brake light MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 100 of 1449

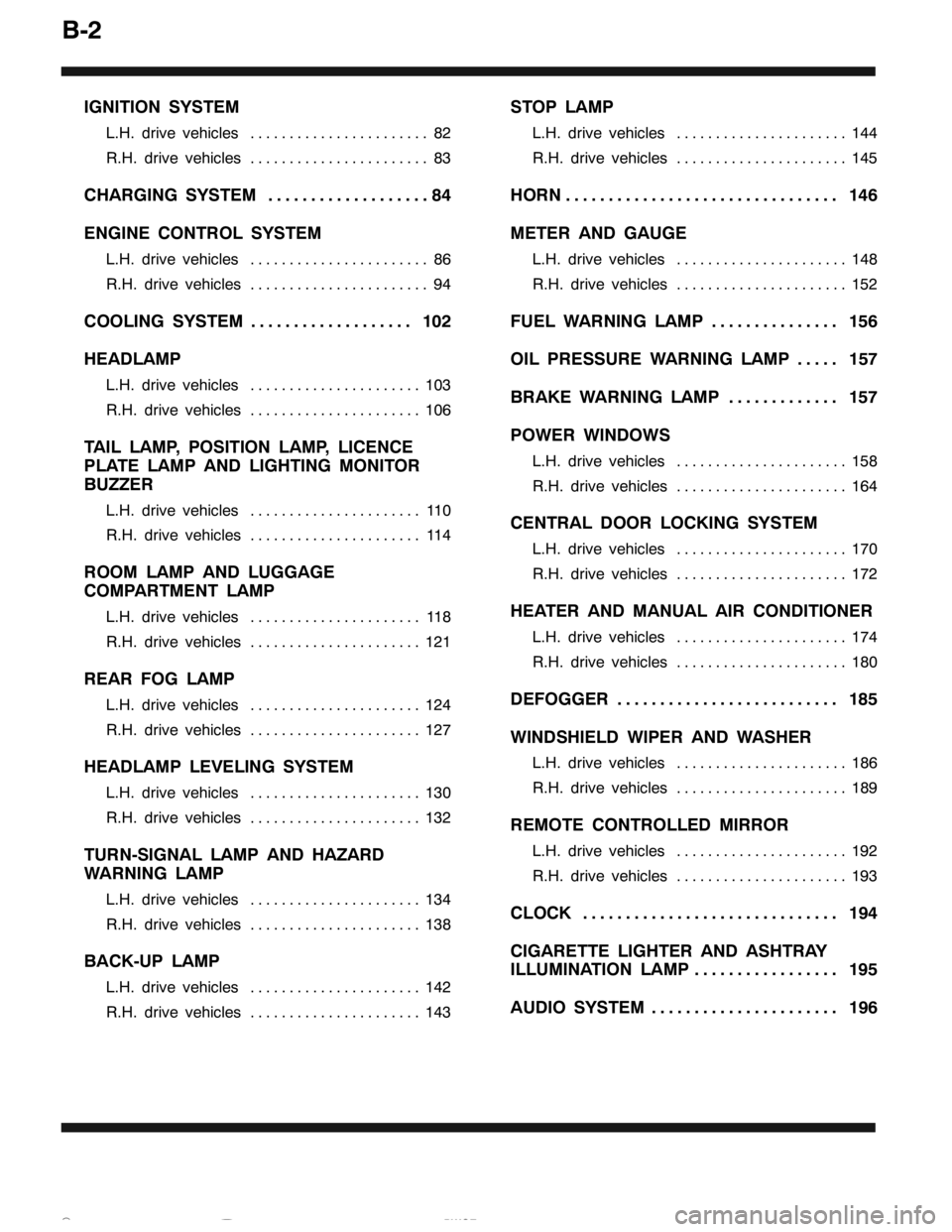

B-2

S

PWGEE

IGNITION SYSTEM

L.H. drive vehicles 82.......................

R.H. drive vehicles 83.......................

CHARGING SYSTEM 84...................

ENGINE CONTROL SYSTEM

L.H. drive vehicles 86.......................

R.H. drive vehicles 94.......................

COOLING SYSTEM 102...................

HEADLAMP

L.H. drive vehicles 103......................

R.H. drive vehicles 106......................

TAIL LAMP, POSITION LAMP, LICENCE

PLATE LAMP AND LIGHTING MONITOR

BUZZER

L.H. drive vehicles 110......................

R.H. drive vehicles 114......................

ROOM LAMP AND LUGGAGE

COMPARTMENT LAMP

L.H. drive vehicles 118......................

R.H. drive vehicles 121......................

REAR FOG LAMP

L.H. drive vehicles 124......................

R.H. drive vehicles 127......................

HEADLAMP LEVELING SYSTEM

L.H. drive vehicles 130......................

R.H. drive vehicles 132......................

TURN-SIGNAL LAMP AND HAZARD

WARNING LAMP

L.H. drive vehicles 134......................

