fuel MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1337 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-17

Inspection procedure 3

Fuel gauge inoperative (other meters are operated)

Probable cause

When speedometer and tachometer are properly operated, harness from power

source to combination meter is normal.DFuel gauge unit fault

DHarness or connector fault

DMeter assembly fault

OKReplace main fuel gauge unit.

NG

Check harness from main fuel gauge unit to combination

meter.Repair

Check trouble symptom.

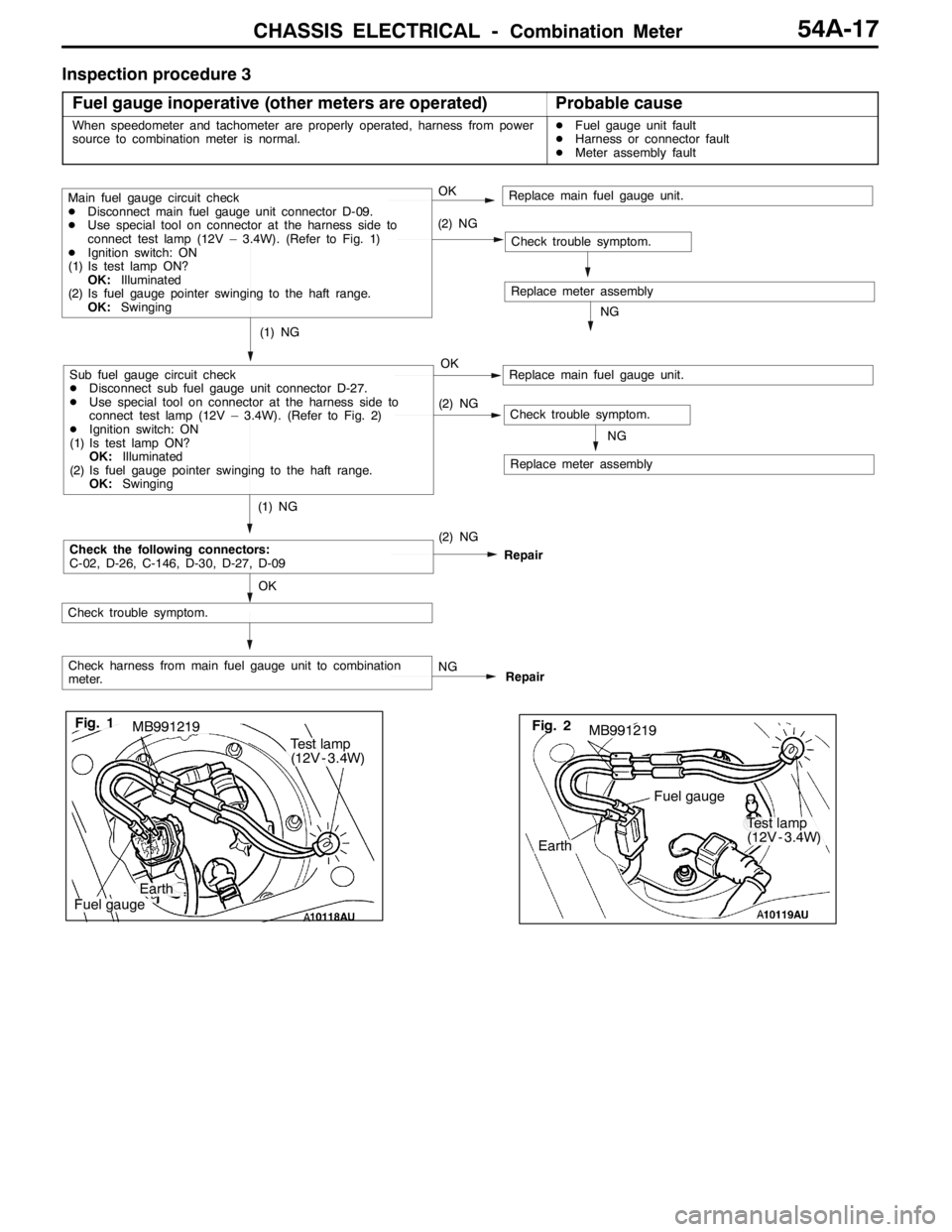

Main fuel gauge circuit check

DDisconnect main fuel gauge unit connector D-09.

