ad blue MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 167 of 1449

CIRCUIT DIAGRAMSB-69

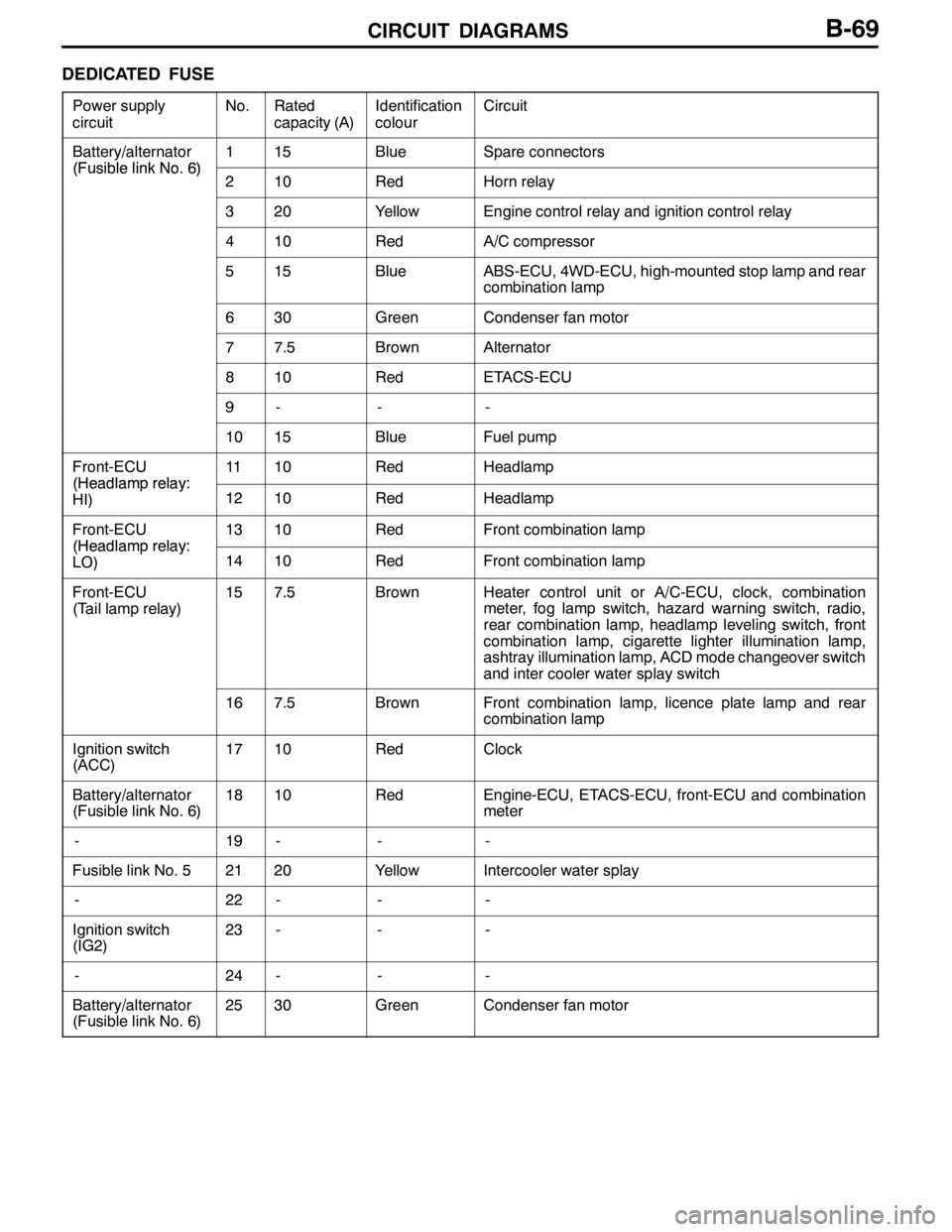

DEDICATED FUSE

Power supply

circuitNo.Rated

capacity (A)Identification

colourCircuit

Battery/alternator

(FusiblelinkNo6)

115BlueSpare connectors

(FusiblelinkNo.6)210RedHorn relay

320YellowEngine control relay and ignition control relay

410RedA/C compressor

515BlueABS-ECU, 4WD-ECU, high-mounted stop lamp and rear

combination lamp

630GreenCondenser fan motor

77.5BrownAlternator

810RedETACS-ECU

9---

1015BlueFuel pump

Front-ECU

(Headlamprelay:

1110RedHeadlamp

(Headlamp relay:

HI)1210RedHeadlamp

Front-ECU

(Headlamprelay:

1310RedFront combination lamp

(Headlamp relay:

LO)1410RedFront combination lamp

Front-ECU

(Tail lamp relay)157.5BrownHeater control unit or A/C-ECU, clock, combination

meter, fog lamp switch, hazard warning switch, radio,

rear combination lamp, headlamp leveling switch, front

combination lamp, cigarette lighter illumination lamp,

ashtray illumination lamp, ACD mode changeover switch

and inter cooler water splay switch

167.5BrownFront combination lamp, licence plate lamp and rear

combination lamp

Ignition switch

(ACC)1710RedClock

Battery/alternator

(Fusible link No. 6)1810RedEngine-ECU, ETACS-ECU, front-ECU and combination

meter

-19---

Fusible link No. 52120YellowIntercooler water splay

-22---

Ignition switch

(IG2)23---

-24---

Battery/alternator

(Fusible link No. 6)2530GreenCondenser fan motor

Page 169 of 1449

CIRCUIT DIAGRAMSB-71

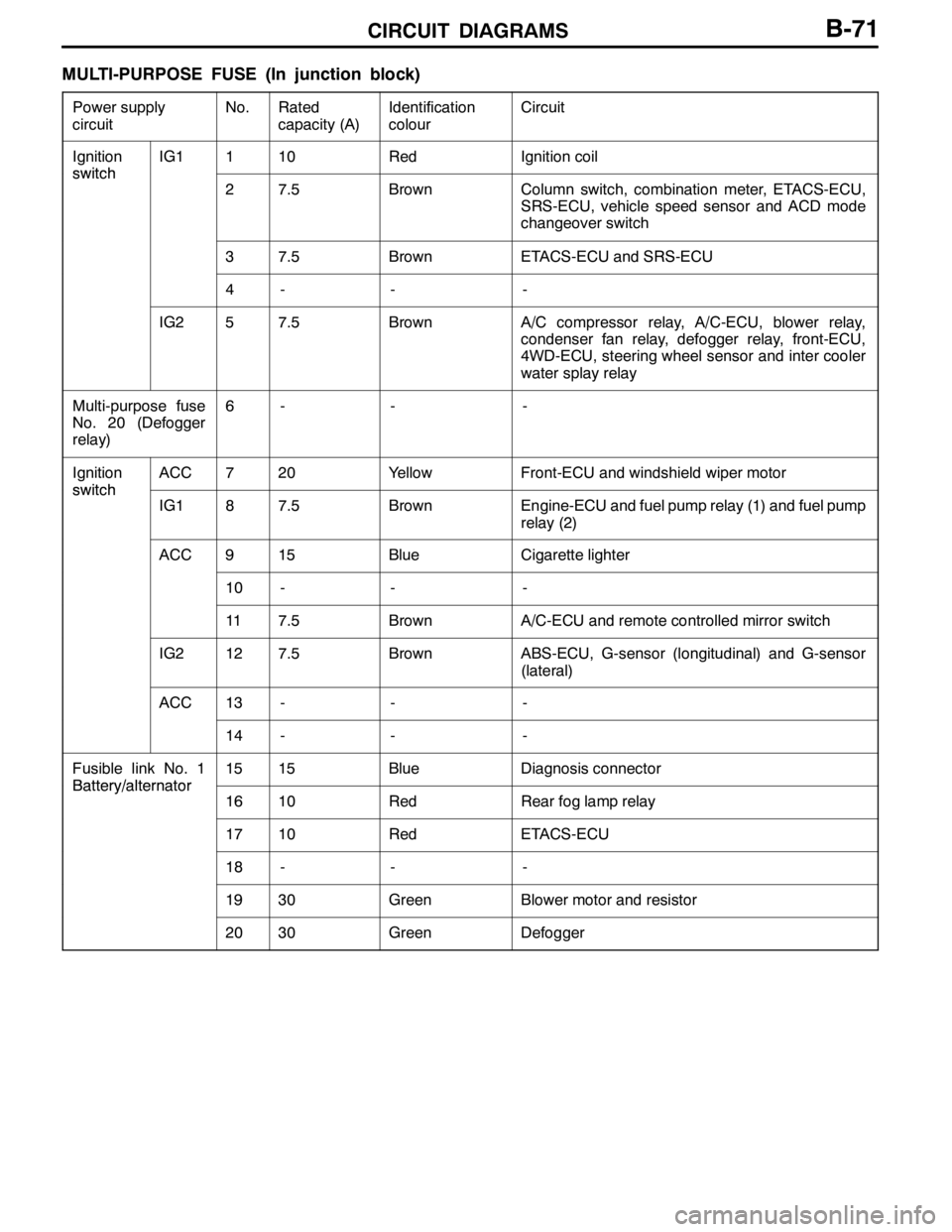

MULTI-PURPOSE FUSE (In junction block)

Power supply

circuitNo.Rated

capacity (A)Identification

colourCircuit

Ignition

switch

IG1110RedIgnition coil

switch

27.5BrownColumn switch, combination meter, ETACS-ECU,

SRS-ECU, vehicle speed sensor and ACD mode

changeover switch

37.5BrownETACS-ECU and SRS-ECU

4---

IG257.5BrownA/C compressor relay, A/C-ECU, blower relay,

condenser fan relay, defogger relay, front-ECU,

4WD-ECU, steering wheel sensor and inter cooler

water splay relay

Multi-purpose fuse

No. 20 (Defogger

relay)6---

Ignition

switch

ACC720YellowFront-ECU and windshield wiper motor

switch

IG187.5BrownEngine-ECU and fuel pump relay (1) and fuel pump

relay (2)

ACC915BlueCigarette lighter

10---

117.5BrownA/C-ECU and remote controlled mirror switch

IG2127.5BrownABS-ECU, G-sensor (longitudinal) and G-sensor

(lateral)