R.H. drive vehicles 138......................

BACK-UP LAMP

L.H. drive vehicles 142......................

R.H. drive vehicles 143......................

STOP LAMP

L.H. drive vehicles 144......................

R.H. drive vehicles 145......................

HORN 146................................

METER AND GAUGE

L.H. drive vehicles 148......................

R.H. drive vehicles 152......................

FUEL WARNING LAMP 156...............

OIL PRESSURE WARNING LAMP 157.....

BRAKE WARNING LAMP 157.............

POWER WINDOWS

L.H. drive vehicles 158......................

R.H. drive vehicles 164......................

CENTRAL DOOR LOCKING SYSTEM

L.H. drive vehicles 170......................

R.H. drive vehicles 172......................

HEATER AND MANUAL AIR CONDITIONER

L.H. drive vehicles 174......................

R.H. drive vehicles 180......................

DEFOGGER 185..........................

WINDSHIELD WIPER AND WASHER

L.H. drive vehicles 186......................

R.H. drive vehicles 189......................

REMOTE CONTROLLED MIRROR

L.H. drive vehicles 192......................

R.H. drive vehicles 193......................

CLOCK 194..............................

CIGARETTE LIGHTER AND ASHTRAY

ILLUMINATION LAMP 195.................

AUDIO SYSTEM 196......................