DUse special tool on connector at the harness side to

connect test lamp (12V – 3.4W). (Refer to Fig. 1)

DIgnition switch: ON

(1) Is test lamp ON?

OK:Illuminated

(2) Is fuel gauge pointer swinging to the haft range.

OK:Swinging

(1) NG

Fig. 1MB991219

Earth

Fuel gauge

Test lamp

(12V - 3.4W)

Repair

Check trouble symptom.

Check the following connectors:

C-02, D-26, C-146, D-30, D-27, D-09

Earth

Test lamp

(12V - 3.4W)

Fuel gauge

MB991219Fig. 2

Sub fuel gauge circuit check

DDisconnect sub fuel gauge unit connector D-27.

DUse special tool on connector at the harness side to

connect test lamp (12V – 3.4W). (Refer to Fig. 2)

DIgnition switch: ON

(1) Is test lamp ON?

OK:Illuminated

(2) Is fuel gauge pointer swinging to the haft range.

OK:Swinging

Replace meter assembly

OK (2) NG

(2) NG

Check trouble symptom.

Replace meter assemblyNG

Replace main fuel gauge unit.

(1) NG

OK

NG (2) NG

Page 1340 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-20

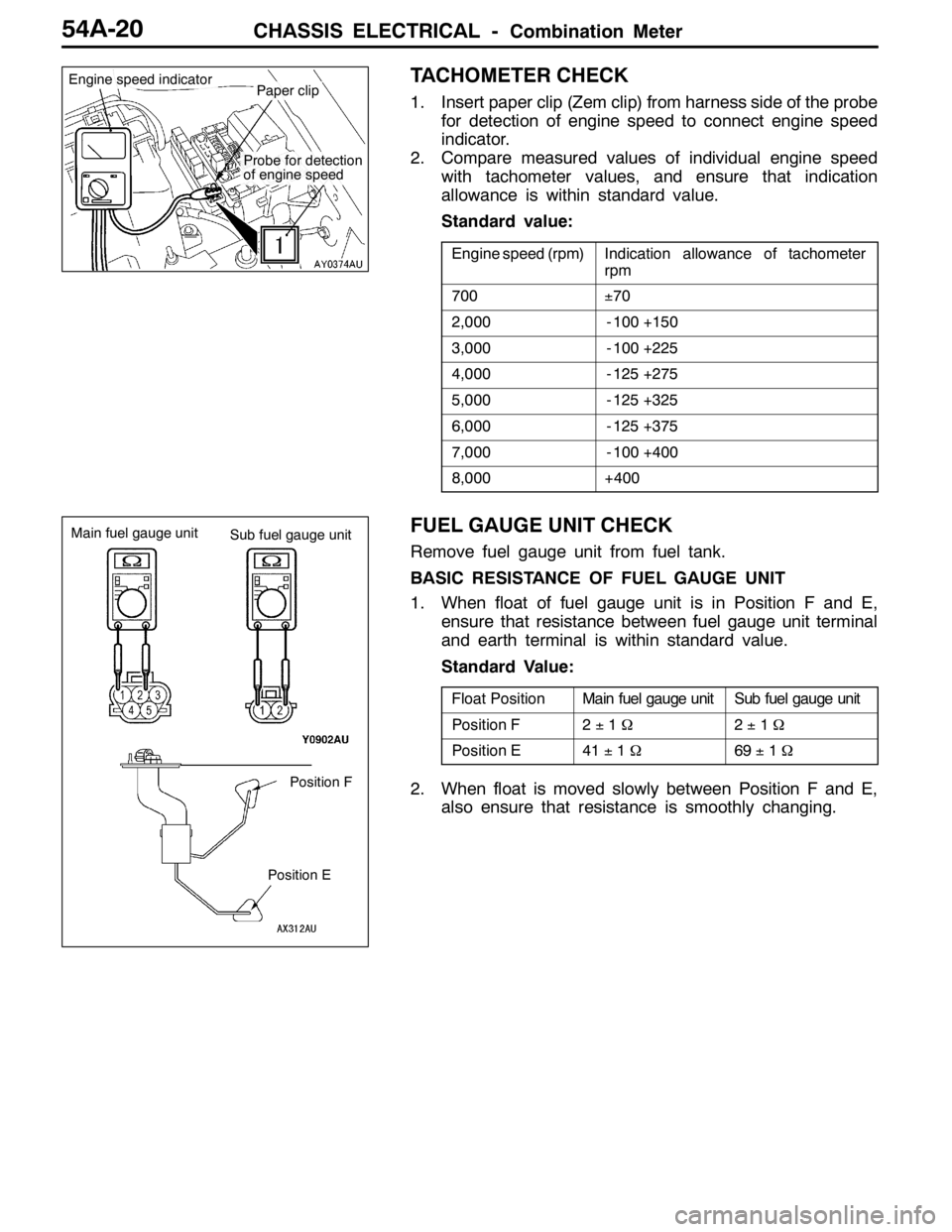

TACHOMETER CHECK

1. Insert paper clip (Zem clip) from harness side of the probe

for detection of engine speed to connect engine speed

indicator.

2. Compare measured values of individual engine speed

with tachometer values, and ensure that indication

allowance is within standard value.

Standard value:

Engine speed (rpm)Indication allowance of tachometer

rpm

700±70

2,000- 100 +150

3,000- 100 +225

4,000- 125 +275

5,000- 125 +325

6,000- 125 +375

7,000- 100 +400

8,000+400

FUEL GAUGE UNIT CHECK

Remove fuel gauge unit from fuel tank.

BASIC RESISTANCE OF FUEL GAUGE UNIT

1. When float of fuel gauge unit is in Position F and E,

ensure that resistance between fuel gauge unit terminal

and earth terminal is within standard value.

Standard Value:

Float PositionMain fuel gauge unitSub fuel gauge unit

Position F2±1Ω2±1Ω

Position E41±1Ω69±1Ω

2. When float is moved slowly between Position F and E,

also ensure that resistance is smoothly changing.

