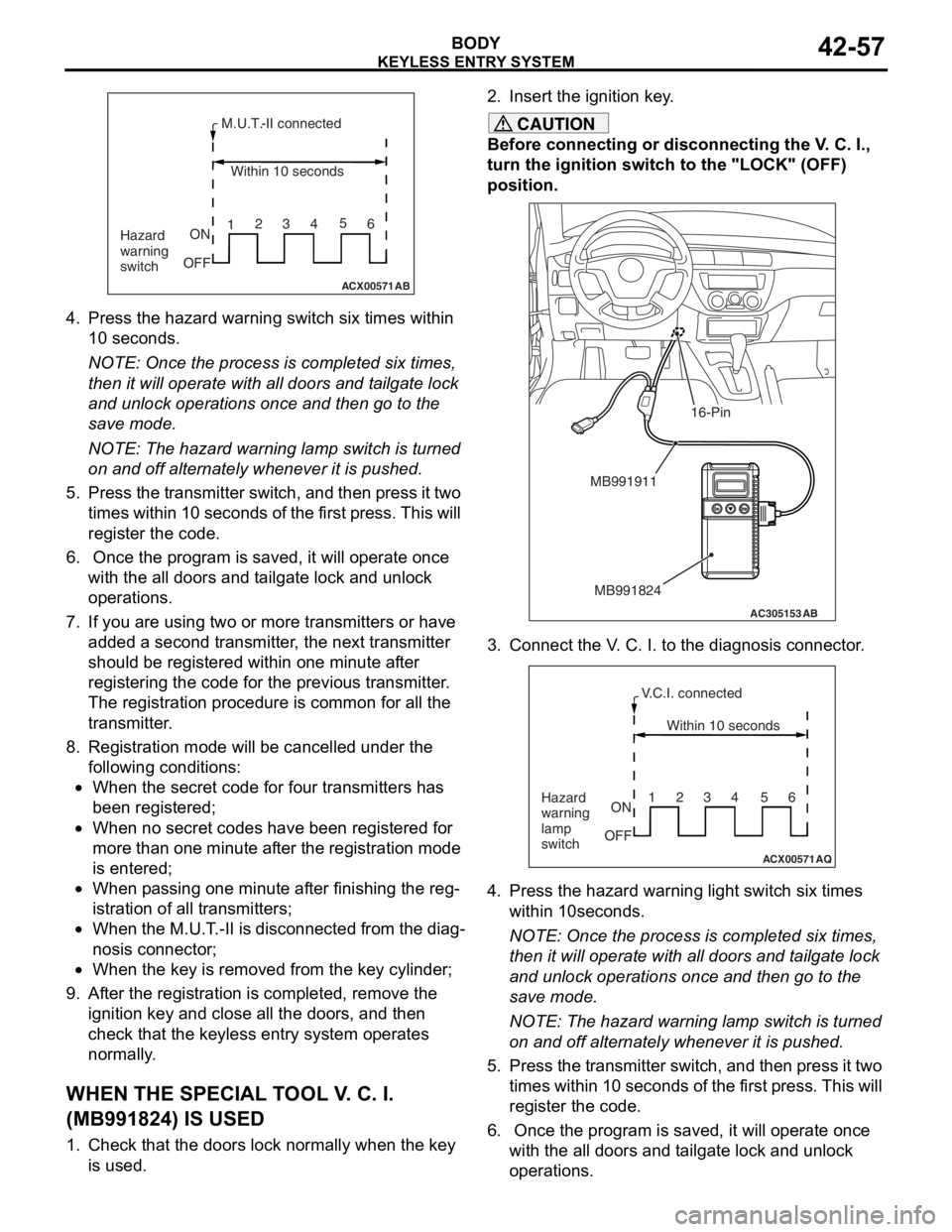

ACX00571

M.U.T.-II connectedWithin 10 seconds

Hazard

warning

switch ON

OFF 1

23

45

6

AB

KEYLE SS ENTR Y SYSTEM

BOD Y42-57

4.Press th e hazard warning switch six times within

10 seconds.