Page 129 of 1449

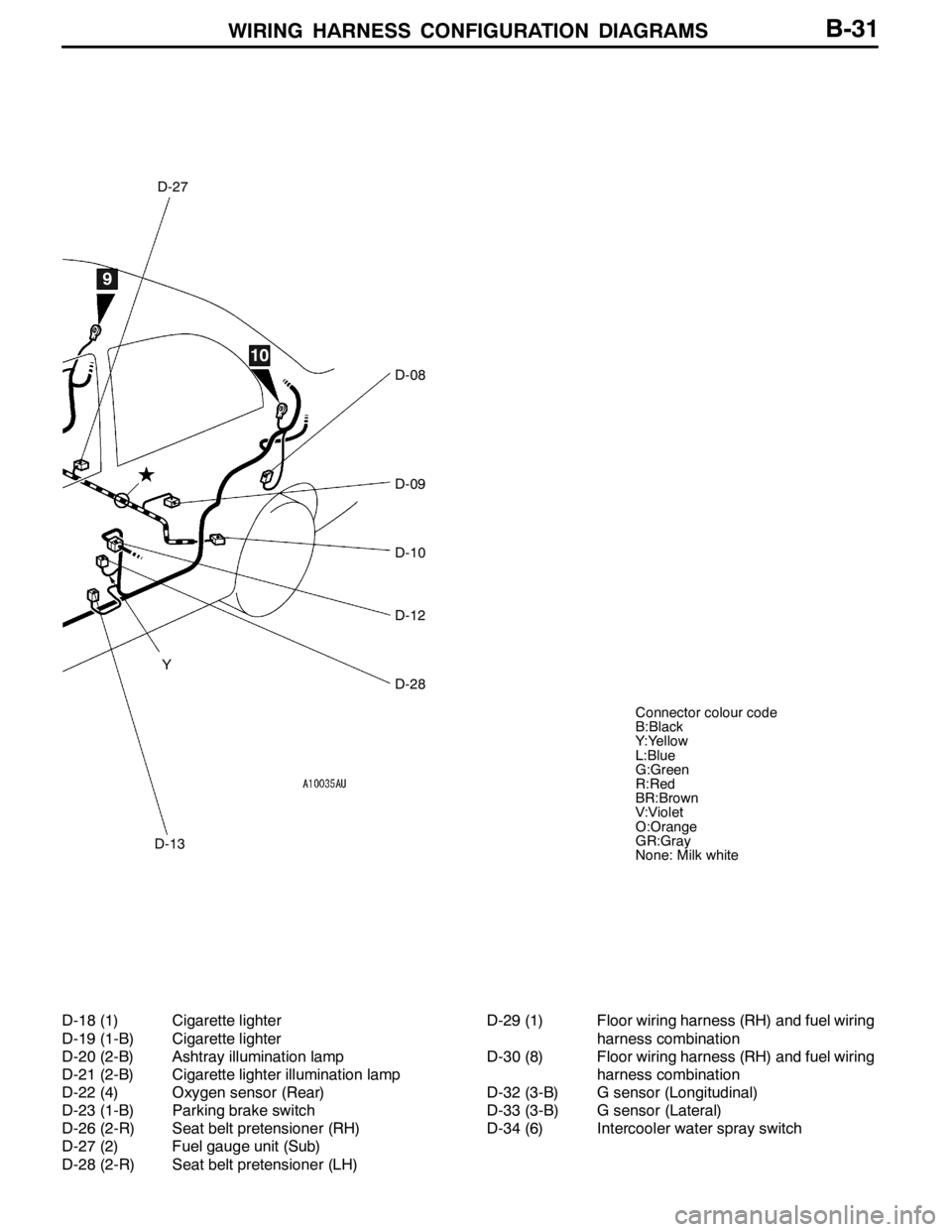

WIRING HARNESS CONFIGURATION DIAGRAMS

D-13

D-27

D-08

D-09

D-10

D-12

D-28 Y

9

10

Connector colour code

B:Black

Y:Yellow

L:Blue

G:Green

R:Red

BR:Brown

V:Violet

O:Orange

GR:Gray

None: Milk white

B-31

D-18 (1) Cigarette lighter

D-19 (1-B) Cigarette lighter

D-20 (2-B) Ashtray illumination lamp

D-21 (2-B) Cigarette lighter illumination lamp

D-22 (4) Oxygen sensor (Rear)

D-23 (1-B) Parking brake switch

D-26 (2-R) Seat belt pretensioner (RH)

D-27 (2) Fuel gauge unit (Sub)

D-28 (2-R) Seat belt pretensioner (LH)D-29 (1) Floor wiring harness (RH) and fuel wiring

harness combination

D-30 (8) Floor wiring harness (RH) and fuel wiring

harness combination

D-32 (3-B) G sensor (Longitudinal)

D-33 (3-B) G sensor (Lateral)