ACC13---

14---

Fusible link No. 1

Battery/alternator

1515BlueDiagnosis connector

Battery/alternator

1610RedRear fog lamp relay

1710RedETACS-ECU

18---

1930GreenBlower motor and resistor

2030GreenDefogger

Page 513 of 1449

ENGINE OVERHAUL -Piston and Connecting Rod11B-59

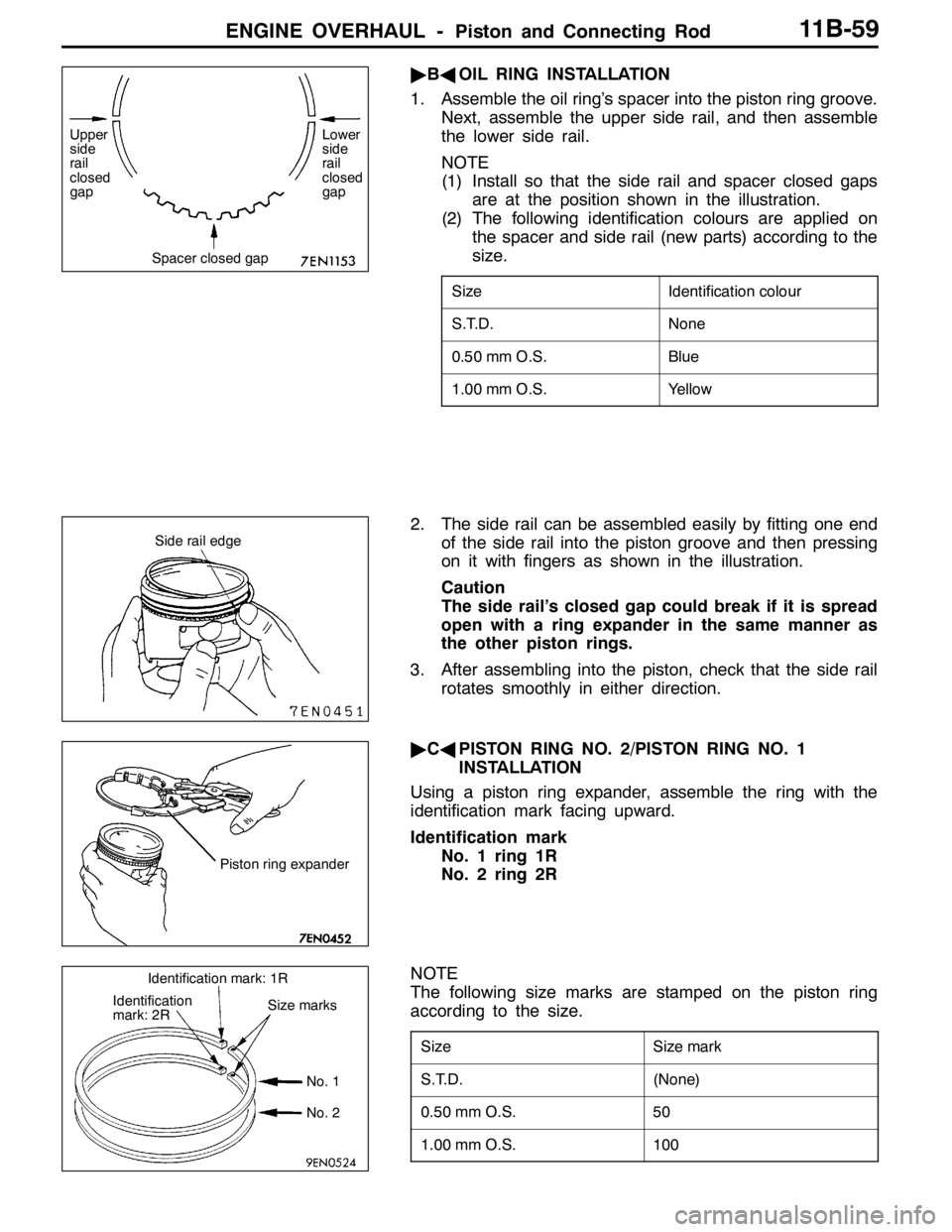

"BAOIL RING INSTALLATION

1. Assemble the oil ring’s spacer into the piston ring groove.

Next, assemble the upper side rail, and then assemble

the lower side rail.

NOTE

(1) Install so that the side rail and spacer closed gaps

are at the position shown in the illustration.

(2) The following identification colours are applied on

the spacer and side rail (new parts) according to the

size.

SizeIdentification colour

S.T.D.None

0.50 mm O.S.Blue

1.00 mm O.S.Yellow

2. The side rail can be assembled easily by fitting one end

of the side rail into the piston groove and then pressing

on it with fingers as shown in the illustration.

Caution

The side rail’s closed gap could break if it is spread

open with a ring expander in the same manner as

the other piston rings.

3. After assembling into the piston, check that the side rail

rotates smoothly in either direction.

"CAPISTON RING NO. 2/PISTON RING NO. 1

INSTALLATION

Using a piston ring expander, assemble the ring with the

identification mark facing upward.

Identification mark

No. 1 ring 1R

No. 2 ring 2R

NOTE

The following size marks are stamped on the piston ring

according to the size.

SizeSize mark

S.T.D.(None)

0.50 mm O.S.50

1.00 mm O.S.100

Spacer closed gap Upper

side

rail

closed

gapLower

side

rail

closed

gap

Side rail edge

Piston ring expander

Identification

mark: 2RSize marks

No. 1

No. 2 Identification mark: 1R

Page 666 of 1449

MPI -On-vehicle Service13A-134

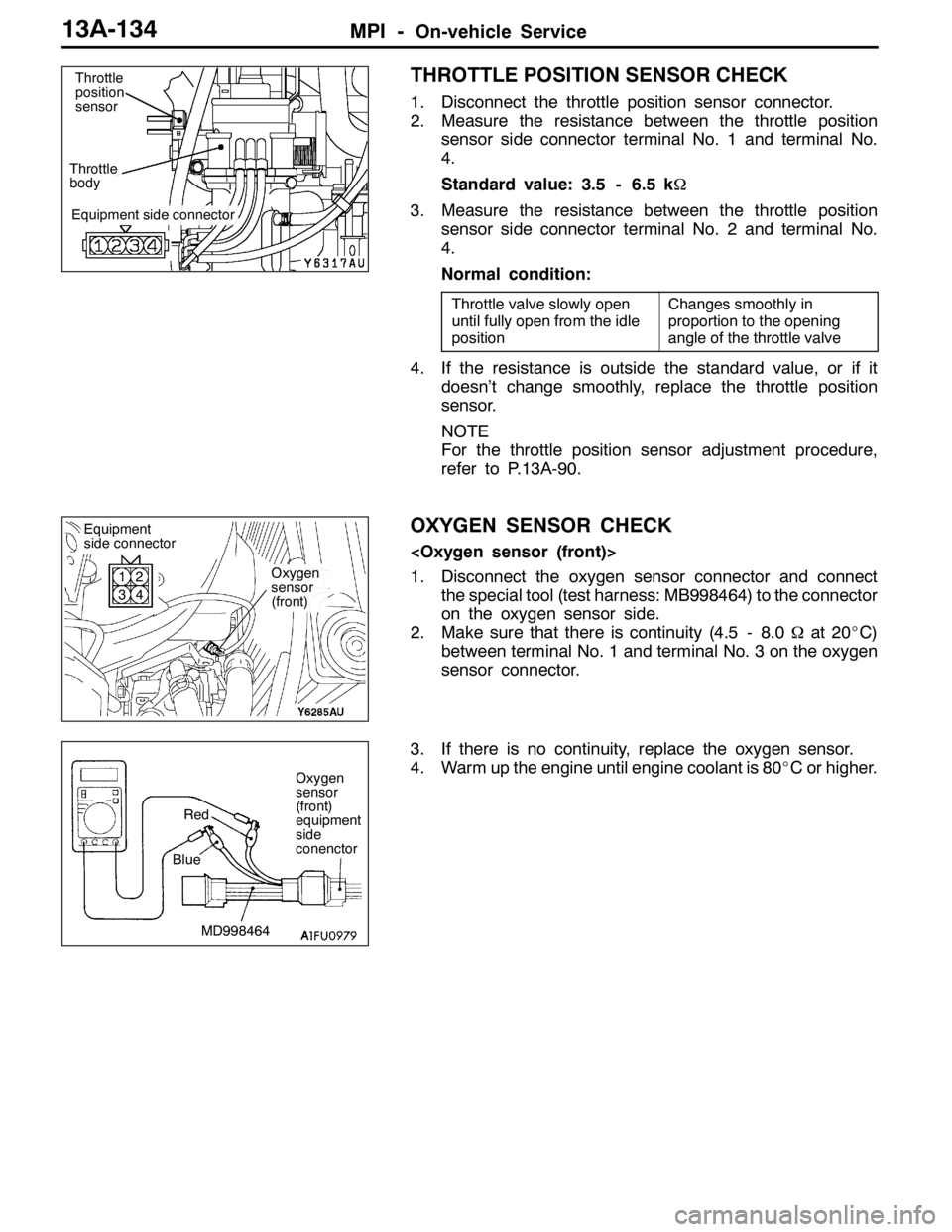

THROTTLE POSITION SENSOR CHECK

1. Disconnect the throttle position sensor connector.

2. Measure the resistance between the throttle position

sensor side connector terminal No. 1 and terminal No.

4.