Paper clipEngine speed indicator

Probe for detection

of engine speed

Position F

Position E Main fuel gauge unit

Sub fuel gauge unit

Page 1341 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-21

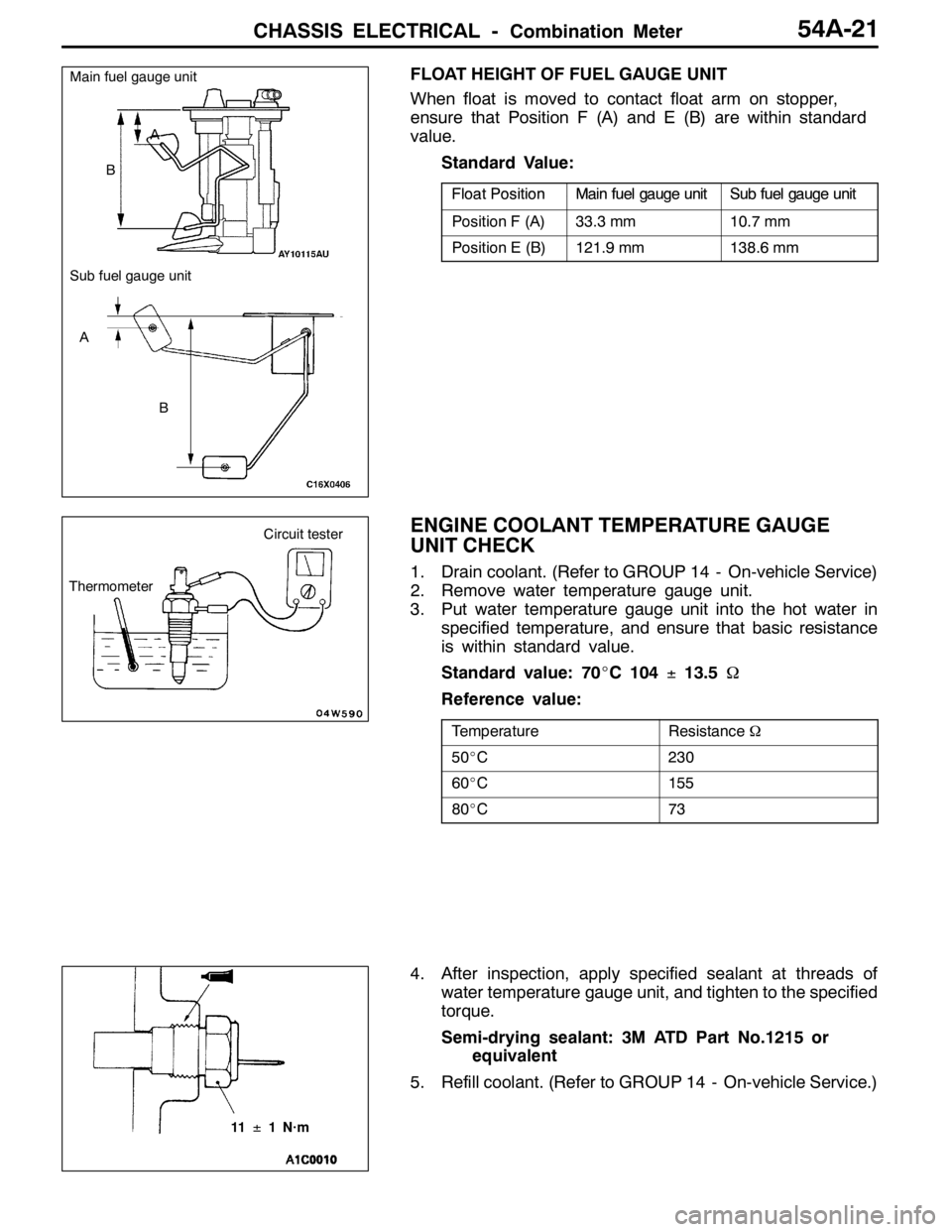

FLOAT HEIGHT OF FUEL GAUGE UNIT

When float is moved to contact float arm on stopper,

ensure that Position F (A) and E (B) are within standard

value.

Standard Value:

FloatPositionMainfuelgaugeunitSubfuelgaugeunitFloatPositionMainfuelgaugeunitSubfuelgaugeunit

Position F (A)33.3 mm10.7 mm

Position E (B)121.9 mm138.6 mm

ENGINE COOLANT TEMPERATURE GAUGE

UNIT CHECK

1. Drain coolant. (Refer to GROUP 14 - On-vehicle Service)

2. Remove water temperature gauge unit.

3. Put water temperature gauge unit into the hot water in

specified temperature, and ensure that basic resistance

is within standard value.

Standard value: 70_C 104±13.5Ω

Reference value:

TemperatureResistanceΩ

50_C230

60_C155

80_C73

4. After inspection, apply specified sealant at threads of

water temperature gauge unit, and tighten to the specified

torque.