D-34 (6) Intercooler water spray switch

Page 131 of 1449

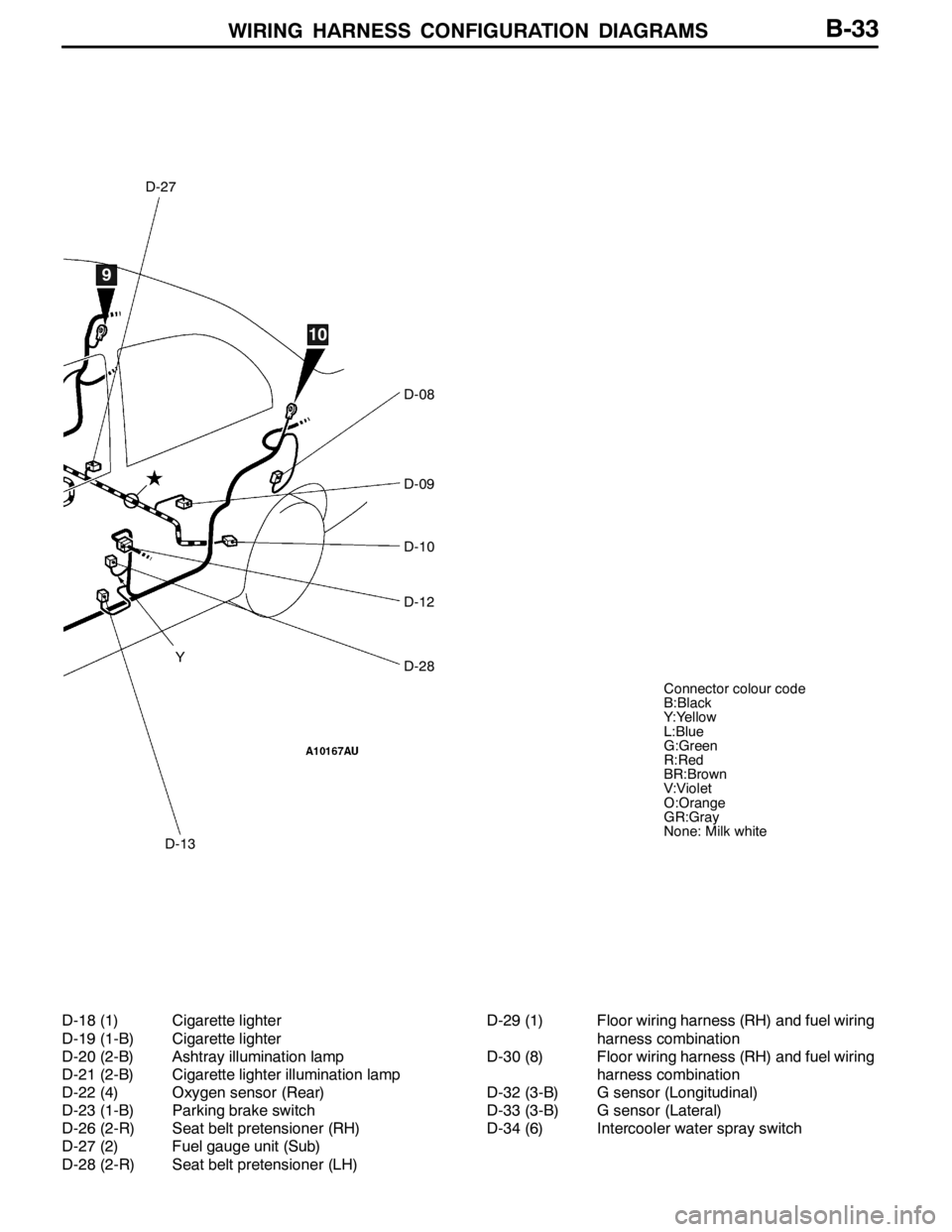

WIRING HARNESS CONFIGURATION DIAGRAMS

D-27

D-13

D-08

D-09

D-10

D-12

D-28

9

10

Y

Connector colour code

B:Black

Y:Yellow

L:Blue

G:Green

R:Red

BR:Brown

V:Violet

O:Orange

GR:Gray

None: Milk white

B-33

D-18 (1) Cigarette lighter

D-19 (1-B) Cigarette lighter

D-20 (2-B) Ashtray illumination lamp

D-21 (2-B) Cigarette lighter illumination lamp

D-22 (4) Oxygen sensor (Rear)

D-23 (1-B) Parking brake switch

D-26 (2-R) Seat belt pretensioner (RH)

D-27 (2) Fuel gauge unit (Sub)

D-28 (2-R) Seat belt pretensioner (LH)D-29 (1) Floor wiring harness (RH) and fuel wiring

harness combination

D-30 (8) Floor wiring harness (RH) and fuel wiring

harness combination

D-32 (3-B) G sensor (Longitudinal)

D-33 (3-B) G sensor (Lateral)

D-34 (6) Intercooler water spray switch

Page 364 of 1449

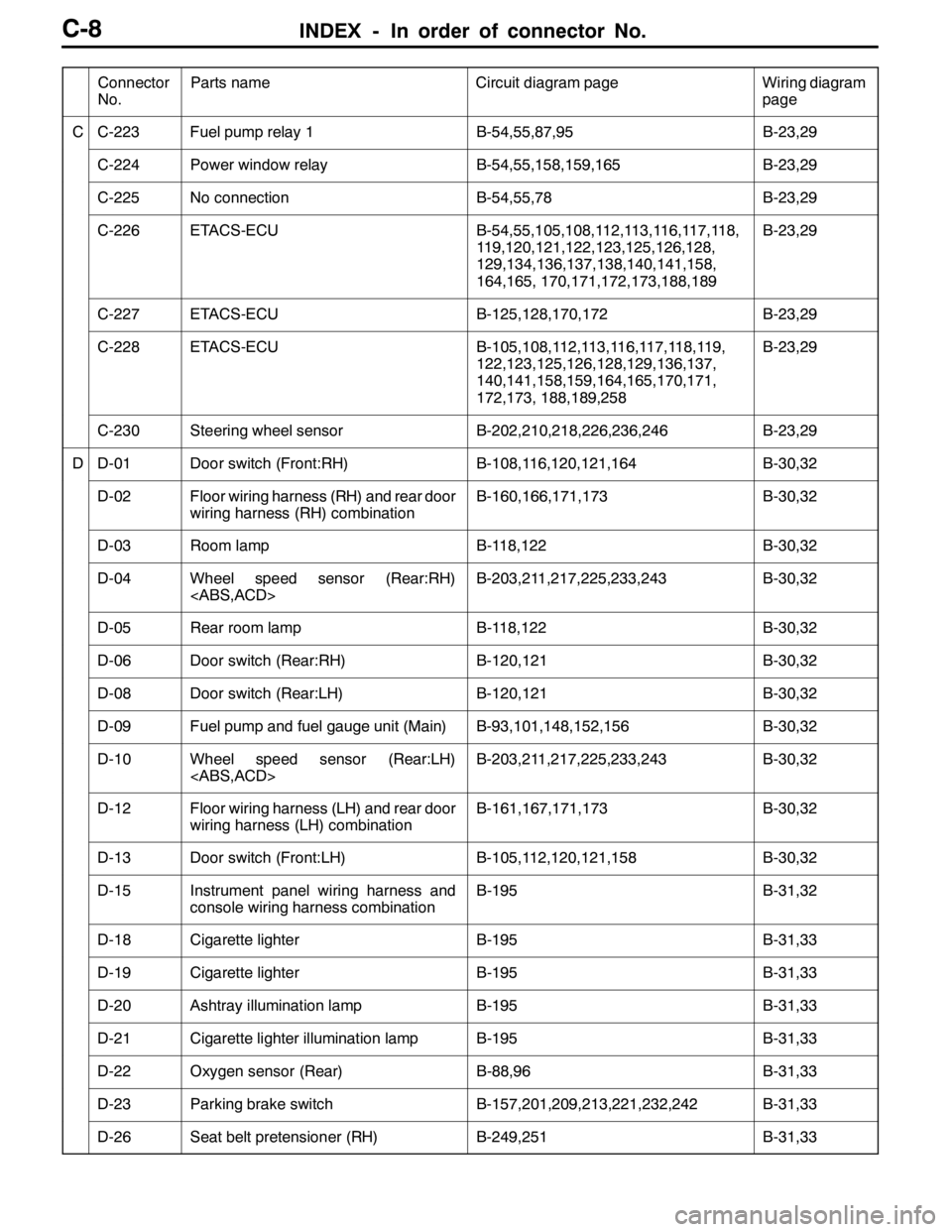

INDEX - In order of connector No.C-8

Wiring diagram

page Circuit diagram page Parts name Connector

No.