Standard value: 3.5 - 6.5 kΩ

3. Measure the resistance between the throttle position

sensor side connector terminal No. 2 and terminal No.

4.

Normal condition:

Throttle valve slowly open

until fully open from the idle

positionChanges smoothly in

proportion to the opening

angle of the throttle valve

4. If the resistance is outside the standard value, or if it

doesn’t change smoothly, replace the throttle position

sensor.

NOTE

For the throttle position sensor adjustment procedure,

refer to P.13A-90.

OXYGEN SENSOR CHECK

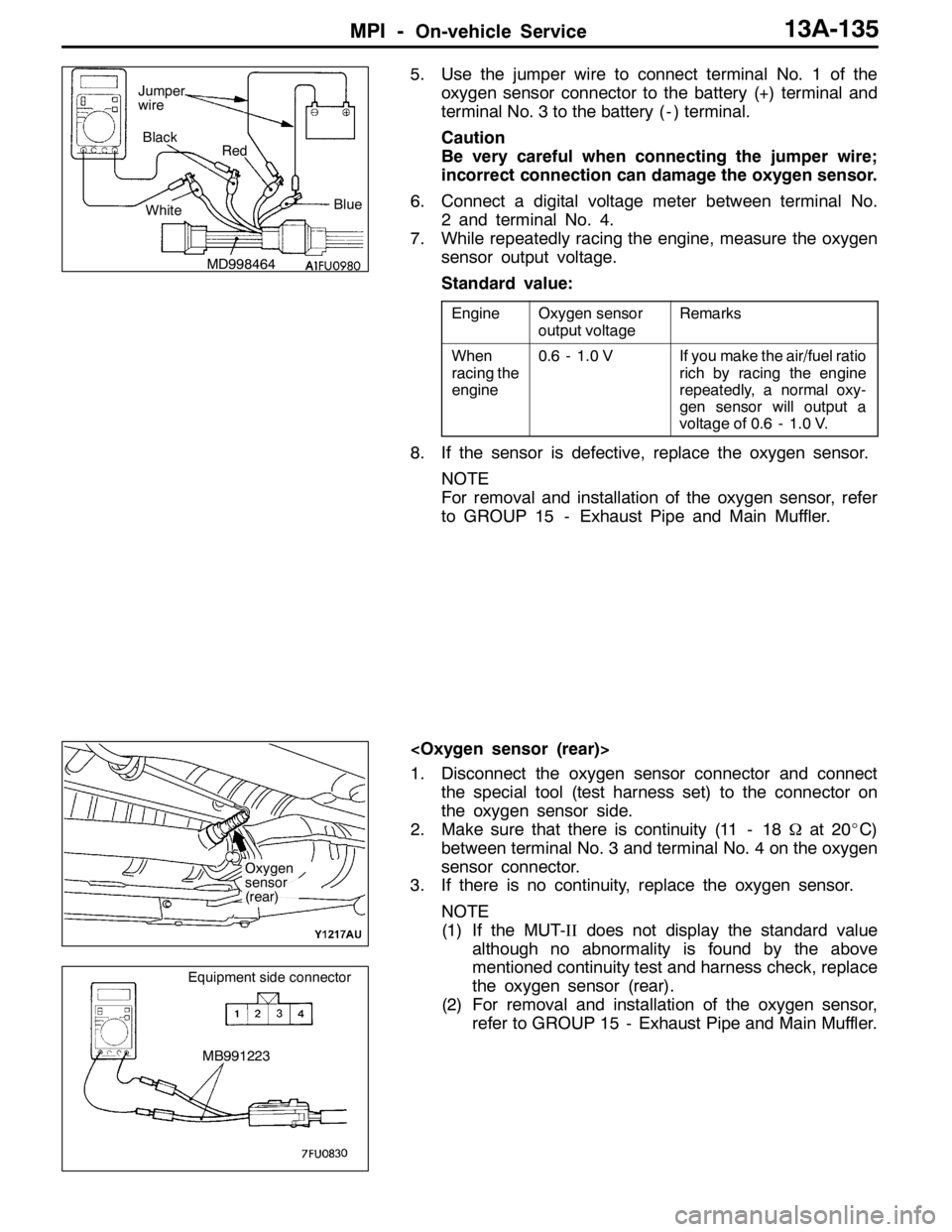

1. Disconnect the oxygen sensor connector and connect

the special tool (test harness: MB998464) to the connector

on the oxygen sensor side.

2. Make sure that there is continuity (4.5 - 8.0Ωat 20_C)

between terminal No. 1 and terminal No. 3 on the oxygen

sensor connector.

3. If there is no continuity, replace the oxygen sensor.

4. Warm up the engine until engine coolant is 80_C or higher.

Equipment side connector

Throttle

bodyThrottle

position

sensor

Oxygen

sensor

(front)

Equipment

side connector

1

32

4

Oxygen

sensor

(front)

equipment

side

conenctor

MD998464 BlueRed

Page 667 of 1449

MPI -On-vehicle Service13A-135

5. Use the jumper wire to connect terminal No. 1 of the

oxygen sensor connector to the battery (+) terminal and

terminal No. 3 to the battery ( - ) terminal.

Caution

Be very careful when connecting the jumper wire;

incorrect connection can damage the oxygen sensor.

6. Connect a digital voltage meter between terminal No.

2 and terminal No. 4.

7. While repeatedly racing the engine, measure the oxygen

sensor output voltage.

Standard value:

EngineOxygen sensor

output voltageRemarks

When

racing the

engine0.6 - 1.0 VIf you make the air/fuel ratio

rich by racing the engine

repeatedly, a normal oxy-

gen sensor will output a

voltage of 0.6 - 1.0 V.

8. If the sensor is defective, replace the oxygen sensor.

NOTE

For removal and installation of the oxygen sensor, refer

to GROUP 15 - Exhaust Pipe and Main Muffler.

1. Disconnect the oxygen sensor connector and connect

the special tool (test harness set) to the connector on

the oxygen sensor side.

2. Make sure that there is continuity (11 - 18Ωat 20_C)

between terminal No. 3 and terminal No. 4 on the oxygen

sensor connector.

3. If there is no continuity, replace the oxygen sensor.

NOTE

(1) If the MUT-IIdoes not display the standard value

although no abnormality is found by the above

mentioned continuity test and harness check, replace

the oxygen sensor (rear).

(2) For removal and installation of the oxygen sensor,

refer to GROUP 15 - Exhaust Pipe and Main Muffler.