NOTE: Once th e process is comple ted six t i me s,

th

en it

will operate with al l do ors an d t a ilgate lock

an

d unlock opera t ions once and then go to th e

save

mode .

NOTE: The h a zard warnin g lamp switch is turned

on

and o ff alt e rnately when ever it is pushed.

5.Pre s s th e tr ansmitter switch, a nd then pre s s it two

t i mes within 10 second s of th e f i rst pre s s. This will

reg i st er the code.

6. Once the p r ogram is saved, it will opera t e once

wit h the a ll d oors a nd t a ilgate lock and unlo ck

op erations.

7.If you a r e using t w o or mo re transmitters or have

ad ded a second tra n smitter , the n e xt tra n smitter

should be re gistered within o ne minute af ter

reg i st ering the code fo r the pre v io us tra n smitter .

Th e registration pr oced ure is co mmo n for a ll th e

tra n smitter .

8.Registra tion mode will be ca ncelled under the

fo llowing condit i ons:

‚ÄĘWhen the secr et co de for fo ur transmitters has

bee

n registere d ;

‚ÄĘWhen no secre t cod e s h a ve b een re gist ered fo r

more tha

n one minute af ter the registration mode

is ente

r ed;

‚ÄĘWhen p a ssing o ne minute af ter fin i sh ing t he reg-

istration of all t r ansmitte rs;

‚ÄĘWhen the M.U.T . -II is d i sconne cted from th e dia g-

nosis connecto r;

‚ÄĘWhen the key is re moved fro m the key cylin der;

9.Af ter the registration is completed, remove the

ignition key a nd close all the d oors, and th en

check tha t the keyless entry syste m op erates

no rmally .

WH EN THE SPECIAL T O OL V . C. I.

(

M B991824) I S USED

1.Check t hat the doors lock n o rmally wh en the key

is used.

2. In sert t he ig nition ke y .

CAUTION

Before connecting or disconnecting the V. C. I.,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305153AB

MB991911

MB991824

16-Pin

3. Connect the V. C. I. to the diagnosis connector.

ACX00571

Within 10 seconds

Hazard

warning

lamp

switch ON

OFF 1234 56

AQ

V.C.I. connected

4. Press the hazard warning

light switch six times

within 10seconds.

NOTE: Once the process is completed six times,

then it will operate with all doors and tailgate lock

and unlock operations once and then go to the

save mode.

NOTE: The hazard warning lamp switch is turned

on and off alternately whenever it is pushed.

5. Press the transmitter switch, and then press it two times within 10 seconds of the first press. This will

register the code.

6. Once the program is saved, it will operate once with the all doors and tailgate lock and unlock

operations.