CC-223Fuel pump relay 1B-54,55,87,95B-23,29

C-224Power window relayB-54,55,158,159,165B-23,29

C-225No connectionB-54,55,78B-23,29

C-226ETACS-ECUB-54,55,105,108,112,113,116,117,118,

119,120,121,122,123,125,126,128,

129,134,136,137,138,140,141,158,

164,165, 170,171,172,173,188,189B-23,29

C-227ETACS-ECUB-125,128,170,172B-23,29

C-228ETACS-ECUB-105,108,112,113,116,117,118,119,

122,123,125,126,128,129,136,137,

140,141,158,159,164,165,170,171,

172,173, 188,189,258B-23,29

C-230Steering wheel sensorB-202,210,218,226,236,246B-23,29

DD-01Door switch (Front:RH)B-108,116,120,121,164B-30,32

D-02Floor wiring harness (RH) and rear door

wiring harness (RH) combinationB-160,166,171,173B-30,32

D-03Room lampB-118,122B-30,32

D-04Wheel speed sensor (Rear:RH)

D-05Rear room lampB-118,122B-30,32

D-06Door switch (Rear:RH)B-120,121B-30,32

D-08Door switch (Rear:LH)B-120,121B-30,32

D-09Fuel pump and fuel gauge unit (Main)B-93,101,148,152,156B-30,32

D-10Wheel speed sensor (Rear:LH)