MD998464Blue Black

Red

White Jumper

wire

Oxygen

sensor

(rear)

MB991223

Equipment side connector

Page 739 of 1449

ENGINE ELECTRICAL -Charging System16-7

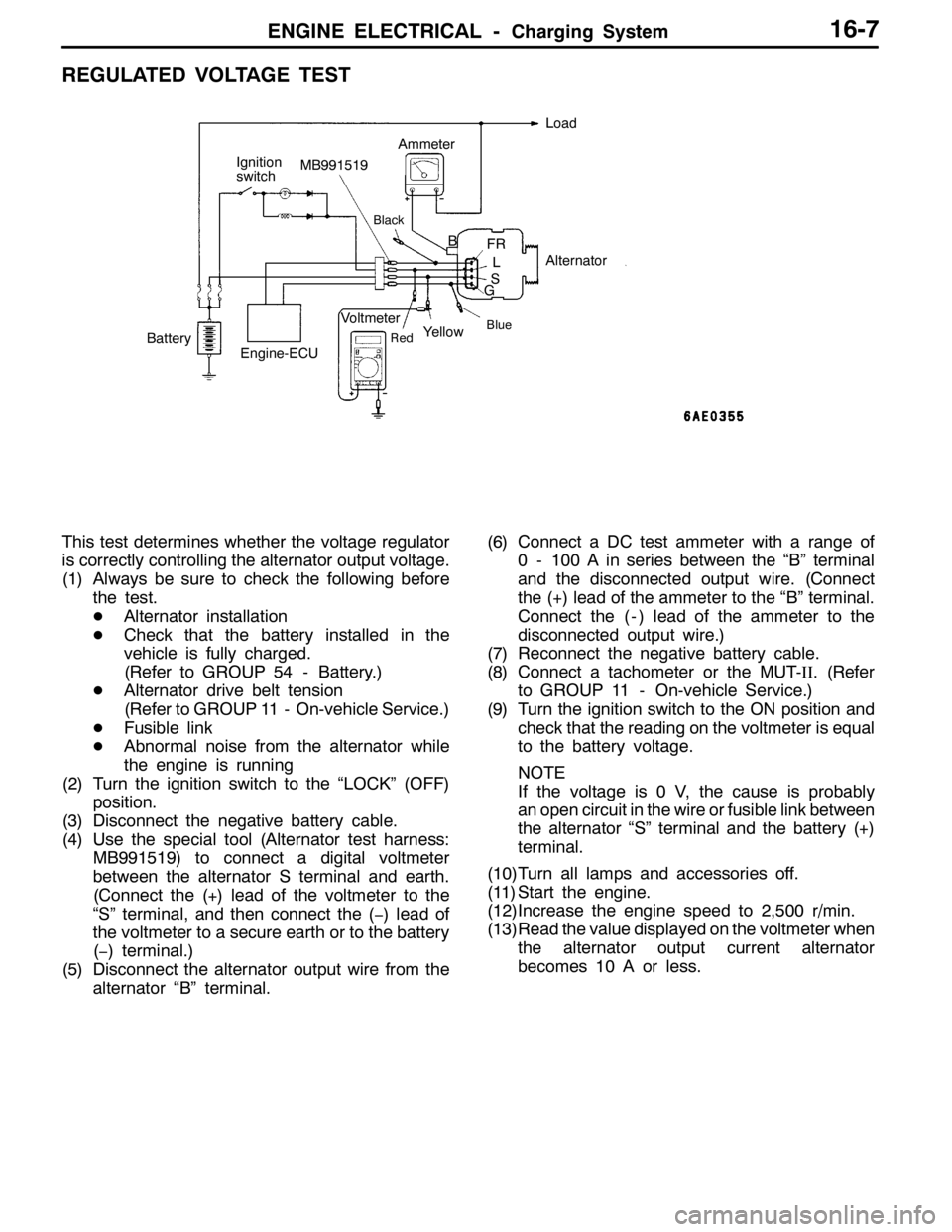

REGULATED VOLTAGE TEST

B

BlueRed

Ignition

switchLoad

FR

L

S

GMB991519

Alternator

BatteryVoltmeterAmmeter

Yellow

Engine-ECU

Black

This test determines whether the voltage regulator

is correctly controlling the alternator output voltage.

(1) Always be sure to check the following before

the test.

DAlternator installation

DCheck that the battery installed in the

vehicle is fully charged.

(Refer to GROUP 54 - Battery.)

DAlternator drive belt tension

(Refer to GROUP 11 - On-vehicle Service.)

DFusible link

DAbnormal noise from the alternator while

the engine is running

(2) Turn the ignition switch to the “LOCK” (OFF)

position.

(3) Disconnect the negative battery cable.

(4) Use the special tool (Alternator test harness:

MB991519) to connect a digital voltmeter

between the alternator S terminal and earth.

(Connect the (+) lead of the voltmeter to the

“S” terminal, and then connect the (−) lead of

the voltmeter to a secure earth or to the battery

(−) terminal.)

(5) Disconnect the alternator output wire from the

alternator “B” terminal.(6) Connect a DC test ammeter with a range of

0 - 100 A in series between the “B” terminal

and the disconnected output wire. (Connect

the (+) lead of the ammeter to the “B” terminal.

Connect the ( - ) lead of the ammeter to the

disconnected output wire.)

(7) Reconnect the negative battery cable.

(8) Connect a tachometer or the MUT-II. (Refer

to GROUP 11 - On-vehicle Service.)

(9) Turn the ignition switch to the ON position and

check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator “S” terminal and the battery (+)

terminal.

(10)Turn all lamps and accessories off.

(11) Start the engine.

(12)Increase the engine speed to 2,500 r/min.

(13)Read the value displayed on the voltmeter when

the alternator output current alternator

becomes 10 A or less.