Page 466 of 800

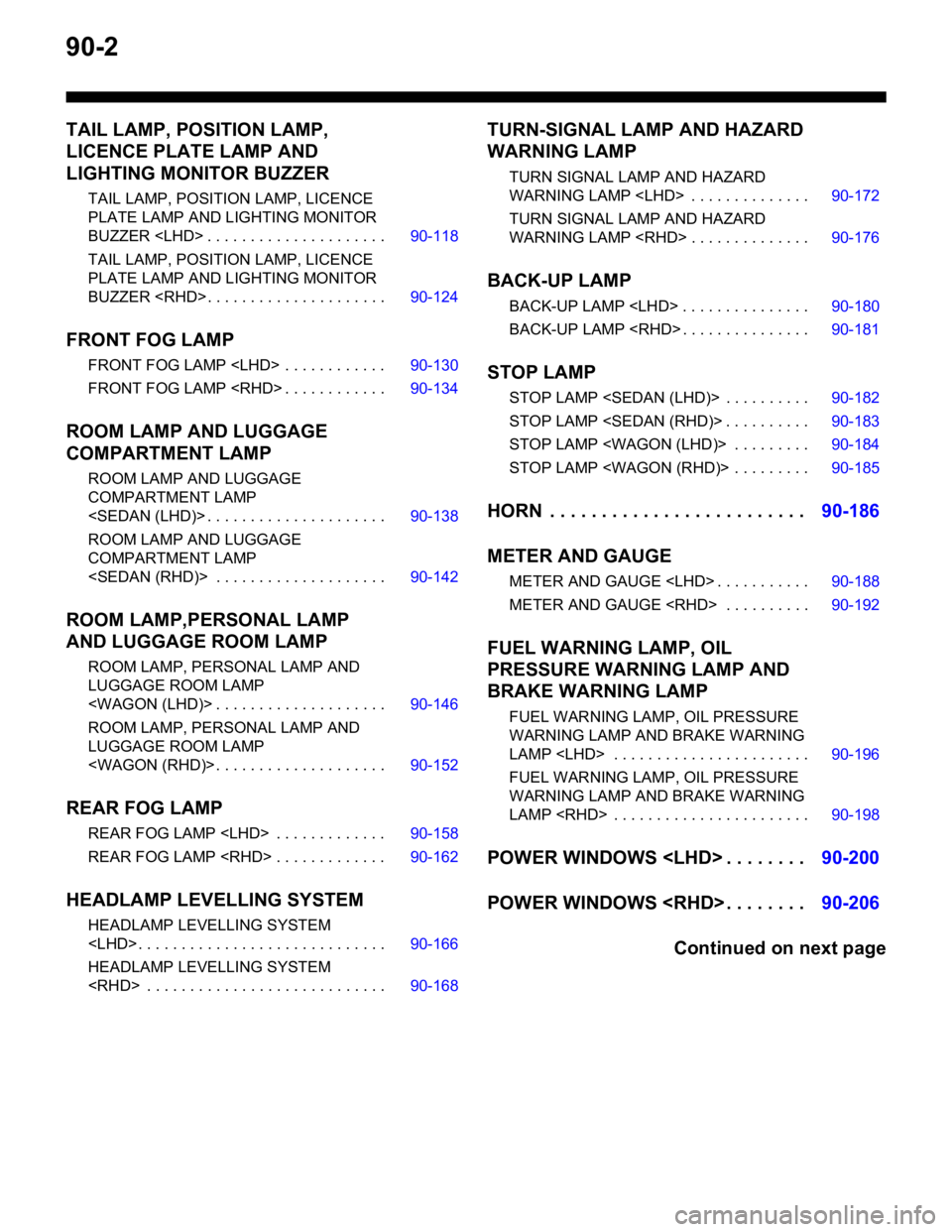

90-2

TAIL LAMP, POSITION LAMP,

LICENCE PLATE LAMP AND

LIGHTING MONITOR BUZZER

TAIL LAMP, POSITION LAMP, LICENCE

PLATE LAMP AND LIGHTING MONITOR

BUZZER

TAIL LAMP, POSITION LAMP, LICENCE

PLATE LAMP AND LIGHTING MONITOR

BUZZER

FRONT FOG LAMP

FRONT FOG LAMP

FRONT FOG LAMP

ROOM LAMP AND LUGGAGE

COMPARTMENT LAMP

ROOM LAMP AND LUGGAGE

COMPARTMENT LAMP

ROOM LAMP AND LUGGAGE

COMPARTMENT LAMP

ROOM LAMP,PERSONAL LAMP

AND LUGGAGE ROOM LAMP

ROOM LAMP, PERSONAL LAMP AND

LUGGAGE ROOM LAMP

ROOM LAMP, PERSONAL LAMP AND

LUGGAGE ROOM LAMP

REAR FOG LAMP

REAR FOG LAMP

REAR FOG LAMP

HEADLAMP LEVELLING SYSTEM

HEADLAMP LEVELLING SYSTEM

HEADLAMP LEVELLING SYSTEM

TURN-SIGNAL LAMP AND HAZARD

WARNING LAMP