D-12Floor wiring harness (LH) and rear door

wiring harness (LH) combinationB-161,167,171,173B-30,32

D-13Door switch (Front:LH)B-105,112,120,121,158B-30,32

D-15Instrument panel wiring harness and

console wiring harness combinationB-195B-31,32

D-18Cigarette lighterB-195B-31,33

D-19Cigarette lighterB-195B-31,33

D-20Ashtray illumination lampB-195B-31,33

D-21Cigarette lighter illumination lampB-195B-31,33

D-22Oxygen sensor (Rear)B-88,96B-31,33

D-23Parking brake switchB-157,201,209,213,221,232,242B-31,33

D-26Seat belt pretensioner (RH)B-249,251B-31,33

Page 367 of 1449

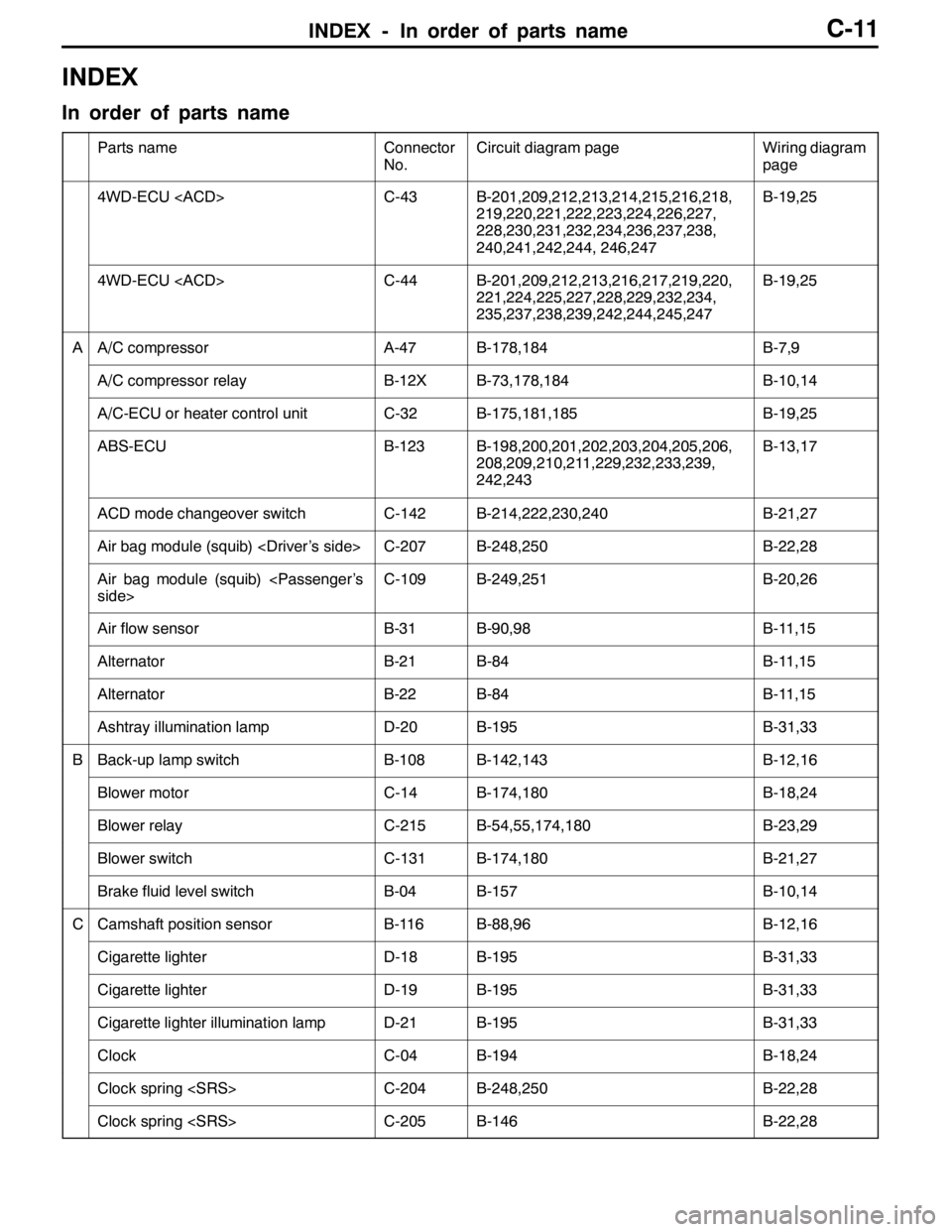

INDEX - In order of parts nameC-11

INDEX

In order of parts name

Parts nameConnector

No.Circuit diagram pageWiring diagram

page

4WD-ECU

219,220,221,222,223,224,226,227,

228,230,231,232,234,236,237,238,

240,241,242,244, 246,247B-19,25

4WD-ECU

221,224,225,227,228,229,232,234,

235,237,238,239,242,244,245,247B-19,25

AA/C compressorA-47B-178,184B-7,9

A/C compressor relayB-12XB-73,178,184B-10,14

A/C-ECU or heater control unitC-32B-175,181,185B-19,25

ABS-ECUB-123B-198,200,201,202,203,204,205,206,

208,209,210,211,229,232,233,239,

242,243B-13,17

ACD mode changeover switchC-142B-214,222,230,240B-21,27

Air bag module (squib)

Air bag module (squib)

Air flow sensorB-31B-90,98B-11,15

AlternatorB-21B-84B-11,15

AlternatorB-22B-84B-11,15

Ashtray illumination lampD-20B-195B-31,33

BBack-up lamp switchB-108B-142,143B-12,16

Blower motorC-14B-174,180B-18,24

Blower relayC-215B-54,55,174,180B-23,29

Blower switchC-131B-174,180B-21,27

Brake fluid level switchB-04B-157B-10,14

CCamshaft position sensorB-116B-88,96B-12,16

Cigarette lighterD-18B-195B-31,33

Cigarette lighterD-19B-195B-31,33

Cigarette lighter illumination lampD-21B-195B-31,33

ClockC-04B-194B-18,24

Clock spring

Clock spring

Page 449 of 1449

ENGINE -Engine Assembly11A-43

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Caution

1. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper because the paint of caliper will be scratched.

2. Tightening sections indicated in the mark (*) should be finally tightened with engine weight

applied on the body after lightly tightening.

Pre-removal and Post-installation Operation

DFuel Outflow Preventive Operation (Refer to GROUP 13A - On-vehicle Service.)

DFuel Leak Check

DRemoval and Installation of Hood (Refer to GROUP 42.)

DRemoval and Installation of Strut Tower Bar (Refer to GROUP 42.)

DRemoval and Installation of Under Cover (Refer to GROUP 51 - Front Bumper.)

DRemoval and Installation of Side Cover.

DDrive Belt Tension Check (Refer to P.11A - 7.)

DAccelerator Cable Adjustment (Refer to GROUP 17 - On-vehicle Service.)

DDrainage and Refilling Engine Oil(Refer to GROUP 12 - On-vehicle Service.)

DDrainage and Refilling of Engine Coolant (Refer to GROUP 14 - On-vehicle Service.)

DAir Cleaner Removal and Installation (Refer to GROUP 15)

DRemoval and Installation of Air Pipe C, Air Pipe B and Air Hose A (Refer to GROUP 15 - Intercooler.)

DBattery and Battery Tray Removal and Installation

DRemoval and Installation of Center Cover (Refer to P.11A - 17.)

DRemoval and Installation of Accelerator Cable (Refer to GROUP 17.)

DRemoval and Installation of Radiator (Refer to GROUP 14.)

DRemoval and Installation of Crossmember Bar (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

DRemoval and Installation of Front Exhaust Pipe (Refer to GROUP 15.)

DRemoval and Installation of Air Outlet Fitting (Refer to GROUP 15 - Exhaust manifold.)