Page 776 of 1449

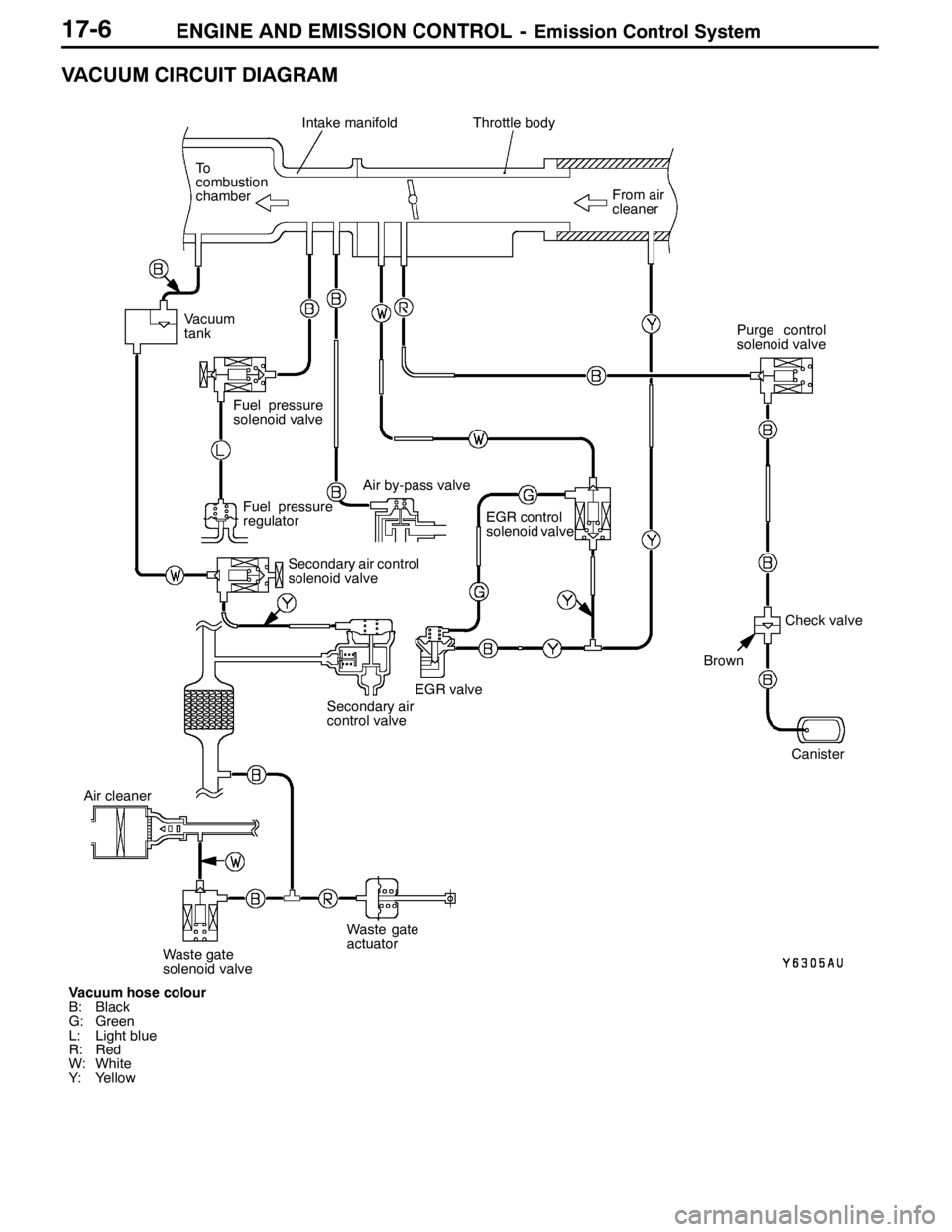

ENGINE AND EMISSION CONTROL -Emission Control System17-6

VACUUM CIRCUIT DIAGRAM

Vacuum hose colour

B: Black

G: Green

L: Light blue

R: Red

W: White

Y: YellowFrom air

cleaner

Intake manifoldThrottle body

To

combustion

chamber

Fuel pressure

regulator

EGR control

solenoid valve

Canister

EGR valve

Brown

Check valve Vacuum

tank

Fuel pressure

solenoid valve

Air by-pass valve

Secondary air control

solenoid valve

Secondary air

control valvePurge control

solenoid valve

Air cleaner

Waste gate

solenoid valveWaste gate

actuator

Page 875 of 1449

MANUAL TRANSMISSION OVERHAUL -Snap Rings, Spacers and Thrust

Plates for Adjustment22B-9

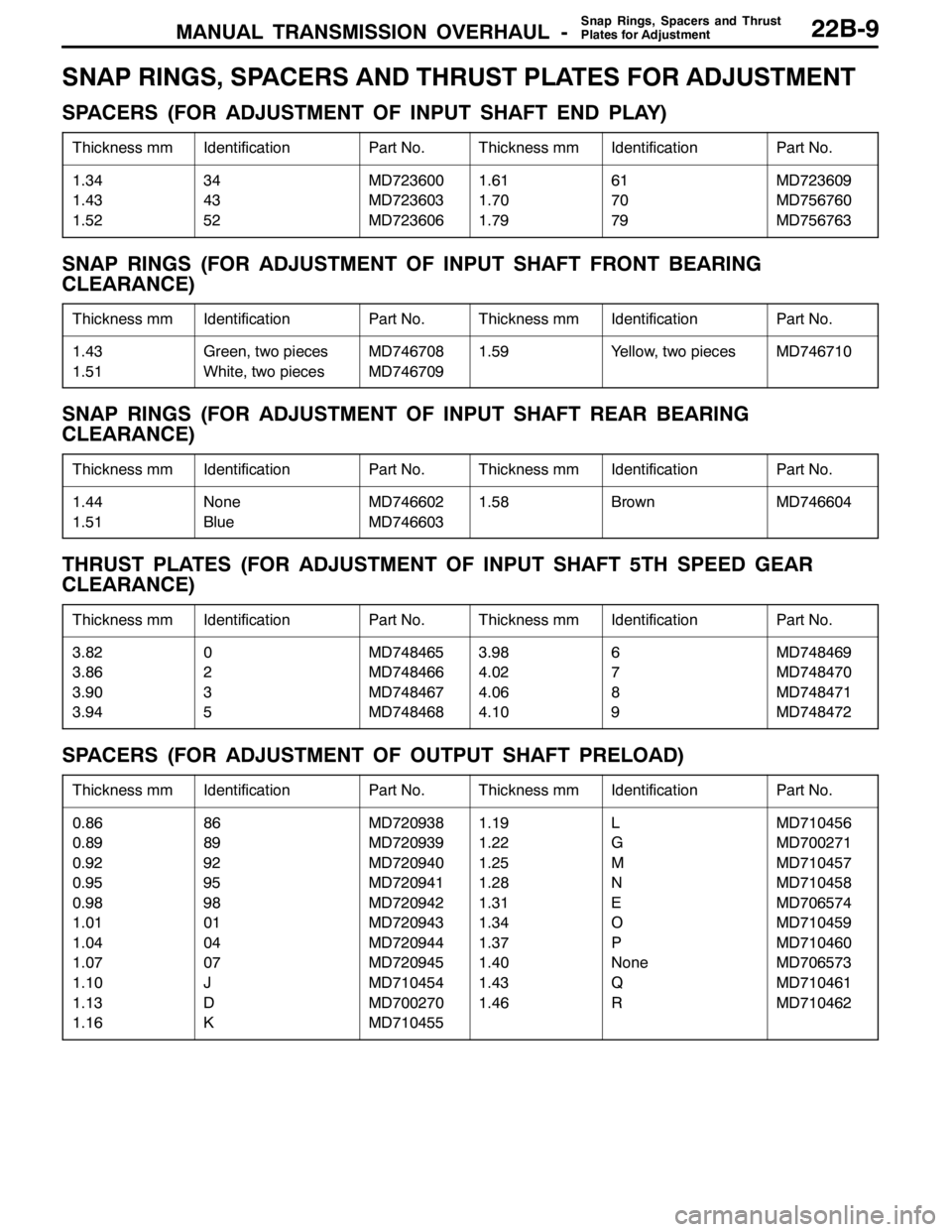

SNAP RINGS, SPACERS AND THRUST PLATES FOR ADJUSTMENT

SPACERS (FOR ADJUSTMENT OF INPUT SHAFT END PLAY)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

1.34

1.43

1.5234

43

52MD723600

MD723603

MD7236061.61

1.70

1.7961

70

79MD723609

MD756760

MD756763

SNAP RINGS (FOR ADJUSTMENT OF INPUT SHAFT FRONT BEARING

CLEARANCE)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

1.43

1.51Green, two pieces

White, two piecesMD746708

MD7467091.59Yellow, two piecesMD746710

SNAP RINGS (FOR ADJUSTMENT OF INPUT SHAFT REAR BEARING

CLEARANCE)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

1.44

1.51None

BlueMD746602

MD7466031.58BrownMD746604

THRUST PLATES (FOR ADJUSTMENT OF INPUT SHAFT 5TH SPEED GEAR

CLEARANCE)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

3.82

3.86

3.90

3.940

2

3

5MD748465

MD748466

MD748467

MD7484683.98

4.02

4.06

4.106

7

8

9MD748469

MD748470

MD748471