Semi-drying sealant: 3M ATD Part No.1215 or

equivalent

5. Refill coolant. (Refer to GROUP 14 - On-vehicle Service.)

Main fuel gauge unit

Sub fuel gauge unit

A

B

A

B

ThermometerCircuit tester

11±1 N·m

Page 1342 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-22

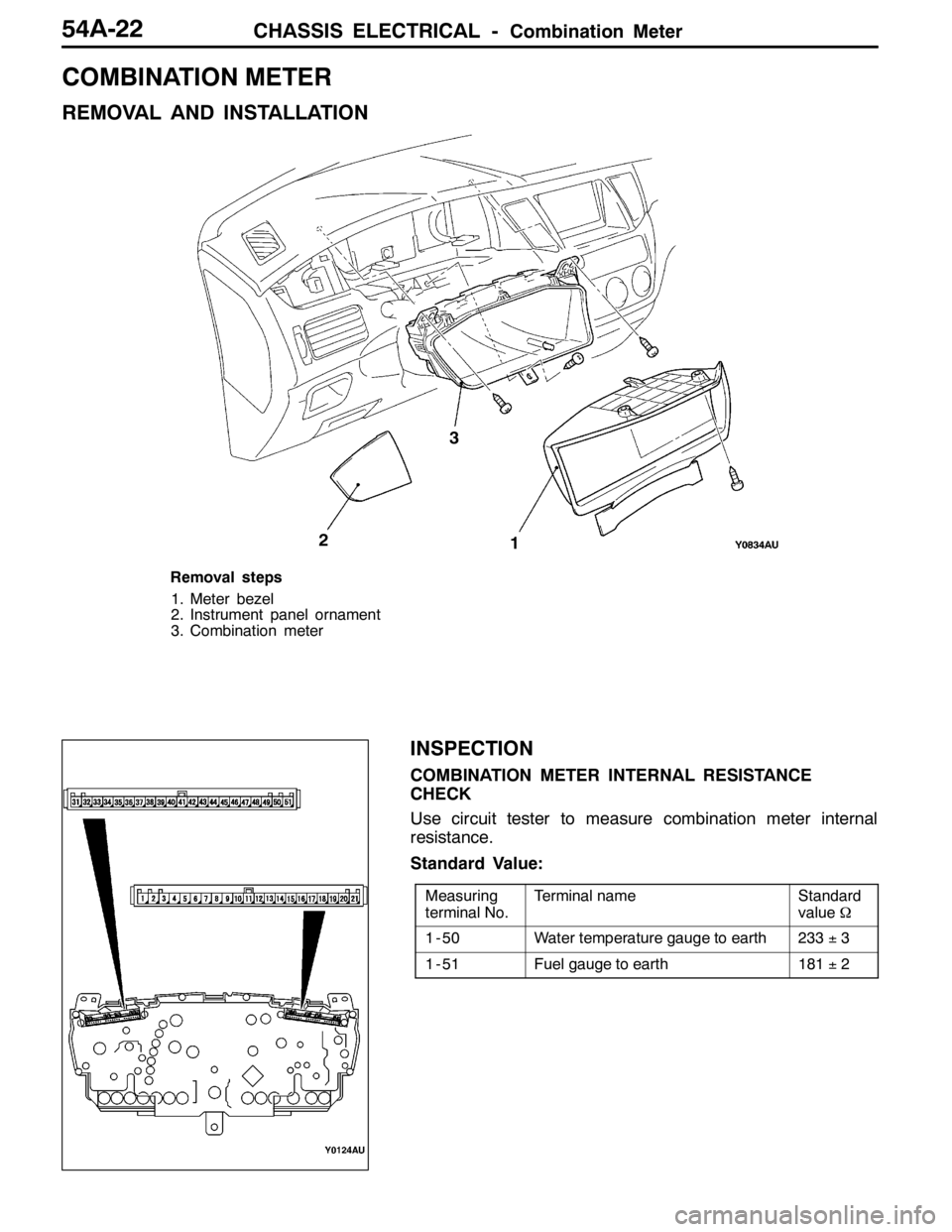

COMBINATION METER

REMOVAL AND INSTALLATION

3

1 2

Removal steps

1. Meter bezel

2. Instrument panel ornament

3. Combination meter

INSPECTION

COMBINATION METER INTERNAL RESISTANCE

CHECK

Use circuit tester to measure combination meter internal

resistance.

Standard Value:

Measuring

terminal No.Terminal nameStandard

valueΩ

1-50Water temperature gauge to earth233±3

1-51Fuel gauge to earth181±2

Page 1345 of 1449

CHASSIS ELECTRICAL -Headlamp Assembly54A-25

4. If the fuel tank is not full, place a weight in luggage room

of vehicle to simulate weight of a full tank 0.8 kg per litre.

5. There should be no other load in the vehicle other than

driver or substituted weight of approximately 75 kg placed

in driver’s position.

6. Thoroughly clean headlamp lenses.

7. Place the vehicle on a level floor, perpendicular to a flat

screen 10m away from the bulb center - marks on the

headlamp lens.

8. Rock vehicle sideways to allow vehicle to assume its

normal position.

9. Bounce the front suspension through three (3) oscillations

by applying the body weight to hood or bumper.