Page 1050 of 1449

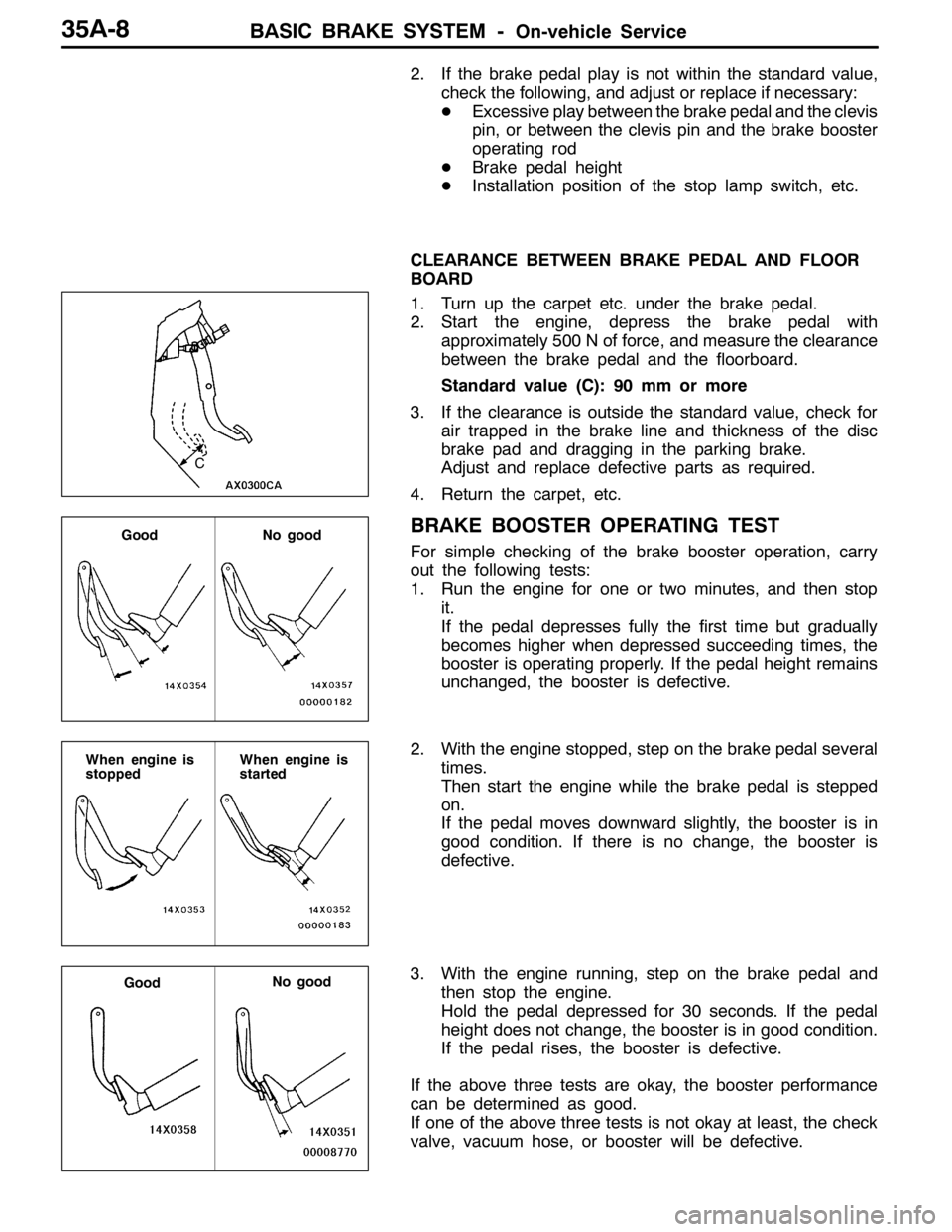

BASIC BRAKE SYSTEM -On-vehicle Service35A-8

2. If the brake pedal play is not within the standard value,

check the following, and adjust or replace if necessary:

DExcessive play between the brake pedal and the clevis

pin, or between the clevis pin and the brake booster

operating rod

DBrake pedal height

DInstallation position of the stop lamp switch, etc.

CLEARANCE BETWEEN BRAKE PEDAL AND FLOOR

BOARD

1. Turn up the carpet etc. under the brake pedal.

2. Start the engine, depress the brake pedal with

approximately 500 N of force, and measure the clearance

between the brake pedal and the floorboard.

Standard value (C): 90 mm or more

3. If the clearance is outside the standard value, check for

air trapped in the brake line and thickness of the disc

brake pad and dragging in the parking brake.

Adjust and replace defective parts as required.

4. Return the carpet, etc.

BRAKE BOOSTER OPERATING TEST

For simple checking of the brake booster operation, carry

out the following tests:

1. Run the engine for one or two minutes, and then stop

it.

If the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly. If the pedal height remains

unchanged, the booster is defective.

2. With the engine stopped, step on the brake pedal several

times.

Then start the engine while the brake pedal is stepped

on.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is

defective.

3. With the engine running, step on the brake pedal and

then stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is defective.

If the above three tests are okay, the booster performance

can be determined as good.