MD748472

SPACERS (FOR ADJUSTMENT OF OUTPUT SHAFT PRELOAD)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

0.86

0.89

0.92

0.95

0.98

1.01

1.04

1.07

1.10

1.13

1.1686

89

92

95

98

01

04

07

J

D

KMD720938

MD720939

MD720940

MD720941

MD720942

MD720943

MD720944

MD720945

MD710454

MD700270

MD7104551.19

1.22

1.25

1.28

1.31

1.34

1.37

1.40

1.43

1.46L

G

M

N

E

O

P

None

Q

RMD710456

MD700271

MD710457

MD710458

MD706574

MD710459

MD710460

MD706573

MD710461

MD710462

Page 876 of 1449

MANUAL TRANSMISSION OVERHAUL -Snap Rings, Spacers and Thrust

Plates for Adjustment22B-10

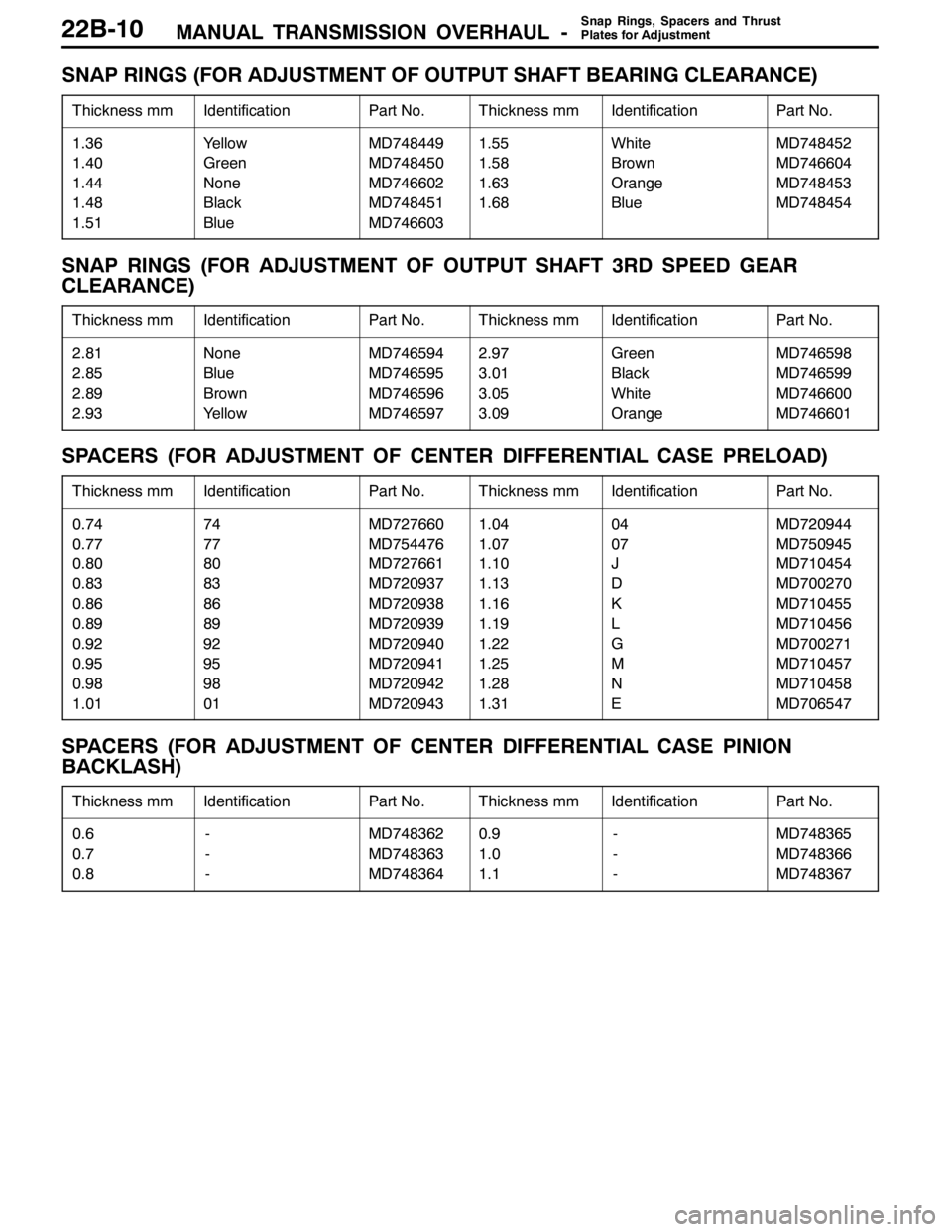

SNAP RINGS (FOR ADJUSTMENT OF OUTPUT SHAFT BEARING CLEARANCE)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

1.36

1.40

1.44

1.48

1.51Yellow

Green

None

Black

BlueMD748449

MD748450

MD746602

MD748451

MD7466031.55

1.58

1.63

1.68White

Brown

Orange

BlueMD748452

MD746604

MD748453

MD748454

SNAP RINGS (FOR ADJUSTMENT OF OUTPUT SHAFT 3RD SPEED GEAR

CLEARANCE)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

2.81

2.85

2.89

2.93None

Blue

Brown

YellowMD746594

MD746595

MD746596

MD7465972.97

3.01

3.05

3.09Green

Black

White

OrangeMD746598

MD746599

MD746600

MD746601

SPACERS (FOR ADJUSTMENT OF CENTER DIFFERENTIAL CASE PRELOAD)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

0.74

0.77

0.80

0.83

0.86

0.89

0.92

0.95

0.98

1.0174

77

80

83

86

89

92

95

98

01MD727660

MD754476

MD727661

MD720937

MD720938

MD720939

MD720940

MD720941

MD720942

MD7209431.04

1.07

1.10

1.13

1.16

1.19

1.22

1.25

1.28

1.3104

07

J

D

K

L

G

M

N

EMD720944