TURN SIGNAL LAMP AND HAZARD

WARNING LAMP

TURN SIGNAL LAMP AND HAZARD

WARNING LAMP

BACK-UP LAMP

BACK-UP LAMP

BACK-UP LAMP

STOP LAMP

STOP LAMP

STOP LAMP

STOP LAMP

STOP LAMP

HORN . . . . . . . . . . . . . . . . . . . . . . . . .90-186

METER AND GAUGE

METER AND GAUGE

METER AND GAUGE

FUEL WARNING LAMP, OIL

PRESSURE WARNING LAMP AND

BRAKE WARNING LAMP

FUEL WARNING LAMP, OIL PRESSURE

WARNING LAMP AND BRAKE WARNING

LAMP

FUEL WARNING LAMP, OIL PRESSURE

WARNING LAMP AND BRAKE WARNING

LAMP

POWER WINDOWS

POWER WINDOWS

Continued on next page

Page 470 of 800

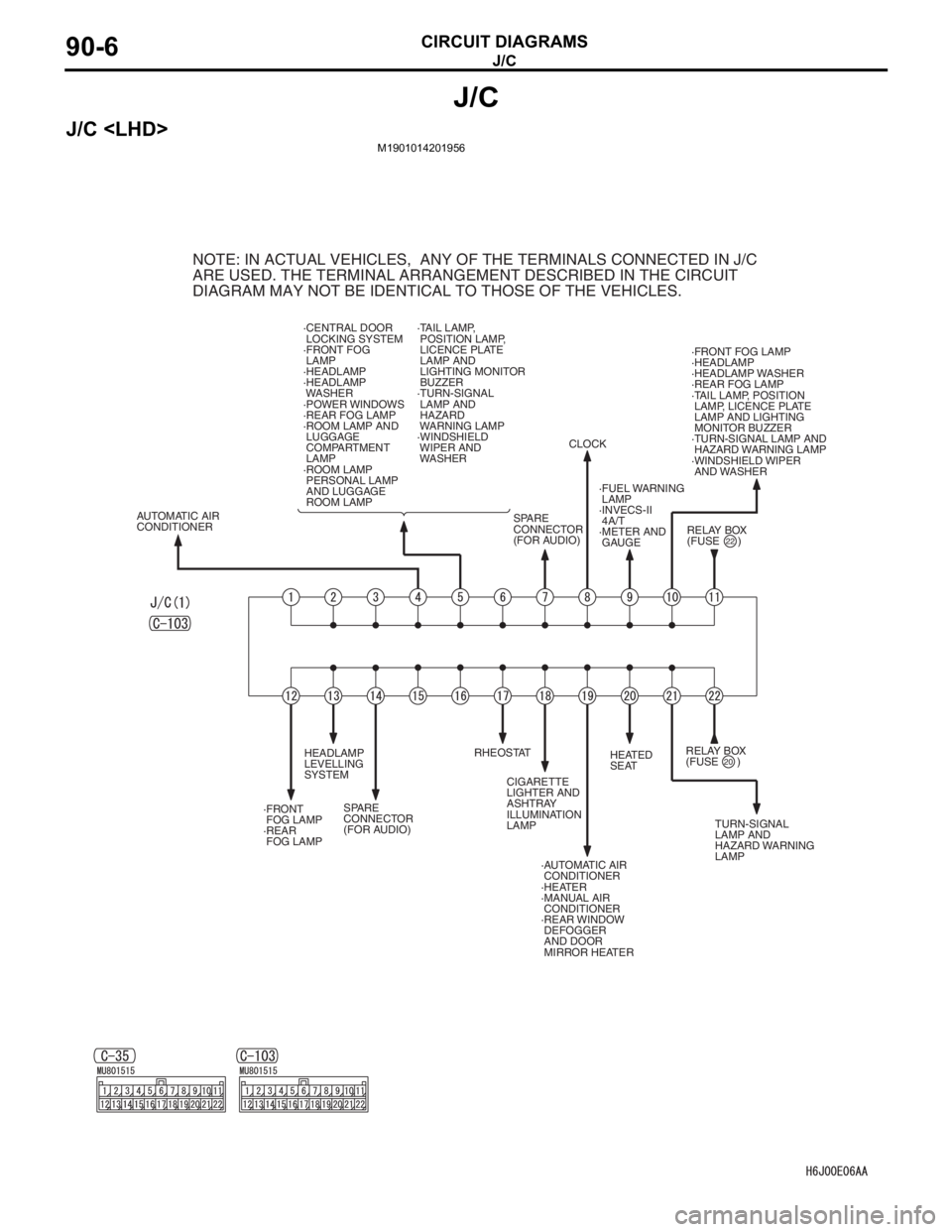

J/C

CIRCUIT DIAGRAMS90-6

J/C

J/C

NOTE: IN ACTUAL VEHICLES, ANY OF THE TERMINALS CONNECTED IN J/C

ARE USED. THE TERMINAL ARRANGEMENT DESCRIBED IN THE CIRCUIT

DIAGRAM MAY NOT BE IDENTICAL TO THOSE OF THE VEHICLES.

·CENTRAL DOOR

LOCKING SYSTEM

·FRONT FOG

LAMP

·HEADLAMP

·HEADLAMP

WASHER

·POWER WINDOWS

·REAR FOG LAMP

·ROOM LAMP AND

LUGGAGE

COMPARTMENT

LAMP

·ROOM LAMP

PERSONAL LAMP

AND LUGGAGE

ROOM LAMP ·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND

LIGHTING MONITOR

BUZZER

·TURN-SIGNAL

LAMP AND

HAZARD

WARNING LAMP

·WINDSHIELD

WIPER AND

WASHER

RELAY BOX

(FUSE )·FRONT FOG LAMP

·HEADLAMP

·HEADLAMP WASHER

·REAR FOG LAMP

·TAIL LAMP, POSITION

LAMP, LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·TURN-SIGNAL LAMP AND

HAZARD WARNING LAMP

·WINDSHIELD WIPER

AND WASHER

SPARE

CONNECTOR

(FOR AUDIO)CLOCK

·FUEL WARNING

LAMP

·INVECS-II

4A/T

·METER AND

GAUGE

RELAY BOX

(FUSE )