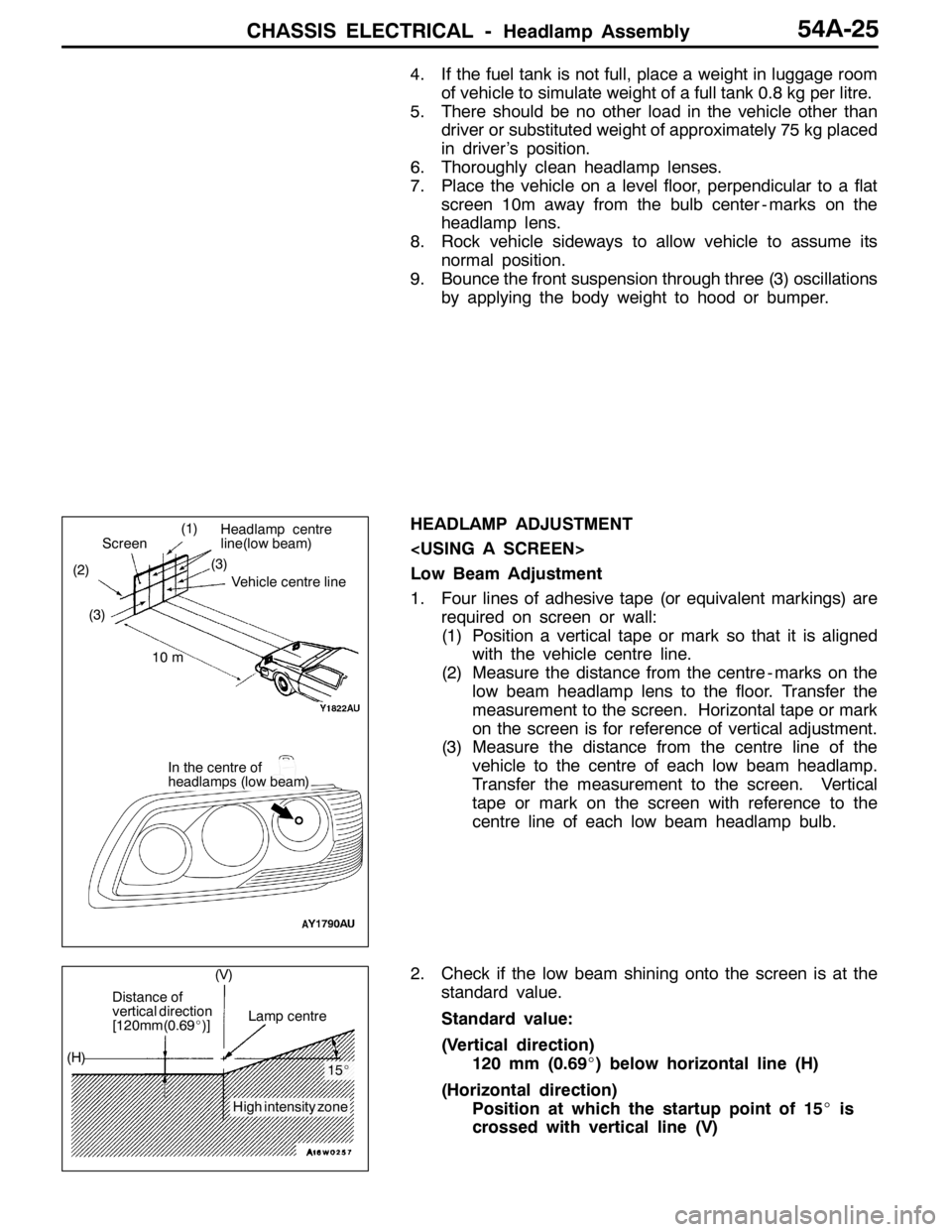

HEADLAMP ADJUSTMENT

Low Beam Adjustment

1. Four lines of adhesive tape (or equivalent markings) are

required on screen or wall:

(1) Position a vertical tape or mark so that it is aligned

with the vehicle centre line.

(2) Measure the distance from the centre - marks on the

low beam headlamp lens to the floor. Transfer the

measurement to the screen. Horizontal tape or mark

on the screen is for reference of vertical adjustment.

(3) Measure the distance from the centre line of the

vehicle to the centre of each low beam headlamp.

Transfer the measurement to the screen. Vertical

tape or mark on the screen with reference to the

centre line of each low beam headlamp bulb.

2. Check if the low beam shining onto the screen is at the

standard value.

Standard value:

(Vertical direction)

120 mm (0.69_) below horizontal line (H)

(Horizontal direction)

Position at which the startup point of 15_is

crossed with vertical line (V)

(1)

(2)(3)

Headlamp centre

line(low beam)

Vehicle centre line

Screen

10 m

In the centre of

headlamps (low beam) (3)

Distance of

vertical direction

[120mm(0.69_)]Lamp centre

15_

High intensity zone (H)(V)