If one of the above three tests is not okay at least, the check

valve, vacuum hose, or booster will be defective.

C

Good No good

When engine is

stoppedWhen engine is

started

GoodNo good

Page 1144 of 1449

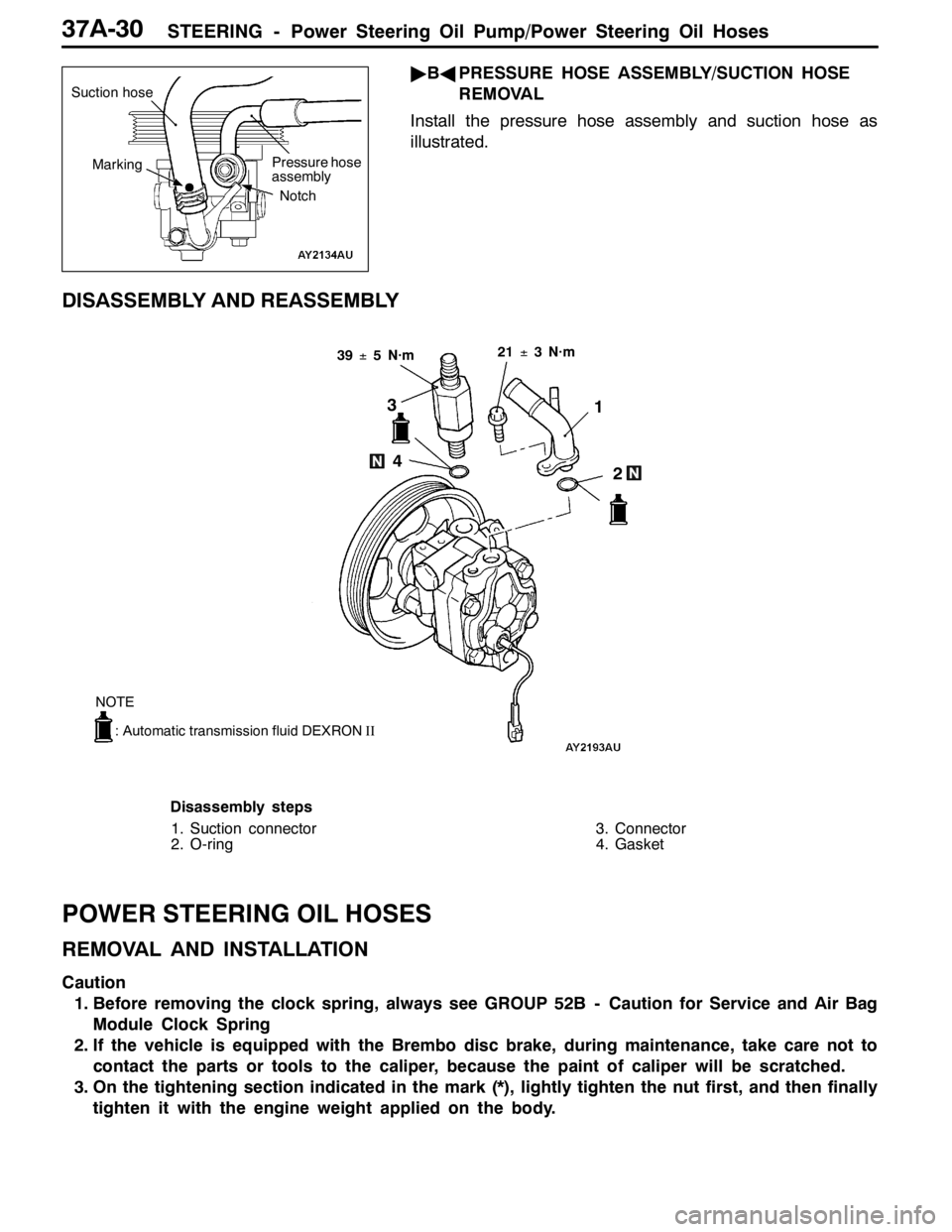

STEERING - Power Steering Oil Pump/Power Steering Oil Hoses37A-30

"BAPRESSURE HOSE ASSEMBLY/SUCTION HOSE

REMOVAL

Install the pressure hose assembly and suction hose as

illustrated.

DISASSEMBLY AND REASSEMBLY

21±3 N·m

3

4

2 1

39±5 N·m

: Automatic transmission fluid DEXRONII

NOTE

Disassembly steps

1. Suction connector

2. O-ring3. Connector

4. Gasket

POWER STEERING OIL HOSES

REMOVAL AND INSTALLATION

Caution

1. Before removing the clock spring, always see GROUP 52B - Caution for Service and Air Bag

Module Clock Spring

2. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper, because the paint of caliper will be scratched.

3. On the tightening section indicated in the mark (*), lightly tighten the nut first, and then finally

tighten it with the engine weight applied on the body.

Suction hose

Pressure hose

assembly

Marking

Notch