TURN-SIGNAL

LAMP AND

HAZARD WARNING

LAMP HEATED

SEAT

·AUTOMATIC AIR

CONDITIONER

·HEATER

·MANUAL AIR

CONDITIONER

·REAR WINDOW

DEFOGGER

AND DOOR

MIRROR HEATER CIGARETTE

LIGHTER AND

ASHTRAY

ILLUMINATION

LAMP RHEOSTAT

SPARE

CONNECTOR

(FOR AUDIO) HEADLAMP

LEVELLING

SYSTEM

·FRONT

FOG LAMP

·REAR

FOG LAMP

20

22

AUTOMATIC AIR

CONDITIONER

Page 471 of 800

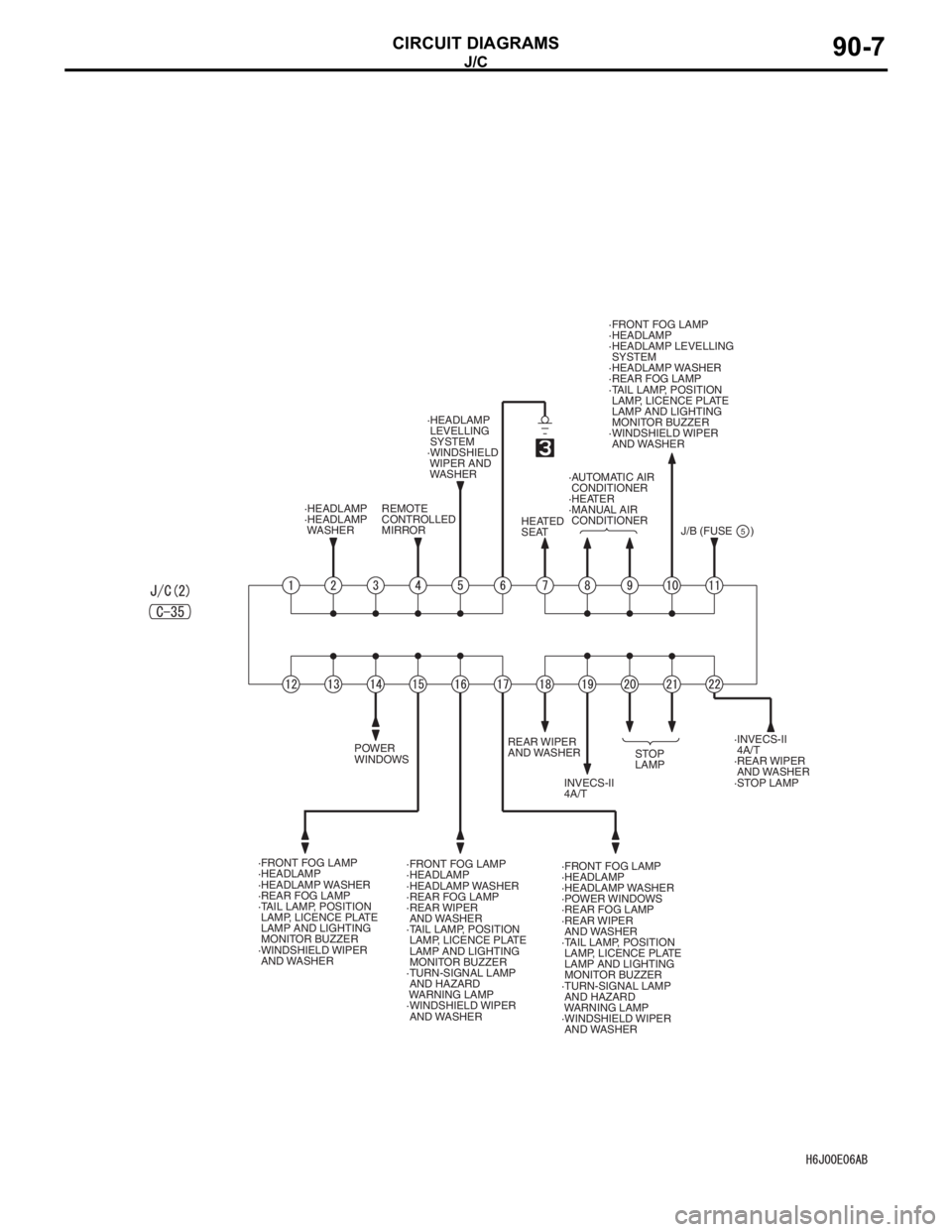

J/C

CIRCUIT DIAGRAMS90-7

REAR WIPER

AND WASHER

·FRONT FOG LAMP

·HEADLAMP

·HEADLAMP WASHER

·REAR FOG LAMP

·TAIL LAMP, POSITION

LAMP, LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·WINDSHIELD WIPER

AND WASHERINVECS-II

4A/T POWER

WINDOWSSTOP

LAMP·INVECS-II

4A/T

·REAR WIPER

AND WASHER

·STOP LAMP

·FRONT FOG LAMP

·HEADLAMP

·HEADLAMP WASHER

·REAR FOG LAMP

·REAR WIPER

AND WASHER

·TAIL LAMP, POSITION

LAMP, LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·TURN-SIGNAL LAMP

AND HAZARD

WARNING LAMP

·WINDSHIELD WIPER

AND WASHER·FRONT FOG LAMP

·HEADLAMP

·HEADLAMP WASHER

·POWER WINDOWS

·REAR FOG LAMP

·REAR WIPER

AND WASHER

·TAIL LAMP, POSITION

LAMP, LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·TURN-SIGNAL LAMP

AND HAZARD

WARNING LAMP

·WINDSHIELD WIPER

AND WASHER·FRONT FOG LAMP

·HEADLAMP

·HEADLAMP LEVELLING

SYSTEM

·HEADLAMP WASHER

·REAR FOG LAMP

·TAIL LAMP, POSITION

LAMP, LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·WINDSHIELD WIPER

AND WASHER

·AUTOMATIC AIR

CONDITIONER

·HEATER

·MANUAL AIR

CONDITIONER

J/B (FUSE ) HEATED

SEAT ·HEADLAMP

LEVELLING

SYSTEM

·WINDSHIELD

WIPER AND

WASHER

REMOTE

CONTROLLED

MIRROR ·HEADLAMP

·HEADLAMP

WASHER

5