MD750945

MD710454

MD700270

MD710455

MD710456

MD700271

MD710457

MD710458

MD706547

SPACERS (FOR ADJUSTMENT OF CENTER DIFFERENTIAL CASE PINION

BACKLASH)

Thickness mmIdentificationPart No.Thickness mmIdentificationPart No.

0.6

0.7

0.8-

-

-MD748362

MD748363

MD7483640.9

1.0

1.1-

-

-MD748365

MD748366

MD748367

Page 985 of 1449

REAR AXLE -Differential Carrier

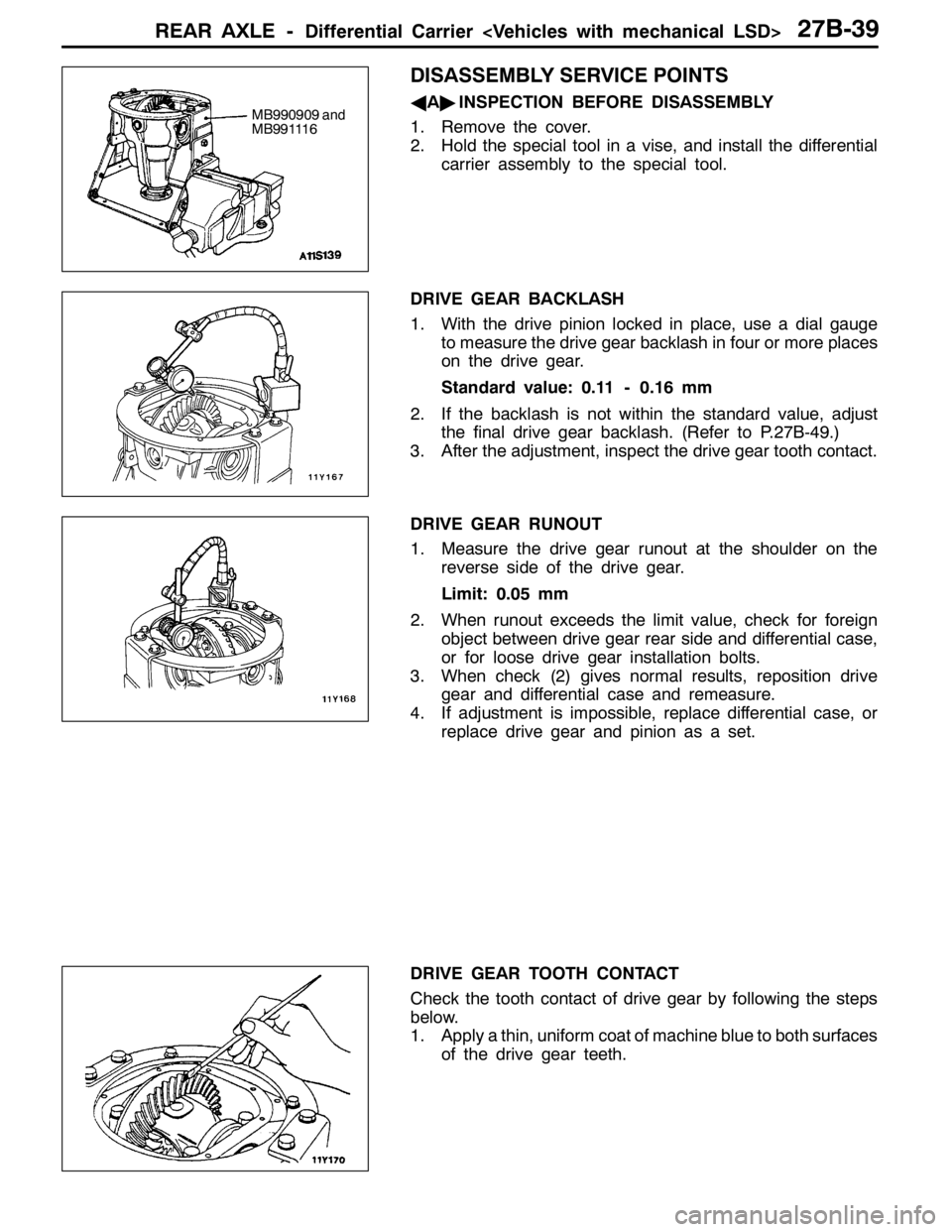

DISASSEMBLY SERVICE POINTS

AA"INSPECTION BEFORE DISASSEMBLY

1. Remove the cover.

2. Hold the special tool in a vise, and install the differential

carrier assembly to the special tool.

DRIVE GEAR BACKLASH

1. With the drive pinion locked in place, use a dial gauge

to measure the drive gear backlash in four or more places

on the drive gear.

Standard value: 0.11 - 0.16 mm

2. If the backlash is not within the standard value, adjust

the final drive gear backlash. (Refer to P.27B-49.)

3. After the adjustment, inspect the drive gear tooth contact.

DRIVE GEAR RUNOUT

1. Measure the drive gear runout at the shoulder on the

reverse side of the drive gear.

Limit: 0.05 mm

2. When runout exceeds the limit value, check for foreign

object between drive gear rear side and differential case,

or for loose drive gear installation bolts.

3. When check (2) gives normal results, reposition drive

gear and differential case and remeasure.

4. If adjustment is impossible, replace differential case, or

replace drive gear and pinion as a set.

DRIVE GEAR TOOTH CONTACT

Check the tooth contact of drive gear by following the steps

below.

1. Apply a thin, uniform coat of machine blue to both surfaces

of the drive gear teeth.MB990909 and

MB991116